- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

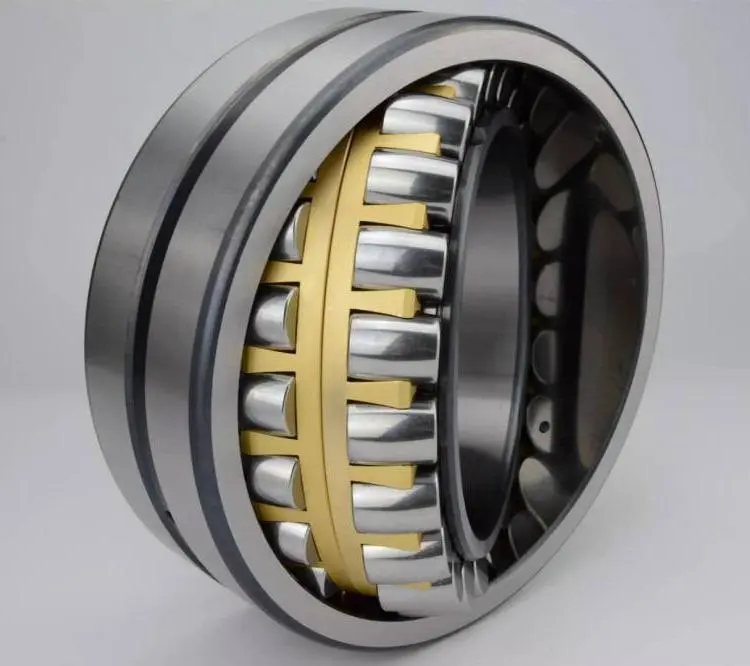

Spherical Rollers

2.Structure Type: Double spherical shape (the convex surface fits the inner ring raceway), with precision grinding on the surface and no ribs (suitable for self-aligning movement).

3.Size Range: Diameter 10 - 200mm, length 15 - 250mm (matched according to the bearing model).

4.Material: GCr15 bearing steel (conventional), GCr15SiMn (for impact-resistant and heavy-load applications), with a quenching hardness of HRC60 - 65.

5.Precision: P0/P6 level (matched according to the precision of the applicable bearing).

6.Common Inner Tapered Hole: There is no inner tapered hole (it is a bearing component, not a complete bearing).

7.Application Fields: Maintenance and replacement of self-aligning roller bearings, customized bearing production.

8.Key Inspection Items: Spherical roundness, surface roughness, fitting degree with the raceway, hardness.

High-Performance Spherical Rollers for Heavy Industrial Applications – Precision, Durability & Fast Global Delivery

30+ years of expertise in manufacturing spherical rollers optimized for extreme loads, high temperatures, and critical industrial operations. Custom Solutions delivered in 15-20 days.

Why Choose Us?

Our products are engineered to handle misalignment, heavy loads, and harsh conditions while reducing friction. At LUOYANG INNO, we’ve spent three decades perfecting these components for industries where reliability is non-negotiable. Whether you need standard replacements or custom-designed solutions, our rollers deliver unmatched performance in mining, wind energy, agriculture, and beyond.

Core Advantages

- 30+ Years of Precision Engineering: Mastery in crafting products up to φ5000mm, tailored for radial/axial load balance and thermal stability.

- Extreme Environment Ready: Operate seamlessly in temperatures from -50°C to 150°C with high-purity steel or ceramic hybrids.

- Rapid Delivery: 1,000+ standard models ship in 48 hours; custom orders (e.g., oversized, corrosion-coated) completed 30% faster than industry norms.

- Lifespan Optimization: IoT-driven maintenance plans and on-site retrofitting support to minimize downtime.

Technical Excellence for Demanding Applications

Key Specifications

-

Load Capacity: Dynamic up to 200kN, static up to 400kN.

-

Precision Grades: P0 to P4, with surface roughness as low as Ra 0.2μm.

-

Materials: GCr15 bearing steel (standard), stainless steel, or carbide coatings for abrasive environments.

-

Dimensional Range: Diameter 10–200mm (standard), up to φ5000mm (custom).

Customization Options

- Geometry Tweaks: Adjust roller curvature to match legacy bearing housings.

- Material Upgrades: Enhance heat resistance or corrosion protection.

- Hybrid Designs: Integrate shock-absorbing layers for high-impact machinery.

Built for Your Industry's Challenges

Mining & Mineral Processing

-

Durability: Carbide-coated spherical rollers withstand dust, slurry, and 200kN+ shock loads.

-

Compliance: MSHA and ATEX certifications for explosive environments.

Wind Energy Turbines

-

Precision: ABEC-5/P5 rollers reduce gearbox noise (<45dB) and extend service intervals.

-

Smart Monitoring: Sensor-enabled rollers predict failures before downtime occurs.

Agricultural Machinery

- Contamination Resistance: Triple-lip seals keep out dirt and moisture in tractors/harvesters.

- Cost Efficiency: Modular designs allow easy retrofits to existing equipment.

Quality You Can Trust

- Material Testing: Spectral analysis ensures 99.9% steel purity.

- Process Validation: ISO 683-17 heat treatment and <1μm grinding tolerances.

- Lifetime Support: Free lubrication training and performance dashboards.

Agile Supply, Global Reach

- Standard Inventory: 50,000+ SKUs ready for immediate dispatch.

- Custom Production: Modular manufacturing slashes lead times (e.g., φ3000mm rollers in 15 days).

- Shipping Flexibility: FOB/CIF terms available for bulk orders.

FAQ

1. Can your products handle 150°C environments?

Yes! Our heat-treated GCr15SiMn rollers retain hardness (HRC 60–65) even in metallurgy applications.

2. What’s the lead time for a non-standard order?

Most custom designs ship in 15–20 days. Urgent requests? Contact Us for expedited options.

3. Do you provide IoT integration?

Absolutely. We equip rollers with sensors to track vibration, temperature, and load in real time.

4. Are your products certified?

We meet ISO 9001, ABEC-5, and industry-specific standards like GL (wind) and MSHA (mining).

Contact Us

Need a Solution That Outlasts the Competition with our spherical rollers?

→ Request a Custom Quote (15-20 Day Lead Time)

→ Download Technical Datasheets

Email us today at sales@inno-bearing.com to discuss your project.

Serving 500+ clients across 30 countries since 1992.

