- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

22218 bearing

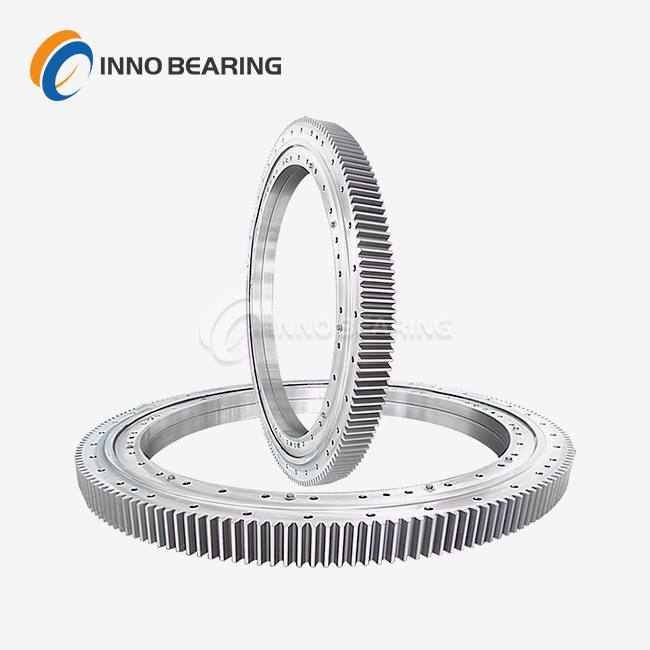

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row spherical rollers + stamped steel cage, and an open structure.

3.Size Range: Inner diameter 90mm, outer diameter 160mm, width 40mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel, rollers: GCr15 bearing steel, cage: stamped steel.

5.Precision: Conventional P0 level, precision version is P6 level.

6.Common Inner Tapered Hole: Optionally with a 1:12 tapered hole (suitable for a shaft diameter of 90mm), and the conventional one is a straight hole.

7.Application Fields: Electric motor spindles, reducers, mining machinery, paper-making equipment.

8.Key Inspection Items: Radial clearance, self-aligning angle, dimensional accuracy, consistency of roller arrangement.

22218 Bearing Spherical Roller for Heavy Industrial Equipment – High-Temperature Resistance (150℃+), Extreme Load Capacity, and Extended Service Life

When your heavy machinery faces extreme radial loads, misalignment challenges, or high-temperature environments, the 22218 bearing delivers unmatched reliability. Designed for metallurgical, mining, and port equipment, this double-row spherical roller bearing combines a self-aligning design (±2° compensation) with robust construction to withstand dynamic loads up to 245 kN. Its open structure, precision-ground raceways, and high-purity GCr15 steel ensure smooth operation even under 150℃ conditions.

Key Specifications & Technical Parameters

- Dimensions: 90mm (Inner Diameter) × 160mm (Outer Diameter) × 40mm (Width)

- Load Capacity: Dynamic 245 kN | Static 255 kN

- Temperature Range: -30℃ to +150℃ (customizable for higher thresholds)

- Precision: Standard P0 | High-Precision P4/P6 (ISO 492)

- Material: GCr15 bearing steel with carburizing heat treatment (60-64 HRC hardness)

- Cage: Stamped steel for durability and reduced friction

Built for Heavy-Duty Performance

1. Metallurgy & Mining Applications

The 22218 spherical roller bearing excels in rolling mills, crushers, and sintering machines where heavy loads, thermal stress, and shaft misalignment are common. Our triple-lip sealing variants (22218-SE) prevent abrasive dust ingress, extending service life by 30% in mining conveyors.

2. High-Temperature Resilience

Specially heat-treated versions (22218-HT) withstand furnace-side applications up to 150℃ using graphite-enriched lubrication. Precision grinding reduces surface roughness to ≤0.2μm, minimizing friction-induced heat buildup.

3. Impact-Resistant Design

Reinforced cages and ceramic-coated rollers (optional) enhance shock load capacity by 35% for port cranes and mining drills exposed to sudden force spikes.

Customization to Match Your Needs

- Material Upgrades: SUJ2 steel or ceramic rollers for corrosive/chemical environments

- Sealing Solutions: Labyrinth seals or triple-lip designs for dusty conditions

- Lubrication: High-temperature grease, solid oil films, or food-grade options

- Tapered Holes: 1:12 taper adapters for simplified installation on 90mm shafts

Rigorous Quality Assurance

Every 22218 bearing undergoes 12+ tests, including:

- Vibration Analysis: <4.5 μm amplitude

- Noise Testing: <35 dB for medical-grade applications

- Lifespan Simulation: 500-hour accelerated load cycles

- Dimensional Accuracy: ±0.01mm tolerance

Certifications: ISO 9001, CE, GOST (available upon request).

Bulk Order Advantages

- Stock Availability: 5,000+ units ready for 48-hour dispatch

- MOQ Flexibility: As low as 50 units for new clients

- Global Logistics: Regional hubs in EU, Asia, and North America ensure 72-hour emergency delivery

Technical Support & Services

- Bearing Selection Guidance: Share your operating parameters (load, RPM, environment) for tailored solutions

- Predictive Maintenance: IoT-enabled wear monitoring and vibration analysis

- 24/7 Support: On-call engineers for installation troubleshooting

FAQ

Q: Can the product operate in humid or corrosive environments?

A: Yes! Opt for our 22218-SE variant with anti-corrosion coatings and triple-lip seals.

Q: What lubrication is best for high-speed applications?

A: We recommend synthetic grease (NLGI 2) or solid oil films for RPMs exceeding 3,000.

Q: Do you provide CAD models for customizations?

A: Absolutely. Share your equipment specs or OEM drawings for precision-matched designs.

Q: How does your product achieve longer fatigue life?

A: Advanced carburizing heat treatment and ultra-fine grain steel enhance fatigue resistance by 40%.

Q: What’s the lead time for 1,000+ units?

A: Standard orders ship in 7-15 days. Repeat clients enjoy 30% faster production.

Contact Us

Optimize Your Machinery's Performance Today

Email your requirements to sales@inno-bearing.com for a 22218 bearing solution tailored to your load, speed, and environmental conditions. Our engineers will respond within 4 hours with technical specs, pricing, and delivery options.

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 25 | 52 | 18 | 1 | 36.1 | 36.6 | 8500 | 11000 | 22205CA/W33 | 22205CAKW33 | 31 | 46 | 1 | 0.36 | 1.9 | 2.8 | 1.8 | 0.178 | ||

| 30 | 62 | 20 | 1 | 51.7 | 55 | 7500 | 9500 | 22206C/W33 | 22206CK/W33 | 36 | 56 | 1 | 0.33 | 2 | 3 | 2 | 0.281 | ||

| 68 | 20 | 51.7 | 55 | 7400 | 9400 | 22206XICN | 22206XICNK | 36 | 62 | 1 | 0.33 | 2 | 3 | 2 | 0.369 | ||||

| 35 | 72 | 23 | 1.1 | 68.9 | 72.5 | 6300 | 8000 | 22207/W33 | 22207KW33 | 3507Y | 113507Y | 42 | 65 | 1 | 35 | 1.9 | 2.9 | 1.8 | 0.477 |

| 40 | 80 | 23 | 1.1 | 86.9 | 93.9 | 6000 | 7500 | 22208C/W33 | 22208CK/W33 | 53508Y | 153508Y | 47 | 73 | 1 | 0.28 | 2.4 | 3.6 | 2.5 | 0.575 |

| 90 | 33 | 1.5 | 123.0 | 133 | 4500 | 5600 | 22308C/W33 | 22308CKW33 | 49 | 81 | 1.5 | 0.37 | 1.8 | 2.7 | 1.8 | 1.02 | |||

| 90 | 33 | 1.5 | 121.0 | 129 | 4400 | 5500 | 22308/W33 | 22308KW33 | 3608Y | 113608Y | 49 | 81 | 1.5 | 42 | 1.6 | 2.4 | 1.6 | 1.05 | |

| 45 | 85 | 23 | 1.1 | 86.7 | 101 | 5300 | 6700 | 22209C/W33 | 22209CKW33 | 53509Y | 153509Y | 52 | 78 | 1 | 0.27 | 2.5 | 3.7 | 2.5 | 0.618 |

| 85 | 23 | 1.1 | 78.6 | 91.9 | 5200 | 6600 | 22209/W33 | 22209KW33 | 3509Y1 | 113509Y | 52 | 78 | 1 | 0.3 | 2.3 | 3.4 | 2.2 | 0.617 | |

| 100 | 36 | 1.5 | 141.0 | 154 | 3800 | 4800 | 22309C/W33 | 22309CKW33 | 54 | 91 | 1.5 | 0.37 | 1.8 | 2.7 | 1.8 | 137 | |||

| 50 | 90 | 23 | 1.1 | 90.3 | 97 | 5000 | 6300 | 22210C/W33 | 22210CK/W33 | 53510Y | 153510Y | 57 | 83 | 1 | 25 | 2.7 | 4 | 2.7 | 0.65 |

| 90 | 23 | 1.1 | 81.5 | 95.4 | 5000 | 6300 | 22210CA/W33 | 22210CAW33 | 57 | 83 | 1 | 0.25 | 2.7 | 4 | 2.7 | 0.614 | |||

| 110 | 40 | 2 | 176.0 | 193 | 3400 | 4300 | 22310C/W33 | 22310CK/W33 | 64 | 91 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 1.83 | |||

