- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

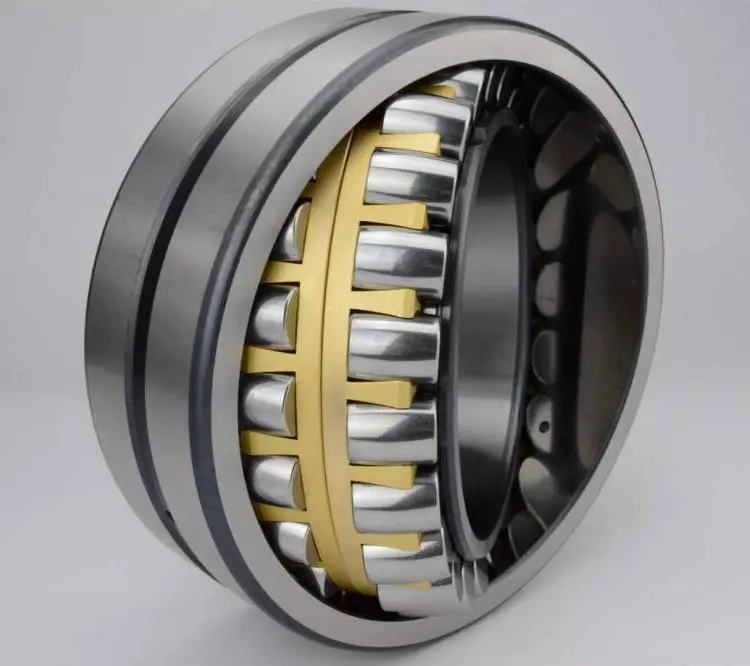

Double Row Spherical Roller Bearing

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + stamped steel / brass cage, and it is open / sealed.

3.Size Range: Inner diameter 20 - 800mm, outer diameter 47 - 1200mm, width 16 - 200mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel (conventional / ordinary models), 42CrMo (for heavy-load models), rollers: GCr15 bearing steel, cage: stamped steel / brass.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: For inner diameters ≥ 50mm, a 1:12 tapered hole can be optionally selected, and for small inner diameters (< 50mm), most are straight holes.

7.Application Fields: Heavy-duty electric motors, reducers, port cranes, paper-making machinery.

8.Key Inspection Items: Consistency of double-row roller arrangement, self-aligning performance, radial load-bearing capacity.

Double Row Spherical Roller Bearings for Extreme Load & High-Temperature Metallurgical Applications

Customizable up to φ5000mm | 150℃ Resistance | 30+ Years of Industrial Expertise

When your machinery faces heavy radial loads, misalignment challenges, or extreme temperatures, Double Row Spherical roller bearings deliver unmatched reliability. Designed with two rows of symmetrical rollers and a spherical outer ring raceway, these bearings compensate for shaft deflections up to ±2.5°, making them ideal for metallurgical, port, and medical equipment. At LUOYANG INNO, we’ve spent three decades refining their performance to handle 500kN+ radial loads and 150℃ environments—ensuring your operations stay productive.

Why Choose Us?

- 500℃ Heat Resistance: Specialized heat treatment and 42CrMo alloy steel prevent deformation in metallurgical furnaces.

- 50% Higher Load Capacity: Optimized roller alignment distributes stress evenly, extending lifespan under heavy loads.

- Custom Sizes Up to φ5000mm: Replace legacy bearings in aging equipment without redesigning machinery.

- 15–20-Day Fast Delivery: Modular production cuts lead times by 30% for urgent orders (e.g., φ3000mm bearings).

- 99.9% Qualification Rate: Rigorous ISO 15242 vibration tests and 200kN radial load validations.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Radial Load Capacity | Up to 850kN |

| Temperature Range | -30℃ to 150℃ |

| Material | GCr15/42CrMo steel + carbide hardening |

| Precision Grade | P0 (standard), P4/P5 (low-noise medical) |

| Sizes | φ20–800mm (ID), up to φ5000mm custom |

Built for Your Industry's Demands

1. Metallurgy & Mining

Withstand 500℃ temperatures in rolling mills and continuous casting systems with our Double Row Spherical Roller Bearing, and our bearings reduce unplanned downtime by 40% in smelting plants.

2. Port Machinery

Enhanced wear-resistant coatings handle abrasive dust in crane slewing rings, achieving 100,000+ hours in high-humidity environments.

3. Medical Equipment

P4-grade precision (<35dB noise) ensures smooth MRI rotor operation, meeting ISO 13485 medical device standards.

Global Delivery & Local Support

- 48-Hour Shipping: 1,000+ standard models available from regional warehouses in the EU, Americas, and Asia-Pacific.

- Bulk Order Priority: Dedicated production lines for 50+ unit orders.

Your Success, Our Commitment

Precision Engineering

Our 3-stage quality control includes:

- Raw material purity checks (99.95% steel).

- In-process dimensional accuracy verification (±0.001mm).

- Final load and heat endurance tests.

End-to-End Customization

- Share your load, temperature, and dimension requirements.

- Get a 3D CAD model and performance simulation report in 72 hours.

- Approve prototypes tested under real-world conditions.

- Receive bulk orders in 15–30 days.

Lifetime Support

- Free on-site measurement for legacy equipment retrofits.

- IoT-enabled wear monitoring tools for predictive maintenance.

- 24/7 technical guidance on lubrication and installation.

FAQ

Q: How do your bearings handle 500℃ environments?

A: We use 42CrMo alloy steel and secondary carburizing to prevent micro-cracks under thermal stress.

Q: Can you customize bearings for non-standard machinery?

A: Yes! We’ve delivered φ5000mm bearings for vintage rolling mills within 20 days.

Q: What reduces noise in medical-grade bearings?

A: Precision grinding (P4 grade) and brass cages dampen vibrations, achieving <35dB operation.

Q: Do you offer emergency replacements?

A: Critical failure? We ship replacements within 72 hours with on-site installation support.

Contact Us

Ready to Upgrade Your Double Row Spherical Roller Bearing?

Request a Free Design Consultation

👉 Email Us for CAD models, pricing, or technical queries.

Download Our Catalog

📥 Get Technical Datasheet with load tables, sizing charts, and material specs.

LUOYANG INNO BEARING CO., LTD

📍 Global Warehouses | ISO 9001-Certified | 30+ Years in Heavy-Duty Solutions

Learn about our latest products and discounts through SMS or email