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 25 | 52 | 18 | 1 | 36.1 | 36.6 | 8500 | 11000 | 22205CA/W33 | 22205CAKW33 | 31 | 46 | 1 | 0.36 | 1.9 | 2.8 | 1.8 | 0.178 | ||

| 30 | 62 | 20 | 1 | 51.7 | 55 | 7500 | 9500 | 22206C/W33 | 22206CK/W33 | 36 | 56 | 1 | 0.33 | 2 | 3 | 2 | 0.281 | ||

| 68 | 20 | 51.7 | 55 | 7400 | 9400 | 22206XICN | 22206XICNK | 36 | 62 | 1 | 0.33 | 2 | 3 | 2 | 0.369 | ||||

| 35 | 72 | 23 | 1.1 | 68.9 | 72.5 | 6300 | 8000 | 22207/W33 | 22207KW33 | 3507Y | 113507Y | 42 | 65 | 1 | 35 | 1.9 | 2.9 | 1.8 | 0.477 |

| 40 | 80 | 23 | 1.1 | 86.9 | 93.9 | 6000 | 7500 | 22208C/W33 | 22208CK/W33 | 53508Y | 153508Y | 47 | 73 | 1 | 0.28 | 2.4 | 3.6 | 2.5 | 0.575 |

| 90 | 33 | 1.5 | 123.0 | 133 | 4500 | 5600 | 22308C/W33 | 22308CKW33 | 49 | 81 | 1.5 | 0.37 | 1.8 | 2.7 | 1.8 | 1.02 | |||

| 90 | 33 | 1.5 | 121.0 | 129 | 4400 | 5500 | 22308/W33 | 22308KW33 | 3608Y | 113608Y | 49 | 81 | 1.5 | 42 | 1.6 | 2.4 | 1.6 | 1.05 | |

| 45 | 85 | 23 | 1.1 | 86.7 | 101 | 5300 | 6700 | 22209C/W33 | 22209CKW33 | 53509Y | 153509Y | 52 | 78 | 1 | 0.27 | 2.5 | 3.7 | 2.5 | 0.618 |

| 85 | 23 | 1.1 | 78.6 | 91.9 | 5200 | 6600 | 22209/W33 | 22209KW33 | 3509Y1 | 113509Y | 52 | 78 | 1 | 0.3 | 2.3 | 3.4 | 2.2 | 0.617 | |

| 100 | 36 | 1.5 | 141.0 | 154 | 3800 | 4800 | 22309C/W33 | 22309CKW33 | 54 | 91 | 1.5 | 0.37 | 1.8 | 2.7 | 1.8 | 137 | |||

| 50 | 90 | 23 | 1.1 | 90.3 | 97 | 5000 | 6300 | 22210C/W33 | 22210CK/W33 | 53510Y | 153510Y | 57 | 83 | 1 | 25 | 2.7 | 4 | 2.7 | 0.65 |

| 90 | 23 | 1.1 | 81.5 | 95.4 | 5000 | 6300 | 22210CA/W33 | 22210CAW33 | 57 | 83 | 1 | 0.25 | 2.7 | 4 | 2.7 | 0.614 | |||

| 110 | 40 | 2 | 176.0 | 193 | 3400 | 4300 | 22310C/W33 | 22310CK/W33 | 64 | 91 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 1.83 | |||

| 110 | 40 | 2 | 175.0 | 192 | 3300 | 4200 | 22310/W33 | 22310KW33 | 3610Y | 113610Y | 64 | 91 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 1.8 | |

| 55 | 100 | 25 | 1.5 | 109.0 | 130 | 4500 | 5600 | 22211C/W33 | 22211CKW33 | 53511Y | 153511Y | 66 | 88 | 1.5 | 0.25 | 2.7 | 4 | 2.7 | 0.88 |

| 100 | 25 | 1.5 | 109.0 | 130 | 4500 | 5600 | 22211CA/W33 | 2221CAK/W33 | 66 | 88 | 1.5 | 0.25 | 2.7 | 4 | 2.7 | 0.82 | |||

| 120 | 43 | 2 | 210.0 | 243 | 3200 | 4000 | 22311C/W33 | 22311CKW33 | 66 | 109 | 2 | 37 | 1.8 | 2.7 | 1.8 | 2.38 | |||

| 60 | 110 | 28 | 1.5 | 129.0 | 157 | 4000 | 5000 | 22212C/W33 | 22212CK/W33 | 53512Y | 153512Y | 69 | 101 | 1.5 | 25 | 2.7 | 4 | 2.7 | 1.22 |

| 130 | 46 | 2.1 | 246.0 | 288 | 2900 | 3800 | 22312C/W33 | 22312CKW33 | 72 | 118 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 2.95 | |||

| 130 | 46 | 2.1 | 233.0 | 260 | 2900 | 3800 | 22312/W33 | 22312KW33 | 3612Y | 113612Y | 72 | 118 | 2 | 0.4 | 1.7 | 2.5 | 1.6 | 2.88 | |

| 130 | 46 | 2.1 | 233.0 | 274 | 2900 | 3800 | 22312CA/W33 | 22312CAKW33 | 72 | 118 | 2 | 0.37 | 1.8 | 2.7 | 1.8 | 2.96 | |||

| 65 | 120 | 31 | 1.5 | 144.0 | 178 | 3800 | 4800 | 22213C/W33 | 22213CKW33 | 53513Y | 153513Y | 74 | 111 | 1.5 | 26 | 2.6 | 3.9 | 2.5 | 1.58 |

| d 65~90mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 65 | 120 | 31 | 1.5 | 156 | 195 | 3800 | 4800 | 22213CA/W33 | 22213CAKW33 | 53513HY | 153513HY | 74 | 111 | 1.5 | 0.27 | 2.5 | 3.7 | 2.5 | 152 |

| 140 | 33 | 2.1 | 203 | 242 | 3800 | 3600 | 21313 | 3313 | 77 | 128 | 2 | 0.25 | 2.7 | 4 | 2.7 | 2.58 | |||

| 140 | 48 | 2.1 | 285 | 315 | 2600 | 3400 | 22313/W33 | 22313KW33 | 77 | 128 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 1.6 | |||

| 140 | 48 | 2.1 | 285 | 315 | 2600 | 3400 | 22313CA/W33 | 22313CAKW33 | 77 | 128 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 3.54 | |||

| 70 | 125 | 31 | 1.5 | 163 | 207 | 3600 | 4500 | 22214C/W33 | 22214CKW33 | 53514Y | 153514Y | 79 | 116 | 1.5 | 0.24 | 2.8 | 4.2 | 2.8 | 1.69 |

| 125 | 31 | 1.5 | 156 | 199 | 3500 | 4400 | 22214/W33 | 22214KW33 | 3514Y | 113514Y | 79 | 116 | 1.5 | 0.27 | 2.5 | 3.7 | 2.5 | 1.64 | |

| 150 | 35 | 2.1 | 216 | 276 | 2600 | 3400 | 21314 | 3314 | 82 | 138 | 2 | 0.25 | 2.7 | 4 | 2.7 | 3.01 | |||

| 150 | 51 | 2.1 | 306 | 370 | 2400 | 3200 | 22314C/W33 | 22314CKW33 | 53614Y | 153614Y | 82 | 138 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 4.4 | |

| 150 | 51 | 2.1 | 311 | 352 | 2000 | 2800 | 22314/W33 | 22314KW33 | 3614Y | 113614Y | 82 | 138 | 2 | 0.37 | 1.8 | 2.7 | 1.8 | 4.21 | |

| 150 | 51 | 2.1 | 293 | 351 | 2000 | 2800 | 22314CA/W33 | 22314CAKW33 | 82 | 138 | 2 | 36 | 1.9 | 2.8 | 1.8 | 4.22 | |||

| 75 | 130 | 31 | 1.5 | 162 | 212 | 3400 | 4300 | 22215C/W33 | 22215CKW | 53515Y | 153515Y | 84 | 121 | 1.5 | 0.22 | 3 | 4.5 | 2.9 | 1.73 |

| 130 | 31 | 1.5 | 155 | 211 | 3400 | 4300 | 22215/W33 | 22215KW33 | 3515Y | 113515Y | 84 | 121 | 1.5 | 0.26 | 2.6 | 3.9 | 2.5 | 1.75 | |