| 110 | 40 | 2 | 175.0 | 192 | 3300 | 4200 | 22310/W33 | 22310KW33 | 3610Y | 113610Y | 64 | 91 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 1.8 | |

| 55 | 100 | 25 | 1.5 | 109.0 | 130 | 4500 | 5600 | 22211C/W33 | 22211CKW33 | 53511Y | 153511Y | 66 | 88 | 1.5 | 0.25 | 2.7 | 4 | 2.7 | 0.88 |

| 100 | 25 | 1.5 | 109.0 | 130 | 4500 | 5600 | 22211CA/W33 | 2221CAK/W33 | 66 | 88 | 1.5 | 0.25 | 2.7 | 4 | 2.7 | 0.82 | |||

| 120 | 43 | 2 | 210.0 | 243 | 3200 | 4000 | 22311C/W33 | 22311CKW33 | 66 | 109 | 2 | 37 | 1.8 | 2.7 | 1.8 | 2.38 | |||

| 60 | 110 | 28 | 1.5 | 129.0 | 157 | 4000 | 5000 | 22212C/W33 | 22212CK/W33 | 53512Y | 153512Y | 69 | 101 | 1.5 | 25 | 2.7 | 4 | 2.7 | 1.22 |

| 130 | 46 | 2.1 | 246.0 | 288 | 2900 | 3800 | 22312C/W33 | 22312CKW33 | 72 | 118 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 2.95 | |||

| 130 | 46 | 2.1 | 233.0 | 260 | 2900 | 3800 | 22312/W33 | 22312KW33 | 3612Y | 113612Y | 72 | 118 | 2 | 0.4 | 1.7 | 2.5 | 1.6 | 2.88 | |

| 130 | 46 | 2.1 | 233.0 | 274 | 2900 | 3800 | 22312CA/W33 | 22312CAKW33 | 72 | 118 | 2 | 0.37 | 1.8 | 2.7 | 1.8 | 2.96 | |||

| 65 | 120 | 31 | 1.5 | 144.0 | 178 | 3800 | 4800 | 22213C/W33 | 22213CKW33 | 53513Y | 153513Y | 74 | 111 | 1.5 | 26 | 2.6 | 3.9 | 2.5 | 1.58 |

| d 65~90mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 65 | 120 | 31 | 1.5 | 156 | 195 | 3800 | 4800 | 22213CA/W33 | 22213CAKW33 | 53513HY | 153513HY | 74 | 111 | 1.5 | 0.27 | 2.5 | 3.7 | 2.5 | 152 |

| 140 | 33 | 2.1 | 203 | 242 | 3800 | 3600 | 21313 | 3313 | 77 | 128 | 2 | 0.25 | 2.7 | 4 | 2.7 | 2.58 | |||

| 140 | 48 | 2.1 | 285 | 315 | 2600 | 3400 | 22313/W33 | 22313KW33 | 77 | 128 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 1.6 | |||

| 140 | 48 | 2.1 | 285 | 315 | 2600 | 3400 | 22313CA/W33 | 22313CAKW33 | 77 | 128 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 3.54 | |||

| 70 | 125 | 31 | 1.5 | 163 | 207 | 3600 | 4500 | 22214C/W33 | 22214CKW33 | 53514Y | 153514Y | 79 | 116 | 1.5 | 0.24 | 2.8 | 4.2 | 2.8 | 1.69 |

| 125 | 31 | 1.5 | 156 | 199 | 3500 | 4400 | 22214/W33 | 22214KW33 | 3514Y | 113514Y | 79 | 116 | 1.5 | 0.27 | 2.5 | 3.7 | 2.5 | 1.64 | |

| 150 | 35 | 2.1 | 216 | 276 | 2600 | 3400 | 21314 | 3314 | 82 | 138 | 2 | 0.25 | 2.7 | 4 | 2.7 | 3.01 | |||

| 150 | 51 | 2.1 | 306 | 370 | 2400 | 3200 | 22314C/W33 | 22314CKW33 | 53614Y | 153614Y | 82 | 138 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 4.4 | |

| 150 | 51 | 2.1 | 311 | 352 | 2000 | 2800 | 22314/W33 | 22314KW33 | 3614Y | 113614Y | 82 | 138 | 2 | 0.37 | 1.8 | 2.7 | 1.8 | 4.21 | |

| 150 | 51 | 2.1 | 293 | 351 | 2000 | 2800 | 22314CA/W33 | 22314CAKW33 | 82 | 138 | 2 | 36 | 1.9 | 2.8 | 1.8 | 4.22 | |||

| 75 | 130 | 31 | 1.5 | 162 | 212 | 3400 | 4300 | 22215C/W33 | 22215CKW | 53515Y | 153515Y | 84 | 121 | 1.5 | 0.22 | 3 | 4.5 | 2.9 | 1.73 |

| 130 | 31 | 1.5 | 155 | 211 | 3400 | 4300 | 22215/W33 | 22215KW33 | 3515Y | 113515Y | 84 | 121 | 1.5 | 0.26 | 2.6 | 3.9 | 2.5 | 1.75 | |

| 160 | 55 | 2.1 | 350 | 427 | 2200 | 3000 | 22315C/W33 | 22315CKW33 | 87 | 148 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 5.4 | |||

| 80 | 140 | 33 | 2 | 187 | 248 | 3200 | 4000 | 22216C/W33 | 22216CKW33 | 53516Y | 15316Y | 90 | 130 | 2 | 0.22 | 3 | 4.5 | 2.9 | 2.23 |

| 140 | 33 | 2 | 186 | 252 | 3200 | 4000 | 22216/W33 | 22216KW33 | 3516Y | 13516Y | 90 | 130 | 2 | 25 | 2.7 | 4 | 2.7 | 2.23 | |

| 170 | 58 | 2.1 | 400 | 504 | 2000 | 2800 | 22316C/W33 | 22316CKW33 | 53616Y | 153616Y | 92 | 158 | 2 | 0.34 | 2 | 2.9 | 1.9 | 6.59 | |

| 170 | 58 | 2.1 | 388 | 446 | 2000 | 2800 | 22316/W33 | 22316KW33 | 3616Y | 113616Y | 92 | 158 | 2 | 37 | 1.8 | 2.7 | 1.8 | 6.19 | |

| 85 | 150 | 36 | 2 | 204 | 262 | 3000 | 3800 | 22217C/W33 | 22217CKW33 | 53517Y | 153517Y | 95 | 140 | 2 | 23 | 29 | 4.4 | 2.8 | 2.8 |

| 150 | 36 | 2 | 192 | 250 | 3000 | 3800 | 22217/W33 | 22217KW33 | 3517Y | 113517Y | 95 | 140 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 2.79 | |

| 180 | 60 | 3 | 426 | 512 | 1900 | 2600 | 22317/W33 | 22317KW33 | 3617Y | 113617Y | 99 | 166 | 2.5 | 0.37 | 1.8 | 2.7 | 1.8 | 7.07 | |

| 90 | 140 | 50 | 1.5 | 265 | 440 | 2700 | 3500 | 24018C | 24018CK | 100 | 130 | 1.5 | 0.32 | 2.1 | 3.1 | 2 | 2.97 | ||

| 160 | 40 | 2 | 257 | 340 | 2600 | 3400 | 22218C/W33 | 22218CKW33 | 53518Y | 153518Y | 101 | 149 | 2 | 0.23 | 2.9 | 4.4 | 2.8 | 3.24 | |

| 160 | 40 | 2 | 250 | 334 | 2600 | 3400 | 22218/W33 | 22218KW33 | 3518Y | 113518Y | 101 | 149 | 2 | 0.27 | 2.5 | 3.7 | 2.5 | 3.11 | |

| 160 | 52.4 | 2 | 305 | 434 | 1900 | 2600 | 23218C/W33 | 23218CKW33 | 3053218Y | 3153218Y | 101 | 149 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 4.61 | |

| d 90~110mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 90 | 190 | 64 | 3 | 494 | 636 | 1800 | 2400 | 22318C/W33 | 22318CK/W33 | 53618Y | 153618Y | 104 | 176 | 2.5 | 0.34 | 2 | 2.9 | 1.9 | 9.12 |

| 190 | 64 | 3 | 483 | 594 | 1800 | 2400 | 22318CAW33 | 22318CAK/W33 | 53618HY | 153618HY | 104 | 176 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 8.72 | |

| 190 | 64 | 3 | 475 | 583 | 1800 | 2400 | 22318/W33 | 22318K/W33 | 3618Y | 113618Y | 104 | 176 | 2.5 | 0.37 | 1.8 | 27 | 1.8 | 8.6 | |

| 95 | 170 | 43 | 2.1 | 284 | 380 | 2400 | 3200 | 22219C/W33 | 22219CK/W33 | 107 | 158 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 4.2 | ||

| 200 | 67 | 3 | 509 | 637 | 1700 | 2200 | 22319CA/W33 | 22319CAK/W33 | 109 | 186 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 9.95 | |||

| 200 | 67 | 3 | 517 | 617 | 1600 | 2100 | 22319W33 | 22319K/W33 | 3619Y | 113619Y | 109 | 186 | 2.5 | 0.38 | 1.7 | 2.6 | 1.7 | 9.93 | |

| 100 | 180 | 46 | 2.1 | 331 | 441 | 2200 | 3000 | 22220C/W33 | 22220CK/W33 | 53520Y | 153520Y | 112 | 168 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 4.95 |

