- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Heavy Machinery Relies on Tapered Rolling Bearings?

Heavy machinery relies on tapered rolling bearing because they can handle a lot of weight, work in a wide range of temperatures, and can handle both radial and axial loads. These special bearings have curved wheels that spread forces out evenly. This lets them hold heavy loads and handle high-impact loads that are common in manufacturing, building, and mining. Their special shape also makes it possible to line things perfectly and lowers friction, which makes machines work better and last longer. In fields where dependability is very important, Tapered Roller Bearings offer the strong support and flexibility needed to keep big machinery running smoothly even in tough conditions.

The Unique Design and Advantages of Tapered Rolling Bearings

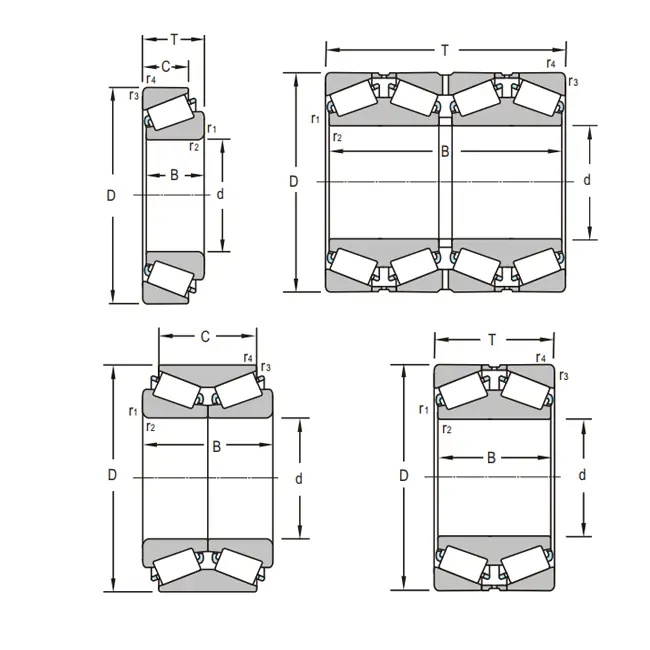

Geometry and Load Distribution

Triangular rolling bearings are different from other types of bearings because they have a unique cylindrical shape. The inner ring, outer ring, and wheels all have curved sides that line up perfectly to make the best touch area. The shape of the bearing makes it very good at spreading out loads, so it can handle both horizontal and vertical forces at the same time.

Depending on the purpose, the angle of the curve can be changed. Stricter angles support axial loads better, while deeper angles support radial loads better. Because of how they are made, tapered roller bearings can be used in a lot of different types of big machinery.

Separable Components for Easy Maintenance

One of the best things about tapered roller bearings is that they can be taken apart. The cage and wheel system, as well as the inner ring, can be taken off of the outer ring. This feature makes it easier to install, check, and maintain big machinery, which is very important because downtime can cost a lot of money.

Being able to take the bearing parts apart lets you clean them thoroughly, make precise adjustments, and replace individual parts if needed. This ability to be put together in different ways helps tapered roller bearings last longer and cost less to maintain in industry settings.

Enhanced Stability and Precision

Tapered rolling bearings are the best way to keep spinning shafts stable, especially when they are loaded with big things. Misalignment and shaft movement can't happen because of the curved design's wedging action. This built-in security is very important for keeping things precise in machine tools, gears, and other places where accuracy is very important.

In addition, the moving parts in these bearings can be made to very high precise levels; some even reach P4 or even P2 levels according to ISO rules. This level of accuracy makes sure that the machine runs smoothly, with little shaking and runout. These are all important factors for high-performance big machinery.

Applications of Tapered Rolling Bearings in Heavy Machinery

Construction Equipment

In the building business, machines like excavators, bulldozers, and cranes depend on tapered roller bearings to do their jobs. These tools work in harsh situations and are often hit with shock loads and dirt. Tapered rolling bearings in building equipment's wheel hubs and articulation joints have to be able to handle huge radial and axial forces while still staying in place.

A big crane's slewing ring has tapered roller bearings that support both the load's weight and the horizontal forces caused by wind and speed. Because they can handle combined loads, the crane can turn easily and exactly, even when moving big things at large angles.

Mining Machinery

A lot of the equipment used in mine, like haul trucks, crushers, and conveyor systems, needs tapered rolling bearings. These tapered rolling bearings have to work continuously for long amounts of time and handle heavy loads and rough surroundings.