| 160 | 55 | 2.1 | 350 | 427 | 2200 | 3000 | 22315C/W33 | 22315CKW33 | 87 | 148 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 5.4 | |||

| 80 | 140 | 33 | 2 | 187 | 248 | 3200 | 4000 | 22216C/W33 | 22216CKW33 | 53516Y | 15316Y | 90 | 130 | 2 | 0.22 | 3 | 4.5 | 2.9 | 2.23 |

| 140 | 33 | 2 | 186 | 252 | 3200 | 4000 | 22216/W33 | 22216KW33 | 3516Y | 13516Y | 90 | 130 | 2 | 25 | 2.7 | 4 | 2.7 | 2.23 | |

| 170 | 58 | 2.1 | 400 | 504 | 2000 | 2800 | 22316C/W33 | 22316CKW33 | 53616Y | 153616Y | 92 | 158 | 2 | 0.34 | 2 | 2.9 | 1.9 | 6.59 | |

| 170 | 58 | 2.1 | 388 | 446 | 2000 | 2800 | 22316/W33 | 22316KW33 | 3616Y | 113616Y | 92 | 158 | 2 | 37 | 1.8 | 2.7 | 1.8 | 6.19 | |

| 85 | 150 | 36 | 2 | 204 | 262 | 3000 | 3800 | 22217C/W33 | 22217CKW33 | 53517Y | 153517Y | 95 | 140 | 2 | 23 | 29 | 4.4 | 2.8 | 2.8 |

| 150 | 36 | 2 | 192 | 250 | 3000 | 3800 | 22217/W33 | 22217KW33 | 3517Y | 113517Y | 95 | 140 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 2.79 | |

| 180 | 60 | 3 | 426 | 512 | 1900 | 2600 | 22317/W33 | 22317KW33 | 3617Y | 113617Y | 99 | 166 | 2.5 | 0.37 | 1.8 | 2.7 | 1.8 | 7.07 | |

| 90 | 140 | 50 | 1.5 | 265 | 440 | 2700 | 3500 | 24018C | 24018CK | 100 | 130 | 1.5 | 0.32 | 2.1 | 3.1 | 2 | 2.97 | ||

| 160 | 40 | 2 | 257 | 340 | 2600 | 3400 | 22218C/W33 | 22218CKW33 | 53518Y | 153518Y | 101 | 149 | 2 | 0.23 | 2.9 | 4.4 | 2.8 | 3.24 | |

| 160 | 40 | 2 | 250 | 334 | 2600 | 3400 | 22218/W33 | 22218KW33 | 3518Y | 113518Y | 101 | 149 | 2 | 0.27 | 2.5 | 3.7 | 2.5 | 3.11 | |

| 160 | 52.4 | 2 | 305 | 434 | 1900 | 2600 | 23218C/W33 | 23218CKW33 | 3053218Y | 3153218Y | 101 | 149 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 4.61 | |

| d 90~110mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 90 | 190 | 64 | 3 | 494 | 636 | 1800 | 2400 | 22318C/W33 | 22318CK/W33 | 53618Y | 153618Y | 104 | 176 | 2.5 | 0.34 | 2 | 2.9 | 1.9 | 9.12 |

| 190 | 64 | 3 | 483 | 594 | 1800 | 2400 | 22318CAW33 | 22318CAK/W33 | 53618HY | 153618HY | 104 | 176 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 8.72 | |

| 190 | 64 | 3 | 475 | 583 | 1800 | 2400 | 22318/W33 | 22318K/W33 | 3618Y | 113618Y | 104 | 176 | 2.5 | 0.37 | 1.8 | 27 | 1.8 | 8.6 | |

| 95 | 170 | 43 | 2.1 | 284 | 380 | 2400 | 3200 | 22219C/W33 | 22219CK/W33 | 107 | 158 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 4.2 | ||

| 200 | 67 | 3 | 509 | 637 | 1700 | 2200 | 22319CA/W33 | 22319CAK/W33 | 109 | 186 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 9.95 | |||

| 200 | 67 | 3 | 517 | 617 | 1600 | 2100 | 22319W33 | 22319K/W33 | 3619Y | 113619Y | 109 | 186 | 2.5 | 0.38 | 1.7 | 2.6 | 1.7 | 9.93 | |

| 100 | 180 | 46 | 2.1 | 331 | 441 | 2200 | 3000 | 22220C/W33 | 22220CK/W33 | 53520Y | 153520Y | 112 | 168 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 4.95 |

| 180 | 46 | 2.1 | 331 | 441 | 2100 | 2900 | 22220CA/W33 | 22220CAK/W33 | 112 | 168 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 4.97 | |||

| 180 | 46 | 2.1 | 314 | 416 | 2100 | 2900 | 22220/W33 | 22220K/W33 | 3520Y | 113520Y | 112 | 168 | 2 | 0.27 | 2.5 | 3.7 | 2.5 | 5.03 | |

| 180 | 60.3 | 2.1 | 420 | 605 | 1700 | 2200 | 23220C/W33 | 23220CK/W33 | 3053220Y | 3153220Y | 112 | 168 | 2 | 0.33 | 2 | 3 | 2 | 6.71 | |

| 215 | 73 | 3 | 623 | 792 | 1700 | 2200 | 22320C/W33 | 22320CK/W33 | 53620Y | 153620Y | 114 | 201 | 2.5 | 0.36 | 1.9 | 2.8 | 1.8 | 13.6 | |

| 215 | 73 | 3 | 614 | 785 | 1600 | 2100 | 22320CA/W33 | 22320CAK/W33 | 53620HY | 153620HY | 114 | 201 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 12.4 | |

| 215 | 73 | 3 | 614 | 785 | 1600 | 2100 | 22320/W33 | 22320K/W33 | 3620Y | 113620Y | 114 | 201 | 2.5 | 0.37 | 1.8 | 2.7 | 1.8 | 13 | |

| 105 | 175 | 56 | 2 | 351 | 564 | 1900 | 2600 | 23121/W33 | 23121K/W33 | 3003721Y | 3113721Y | 115 | 165 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.64 |

| 175 | 56 | 2 | 351 | 564 | 1900 | 2600 | 23121N | 3203721 | 115 | 165 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.59 | |||

| 110 | 170 | 45 | 2 | 293 | 465 | 2200 | 3000 | 23022W33 | 23022K/W33 | 3003122Y | 3113122Y | 120 | 160 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 4.2 |

| 170 | 45 | 2 | 293 | 465 | 2200 | 3000 | 23022N | 3203122 | 120 | 160 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 4.18 | |||

| 170 | 60 | 2 | 359 | 605 | 1700 | 2500 | 24022C | 24022CK30 | 120 | 160 | 2 | 0.32 | 2.1 | 3.1 | 2 | 5.18 | |||

| 180 | 56 | 2 | 365 | 562 | 1900 | 2600 | 23122W33 | 23122K/W33 | 3003722Y | 3113722Y | 120 | 170 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.25 | |

| 180 | 56 | 2 | 365 | 562 | 1900 | 2600 | 23122N | 3203722 | 120 | 170 | 2 | 0.32 | 2.1 | 3.1 | 2 | 6.2 | |||

| 180 | 69 | 2 | 483 | 754 | 1600 | 2000 | 24122C/W33 | 24122K30/W33 | 4053722Y | 4453722Y | 120 | 170 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 6.88 | |