| 180 | 46 | 2.1 | 331 | 441 | 2100 | 2900 | 22220CA/W33 | 22220CAK/W33 | 112 | 168 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 4.97 | |||

| 180 | 46 | 2.1 | 314 | 416 | 2100 | 2900 | 22220/W33 | 22220K/W33 | 3520Y | 113520Y | 112 | 168 | 2 | 0.27 | 2.5 | 3.7 | 2.5 | 5.03 | |

| 180 | 60.3 | 2.1 | 420 | 605 | 1700 | 2200 | 23220C/W33 | 23220CK/W33 | 3053220Y | 3153220Y | 112 | 168 | 2 | 0.33 | 2 | 3 | 2 | 6.71 | |

| 215 | 73 | 3 | 623 | 792 | 1700 | 2200 | 22320C/W33 | 22320CK/W33 | 53620Y | 153620Y | 114 | 201 | 2.5 | 0.36 | 1.9 | 2.8 | 1.8 | 13.6 | |

| 215 | 73 | 3 | 614 | 785 | 1600 | 2100 | 22320CA/W33 | 22320CAK/W33 | 53620HY | 153620HY | 114 | 201 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 12.4 | |

| 215 | 73 | 3 | 614 | 785 | 1600 | 2100 | 22320/W33 | 22320K/W33 | 3620Y | 113620Y | 114 | 201 | 2.5 | 0.37 | 1.8 | 2.7 | 1.8 | 13 | |

| 105 | 175 | 56 | 2 | 351 | 564 | 1900 | 2600 | 23121/W33 | 23121K/W33 | 3003721Y | 3113721Y | 115 | 165 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.64 |

| 175 | 56 | 2 | 351 | 564 | 1900 | 2600 | 23121N | 3203721 | 115 | 165 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.59 | |||

| 110 | 170 | 45 | 2 | 293 | 465 | 2200 | 3000 | 23022W33 | 23022K/W33 | 3003122Y | 3113122Y | 120 | 160 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 4.2 |

| 170 | 45 | 2 | 293 | 465 | 2200 | 3000 | 23022N | 3203122 | 120 | 160 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 4.18 | |||

| 170 | 60 | 2 | 359 | 605 | 1700 | 2500 | 24022C | 24022CK30 | 120 | 160 | 2 | 0.32 | 2.1 | 3.1 | 2 | 5.18 | |||

| 180 | 56 | 2 | 365 | 562 | 1900 | 2600 | 23122W33 | 23122K/W33 | 3003722Y | 3113722Y | 120 | 170 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.25 | |

| 180 | 56 | 2 | 365 | 562 | 1900 | 2600 | 23122N | 3203722 | 120 | 170 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.2 | |||

| 180 | 69 | 2 | 483 | 754 | 1600 | 2000 | 24122C/W33 | 24122K30/W33 | 4053722Y | 4453722Y | 120 | 170 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 6.88 | |

| 180 | 69 | 2 | 435 | 721 | 1500 | 1800 | 24122CA/W33 | 24122CAK30/W33 | 120 | 170 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 6.86 | |||

| 200 | 53 | 2.1 | 426 | 588 | 2000 | 2800 | 22222C/W33 | 22222CK/W33 | 53522Y | 153522Y | 122 | 188 | 2 | 0.25 | 2.7 | 4 | 2.7 | 7.25 | |

| 200 | 53 | 2.1 | 366 | 531 | 1900 | 2700 | 2222W33 | 22222K/W33 | 3522Y | 113522Y | 122 | 188 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 7.37 | |

| 200 | 69.8 | 2.1 | 515 | 760 | 1600 | 2000 | 23222C/W33 | 23222CK/W33 | 3053222Y | 3153222Y | 122 | 188 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 9.66 | |

| d 110~130mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 110 | 240 | 80 | 3 | 739 | 982 | 1600 | 2000 | 22322CA/W33 | 22322CAK/W33 | 53622HY | 153622HY | 124 | 226 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 17.5 |

| 240 | 80 | 3 | 750 | 915 | 1500 | 1900 | 22322/W33 | 22322K/W33 | 3622Y | 113622Y | 124 | 226 | 2.5 | 0.37 | 1.8 | 2.7 | 1.8 | 18 | |

| 240 | 92.1 | 3 | 799 | 998 | 1400 | 1700 | 23322W33 | 23322K/W33 | 3003322Y | 3113322Y | 124 | 226 | 2.5 | 0.44 | 1.5 | 2.3 | 1.5 | 23.6 | |

| 120 | 180 | 46 | 2 | 315 | 527 | 1800 | 2500 | 23024/W33 | 23024K/W33 | 3003124Y | 4453124HY | 130 | 170 | 2 | 0.25 | 2.7 | 4 | 2.7 | 4.63 |

| 180 | 46 | 2 | 315 | 527 | 1800 | 2500 | 3024N | 3203124 | 130 | 170 | 2 | 0.25 | 2.7 | 4 | 2.7 | 4.61 | |||

| 180 | 60 | 2 | 395 | 686 | 1500 | 2000 | 24024CA/W33 | 24024CAK30/W33 | 130 | 170 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 5.41 | |||

| 180 | 60 | 2 | 395 | 686 | 1600 | 2000 | 24024C/W33 | 4053124Y | 130 | 170 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 5.41 | |||

| 200 | 62 | 2 | 410 | 660 | 1700 | 2300 | 23124/W33 | 23124K/W33 | 3003724Y | 3113724Y | 130 | 190 | 2 | 0.32 | 2.1 | 3.1 | 2 | 7.61 | |

| 200 | 62 | 2 | 410 | 660 | 1700 | 2300 | 23124N | 3203724 | 130 | 190 | 2 | 0.32 | 2.1 | 3.1 | 2 | 7.57 | |||

| 200 | 80 | 2 | 561 | 919 | 1300 | 1700 | 24124CA/W33 | 24124CAK30/W33 | 130 | 190 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 10 | |||

| 200 | 80 | 2 | 589 | 949 | 1400 | 1800 | 24124C/W33 | 24124CK30/W33 | 4053724Y | 4453724Y | 130 | 190 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 10 | |

| 215 | 58 | 2.1 | 495 | 689 | 1900 | 2600 | 22224C/W33 | 22224CKW33 | 53524Y | 153524Y | 132 | 203 | 2 | 0.25 | 2.7 | 4 | 2.7 | 9.08 | |

| 215 | 58 | 2.1 | 489 | 656 | 1800 | 2500 | 22224W33 | 22224K/W33 | 3524Y | 113524Y | 132 | 203 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 9.13 | |

| 215 | 76 | 2.1 | 595 | 910 | 1500 | 1900 | 23224C/W33 | 23224CK/W33 | 3053224Y | 3153224Y | 132 | 203 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 12 | |

| 260 | 86 | 3 | 842 | 1110 | 1400 | 1800 | 22324CW33 | 22324CKW33 | 53624Y | 53624HY | 134 | 246 | 2.5 | 0.4 | 1.7 | 2.5 | 1.6 | 22.7 | |

| 130 | 200 | 52 | 2 | 400 | 655 | 1700 | 2300 | 23026/W33 | 23026K/W33 | 3003126Y | 3113126Y | 140 | 190 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 6.8 |

| 200 | 52 | 2 | 400 | 655 | 1700 | 2300 | 23026N | 3203126 | 140 | 190 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 6.72 | |||

| 200 | 69 | 2 | 482 | 838 | 1800 | 2400 | 24026CCIW33 | 140 | 190 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 7.85 | ||||

| 210 | 64 | 2 | 499 | 777 | 1600 | 2200 | 23126CA/W33 | 23126CAK30/W33 | 140 | 200 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 9.55 | |||

| 210 | 80 | 2 | 633 | 1070 | 1300 | 1700 | 24126C/W33 | 24126CAK30/W34 | 4053726Y | 4453726Y | 140 | 200 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 10.9 | |

| 230 | 64 | 3 | 582 | 830 | 1800 | 2400 | 22226C/W33 | 22226CKW33 | 53526Y | 153626Y | 144 | 216 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 11.7 | |

| 230 | 64 | 3 | 552 | 786 | 1700 | 2300 | 22226CA/W33 | 22226CAK/W33 | 144 | 216 | 2.5 | 0.27 | 2.5 | 3.7 | 2.5 | 11.4 | |||

| 230 | 64 | 3 | 564 | 800 | 1700 | 2300 | 22226/W33 | 22226K/W33 | 3526Y | 113526Y | 144 | 216 | 2.5 | 0.29 | 2.4 | 3.5 | 2.3 | 11.1 | |

| 230 | 80 | 3 | 700 | 1080 | 1300 | 1700 | 23226C/W33 | 23226K/W33 | 3053226Y | 3153226Y | 144 | 216 | 2.5 | 0.33 | 2 | 3 | 2 | 14.4 | |

| 280 | 93 | 4 | 930 | 1250 | 1300 | 1700 | 22326CAW33 | 22326CAK/W33 | 53626HY | 153626HY | 148 | 262 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 27.1 | |

| 280 | 93 | 4 | 836 | 1090 | 1200 | 1600 | 22326ZMB | 148 | 262 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 28.6 | ||||

| d 140~160mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 140 | 210 | 53 | 2 | 395 | 705 | 1600 | 2100 | 23028/W33 | 23028K/W33 | 3003128Y | 3113128Y | 150 | 200 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 7.65 |

