Double-Row Angular Contact Ball Slewing Bearings with zero lubricant leakage, <25dB operation, and 0.001° rotational accuracy for MRI/CT systems. ISO 13485 & USP Class VI certified.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

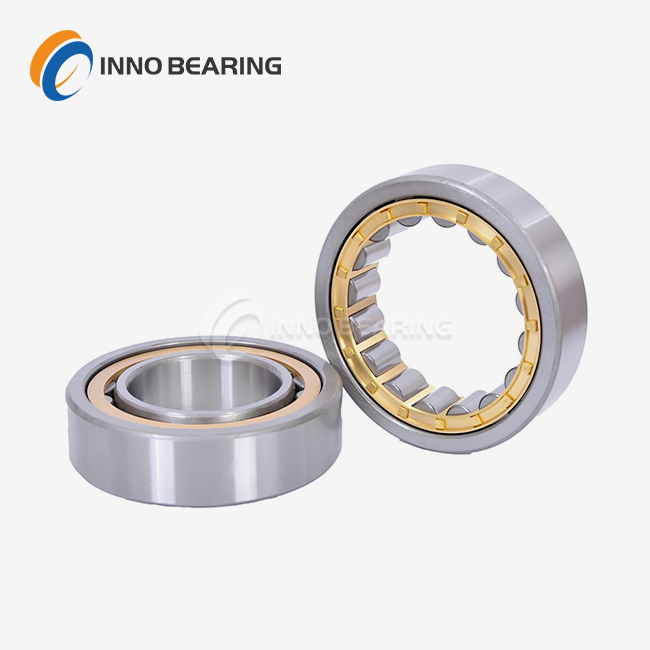

Double-Row Angular Contact Ball Slewing Bearings

2.Structure Type: It has an annular shape. The inner and outer rings have double-row angular contact raceways, with built-in double-row steel balls (with cages), seals on both sides, and some models have positioning steps.

3.Size Range: Outer ring diameter: 200 - 2000mm, inner ring diameter: 160 - 1850mm, height: 25 - 80mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Precision machine tools, robot joints, inspection instruments, high-end medical equipment.

6.Key Inspection Items: Accuracy of contact angle, radial runout, slewing resistance.

Double-Row Angular Contact Ball Slewing Bearings for Extreme Heavy-Duty Applications

Engineered for High Axial/Radial Loads, Precision Alignment, and Harsh Environment Durability

Double-Row Angular Contact Ball Slewing Bearings are the backbone of industrial machinery requiring unmatched load capacity and rotational accuracy. With 30+ years of expertise, our bearings combine dual-row angular contact design, advanced material science, and precision engineering to handle axial and radial forces simultaneously. Ideal for wind turbines, port cranes, and medical imaging systems, they deliver P5-grade precision, corrosion resistance, and a 99.9% defect-free rate—ensuring reliability where failure isn’t an option.

Why Choose Us?

- Dual-Load Mastery: Simultaneously manage axial loads up to 15,000 kN and radial loads with optimized 25°/40° contact angles.

- Harsh Environment Ready: Operate between -50°C to +150°C using 42CrMo/50Mn steel with multi-layer hardening (60-62 HRC).

- Precision Ground: Achieve ±0.01mm dimensional accuracy via CNC profile grinding for critical alignment in medical CT scanners or tunnel boring machines.

- Custom-Built Solutions: Tailor bore diameters (200mm–5000mm), sealing (IP68/IP69K), or materials (non-magnetic titanium/ceramic hybrids) for your application.

Technical Specifications

| Parameter | Value/Range |

|---|---|

| Bore Diameter | 200mm - 5000mm |

| Static Load Capacity | 5,000 - 15,000 kN |

| Rotational Speed | Up to 200 RPM |

| Precision Grade | P4/P5 (ISO 492) |

| Noise Level | <50dB in medical systems |

Where Excellence Meets Demand?

Wind Energy

Withstand 20+ years of offshore saltwater exposure and 15 MN·m static loads in 5MW turbines. GL Wind Energy-certified with IoT-ready condition monitoring.

Construction & Mining

Absorb 300% shock loads in crawler cranes. Tungsten carbide-coated raceways combat abrasive debris. MSHA/CE compliant.

Medical Imaging

Built for Your Needs

1. Analyze: Share load profiles, RPM, and environmental challenges.

2. Simulate: CAD-based fatigue life calculation (250,000+ cycles guaranteed).

3. Test: Prototypes undergo 12+ tests, including torque measurement and -40°C/120°C thermal cycling.

4. Deliver: Batch production with 3-stage inspections. MOQ 1 unit.

Quality You Can Trust

- Traceable Materials: EN 10204 3.1 certificates for every batch.

- Precision Verification: CMM-checked raceway geometry and <4.5µm/s vibration levels.

- Real-World Testing: 500-hour accelerated life simulations replicating port crane duty cycles.

Global Support, Local Speed

- 48-Hour Emergency Dispatch: 1,000+ standard bearings stocked globally.

- Lifecycle Management: Installation guidance, lubrication plans, and 24/7 breakdown support.

- Regional Warehouses: Reduce lead times to 15 days for custom φ3000mm+ units.

FAQ

Q: Can these bearings handle saltwater environments in offshore turbines?

A: Yes. Our ISO 12944 C5-M compliant models use fluororubber seals and 316L stainless steel components.

Q: What precision is achievable for medical equipment?

A: We deliver ≤0.3µm runout (DIN 620-6 P2S class) using ceramic hybrid balls and vacuum-grade lubrication.

Q: How do you ensure large bearings (φ4000mm) meet tolerance specs?

A: In-house CNC grinding achieves ±0.03mm radial runout, verified via laser alignment systems.

Contact Us

Need a Bearing That Never Compromises?

Email your requirements to sales@inno-bearing.com for:

- Free load capacity calculations

- CAD model reviews within 6 hours

- Expedited quotes for wind/medical projects

Double-Row Angular Contact Ball Slewing Bearings from LUOYANG INNO BEARING CO., LTD—where innovation rotates with precision.

Learn about our latest products and discounts through SMS or email