| 180 | 69 | 2 | 435 | 721 | 1500 | 1800 | 24122CA/W33 | 24122CAK30/W33 | 120 | 170 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 6.86 | |||

| 200 | 53 | 2.1 | 426 | 588 | 2000 | 2800 | 22222C/W33 | 22222CK/W33 | 53522Y | 153522Y | 122 | 188 | 2 | 0.25 | 2.7 | 4 | 2.7 | 7.25 | |

| 200 | 53 | 2.1 | 366 | 531 | 1900 | 2700 | 2222W33 | 22222K/W33 | 3522Y | 113522Y | 122 | 188 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 7.37 | |

| 200 | 69.8 | 2.1 | 515 | 760 | 1600 | 2000 | 23222C/W33 | 23222CK/W33 | 3053222Y | 3153222Y | 122 | 188 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 9.66 | |

| d 110~130mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 110 | 240 | 80 | 3 | 739 | 982 | 1600 | 2000 | 22322CA/W33 | 22322CAK/W33 | 53622HY | 153622HY | 124 | 226 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 17.5 |

| 240 | 80 | 3 | 750 | 915 | 1500 | 1900 | 22322/W33 | 22322K/W33 | 3622Y | 113622Y | 124 | 226 | 2.5 | 0.37 | 1.8 | 2.7 | 1.8 | 18 | |

| 240 | 92.1 | 3 | 799 | 998 | 1400 | 1700 | 23322W33 | 23322K/W33 | 3003322Y | 3113322Y | 124 | 226 | 2.5 | 0.44 | 1.5 | 2.3 | 1.5 | 23.6 | |

| 120 | 180 | 46 | 2 | 315 | 527 | 1800 | 2500 | 23024/W33 | 23024K/W33 | 3003124Y | 4453124HY | 130 | 170 | 2 | 0.25 | 2.7 | 4 | 2.7 | 4.63 |

| 180 | 46 | 2 | 315 | 527 | 1800 | 2500 | 3024N | 3203124 | 130 | 170 | 2 | 0.25 | 2.7 | 4 | 2.7 | 4.61 | |||

| 180 | 60 | 2 | 395 | 686 | 1500 | 2000 | 24024CA/W33 | 24024CAK30/W33 | 130 | 170 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 5.41 | |||

| 180 | 60 | 2 | 395 | 686 | 1600 | 2000 | 24024C/W33 | 4053124Y | 130 | 170 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 5.41 | |||

| 200 | 62 | 2 | 410 | 660 | 1700 | 2300 | 23124/W33 | 23124K/W33 | 3003724Y | 3113724Y | 130 | 190 | 2 | 0.32 | 2.1 | 3.1 | 2 | 7.61 | |

| 200 | 62 | 2 | 410 | 660 | 1700 | 2300 | 23124N | 3203724 | 130 | 190 | 2 | 0.32 | 2.1 | 3.1 | 2 | 7.57 | |||

| 200 | 80 | 2 | 561 | 919 | 1300 | 1700 | 24124CA/W33 | 24124CAK30/W33 | 130 | 190 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 10 | |||

| 200 | 80 | 2 | 589 | 949 | 1400 | 1800 | 24124C/W33 | 24124CK30/W33 | 4053724Y | 4453724Y | 130 | 190 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 10 | |

| 215 | 58 | 2.1 | 495 | 689 | 1900 | 2600 | 22224C/W33 | 22224CKW33 | 53524Y | 153524Y | 132 | 203 | 2 | 0.25 | 2.7 | 4 | 2.7 | 9.08 | |

| 215 | 58 | 2.1 | 489 | 656 | 1800 | 2500 | 22224W33 | 22224K/W33 | 3524Y | 113524Y | 132 | 203 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 9.13 | |

| 215 | 76 | 2.1 | 595 | 910 | 1500 | 1900 | 23224C/W33 | 23224CK/W33 | 3053224Y | 3153224Y | 132 | 203 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 12 | |

| 260 | 86 | 3 | 842 | 1110 | 1400 | 1800 | 22324CW33 | 22324CKW33 | 53624Y | 53624HY | 134 | 246 | 2.5 | 0.4 | 1.7 | 2.5 | 1.6 | 22.7 | |

| 130 | 200 | 52 | 2 | 400 | 655 | 1700 | 2300 | 23026/W33 | 23026K/W33 | 3003126Y | 3113126Y | 140 | 190 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 6.8 |

| 200 | 52 | 2 | 400 | 655 | 1700 | 2300 | 23026N | 3203126 | 140 | 190 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 6.72 | |||

| 200 | 69 | 2 | 482 | 838 | 1800 | 2400 | 24026CCIW33 | 140 | 190 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 7.85 | ||||

| 210 | 64 | 2 | 499 | 777 | 1600 | 2200 | 23126CA/W33 | 23126CAK30/W33 | 140 | 200 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 9.55 | |||

| 210 | 80 | 2 | 633 | 1070 | 1300 | 1700 | 24126C/W33 | 24126CAK30/W34 | 4053726Y | 4453726Y | 140 | 200 | 2 | 0.36 | 1.9 | 2.8 | 1.8 | 10.9 | |

| 230 | 64 | 3 | 582 | 830 | 1800 | 2400 | 22226C/W33 | 22226CKW33 | 53526Y | 153626Y | 144 | 216 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 11.7 | |

| 230 | 64 | 3 | 552 | 786 | 1700 | 2300 | 22226CA/W33 | 22226CAK/W33 | 144 | 216 | 2.5 | 0.27 | 2.5 | 3.7 | 2.5 | 11.4 | |||

| 230 | 64 | 3 | 564 | 800 | 1700 | 2300 | 22226/W33 | 22226K/W33 | 3526Y | 113526Y | 144 | 216 | 2.5 | 0.29 | 2.4 | 3.5 | 2.3 | 11.1 | |

| 230 | 80 | 3 | 700 | 1080 | 1300 | 1700 | 23226C/W33 | 23226K/W33 | 3053226Y | 3153226Y | 144 | 216 | 2.5 | 0.33 | 2 | 3 | 2 | 14.4 | |

| 280 | 93 | 4 | 930 | 1250 | 1300 | 1700 | 22326CAW33 | 22326CAK/W33 | 53626HY | 153626HY | 148 | 262 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 27.1 | |

| 280 | 93 | 4 | 836 | 1090 | 1200 | 1600 | 22326ZMB | 148 | 262 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 28.6 | ||||

| d 140~160mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 140 | 210 | 53 | 2 | 395 | 705 | 1600 | 2100 | 23028/W33 | 23028K/W33 | 3003128Y | 3113128Y | 150 | 200 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 7.65 |

| 210 | 53 | 2 | 395 | 705 | 1600 | 2100 | 23028N | 3203128 | 150 | 200 | 2 | 0.24 | 2.8 | 4.2 | 2.8 | 7.64 | |||

| 140 | 210 | 69 | 2 | 530 | 910 | 1400 | 1800 | 24028C/W33 | 24028CK30/W33 | 4053128Y | 4153128Y | 150 | 200 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 8.09 |