| 210 | 53 | 2 | 395 | 705 | 1600 | 2100 | 23028N | 3203128 | 150 | 200 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 7.64 | |||

| 140 | 210 | 69 | 2 | 530 | 910 | 1400 | 1800 | 24028C/W33 | 24028CK30/W33 | 4053128Y | 4153128Y | 150 | 200 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 8.09 |

| 225 | 68 | 2.1 | 560 | 925 | 1500 | 1800 | 23128CA/W33 | 23128CAK/W33 | 3053728HY | 3153728HY | 152 | 213 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 10.4 | |

| 225 | 85 | 2.1 | 620 | 1060 | 1100 | 1500 | 24128CA/W33 | 24128CAK30/W33 | 152 | 213 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 12.9 | |||

| 250 | 68 | 3 | 642 | 931 | 1700 | 2200 | 22228C/W33 | 22228CK/W33 | 53528Y | 53528Y | 154 | 236 | 2.5 | 0.26 | 2.6 | 3.9 | 2.5 | 14.2 | |

| 250 | 68 | 3 | 636 | 897 | 1500 | 1900 | 22228CA/W33 | 22228CAK/W33 | 53528HY | 53528HY | 154 | 236 | 2.5 | 0.26 | 2.6 | 3.9 | 2.5 | 14.1 | |

| 250 | 68 | 3 | 662 | 905 | 1500 | 1900 | 22228/W33 | 22228K/W33 | 3528Y | 13528Y | 154 | 236 | 2.5 | 0.29 | 2.4 | 3.5 | 2.3 | 14.5 | |

| 250 | 88 | 3 | 835 | 1300 | 1200 | 1600 | 23228C/W33 | 23228CK/W33 | 3053228Y | 3153228Y | 154 | 236 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 18.8 | |

| 300 | 102 | 4 | 1120 | 1550 | 1100 | 1500 | 22328CA/W33 | 22328CAK/W33 | 53628HY | 53628HY | 158 | 282 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 35.9 | |

| 300 | 102 | 4 | 1100 | 1420 | 1100 | 1500 | 22328/W33 | 22328K/W33 | 3628Y | 13628Y | 158 | 282 | 3 | 0.38 | 1.7 | 2.6 | 1.7 | 36.9 | |

| 150 | 225 | 56 | 2.1 | 407 | 725 | 1500 | 1900 | 23030/W33 | 23030K/W33 | 3003130Y | 3113130Y | 162 | 213 | 2 | 0.25 | 2.7 | 4 | 2.7 | 8.85 |

| 250 | 80 | 2.1 | 683 | 1170 | 1300 | 1600 | 23130CA/W33 | 23130CAK/W33 | 3053730HY | 3153730HY | 162 | 238 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 18.2 | |

| 250 | 100 | 2.1 | 951 | 1570 | 1000 | 1400 | 24130C/W33 | 24130CK30/W33 | 4053730Y | 4453730Y | 162 | 238 | 2 | 0.37 | 1.8 | 2.7 | 1.8 | 20.3 | |

| 250 | 100 | 2.1 | 861 | 1420 | 900 | 1300 | 24130CA'W33 | 24130CAK30/W33 | 162 | 238 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 19.5 | |||

| 270 | 73 | 3 | 749 | 1050 | 1600 | 2000 | 2223C/W33 | 22230CK/W33 | 53530Y | 153530Y | 164 | 256 | 2.5 | 0.27 | 2.5 | 3.7 | 2.5 | 17.9 | |

| 270 | 73 | 3 | 736 | 1030 | 1500 | 1900 | 22230/W33 | 22230K/W33 | 3530Y | 13530Y | 164 | 256 | 2.5 | 0.29 | 2.4 | 3.5 | 2.3 | 17.5 | |

| 270 | 96 | 3 | 907 | 1350 | 1100 | 1500 | 23230C/W33 | 23230CK/W33 | 3053230Y | 3153230Y | 164 | 256 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 24.3 | |

| 320 | 108 | 4 | 1220 | 1680 | 1000 | 1400 | 22330CA/W33 | 22330CAK/W33 | 53630HY | 153630HY | 168 | 302 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 41.7 | |

| 320 | 108 | 4 | 1210 | 1660 | 1000 | 1400 | 22330/W33 | 22330K/W33 | 3630Y | 113630Y | 168 | 302 | 3 | 0.38 | 1.7 | 2.6 | 1.7 | 42 | |

| 160 | 240 | 60 | 2.1 | 495 | 875 | 1500 | 1900 | 23032N | 3203132 | 172 | 228 | 2 | 0.25 | 2.7 | 4 | 2.7 | 13.4 | ||

| 240 | 60 | 2.1 | 495 | 875 | 1500 | 1900 | 23032/W33 | 23032K/W33 | 3003132Y | 113132Y | 172 | 228 | 2 | 0.25 | 2.7 | 4 | 2.7 | 13.4 | |

| 240 | 80 | 2.1 | 660 | 1220 | 1100 | 1500 | 24032C/W33 | 24032CK30/W33 | 4053132Y | 4453132Y | 172 | 228 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 12.8 | |

| 270 | 86 | 2.1 | 820 | 1200 | 1200 | 1600 | 23132 | 23132K | 172 | 258 | 2 | 0.32 | 2.1 | 3.1 | 2 | 20.8 | |||

| 270 | 86 | 2.1 | 833 | 1290 | 1200 | 1600 | 23132CA/W33 | 23132CAK/W33 | 3053732HY | 3153732HY | 172 | 258 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 20.3 | |

| 270 | 109 | 2.1 | 1070 | 1750 | 950 | 1300 | 24132C/W33 | 24132CK30/W33 | 4053732Y | 4453732HY | 172 | 258 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 19.5 | |

| 270 | 109 | 2.1 | 958 | 1590 | 900 | 1200 | 24132 CAW33 | 172 | 258 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 25.3 | ||||

| d 160~190mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 160 | 290 | 80 | 3 | 850 | 1230 | 1400 | 1800 | 22232CA/W33 | 22232CAK/W33 | 53532HY | 153532HY | 174 | 276 | 2.5 | 0.27 | 2.5 | 3.7 | 2.5 | 22.6 |

| 290 | 80 | 3 | 876 | 1230 | 1350 | 1700 | 22232W33 | 22232K/W33 | 3532Y | 13532Y | 174 | 276 | 2.5 | 0.3 | 2.3 | 3.4 | 2.2 | 22.3 | |

| 290 | 104 | 3 | 1020 | 1550 | 900 | 1300 | 23232CA | 23232CAK | 174 | 276 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 29.8 | |||

| 340 | 114 | 4 | 1340 | 1840 | 930 | 1200 | 22332W33 | 22332KW33 | 3632Y | 113632Y | 178 | 322 | 3 | 0.38 | 1.7 | 2.6 | 1.7 | 50.3 | |

| 170 | 260 | 67 | 2.1 | 640 | 1040 | 1400 | 1800 | 23034N | 3203134 | 182 | 248 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 14.6 | ||

| 260 | 67 | 2.1 | 640 | 1040 | 1400 | 1800 | 23034W33 | 23034K/W33 | 3003134Y | 3113134 | 182 | 248 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 14.6 | |

| 260 | 90 | 2.1 | 778 | 1310 | 1000 | 1400 | 24034C/W33 | 24034CK30W33 | 4003134Y | 4113134Y | 182 | 248 | 2 | 0.33 | 2 | 3 | 2 | 19.3 | |

| 310 | 86 | 4 | 981 | 1390 | 1200 | 1600 | 22234W33 | 22234K/W33 | 3534Y | 113534Y | 188 | 292 | 3 | 0.3 | 2.3 | 3.4 | 2.2 | 27.6 | |

| 310 | 110 | 4 | 1200 | 1900 | 950 | 1300 | 23234CA'W33 | 23234CAK/W33 | 3053234HY | 3153234HY | 188 | 292 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 37.1 | |

| 360 | 120 | 4 | 1500 | 2140 | 930 | 1200 | 22334W33 | 22334KW33 | 3634Y | 113634Y | 188 | 342 | 3 | 0.37 | 1.8 | 2.7 | 1.8 | 59.3 | |

| 180 | 280 | 74 | 2.1 | 710 | 1210 | 1300 | 1600 | 23036W33 | 23036KW33 | 3003136Y | 3113136Y | 192 | 268 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 19.3 |

| 280 | 100 | 2.1 | 930 | 1610 | 900 | 1200 | 24036W33 | 24036K30W33 | 4003136Y | 4403136Y | 192 | 268 | 0.35 | 1.9 | 2.9 | 1.8 | 22.3 | ||

| 300 | 96 | 3 | 1060 | 1800 | 1100 | 1500 | 23136C/W33 | 23136CKW33 | 194 | 286 | 2.5 | 0.3 | 2.3 | 3.4 | 2.2 | 27.2 | |||

| 300 | 96 | 3 | 987 | 1720 | 1000 | 1400 | 23136W33 | 23136KW33 | 3003736Y | 3113736Y | 194 | 286 | 2.5 | 0.32 | 2.1 | 3.1 | 2 | 26.8 | |

| 300 | 96 | 3 | 987 | 1720 | 1000 | 1400 | 23136W33YA2 | 3003736KY | 194 | 286 | 2.5 | 0.32 | 2.1 | 3.1 | 2 | 26.8 | |||