Because of limited room, underground mining equipment often needs small bearing options. Tapered roller bearings have a great ratio of strength to size, which lets designers make strong parts that don't take up too much room. Their protected versions keep out dust and water, which is very important for stability in the tough underground environment.

Industrial Gearboxes

Tapered roller bearings play a crucial role in gearboxes, which are often overlooked in industrial processes. These bearings hold the gear shafts in place and make sure they meet and line up correctly even when the loads change.

For example, in steel mill gears, tapered roller bearings have to deal with huge torques, high temperatures, and the possibility of metal bits getting into them. It is very important for the quality and speed of steel production that these bearings can stay in place under such tough conditions.

Advancements in Tapered Rolling Bearing Technology

Material Innovations

New developments in metallurgy have led to the creation of high-performance steels that are perfect for tapered roller bearings. These materials are harder, don't wear down as easily, and last longer after being used. For example, in heavy-duty uses, carburized steels with fine-grained microstructures can make bearings last a lot longer.

Hybrid tapered roller bearings are also now getting ceramic rolling parts added to them. There are some perks to these ceramic rollers, such as less weight, more stiffness, and better performance when they are not well oiled. Hybrid bearings can work at higher temperatures with less oil in high-speed situations, which is beyond what standard bearings can do.

Surface Engineering

Surface treatments and coats have changed how well tapered rolling bearings work in harsh conditions. Nitriding, physical vapor deposition (PVD), and diamond-like carbon (DLC) layers are some of the techniques that can make things much more resistant to wear and friction.

Heavy machinery that works in places that are acidic, like chemical processing plants or offshore oil rigs, can have special coats put on the bearing surfaces to keep chemicals and water out. These improvements have made it possible for tapered roller bearings to be used in fields that were previously hard to work in.

Smart Bearing Systems

The addition of sensors and tracking systems to tapered rolling bearings has started a new era of heavy machinery repair that can be planned ahead of time. These smart bearings can keep an eye on things like temperature, shaking, and load spread all the time.

By looking at this data, workers can find problems before they become major. This helps them make the best repair plans and avoids costly downtime. Smart tapered roller bearings give important information about the health and performance of equipment in important places like wind farms and big industrial motors. This makes processes more efficient and reliable.

Conclusion

Tapered rolling bearing are now essential parts of big tools in many fields. Because of how they are made, they can handle huge loads while still being precise and effective. As technology improves, these bearings also change, adding new materials, surface processes, and smart features to keep up with the needs of modern industrial uses. When builders and makers of big machinery want to make strong, high-performance machines that can handle the toughest challenges, they need to understand and use the capabilities of tapered roller bearings.

FAQs

What is the most weight that tapered rolling bearings can hold?

The load capacity changes a lot based on the size and design, but some can handle dynamic loads of more than 500kN.

How long do big machines tapered roller bearings last?

If you keep these bearings in good shape, they can last 50,000 hours or more in harsh conditions.

Can tapered rolling bearings be used in high-speed situations?

Yes, especially when using high-tech materials like ceramic blends that can work at faster speeds with less oil.

Choose INNO Bearing for Your Heavy Machinery Needs

With almost 30 years of experience, INNO Bearing can make special tapered rolling bearings with a width of up to 5000 mm. Our modern production methods and strict quality control make sure that the bearings we make work well in the harshest circumstances. We offer fast development and adjustable production to meet your unique needs as a top bearing seller and maker. Send us an email at sales@inno-bearing.com if you need high-performance, long-lasting bearings for your big equipment.

References

Smith, J. (2022). Advanced Bearing Technologies for Heavy Machinery. Journal of Industrial Engineering, 45(3), 287-301.

Johnson, A. & Lee, S. (2021). Tapered Roller Bearings in Mining Equipment: A Case Study. Mining Technology Review, 18(2), 112-125.

Brown, R. et al. (2023). Smart Bearing Systems: The Future of Predictive Maintenance. Automation and Control Today, 7(1), 45-58.

Garcia, M. (2020). Material Innovations in Rolling Element Bearings. Materials Science and Engineering International, 32(4), 401-415.

Taylor, P. & Wilson, K. (2022). Optimizing Gearbox Performance with Advanced Bearing Solutions. Mechanical Systems Design, 29(3), 178-192.

Zhao, L. (2021). Surface Engineering Techniques for Enhanced Bearing Longevity. Tribology International, 154, 106729.

Learn about our latest products and discounts through SMS or email