| 225 | 68 | 2.1 | 560 | 925 | 1500 | 1800 | 23128CA/W33 | 23128CAK/W33 | 3053728HY | 3153728HY | 152 | 213 | 2 | 0.28 | 2.4 | 3.6 | 2.5 | 10.4 | |

| 225 | 85 | 2.1 | 620 | 1060 | 1100 | 1500 | 24128CA/W33 | 24128CAK30/W33 | 152 | 213 | 2 | 0.35 | 1.9 | 2.9 | 1.8 | 12.9 | |||

| 250 | 68 | 3 | 642 | 931 | 1700 | 2200 | 22228C/W33 | 22228CK/W33 | 53528Y | 53528Y | 154 | 236 | 2.5 | 0.26 | 2.6 | 3.9 | 2.5 | 14.2 | |

| 250 | 68 | 3 | 636 | 897 | 1500 | 1900 | 22228CA/W33 | 22228CAK/W33 | 53528HY | 53528HY | 154 | 236 | 2.5 | 0.26 | 2.6 | 3.9 | 2.5 | 14.1 | |

| 250 | 68 | 3 | 662 | 905 | 1500 | 1900 | 22228/W33 | 22228K/W33 | 3528Y | 13528Y | 154 | 236 | 2.5 | 0.29 | 2.4 | 3.5 | 2.3 | 14.5 | |

| 250 | 88 | 3 | 835 | 1300 | 1200 | 1600 | 23228C/W33 | 23228CK/W33 | 3053228Y | 3153228Y | 154 | 236 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 18.8 | |

| 300 | 102 | 4 | 1120 | 1550 | 1100 | 1500 | 22328CA/W33 | 22328CAK/W33 | 53628HY | 53628HY | 158 | 282 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 35.9 | |

| 300 | 102 | 4 | 1100 | 1420 | 1100 | 1500 | 22328/W33 | 22328K/W33 | 3628Y | 13628Y | 158 | 282 | 3 | 0.38 | 1.7 | 2.6 | 1.7 | 36.9 | |

| 150 | 225 | 56 | 2.1 | 407 | 725 | 1500 | 1900 | 23030/W33 | 23030K/W33 | 3003130Y | 3113130Y | 162 | 213 | 2 | 0.25 | 2.7 | 4 | 2.7 | 8.85 |

| 250 | 80 | 2.1 | 683 | 1170 | 1300 | 1600 | 23130CA/W33 | 23130CAK/W33 | 3053730HY | 3153730HY | 162 | 238 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 18.2 | |

| 250 | 100 | 2.1 | 951 | 1570 | 1000 | 1400 | 24130C/W33 | 24130CK30/W33 | 4053730Y | 4453730Y | 162 | 238 | 2 | 0.37 | 1.8 | 2.7 | 1.8 | 20.3 | |

| 250 | 100 | 2.1 | 861 | 1420 | 900 | 1300 | 24130CA'W33 | 24130CAK30/W33 | 162 | 238 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 19.5 | |||

| 270 | 73 | 3 | 749 | 1050 | 1600 | 2000 | 2223C/W33 | 22230CK/W33 | 53530Y | 153530Y | 164 | 256 | 2.5 | 0.27 | 2.5 | 3.7 | 2.5 | 17.9 | |

| 270 | 73 | 3 | 736 | 1030 | 1500 | 1900 | 22230/W33 | 22230K/W33 | 3530Y | 13530Y | 164 | 256 | 2.5 | 0.29 | 2.4 | 3.5 | 2.3 | 17.5 | |

| 270 | 96 | 3 | 907 | 1350 | 1100 | 1500 | 23230C/W33 | 23230CK/W33 | 3053230Y | 3153230Y | 164 | 256 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 24.3 | |

| 320 | 108 | 4 | 1220 | 1680 | 1000 | 1400 | 22330CA/W33 | 22330CAK/W33 | 53630HY | 153630HY | 168 | 302 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 41.7 | |

| 320 | 108 | 4 | 1210 | 1660 | 1000 | 1400 | 22330/W33 | 22330K/W33 | 3630Y | 113630Y | 168 | 302 | 3 | 0.38 | 1.7 | 2.6 | 1.7 | 42 | |

| 160 | 240 | 60 | 2.1 | 495 | 875 | 1500 | 1900 | 23032N | 3203132 | 172 | 228 | 2 | 0.25 | 2.7 | 4 | 2.7 | 13.4 | ||

| 240 | 60 | 2.1 | 495 | 875 | 1500 | 1900 | 23032/W33 | 23032K/W33 | 3003132Y | 113132Y | 172 | 228 | 2 | 0.25 | 2.7 | 4 | 2.7 | 13.4 | |

| 240 | 80 | 2.1 | 660 | 1220 | 1100 | 1500 | 24032C/W33 | 24032CK30/W33 | 4053132Y | 4453132Y | 172 | 228 | 2 | 0.3 | 2.3 | 3.4 | 2.2 | 12.8 | |

| 270 | 86 | 2.1 | 820 | 1200 | 1200 | 1600 | 23132 | 23132K | 172 | 258 | 2 | 0.32 | 2.1 | 3.1 | 2 | 20.8 | |||

| 270 | 86 | 2.1 | 833 | 1290 | 1200 | 1600 | 23132CA/W33 | 23132CAK/W33 | 3053732HY | 3153732HY | 172 | 258 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 20.3 | |

| 270 | 109 | 2.1 | 1070 | 1750 | 950 | 1300 | 24132C/W33 | 24132CK30/W33 | 4053732Y | 4453732HY | 172 | 258 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 19.5 | |

| 270 | 109 | 2.1 | 958 | 1590 | 900 | 1200 | 24132 CAW33 | 172 | 258 | 2 | 0.38 | 1.7 | 2.6 | 1.7 | 25.3 | ||||

| d 160~190mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 160 | 290 | 80 | 3 | 850 | 1230 | 1400 | 1800 | 22232CA/W33 | 22232CAK/W33 | 53532HY | 153532HY | 174 | 276 | 2.5 | 0.27 | 2.5 | 3.7 | 2.5 | 22.6 |

| 290 | 80 | 3 | 876 | 1230 | 1350 | 1700 | 22232W33 | 22232K/W33 | 3532Y | 13532Y | 174 | 276 | 2.5 | 0.3 | 2.3 | 3.4 | 2.2 | 22.3 | |

| 290 | 104 | 3 | 1020 | 1550 | 900 | 1300 | 23232CA | 23232CAK | 174 | 276 | 2.5 | 0.35 | 1.9 | 2.9 | 1.8 | 29.8 | |||

| 340 | 114 | 4 | 1340 | 1840 | 930 | 1200 | 22332W33 | 22332KW33 | 3632Y | 113632Y | 178 | 322 | 3 | 0.38 | 1.7 | 2.6 | 1.7 | 50.3 | |

| 170 | 260 | 67 | 2.1 | 640 | 1040 | 1400 | 1800 | 23034N | 3203134 | 182 | 248 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 14.6 | ||

| 260 | 67 | 2.1 | 640 | 1040 | 1400 | 1800 | 23034W33 | 23034K/W33 | 3003134Y | 3113134 | 182 | 248 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 14.6 | |