| 300 | 96 | 3 | 987 | 1720 | 1000 | 1400 | 23136N | 3203736 | 194 | 286 | 2.5 | 0.32 | 2.1 | 3.1 | 2 | 26.4 | |||

| 300 | 118 | 3 | 1170 | 1930 | 900 | 1200 | 24136W33 | 24136K30W33 | 194 | 286 | 2.5 | 0.38 | 1.7 | 2.6 | 1.7 | 33.7 | |||

| 320 | 86 | 4 | 995 | 1510 | 1200 | 1600 | 22236W33 | 22236KW33 | 3536Y | 113536Y | 198 | 302 | 3 | 0.28 | 2.4 | 3.6 | 2.5 | 29.3 | |

| 320 | 112 | 4 | 1310 | 2090 | 900 | 1200 | 23236CA'W33 | 23236CAK/W33 | 3053236HY | 3153236HY | 198 | 302 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 39.5 | |

| 320 | 112 | 紧 | 1310 | 2090 | 900 | 1200 | 23236CAW33YA2 | 3053236HKY | 198 | 302 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 394 | |||

| 380 | 126 | 4 | 1650 | 2330 | 900 | 1200 | 2336W33 | 22336K/W33 | 3636Y | 113636Y | 198 | 362 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 80.7 | |

| 190 | 280 | 67 | 2.1 | 633 | 1120 | 1200 | 1500 | 2638 | 3738 | 202 | 270 | 2 | 0.23 | 2.9 | 4.4 | 2.8 | 13.7 | ||

| 290 | 75 | 2.1 | 800 | 1500 | 1200 | 1500 | 23038W33 | 23038KW33 | 3003138Y | 3113138Y | 202 | 278 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 20.3 | |

| 290 | 100 | 2.1 | 938 | 1690 | 950 | 1300 | 24038C/W33 | 24038CK30W33 | 4003138Y | 113138Y | 202 | 278 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 23.9 | |

| 320 | 104 | 3 | 1050 | 1760 | 950 | 1300 | 23138W33 | 23138KW33 | 204 | 306 | 2.5 | 0.33 | 2 | 3 | 2 | 35.1 | |||

| 320 | 104 | 3 | 1140 | 1960 | 950 | 1300 | 23138CA/W33 | 23138CAK/W3 | 204 | 306 | 2.5 | 0.31 | 2.2 | 3.3 | 2.2 | 45 | |||

| d 190~240mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 190 | 320 | 128 | 3 | 1290 | 2250 | 850 | 1100 | 24138CA | 24138CAK30/W33 | 204 | 306 | 2.5 | 0.4 | 1.7 | 2.5 | 1.6 | 43.8 | ||

| 340 | 92 | 4 | 1140 | 1730 | 1200 | 1600 | 22238CA/W33 | 22238CAKW33 | 53538HY | 153538HY | 208 | 322 | 3 | 0.26 | 2.6 | 3.9 | 2.5 | 35.5 | |

| 340 | 92 | 4 | 1090 | 1640 | 1200 | 1600 | 22238W33 | 22238K/W33 | 3538Y | 113538Y | 208 | 322 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 35.5 | |

| 190 | 340 | 120 | 4 | 1490 | 2380 | 850 | 1100 | 23238CA/W33 | 23238CAK/W33 | 3053238HY | 3153238HY | 208 | 322 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 51 |

| 400 | 132 | 5 | 1850 | 2590 | 850 | 1100 | 22338/W33 | 22338K/W33 | 3638Y | 13638Y | 210 | 380 | 4 | 0.25 | 2.7 | 4 | 2.7 | 79.7 | |

| 200 | 310 | 82 | 2.1 | 870 | 1510 | 1100 | 1400 | 23040/W33 | 23040K/W33 | 3003140Y | 313140Y | 212 | 298 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 26 |

| 340 | 112 | 3 | 1230 | 2240 | 850 | 1200 | 23140/W33 | 23140K/W33 | 3003740Y | 3113740Y | 214 | 326 | 2.5 | 0.34 | 2 | 2.9 | 1.9 | 50.5 | |

| 340 | 140 | 3 | 1660 | 2810 | 800 | 1000 | 24140C/W33 | 24140CK30/W33 | 4053740Y | 4453740Y | 214 | 326 | 2.5 | 0.4 | 1.7 | 2.5 | 1.6 | 51.9 | |

| 360 | 98 | 4 | 1210 | 1870 | 1100 | 1500 | 22240/W33 | 22240K/W33 | 3540Y | 113540Y | 218 | 342 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 44.7 | |

| 360 | 128 | 4 | 1490 | 2370 | 800 | 1000 | 23240/W33 | 23240K/W33 | 218 | 342 | 3 | 0.36 | 1.9 | 2.8 | 1.8 | 56.8 | |||

| 420 | 138 | 5 | 1900 | 2800 | 850 | 1100 | 22340/W33 | 22340K/W33 | 3640Y | 113640Y | 222 | 398 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 93.5 | |

| 220 | 320 | 76 | 3 | 758 | 1280 | 1000 | 1300 | 2644 | 3844 | 232 | 308 | 2.5 | 0.23 | 2.9 | 4.4 | 2.8 | 21.6 | ||

| 340 | 90 | 3 | 1100 | 1750 | 1100 | 1500 | 23044/W33 | 23044K/W33 | 233 | 327 | 2.5 | 0.26 | 2.6 | 3.9 | 2.5 | 30.8 | |||

| 370 | 120 | 4 | 1530 | 2640 | 900 | 1200 | 23144/W33 | 23144K/W33 | 3003744Y | 3113744Y | 237 | 353 | 3 | 0.32 | 2.1 | 3.1 | 2 | 53.5 | |

| 370 | 120 | 4 | 1540 | 2650 | 850 | 1100 | 23144CA/W33 | 23144CAK/W33 | 237 | 353 | 3 | 0.32 | 2.1 | 3.1 | 2 | 54.2 | |||

| 370 | 150 | 4 | 1870 | 3350 | 750 | 950 | 24144C/W33 | 24144CK30/W33 | 4053744Y | 4453744Y | 237 | 353 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 66.1 | |

| 370 | 150 | 4 | 1760 | 3120 | 700 | 900 | 2414CAW33 | 237 | 353 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 65.6 | ||||

| 400 | 108 | 4 | 1570 | 2430 | 950 | 1300 | 224/W33 | 2244K/W33 | 3544Y | 113544Y | 237 | 383 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 62.4 | |

| 400 | 108 | 4 | 1570 | 2430 | 950 | 1300 | 22244CA/W33 | 22244CAK/W33 | 237 | 383 | 3 | 0.27 | 2.5 | 3.7 | 2.5 | 62.4 | |||

| 400 | 144 | 4 | 1860 | 3100 | 750 | 950 | 23244/W33 | 23244K/W33 | 3003244Y | 3113244Y | 237 | 383 | 3 | 0.38 | 1.8 | 2.6 | 1.7 | 94.2 | |

| 460 | 145 | 5 | 2130 | 3170 | 750 | 950 | 22344/W33 | 22344K/W33 | 3644Y | 113644Y | 240 | 440 | 4 | 0.35 | 1.9 | 2.9 | 1.8 | 130 | |

| 240 | 360 | 92 | 3 | 1160 | 1870 | 1000 | 1400 | 23048/W33 | 23048K/W33 | 3003148Y | 3113148Y | 253 | 347 | 2.5 | 0.25 | 2.7 | 4 | 2.7 | 37.4 |

| 360 | 118 | 3 | 1320 | 2610 | 800 | 1000 | 24048CA/W33 | 24048CAK30/W33 | 253 | 347 | 2.5 | 0.3 | 2.3 | 3.4 | 2.2 | 42.4 | |||

| 400 | 128 | 4 | 1870 | 3000 | 850 | 1100 | 23148/W33 | 23148K/W33 | 3003748Y | 3113748Y | 257 | 383 | 3 | 0.33 | 2 | 3 | 2 | 75.2 | |

| 400 | 128 | 4 | 1800 | 2950 | 850 | 1100 | 23148CA/W33 | 23148CAK/W33 | 257 | 383 | 3 | 0.3 | 2.3 | 3.4 | 2.2 | 65 | |||

| 400 | 160 | 4 | 1980 | 3710 | 670 | 850 | 24148/W33 | 24148K30/W33 | 4003748Y | 4403748Y | 257 | 383 | 3 | 0.41 | 1.7 | 2.5 | 1.6 | 81.6 | |

| 440 | 120 | 4 | 1720 | 2700 | 900 | 1200 | 22248/W33 | 22248K/W33 | 3548Y | 113548Y | 257 | 423 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 85 | |

| d 240~280mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 240 | 440 | 160 | 4 | 2280 | 3870 | 670 | 850 | 23248/W33 | 23248K/W3 | 3003248Y | 3113248Y | 257 | 423 | 3 | 37 | 1.8 | 2.7 | 1.8 | 109 |

| 500 | 155 | 5 | 2400 | 3600 | 670 | 850 | 22348/W33 | 22348K/W33 | 3648Y | 13648Y | 260 | 480 | 4 | 35 | 1.9 | 2.9 | 1.8 | 154 | |

| 250 | 365 | 87 | 3 | 956 | 1870 | 880 | 1100 | 2650 | 3750 | 264 | 351 | 2.5 | 0.22 | 3 | 4.5 | 2.9 | 32.2 | ||

| 260 | 400 | 104 | 4 | 1440 | 2570 | 900 | 1200 | 23052/W33 | 23052K/W33 | 3003152Y | 3113152Y | 275 | 385 | 3 | 0.26 | 2.6 | 3.9 | 2.5 | 51.2 |

