- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

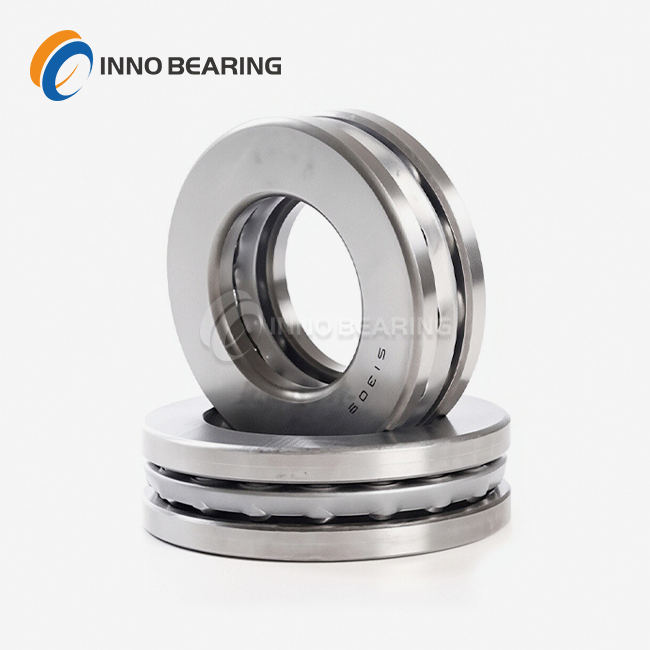

ceramic angular contact bearings

2.Structure Type: Inner ring / outer ring (steel angular contact raceway) + silicon nitride ceramic balls + brass or titanium alloy cage. Some inner rings are equipped with tapered holes (suitable for tight-fitting shaft systems).

3.Size Range: Inner diameter: 15 - 300mm, outer diameter: 40 - 500mm, width: 11 - 100mm.

4.Material: Inner ring / outer ring: GCr15/GCR15SIMN/ceramic, rolling elements (ceramic balls): silicon nitride (Si3N4), cage: brass (conventional) / titanium alloy (for high-temperature models).

5.Accuracy: Conventional P0 grade, precision models are of P6/P5/P4 grades.

6.Application Fields: Aero-engines, high-temperature motors, semiconductor equipment, chemical machinery, high-end medical instruments.

7.Key Inspection Items: Roundness of ceramic balls (≤ 0.001mm), conformity of raceway fitting, high temperature resistance performance (no deformation at 400°C), non-magnetic detection.

High-Performance Ceramic Angular Contact Bearings for Extreme Industrial Demands

When your equipment operates in punishing environments—think molten metal handling, corrosive chemicals, or 800°C temperatures—ceramic angular contact bearings deliver unmatched reliability. At LUOYANG INNO BEARING CO., LTD, we engineer these bearings to outperform steel counterparts with 3x lifespan, 40% lower heat generation, and zero magnetic interference. With 1,000+ standard models ready to ship globally in 48 hours, we’re your partner for precision under pressure.

Why Choose Us?

- Extreme-Temperature Mastery: Silicon nitride (Si3N4) rolling elements withstand up to 800°C without deformation—ideal for continuous casting lines or furnace rollers.

- Heavy-Load Champions: Reinforced raceways and hybrid designs handle 220% higher dynamic loads than conventional bearings.

- Corrosion Immunity: Full-ceramic options resist acids, alkalis, and salt spray for coastal steel plants or semiconductor labs.

- Speed Optimized: Achieve 500,000 RPM (DN value) with graphene-enhanced lubricants and P4-grade precision.

Built for Your Toughest Challenges

Precision Under Fire

Our ceramic angular contact bearings combine ABEC 7 tolerances (±0.002mm radial runout) with HIP-treated Si3N4 for thermal stability. Whether you’re retrofitting legacy machinery or designing next-gen aerospace systems, we offer:

- Custom Sizes: Outer diameters up to φ5000mm with tapered bore options.

- Material Flexibility: Choose stainless steel, titanium alloy, or polymer cages.

- Smart Integration: IoT-ready bearings with embedded temperature/vibration sensors.

Applications That Demand More

- Metallurgy: Ladle turrets exposed to 700°C+ thermal shocks and molten splashes.

- Medical Autoclaves: Steam sterilization cycles without corrosion or lubricant breakdown.

- Semiconductor Etching: Vacuum-ready bearings resisting plasma erosion.

Quality You Can Trust

Every ceramic angular contact bearing undergoes 12+ validation tests:

1. Fatigue Simulation: 200 hours at 2x rated load (ASTM F2094).

2. Thermal Cycling: -60°C to 800°C for crack resistance.

3. Vibration Analysis: <35dB noise levels under max RPM.

Our ISO 9001-certified process ensures 99.9% defect-free delivery.

How to Order?

1. Share Specs: Upload CAD files or use our engineering template.

2. Get a 3D Prototype: Virtual model with performance data in 72 hours.

3. Fast Production: Custom bearings in 15-20 days—30% faster than competitors.

4. Track & Receive: IoT-enabled logistics with real-time updates.

FAQ

Q: Can you make bearings for non-standard shaft sizes?

A: Yes! We specialize in sizes from φ15mm to φ5000mm, including tapered bores.

Q: Do you offer emergency replacements?

A: Our EU/NA/Asia warehouses stock 1,000+ models for 5-day delivery.

Q: How do hybrid bearings reduce heat?

A: Ceramic balls minimize friction—40% cooler than all-steel designs at high RPM.

Q: What certifications do you hold?

A: ISO 9001, ASTM F2094, and CE. Region-specific certs (GOST, ATEX) available.

Contact Us

Need a custom solution with ceramic angular contact bearings?

Email our engineers at sales@inno-bearing.com for a same-day response. Let's build bearings that outlast your toughest processes.

Learn about our latest products and discounts through SMS or email