| 260 | 90 | 2.1 | 778 | 1310 | 1000 | 1400 | 24034C/W33 | 24034CK30W33 | 4003134Y | 4113134Y | 182 | 248 | 2 | 0.33 | 2 | 3 | 2 | 19.3 | |

| 310 | 86 | 4 | 981 | 1390 | 1200 | 1600 | 22234W33 | 22234K/W33 | 3534Y | 113534Y | 188 | 292 | 3 | 0.3 | 2.3 | 3.4 | 2.2 | 27.6 | |

| 310 | 110 | 4 | 1200 | 1900 | 950 | 1300 | 23234CA'W33 | 23234CAK/W33 | 3053234HY | 3153234HY | 188 | 292 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 37.1 | |

| 360 | 120 | 4 | 1500 | 2140 | 930 | 1200 | 22334W33 | 22334KW33 | 3634Y | 113634Y | 188 | 342 | 3 | 0.37 | 1.8 | 2.7 | 1.8 | 59.3 | |

| 180 | 280 | 74 | 2.1 | 710 | 1210 | 1300 | 1600 | 23036W33 | 23036KW33 | 3003136Y | 3113136Y | 192 | 268 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 19.3 |

| 280 | 100 | 2.1 | 930 | 1610 | 900 | 1200 | 24036W33 | 24036K30W33 | 4003136Y | 4403136Y | 192 | 268 | 0.35 | 1.9 | 2.9 | 1.8 | 22.3 | ||

| 300 | 96 | 3 | 1060 | 1800 | 1100 | 1500 | 23136C/W33 | 23136CKW33 | 194 | 286 | 2.5 | 0.3 | 2.3 | 3.4 | 2.2 | 27.2 | |||

| 300 | 96 | 3 | 987 | 1720 | 1000 | 1400 | 23136W33 | 23136KW33 | 3003736Y | 3113736Y | 194 | 286 | 2.5 | 0.32 | 2.1 | 3.1 | 2 | 26.8 | |

| 300 | 96 | 3 | 987 | 1720 | 1000 | 1400 | 23136W33YA2 | 3003736KY | 194 | 286 | 2.5 | 0.32 | 2.1 | 3.1 | 2 | 26.8 | |||

| 300 | 96 | 3 | 987 | 1720 | 1000 | 1400 | 23136N | 3203736 | 194 | 286 | 2.5 | 0.32 | 2.1 | 3.1 | 2 | 26.4 | |||

| 300 | 118 | 3 | 1170 | 1930 | 900 | 1200 | 24136W33 | 24136K30W33 | 194 | 286 | 2.5 | 0.38 | 1.7 | 2.6 | 1.7 | 33.7 | |||

| 320 | 86 | 4 | 995 | 1510 | 1200 | 1600 | 22236W33 | 22236KW33 | 3536Y | 113536Y | 198 | 302 | 3 | 0.28 | 2.4 | 3.6 | 2.5 | 29.3 | |

| 320 | 112 | 4 | 1310 | 2090 | 900 | 1200 | 23236CA'W33 | 23236CAK/W33 | 3053236HY | 3153236HY | 198 | 302 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 39.5 | |

| 320 | 112 | 紧 | 1310 | 2090 | 900 | 1200 | 23236CAW33YA2 | 3053236HKY | 198 | 302 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 394 | |||

| 380 | 126 | 4 | 1650 | 2330 | 900 | 1200 | 2336W33 | 22336K/W33 | 3636Y | 113636Y | 198 | 362 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 80.7 | |

| 190 | 280 | 67 | 2.1 | 633 | 1120 | 1200 | 1500 | 2638 | 3738 | 202 | 270 | 2 | 0.23 | 2.9 | 4.4 | 2.8 | 13.7 | ||

| 290 | 75 | 2.1 | 800 | 1500 | 1200 | 1500 | 23038W33 | 23038KW33 | 3003138Y | 3113138Y | 202 | 278 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 20.3 | |

| 290 | 100 | 2.1 | 938 | 1690 | 950 | 1300 | 24038C/W33 | 24038CK30W33 | 4003138Y | 113138Y | 202 | 278 | 2 | 0.31 | 2.2 | 3.3 | 2.2 | 23.9 | |

| 320 | 104 | 3 | 1050 | 1760 | 950 | 1300 | 23138W33 | 23138KW33 | 204 | 306 | 2.5 | 0.33 | 2 | 3 | 2 | 35.1 | |||

| 320 | 104 | 3 | 1140 | 1960 | 950 | 1300 | 23138CA/W33 | 23138CAK/W3 | 204 | 306 | 2.5 | 0.31 | 2.2 | 3.3 | 2.2 | 45 | |||

| d 190~240mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 190 | 320 | 128 | 3 | 1290 | 2250 | 850 | 1100 | 24138CA | 24138CAK30/W33 | 204 | 306 | 2.5 | 0.4 | 1.7 | 2.5 | 1.6 | 43.8 | ||

| 340 | 92 | 4 | 1140 | 1730 | 1200 | 1600 | 22238CA/W33 | 22238CAKW33 | 53538HY | 153538HY | 208 | 322 | 3 | 0.26 | 2.6 | 3.9 | 2.5 | 35.5 | |

| 340 | 92 | 4 | 1090 | 1640 | 1200 | 1600 | 22238W33 | 22238K/W33 | 3538Y | 113538Y | 208 | 322 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 35.5 | |

| 190 | 340 | 120 | 4 | 1490 | 2380 | 850 | 1100 | 23238CA/W33 | 23238CAK/W33 | 3053238HY | 3153238HY | 208 | 322 | 3 | 0.35 | 1.9 | 2.9 | 1.8 | 51 |

| 400 | 132 | 5 | 1850 | 2590 | 850 | 1100 | 22338/W33 | 22338K/W33 | 3638Y | 13638Y | 210 | 380 | 4 | 0.25 | 2.7 | 4 | 2.7 | 79.7 | |

| 200 | 310 | 82 | 2.1 | 870 | 1510 | 1100 | 1400 | 23040/W33 | 23040K/W33 | 3003140Y | 313140Y | 212 | 298 | 2 | 0.26 | 2.6 | 3.9 | 2.5 | 26 |

| 340 | 112 | 3 | 1230 | 2240 | 850 | 1200 | 23140/W33 | 23140K/W33 | 3003740Y | 3113740Y | 214 | 326 | 2.5 | 0.34 | 2 | 2.9 | 1.9 | 50.5 | |

| 340 | 140 | 3 | 1660 | 2810 | 800 | 1000 | 24140C/W33 | 24140CK30/W33 | 4053740Y | 4453740Y | 214 | 326 | 2.5 | 0.4 | 1.7 | 2.5 | 1.6 | 51.9 | |

| 360 | 98 | 4 | 1210 | 1870 | 1100 | 1500 | 22240/W33 | 22240K/W33 | 3540Y | 113540Y | 218 | 342 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 44.7 | |

| 360 | 128 | 4 | 1490 | 2370 | 800 | 1000 | 23240/W33 | 23240K/W33 | 218 | 342 | 3 | 0.36 | 1.9 | 2.8 | 1.8 | 56.8 | |||

| 420 | 138 | 5 | 1900 | 2800 | 850 | 1100 | 22340/W33 | 22340K/W33 | 3640Y | 113640Y | 222 | 398 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 93.5 | |