| 400 | 140 | 4 | 1700 | 3260 | 700 | 900 | 24052CA/W33 | 24052CAK30/W33 | 275 | 385 | 3 | 0.33 | 2 | 3 | 2 | 63.4 | |||

| 400 | 140 | 4 | 1700 | 3260 | 700 | 900 | 24052CA/C9W3 | 3 | 275 | 385 | 3 | 0.33 | 2 | 3 | 2 | 63.3 | |||

| 440 | 144 | 4 | 2290 | 3510 | 800 | 1000 | 23152/W33 | 23152K/W33 | 3003752Y | 3113752Y | 277 | 423 | 3 | 0.33 | 2 | 3 | 2 | 962 | |

| 440 | 144 | 4 | 2550 | 3900 | 800 | 1000 | 23152S1 | 277 | 423 | 3 | 0.31 | 2.2 | 3.3 | 2.2 | 96 | ||||

| 440 | 180 | 4 | 2500 | 4560 | 720 | 900 | 24152W33 | 24152K30/W33 | 277 | 423 | 3 | 0.42 | 1.6 | 2.4 | 1.6 | 118 | |||

| 440 | 180 | 4 | 2470 | 4320 | 600 | 750 | 24152CA/W33 | 24152CAK30/W33 | 277 | 423 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 103 | |||

| 440 | 180 | 4 | 2350 | 4320 | 600 | 750 | 24152CW33 | 24152CK30/W33 | 4053752Y | 4453752Y | 277 | 423 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 115 | |

| 480 | 130 | 5 | 2160 | 3100 | 850 | 1100 | 22252CA/W33 | 22252CAK/W33 | 53552HY | 153552HY | 280 | 460 | 4 | 0.27 | 2.5 | 3.7 | 2.5 | 101 | |

| 480 | 174 | 5 | 2800 | 4100 | 560 | 720 | 23252CA/W33 | 23252CAK/W33 | 3053252HY | 3153252HY | 280 | 460 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 150 | |

| 490 | 153 | 4 | 2420 | 3940 | 760 | 1050 | 2652 | 3752 | 280 | 460 | 4 | 0.33 | 2 | 3 | 2 | 143 | |||

| 540 | 165 | 6 | 2860 | 4430 | 560 | 720 | 22352W33 | 22352K/W33 | 3652Y | 113652Y | 286 | 514 | 5 | 0.34 | 2 | 2.9 | 1.9 | 20 | |

| 280 | 420 | 106 | 4 | 1560 | 2560 | 850 | 1100 | 23056/W33 | 23056K/W33 | 3003156Y | 3113156Y | 295 | 405 | 3 | 0.25 | 2.7 | 4 | 2.7 | 61.7 |

| 420 | 106 | 4 | 1540 | 2950 | 800 | 1000 | 23056CA/W33 | 23056CAK/W33 | 295 | 405 | 3 | 0.23 | 2.9 | 4.4 | 2.8 | 51.3 | |||

| 420 | 140 | 4 | 1780 | 3500 | 670 | 850 | 24056CA/W33 | 24056CAK30/W33 | 295 | 405 | 0.3 | 2.3 | 3.4 | 2.2 | 71 | ||||

| 460 | 146 | 5 | 2070 | 3960 | 750 | 950 | 23156/W33 | 23156K/W33 | 3003756Y | 3113756Y | 300 | 440 | 4 | 0.32 | 2. | 3.1 | 2 | 95.2 | |

| 460 | 146 | 5 | 2380 | 3880 | 750 | 950 | 23156CA/W33 | 23156CAK/W33 | 300 | 440 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 969 | |||

| 460 | 180 | 5 | 2360 | 4420 | 560 | 700 | 24156CA | 300 | 440 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 119 | ||||

| 460 | 180 | 5 | 2400 | 4500 | 560 | 700 | 24156 CATYA | 300 | 440 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 157 | ||||

| 460 | 180 | 5 | 2400 | 4590 | 560 | 700 | 24156/W33 | 24156K30/W33 | 300 | 440 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 114 | |||

| 500 | 130 | S | 2110 | 3370 | 800 | 1000 | 22256W33 | 22256K/W33 | 3556Y | 13556Y | 300 | 480 | 4 | 0.28 | 2.4 | 3.6 | 2.5 | 122 | |

| 500 | 176 | 5 | 2560 | 4350 | 600 | 750 | 23256/W33 | 23256K/W33 | 3003256Y | 3113256Y | 300 | 480 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 158 | |

| 580 | 175 | 6 | 3180 | 4970 | 600 | 750 | 22356W33 | 22356K/W33 | 3656Y | 113656Y | 306 | 554 | 5 | 0.34 | 2 | 2.9 | 1.9 | 23.5 | |

| d 300~360mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 300 | 420 | 90 | 3 | 1260 | 2460 | 950 | 1300 | 23960C/W33 | 23960CK/W33 | 313 | 407 | 2.5 | 0.19 | 36 | 5.3 | 3.5 | 39.6 | ||

| 460 | 118 | 4 | 1910 | 3170 | 720 | 920 | 23060/W33 | 23060K/W33 | 3003160Y | 3113160Y | 315 | 445 | 3 | 0.26 | 26 | 3.9 | 2.5 | 74.6 | |

| 460 | 118 | 4 | 2090 | 3370 | 800 | 1000 | 23060CAW33 | 23060CAK/W33 | 315 | 445 | 3 | 0.24 | 2.8 | 4.2 | 2.8 | 761 | |||

| 460 | 160 | 4 | 2430 | 4490 | 600 | 750 | 24060CA/W332 | 4060CAK30/W33 | 4053160Y | 4453160Y | 315 | 445 | 3 | 0.32 | 2.1 | 3.1 | 2 | 10 | |

| 500 | 160 | 5 | 2580 | 4590 | 670 | 850 | 23160/W33 | 23160K/W33 | 3003760Y | 311760Y | 320 | 480 | 4 | 0.32 | 2.1 | 3.1 | 2 | 133 | |

| 500 | 160 | 5 | 2880 | 4640 | 670 | 850 | 23160CA/W33 | 23160CAK/W33 | 320 | 480 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 127 | |||

| 500 | 200 | 5 | 3380 | 5940 | 530 | 670 | 24160C/W33 | 24160CK30/W33 | 4053760Y | 4453760Y | 320 | 480 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 159 | |

| 500 | 200 | 5 | 3120 | 5650 | 500 | 600 | 24160CAW33 | 24160CAK3e/W33 | 320 | 480 | 4 | 0.36 | 1.9 | 2.8 | 1.8 | 160 | |||

| 300 | 500 | 200 | 5 | 3180 | 6100 | 450 | 550 | 24160W33 | 24160K30/W33 | 320 | 480 | 4 | 0.39 | 1.7 | 2.6 | 1.7 | 159 | ||

| 540 | 140 | 5 | 2480 | 3820 | 700 | 900 | 22260/W33 | 22260K/W33 | 3560Y | 113560Y | 320 | 520 | 4 | 0.28 | 2.4 | 3.6 | 2.5 | 143 | |

| 320 | 440 | 90 | 3 | 1290 | 2430 | 900 | 1200 | 239641W33 | 23964K/W33 | 3003964Y | 3113964Y | 333 | 427 | 2.5 | 0.19 | 3.6 | 5.3 | 3.5 | 45.1 |

| 480 | 121 | 4 | 1850 | 3450 | 720 | 900 | 23064/W33 | 23064K/W33 | 3003164Y | 3113164Y | 335 | 465 | 3 | 0.26 | 2.6 | 3.9 | 2.5 | 80.9 | |

| 480 | 121 | 4 | 2020 | 3580 | 800 | 1000 | 23064CA/W33 | 23064CAK/W33 | 335 | 465 | 3 | 0.24 | 2.8 | 4.2 | 2.8 | 77.4 | |||

| 480 | 160 | 4 | 2570 | 5060 | 680 | 850 | 24064/W33 | 24064K30/W33 | 4003164Y | 4113164Y | 335 | 465 | 3 | 0.32 | 2.1 | 3.1 | 2 | 103 | |

| 540 | 176 | 5 | 3390 | 5538 | 630 | 800 | 23164CA/W33 | 23164CAK/W33 | 340 | 520 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 169 | |||

| 540 | 218 | 5 | 3470 | 6430 | 480 | 600 | 24164/W33 | 24164K30/W33 | 4003764Y | 4113764Y | 340 | 520 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 251 | |

| 320 | 540 | 218 | 5 | 3470 | 6430 | 480 | 600 | 24164/W33 | 340 | 520 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 207 | |||

| 580 | 208 | 5 | 3500 | 6360 | 500 | 630 | 23264/W33 | 23264K/W33 | 3003264Y | 3113264Y | 340 | 560 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 259 | |

| 340 | 460 | 90 | 3 | 1310 | 2520 | 880 | 1180 | 23968W33 | 23968K/W33 | 3003968Y | 3113968Y | 353 | 447 | 2.5 | 0.18 | 3.8 | 5.6 | 3.7 | 50.5 |

| 520 | 133 | 5 | 2430 | 4350 | 680 | 880 | 23068W33 | 23068K/W33 | 3003168Y | 3113168Y | 358 | 502 | 4 | 0.25 | 2.7 | 4 | 2.7 | 109 | |

