- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

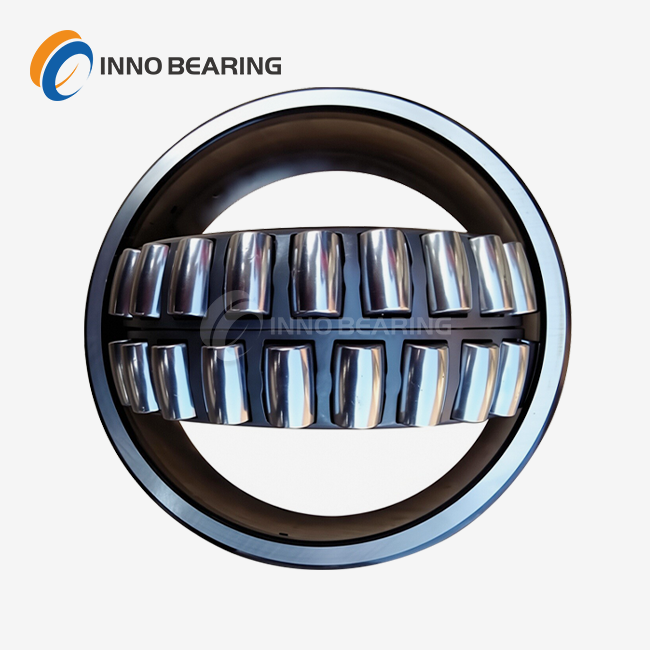

high speed cylindrical roller bearings

2.Structure Type: Outer ring with double ribs, separable inner ring, precision rollers + cage, equipped with high-speed dust caps.

3.Dimension Range: Inner diameter: 10-300mm, Outer diameter: 26-500mm, Width: 8-100mm

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A; Cage: Stamped steel/brass

5.Accuracy: Class P5/P4, Class P2 for ultra-high-speed models.

6.Application Fields: Precision machine tool spindles, high-speed motors, turbochargers, centrifuges.

7.Key Inspection Items: Limit speed (≥8000r/min), operating noise (≤55dB), radial runout (≤0.005mm).

High Speed Cylindrical Roller Bearings: Precision Engineered for Extreme Performance

When your machinery demands unmatched speed and reliability, high speed Cylindrical roller bearings deliver the solution. Designed to operate at rotational speeds up to 20,000 RPM, our bearings combine P4-grade precision with advanced heat-resistant materials, ensuring stability even in 500°C environments. Trusted by metallurgical, medical, and heavy machinery industries, these bearings reduce downtime while handling heavy axial loads and sudden shock impacts.

Why Choose Us?

- 30+ Years of Expertise: Specialized R&D for high-speed applications, from precision spindles to industrial kilns.

- Custom Solutions: Tailor-made designs up to φ5000mm, with 30% faster prototyping than industry standards.

- Rapid Delivery: 48-hour shipping for standard sizes, backed by regional warehouses worldwide.

- Proven Durability: High-purity steel construction and triple-stage quality control ensure a 99.9% defect-free rate.

- Full Lifecycle Support: IoT-driven maintenance plans and installation guidance for optimal performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Speed Limit | 10,000–20,000 RPM (customizable) |

| Temperature Range | -50°C to +150°C |

| Precision Class | ABEC-7/P4 (P2 available for ultra-high speed) |

| Dynamic Load Capacity | Up to 980 kN |

| Material | GCr15/GCr15SiMn steel, brass/stamped steel cages |

Applications: Precision machine tools, steel rolling mills, turbochargers, centrifuges.

Built for High-Speed Challenges

1. Extreme Heat & Heavy Loads

Our bearings thrive in metallurgical environments where temperatures hit 150°C and shock loads exceed 20% of rated capacity. Specialized heat treatment and graphite lubrication prevent premature wear in steel rolling mills and blast furnace systems.

2. Precision in Motion

Medical-grade variants operate below 35dB noise levels with micron-level radial runout (≤0.005mm), ideal for MRI machines and high-speed centrifuges.

3. Agile Customization

Need non-standard dimensions? Our high speed cylindrical roller bearings modular design process adapts to unique shaft/bore fits in 15–20 days, supported by 12+ performance tests including vibration analysis and lifespan validation.

Quality Assurance Process

1. Material Inspection: Spectrometry checks for steel purity and hardness.

2. In-Process Controls: Laser measurement ensures dimensional accuracy within ±0.001mm.

3. Final Validation: Noise (<55dB), vibration, and load testing under simulated operational stress.

Every batch receives a traceable ID for accountability.

Global Supply Chain Excellence

- Urgent Orders: 48-hour delivery for 1,000+ in-stock bearings.

- Oversized Shipments: φ3000mm+ units shipped globally in 20 days.

- Logistics Network: Regional hubs in Asia, Europe, and North America minimize transit times.

FAQ

Q: How do your bearings handle sudden load spikes in rolling mills?

A: The SHOCKPRO series incorporates reinforced roller ends and 20% overload capacity, absorbing impacts without performance loss.

Q: What lubrication works best for 500°C smelting applications?

A: High-temperature graphite-based lubes or ceramic hybrid designs prevent grease degradation.

Q: Can you modify bearings for existing machinery?

A: Yes! Share your operational data (speed, load, temperature), and we'll map a retrofit solution in 72 hours.

Q: How does IoT predictive maintenance work?

A: Embedded sensors monitor vibration and temperature, alerting you to lubrication needs or alignment issues before failures occur.

Contact Us

Ready to Boost Your Machinery's Performance?

Contact Us Today!

📧 Email: sales@inno-bearing.com

🌐 Get a customized quote within 4 hours.

Upgrade to high speed cylindrical roller bearings engineered for reliability, speed, and precision—where every rotation counts.

Learn about our latest products and discounts through SMS or email