| 220 | 320 | 76 | 3 | 758 | 1280 | 1000 | 1300 | 2644 | 3844 | 232 | 308 | 2.5 | 0.23 | 2.9 | 4.4 | 2.8 | 21.6 | ||

| 340 | 90 | 3 | 1100 | 1750 | 1100 | 1500 | 23044/W33 | 23044K/W33 | 233 | 327 | 2.5 | 0.26 | 2.6 | 3.9 | 2.5 | 30.8 | |||

| 370 | 120 | 4 | 1530 | 2640 | 900 | 1200 | 23144/W33 | 23144K/W33 | 3003744Y | 3113744Y | 237 | 353 | 3 | 0.32 | 2.1 | 3.1 | 2 | 53.5 | |

| 370 | 120 | 4 | 1540 | 2650 | 850 | 1100 | 23144CA/W33 | 23144CAK/W33 | 237 | 353 | 3 | 0.32 | 2.1 | 3.1 | 2 | 54.2 | |||

| 370 | 150 | 4 | 1870 | 3350 | 750 | 950 | 24144C/W33 | 24144CK30/W33 | 4053744Y | 4453744Y | 237 | 353 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 66.1 | |

| 370 | 150 | 4 | 1760 | 3120 | 700 | 900 | 2414CAW33 | 237 | 353 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 65.6 | ||||

| 400 | 108 | 4 | 1570 | 2430 | 950 | 1300 | 224/W33 | 2244K/W33 | 3544Y | 113544Y | 237 | 383 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 62.4 | |

| 400 | 108 | 4 | 1570 | 2430 | 950 | 1300 | 22244CA/W33 | 22244CAK/W33 | 237 | 383 | 3 | 0.27 | 2.5 | 3.7 | 2.5 | 62.4 | |||

| 400 | 144 | 4 | 1860 | 3100 | 750 | 950 | 23244/W33 | 23244K/W33 | 3003244Y | 3113244Y | 237 | 383 | 3 | 0.38 | 1.8 | 2.6 | 1.7 | 94.2 | |

| 460 | 145 | 5 | 2130 | 3170 | 750 | 950 | 22344/W33 | 22344K/W33 | 3644Y | 113644Y | 240 | 440 | 4 | 0.35 | 1.9 | 2.9 | 1.8 | 130 | |

| 240 | 360 | 92 | 3 | 1160 | 1870 | 1000 | 1400 | 23048/W33 | 23048K/W33 | 3003148Y | 3113148Y | 253 | 347 | 2.5 | 0.25 | 2.7 | 4 | 2.7 | 37.4 |

| 360 | 118 | 3 | 1320 | 2610 | 800 | 1000 | 24048CA/W33 | 24048CAK30/W33 | 253 | 347 | 2.5 | 0.3 | 2.3 | 3.4 | 2.2 | 42.4 | |||

| 400 | 128 | 4 | 1870 | 3000 | 850 | 1100 | 23148/W33 | 23148K/W33 | 3003748Y | 3113748Y | 257 | 383 | 3 | 0.33 | 2 | 3 | 2 | 75.2 | |

| 400 | 128 | 4 | 1800 | 2950 | 850 | 1100 | 23148CA/W33 | 23148CAK/W33 | 257 | 383 | 3 | 0.3 | 2.3 | 3.4 | 2.2 | 65 | |||

| 400 | 160 | 4 | 1980 | 3710 | 670 | 850 | 24148/W33 | 24148K30/W33 | 4003748Y | 4403748Y | 257 | 383 | 3 | 0.41 | 1.7 | 2.5 | 1.6 | 81.6 | |

| 440 | 120 | 4 | 1720 | 2700 | 900 | 1200 | 22248/W33 | 22248K/W33 | 3548Y | 113548Y | 257 | 423 | 3 | 0.29 | 2.4 | 3.5 | 2.3 | 85 | |

| d 240~280mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 240 | 440 | 160 | 4 | 2280 | 3870 | 670 | 850 | 23248/W33 | 23248K/W3 | 3003248Y | 3113248Y | 257 | 423 | 3 | 37 | 1.8 | 2.7 | 1.8 | 109 |

| 500 | 155 | 5 | 2400 | 3600 | 670 | 850 | 22348/W33 | 22348K/W33 | 3648Y | 13648Y | 260 | 480 | 4 | 35 | 1.9 | 2.9 | 1.8 | 154 | |

| 250 | 365 | 87 | 3 | 956 | 1870 | 880 | 1100 | 2650 | 3750 | 264 | 351 | 2.5 | 0.22 | 3 | 4.5 | 2.9 | 32.2 | ||

| 260 | 400 | 104 | 4 | 1440 | 2570 | 900 | 1200 | 23052/W33 | 23052K/W33 | 3003152Y | 3113152Y | 275 | 385 | 3 | 0.26 | 2.6 | 3.9 | 2.5 | 51.2 |

| 400 | 140 | 4 | 1700 | 3260 | 700 | 900 | 24052CA/W33 | 24052CAK30/W33 | 275 | 385 | 3 | 0.33 | 2 | 3 | 2 | 63.4 | |||

| 400 | 140 | 4 | 1700 | 3260 | 700 | 900 | 24052CA/C9W3 | 3 | 275 | 385 | 3 | 0.33 | 2 | 3 | 2 | 63.3 | |||

| 440 | 144 | 4 | 2290 | 3510 | 800 | 1000 | 23152/W33 | 23152K/W33 | 3003752Y | 3113752Y | 277 | 423 | 3 | 0.33 | 2 | 3 | 2 | 962 | |

| 440 | 144 | 4 | 2550 | 3900 | 800 | 1000 | 23152S1 | 277 | 423 | 3 | 0.31 | 2.2 | 3.3 | 2.2 | 96 | ||||

| 440 | 180 | 4 | 2500 | 4560 | 720 | 900 | 24152W33 | 24152K30/W33 | 277 | 423 | 3 | 0.42 | 1.6 | 2.4 | 1.6 | 118 | |||

| 440 | 180 | 4 | 2470 | 4320 | 600 | 750 | 24152CA/W33 | 24152CAK30/W33 | 277 | 423 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 103 | |||

| 440 | 180 | 4 | 2350 | 4320 | 600 | 750 | 24152CW33 | 24152CK30/W33 | 4053752Y | 4453752Y | 277 | 423 | 3 | 0.4 | 1.7 | 2.5 | 1.6 | 115 | |

| 480 | 130 | 5 | 2160 | 3100 | 850 | 1100 | 22252CA/W33 | 22252CAK/W33 | 53552HY | 153552HY | 280 | 460 | 4 | 0.27 | 2.5 | 3.7 | 2.5 | 101 | |

| 480 | 174 | 5 | 2800 | 4100 | 560 | 720 | 23252CA/W33 | 23252CAK/W33 | 3053252HY | 3153252HY | 280 | 460 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 150 | |

| 490 | 153 | 4 | 2420 | 3940 | 760 | 1050 | 2652 | 3752 | 280 | 460 | 4 | 0.33 | 2 | 3 | 2 | 143 | |||

| 540 | 165 | 6 | 2860 | 4430 | 560 | 720 | 22352W33 | 22352K/W33 | 3652Y | 113652Y | 286 | 514 | 5 | 0.34 | 2 | 2.9 | 1.9 | 20 | |