| 520 | 180 | 5 | 2920 | 5580 | 510 | 650 | 24068W33 | 24068K30/W33 | 4003168Y | 4113168Y | 358 | 502 | 4 | 0.33 | 2 | 3 | 2 | 160 | |

| 520 | 180 | 5 | 3110 | 5710 | 520 | 660 | 24068CA/W33 | 24068CAK30/W33 | 358 | 502 | 4 | 0.33 | 2 | 3 | 2 | 140 | |||

| 580 | 190 | 5 | 3830 | 6240 | 600 | 750 | 23168CA/W33 | 23168CAK/W33 | 360 | 560 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 209 | |||

| 580 | 243 | 5 | 4180 | 7720 | 450 | 560 | 24168CA/W33 | 24168CAK30/W33 | 360 | 560 | 4 | 39 | 1.7 | 2.6 | 1.7 | 280 | |||

| 360 | 480 | 90 | 3 | 1330 | 2710 | 850 | 1100 | 23972/W33 | 3972K/W33 | 3003972Y | 3113972Y | 373 | 467 | 2.5 | 0.17 | 4 | 5.9 | 3.9 | 49.1 |

| 540 | 134 | 5 | 2480 | 4500 | 670 | 850 | 23072/W33 | 23072K/W33 | 3003172Y | 3113732Y | 378 | 522 | 4 | 0.25 | 2.7 | 4 | 2.7 | 114 | |

| d 360~420mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 360 | 540 | 134 | 5 | 2390 | 4700 | 600 | 760 | 23072CA/W33 | 23072CAK/W33 | 3053172HY 3153172HY | 378 | 522 | 4 | 0.25 | 2.7 | 4 | 2.7 | 113 | |

| 540 | 180 | 5 | 3460 | 6350 | 500 | 630 | 24072C/W33 | 24072CK30/W33 4 | 053172Y | 4453172Y | 378 | 522 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 148 | |

| 540 | 180 | 5 | 3200 | 6160 | 480 | 620 | 24072CA/W33 | 24072CAK30/W33 | 378 | 522 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 148 | |||

| 600 | 192 | 5 | 3400 | 6700 | 560 | 700 | 23172/W33 | 23172K/W33 3 | 003772Y | 3113772Y | 380 | 580 | 4 | 0.32 | 2.1 | 3.1 | 2 | 221 | |

| 600 | 243 | 5 | 4400 | 8370 | 430 | 530 | 24172/W33 | 24172K30/W33 4 | 003772Y | 4113772Y | 380 | 580 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 273 | |

| 600 | 243 | 5 | 4300 | 8210 | 430 | 530 | 24172 CAK30W33 | 380 | 580 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 271 | ||||

| 750 | 224 | 7.5 | 4900 | 7500 | 450 | 550 | 22372/W33 | 22372K/W33 | 390 | 724 | 5 | 0.31 | 2.2 | 3.3 | 2.2 | 489 | |||

| 650 | 232 | 6 | 4520 | 7930 | 420 | 510 | 23272CAK30 | W33 | 386 | 624 | 5. | 0.35 | 1.9 | 2.9 | 1.8 | 332 | |||

| 380 | 520 | 106 | 4 | 1760 | 3420 | 800 | 1000 | 23976/W33 | 23976K/W33 3 | 003976Y | 3113976Y | 395 | 505 | 3 | 0.19 | 3.6 | 5.3 | 3.5 | 73.5 |

| 560 | 135 | 5 | 2280 | 4550 | 630 | 800 | 23076/W33 | 23076K/W33 | 3003176Y | 3113176Y | 398 | 542 | 4 | 0.24 | 2.8 | 4.2 | 2.8 | 122 | |

| 380 | 560 | 135 | 5 | 2610 | 4850 | 630 | 800 | 23076CA/W33 | 23076CAK/W33 | 3003776Y | 3113776Y | 398 | 542 | 4 | 0.22 | 4.5 | 2.9 | 114 | |

| 560 | 180 | 5 | 3240 | 6460 | 480 | 600 | 24076/W33 | 24076K30/W33 | 398 | 542 | 4 | 0.3 | 2.3 | 3.4 | 2.2 | 152 | |||

| 620 | 194 | 5 | 3450 | 6800 | 400 | 500 | 23176/W33 | 23176KW33 | 400 | 600 | 4 | 0.34 | 2 | 2.9 | 1.9 | 243 | |||

| 620 | 194 | 5 | 3700 | 7000 | 400 | 500 | 23176CAQ1/W3 | 323176CAKQI/W33 | 400 | 600 | 4 | 0.3 | 2.3 | 3.4 | 2.2 | 230 | |||

| 780 | 230 | 7.5 | 5340 | 8390 | 340 | 430 | 22376/W33 | 22376K/W33 | 400 | 760 | 6 | 0.31 | 2.2 | 3.3 | 2.2 | 538 | |||

| 400 | 590 | 142 | 5 | 2300 | 5000 | 700 | 900 | 2680/W33 | 2680KW33 | 3003180Y | 3113180Y | 418 | 572 | 4 | 0.23 | 2.9 | 4.4 | 2.8 | 145 |

| 600 | 148 | 5 | 2520 | 5450 | 540 | 670 | 23080/W33 | 23080K/W33 | 3003280Y | 3113280Y | 420 | 582 | 4 | 0.25 | 2.7 | 4 | 2.7 | 165 | |

| 650 | 200 | 6 | 3850 | 7540 | 380 | 480 | 23180/W33 | 23180K/W33 | 426 | 624 | 5 | 0.31 | 2.2 | 3.3 | 2.2 | 238 | |||

| 720 | 256 | 6 | 5300 | 10100 | 340 | 430 | 23280/W33 | 23280KW33 | 3680Y | 426 | 694 | 5 | 0.37 | 1.8 | 2.7 | 1.8 | 530 | ||

| 720 | 315 | 6 | 6620 | 10400 | 310 | 390 | 24280/W33 | 24280K30/W33 | 426 | 694 | 5 | 0.44 | 1.5 | 2.3 | 15 | 549 | |||

| 820 | 243 | 7.5 | 5900 | 9360 | 360 | 450 | 22380/W33 | 22380K/W33 | 3G3-316 | 432 | 788 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 650 | ||

| 401 | 720 | 256 | 6 | 5300 | 10100 | 340 | 430 | 3003184Y | 3113184Y | 426 | 694 | 5 | 0.37 | 1.8 | 2.7 | 1.8 | 515 | ||

| 420 | 620 | 150 | 5 | 2690 | 5750 | 450 | 560 | 23084/W33 | 24084K30/W33 | 3003784Y | 3113784Y | 438 | 602 | 4 | 0.24 | 2.8 | 4.2 | 2.8 | 158 |

| 700 | 224 | 6 | 4850 | 9300 | 360 | 450 | 23184/W33 | 23184K/W33 | 3053284HY | 3153284HY | 446 | 674 | 5 | 0.32 | 2.1 | 3.1 | 2 | 402 | |

| 700 | 280 | 6 | 5700 | 11300 | 300 | 380 | 24184CA/W33 | 24184CAK30/W33 | 446 | 674 | 5 | 0.38 | 1.7 | 2.6 | 1.7 | 434 | |||

| d 360~560mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 360 | 760 | 272 | 7.5 | 6450 | 11700 | 320 | 400 | 23284CA/W33 | 23284CAK/W33 | 3003188Y | 3113188Y | 452 | 728 | 6 | 0.35 | 1.9 | 2.9 | 1.8 | 535 |

| 440 | 650 | 157 | 6 | 2900 | 6050 | 430 | 530 | 23088W33 | 23088K/W33 | 3003788Y | 3113788Y | 463 | 627 | 5 | 0.24 | 2.8 | 4.2 | 2.8 | 192 |

| 720 | 226 | 6 | 4910 | 9600 | 340 | 430 | 23188W33 | 23188K/W33 | 466 | 694 | 5 | 0.31 | 2.2 | 3.3 | 2.2 | 419 | |||

| 720 | 280 | 6 | 5900 | 11900 | 280 | 360 | 24188W33 | 24188K30/W33 | 3003192Y | 3113192Y | 466 | 694 | 5 | 0.38 | 1.7 | 2.6 | 1.7 | 443 | |

| 720 | 280 | 6 | 6150 | 12300 | 300 | 380 | 24188 CAK30C3 | W33 | 466 | 694 | 5 | 0.37 | 1.8 | 2.7 | 1.8 | 446 | |||

| 460 | 680 | 163 | 6 | 3150 | 6860 | 400 | 500 | 23092W33 | 23092K/W33 | 483 | 657 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 220 | ||

| 760 | 240 | 7.5 | 5450 | 10800 | 320 | 400 | 23192W33 | 23192K/W33 | 492 | 728 | 6 | 0.31 | 2.2 | 3.3 | 2.2 | 468 | |||

| 760 | 300 | 7.5 | 6660 | 13100 | 260 | 340 | 24192W33 | 24192K30W33 | 3003996Y | 3113996Y | 492 | 728 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 539 | |

| 480 | 650 | 128 | 5 | 2280 | 5480 | 400 | 500 | 23996/W33 | 23996K/W33 | 498 | 632 | 4 | 0.18 | 3.8 | 5.6 | 3.7 | 161 | ||

| 650 | 128 | 5 | 2900 | 5700 | 400 | 500 | 23996 CAFI/W3 | 3 | 498 | 632 | 4 | 0.18 | 3.8 | 5.6 | 3.6 | 125 | |||

| 700 | 165 | 6 | 3280 | 6910 | 380 | 480 | 23096W33 | 23096KW33 | 3003196Y | 3113196Y | 503 | 677 | 5 | 0.24 | 2.8 | 4.2 | 2.8 | 231 | |

| 790 | 248 | 7.5 | 5800 | 11400 | 300 | 380 | 23196CAW33 | 23196CAKW33 | 512 | 758 | 6 | 0.3 | 2.3 | 3.4 | 2.2 | 492 | |||

| 870 | 310 | 7.5 | 7350 | 13800 | 250 | 320 | 23296W33 | 23296KW33 | 3003296Y | 3113296Y | 512 | 838 | 6 | 0.39 | 1.7 | 2.6 | 1.7 | 837 | |

| 870 | 310 | 7.5 | 7580 | 13800 | 260 | 340 | 23296CAW33 | 23296CAKW33 | 512 | 838 | 6 | 0.36 | 1.9 | 2.8 | 1.8 | 857 | |||

| 494 | 670 | 128 | 5 | 2440 | 6060 | 400 | 500 | 2391494/W33 | 239494KW33 | 512 | 652 | 4 | 0.18 | 3.8 | 5.6 | 3.7 | 135 | ||

| 500 | 670 | 128 | 5 | 2440 | 6060 | 400 | 500 | 2391500/W33 | 239500KW33 | 30039/500Y | 31139/500Y | 518 | 652 | 4 | 0.18 | 3.8 | 5.6 | 3.7 | 130 |

| 720 | 167 | 6 | 3500 | 7600 | 380 | 480 | 230/500/W33 | 2301500K/W33 | 30031/500Y | 31131/500Y | 523 | 697 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 238 | |

| 530 | 780 | 185 | 6 | 3930 | 8550 | 340 | 430 | 2301530/W33 | 230530KW33 | 30031/530Y | 31131/530Y | 553 | 757 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 313 |

| 780 | 185 | 6 | 3560 | 8260 | 340 | 430 | 2301530 D-1 | 553 | 757 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 317 | ||||

| 980 | 355 | 9.5 | 9960 | 18500 | 240 | 320 | 232/530CA/W33 | 232/530CAK30/W3 | 622 | 888 | 6 | 0.36 | 1.9 | 2.8 | 1.8 | 1210 | |||

| 560 | 820 | 195 | 6 | 4460 | 10020 | 300 | 380 | 230/560/W33 | 230560K/W33 | 30031/560Y | 31131/560T | 583 | 797 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 365 |

| 820 | 195 | 6 | 4700 | 10300 | 320 | 400 | 2301560CA/W33 | 230560CAK/W33 | 583 | 797 | 5 | 0.22 | 3 | 4.5 | 2.9 | 354 | |||

| 820 | 258 | 6 | 6160 | 14000 | 340 | 420 | 240/560 CAW33 | 583 | 797 | 5 | 0.28 | 2.4 | 3.6 | 2.5 | 472 | ||||

| d 560~850mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 560 | 920 | 280 | 7.5 | 7990 | 16000 | 240 | 320 | 231/560W33 | 231560K/W33 | 30037/560Y | 31137/560Y | 592 | 888 | 6 | 0.3 | 2.3 | 3.4 | 2.2 | 757 |

| 920 | 355 | 7.5 | 9450 | 19500 | 190 | 260 | 241560CA/W33 | 241560CAK30/W33 | 592 | 888 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 985 | |||

| 920 | 355 | 7.5 | 9450 | 19500 | 190 | 260 | 241/560CA-1/W33 | 592 | 888 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 947 | ||||

| 600 | 870 | 200 | 6 | 4810 | 11000 | 300 | 380 | 2301600W33 | 2301600KW33 | 30031600Y | 3H31/600Y | 623 | 847 | 5 | 0.22 | 3 | 2.7 | 2.9 | 393 |

| 980 | 375 | 7.5 | 10400 | 21300 | 180 | 240 | 241600/W33 | 241600K30'W33 | 40037600Y | 41137/600Y | 632 | 948 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 1079 | |

| 630 | 920 | 212 | 7.5 | 5360 | 12200 | 260 | 340 | 230/630/W33 | 230/630KW33 | 30031/630Y | 31131/630Y | 658 | 892 | 6 | 23 | 2.9 | 4.4 | 2.8 | 509 |

| 670 | 900 | 170 | 6 | 4130 | 9840 | 260 | 340 | 239/670/W33 | 239/670K/W33 | 30039/670Y | 31139/670Y | 693 | 877 | 5 | 18 | 3.8 | 5.6 | 3.7 | 317 |

| 670 | 900 | 170 | 6 | 4260 | 10000 | 260 | 340 | 239670CAFI/W33 | 693 | 877 | 5 | 0.17 | 4 | 5.9 | 4 | 308 | |||

| 980 | 230 | 7.5 | 6240 | 13700 | 240 | 320 | 230670/W33 | 230/670K/W33 | 30031/670Y | 31131/670Y | 698 | 952 | 6 | 0.23 | 2.9 | 4.4 | 2.8 | 655 | |

| 710 | 950 | 180 | 6 | 4290 | 10900 | 240 | 320 | 239/710/W33 | 239710K/W33 | 30039/710Y | 31139/710Y | 732 | 927 | 5 | 0.18 | 3.8 | 5.6 | 3.7 | 387 |

| 1030 | 236 | 7.5 | 6530 | 15130 | 220 | 300 | 230/710/W33 | 230710K/W33 | 3003/710Y | 31131/710Y | 738 | 1002 | 6 | 0.23 | 2.9 | 4.4 | 2.8 | 742 | |

| 1150 | 438 | 9.5 | 13700 | 29940 | 150 | 190 | 241/710/W33 | 241710K30/W33 | 40037710Y | 41137710Y | 750 | 1110 | 8 | 0.38 | 1.7 | 2.6 | 1.7 | 1802 | |

| 750 | 1090 | 250 | 7.5 | 7890 | 17600 | 200 | 280 | 234750W33 | 230750KW33 | 778 | 1062 | 6 | 0.22 | 3 | 4.5 | 2.9 | 855 | ||

| 750 | 1090 | 335 | 7.5 | 9340 | 22300 | 190 | 240 | 240750W33 | 782 | 1058 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1060 | |||

| 800 | 1060 | 258 | 6 | 7170 | 19030 | 200 | 280 | 249180/W33 | 249/800K30W33 | 40039/800Y | 41139.800Y | 823 | 1037 | 5 | 0.22 | 3 | 4.5 | 2.9 | 638 |

| 1150 | 258 | 7.5 | 8630 | 20000 | 190 | 260 | 2301800W33 | 230800KW33 | 3003J/800Y | 31131/800Y | 828 | 1122 | 6 | 0.21 | 3.2 | 4.8 | 3.1 | 986 | |

| 1150 | 345 | 7.5 | 10000 | 25700 | 170 | 220 | 2480W33 | 240800K30/W33 | 40031/800Y | 41131/800Y | 828 | 1122 | 6 | 0.29 | 2.4 | 3.5 | 3.3 | 1246 | |

| 850 | 1120 | 200 | 6 | 6100 | 15800 | 190 | 260 | 239/850W33 | 2391850KW33 | 30039/850Y | 31139850Y | 873 | 1097 | 5 | 0.16 | 4.2 | 6.2 | 4.1 | 531 |

| 1220 | 272 | 7.5 | 9050 | 21100 | 180 | 240 | 230:850W33 | 230:850KW33 | 878 | 1192 | 6 | 0.21 | 32 | 4.8 | 3.1 | 1069 | |||

| 1220 | 365 | 7.5 | 10000 | 26000 | 160 | 200 | 2401850W33 | 240:850K30/W33 | 40031/850Y | 41131/850Y | 878 | 1192 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1398 | |

| d 850~1180mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 850 | 1220 | 365 | 7.5 | 10000 | 26000 | 160 | 200 | 21401850YA | 40031/850Y1 | 878 | 1192 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1396 | ||

| 900 | 1270 | 365 | 7.5 | 12200 | 31100 | 160 | 200 | 26900C3W33XYA3 | 928 | 1242 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1703 | |||

| 1280 | 375 | 7.5 | 12200 | 31100 | 150 | 190 | 240190W33 | 240:900K30W3340 | 031900Y | 41131900Y | 928 | 1252 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1783 | |

| 1000 | 1420 | 412 | 7.5 | 15000 | 40000 | 120 | 160 | 240/100DW33 00Y | 240100K30W33400 | 31/1000Y | 41131/10 | 1028 | 1392 | 6 | 0.27 | 2.5 | 3.72. | 5 | 2117 |

| 1120 | 1580 | 462 | 9.5 | 18500 | 48000 | 100 | 140 | 2401120 CAW33 | 1159 | 1541 | 8 | 0.26 | 2.6 | 3.9 | 2.5 | 2908 | |||

| 1180 | 1540 | 272 | 7.5 | 10400 | 27700 | 100 | 140 | 2391180CAW33 | 1214 | 1506 | 6 | 0.16 | 4.2 | 6.3 | 4 | 1360 | |||

| 1180 | 1660 | 355 | 9.5 | 15500 | 38400 | 90 | 120 | 234/18W33 | 23/1180K/W33 | 1210 | 1630 | 8 | 0.2 | 3.4 | 5.1 | 3.3 | 2480 | ||

Learn about our latest products and discounts through SMS or email