| 280 | 420 | 106 | 4 | 1560 | 2560 | 850 | 1100 | 23056/W33 | 23056K/W33 | 3003156Y | 3113156Y | 295 | 405 | 3 | 0.25 | 2.7 | 4 | 2.7 | 61.7 |

| 420 | 106 | 4 | 1540 | 2950 | 800 | 1000 | 23056CA/W33 | 23056CAK/W33 | 295 | 405 | 3 | 0.23 | 2.9 | 4.4 | 2.8 | 51.3 | |||

| 420 | 140 | 4 | 1780 | 3500 | 670 | 850 | 24056CA/W33 | 24056CAK30/W33 | 295 | 405 | 0.3 | 2.3 | 3.4 | 2.2 | 71 | ||||

| 460 | 146 | 5 | 2070 | 3960 | 750 | 950 | 23156/W33 | 23156K/W33 | 3003756Y | 3113756Y | 300 | 440 | 4 | 0.32 | 2. | 3.1 | 2 | 95.2 | |

| 460 | 146 | 5 | 2380 | 3880 | 750 | 950 | 23156CA/W33 | 23156CAK/W33 | 300 | 440 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 969 | |||

| 460 | 180 | 5 | 2360 | 4420 | 560 | 700 | 24156CA | 300 | 440 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 119 | ||||

| 460 | 180 | 5 | 2400 | 4500 | 560 | 700 | 24156 CATYA | 300 | 440 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 157 | ||||

| 460 | 180 | 5 | 2400 | 4590 | 560 | 700 | 24156/W33 | 24156K30/W33 | 300 | 440 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 114 | |||

| 500 | 130 | S | 2110 | 3370 | 800 | 1000 | 22256W33 | 22256K/W33 | 3556Y | 13556Y | 300 | 480 | 4 | 0.28 | 2.4 | 3.6 | 2.5 | 122 | |

| 500 | 176 | 5 | 2560 | 4350 | 600 | 750 | 23256/W33 | 23256K/W33 | 3003256Y | 3113256Y | 300 | 480 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 158 | |

| 580 | 175 | 6 | 3180 | 4970 | 600 | 750 | 22356W33 | 22356K/W33 | 3656Y | 113656Y | 306 | 554 | 5 | 0.34 | 2 | 2.9 | 1.9 | 23.5 | |

| d 300~360mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 300 | 420 | 90 | 3 | 1260 | 2460 | 950 | 1300 | 23960C/W33 | 23960CK/W33 | 313 | 407 | 2.5 | 0.19 | 36 | 5.3 | 3.5 | 39.6 | ||

| 460 | 118 | 4 | 1910 | 3170 | 720 | 920 | 23060/W33 | 23060K/W33 | 3003160Y | 3113160Y | 315 | 445 | 3 | 0.26 | 26 | 3.9 | 2.5 | 74.6 | |

| 460 | 118 | 4 | 2090 | 3370 | 800 | 1000 | 23060CAW33 | 23060CAK/W33 | 315 | 445 | 3 | 0.24 | 2.8 | 4.2 | 2.8 | 761 | |||

| 460 | 160 | 4 | 2430 | 4490 | 600 | 750 | 24060CA/W332 | 4060CAK30/W33 | 4053160Y | 4453160Y | 315 | 445 | 3 | 0.32 | 2.1 | 3.1 | 2 | 10 | |

| 500 | 160 | 5 | 2580 | 4590 | 670 | 850 | 23160/W33 | 23160K/W33 | 3003760Y | 311760Y | 320 | 480 | 4 | 0.32 | 2.1 | 3.1 | 2 | 133 | |

| 500 | 160 | 5 | 2880 | 4640 | 670 | 850 | 23160CA/W33 | 23160CAK/W33 | 320 | 480 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 127 | |||

| 500 | 200 | 5 | 3380 | 5940 | 530 | 670 | 24160C/W33 | 24160CK30/W33 | 4053760Y | 4453760Y | 320 | 480 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 159 | |

| 500 | 200 | 5 | 3120 | 5650 | 500 | 600 | 24160CAW33 | 24160CAK3e/W33 | 320 | 480 | 4 | 0.36 | 1.9 | 2.8 | 1.8 | 160 | |||

| 300 | 500 | 200 | 5 | 3180 | 6100 | 450 | 550 | 24160W33 | 24160K30/W33 | 320 | 480 | 4 | 0.39 | 1.7 | 2.6 | 1.7 | 159 | ||

| 540 | 140 | 5 | 2480 | 3820 | 700 | 900 | 22260/W33 | 22260K/W33 | 3560Y | 113560Y | 320 | 520 | 4 | 0.28 | 2.4 | 3.6 | 2.5 | 143 | |

| 320 | 440 | 90 | 3 | 1290 | 2430 | 900 | 1200 | 239641W33 | 23964K/W33 | 3003964Y | 3113964Y | 333 | 427 | 2.5 | 0.19 | 3.6 | 5.3 | 3.5 | 45.1 |

| 480 | 121 | 4 | 1850 | 3450 | 720 | 900 | 23064/W33 | 23064K/W33 | 3003164Y | 3113164Y | 335 | 465 | 3 | 0.26 | 2.6 | 3.9 | 2.5 | 80.9 | |

| 480 | 121 | 4 | 2020 | 3580 | 800 | 1000 | 23064CA/W33 | 23064CAK/W33 | 335 | 465 | 3 | 0.24 | 2.8 | 4.2 | 2.8 | 77.4 | |||

| 480 | 160 | 4 | 2570 | 5060 | 680 | 850 | 24064/W33 | 24064K30/W33 | 4003164Y | 4113164Y | 335 | 465 | 3 | 0.32 | 2.1 | 3.1 | 2 | 103 | |

| 540 | 176 | 5 | 3390 | 5538 | 630 | 800 | 23164CA/W33 | 23164CAK/W33 | 340 | 520 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 169 | |||

| 540 | 218 | 5 | 3470 | 6430 | 480 | 600 | 24164/W33 | 24164K30/W33 | 4003764Y | 4113764Y | 340 | 520 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 251 | |

| 320 | 540 | 218 | 5 | 3470 | 6430 | 480 | 600 | 24164/W33 | 340 | 520 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 207 | |||

| 580 | 208 | 5 | 3500 | 6360 | 500 | 630 | 23264/W33 | 23264K/W33 | 3003264Y | 3113264Y | 340 | 560 | 4 | 0.37 | 1.8 | 2.7 | 1.8 | 259 | |

| 340 | 460 | 90 | 3 | 1310 | 2520 | 880 | 1180 | 23968W33 | 23968K/W33 | 3003968Y | 3113968Y | 353 | 447 | 2.5 | 0.18 | 3.8 | 5.6 | 3.7 | 50.5 |

| 520 | 133 | 5 | 2430 | 4350 | 680 | 880 | 23068W33 | 23068K/W33 | 3003168Y | 3113168Y | 358 | 502 | 4 | 0.25 | 2.7 | 4 | 2.7 | 109 | |

| 520 | 180 | 5 | 2920 | 5580 | 510 | 650 | 24068W33 | 24068K30/W33 | 4003168Y | 4113168Y | 358 | 502 | 4 | 0.33 | 2 | 3 | 2 | 160 | |

| 520 | 180 | 5 | 3110 | 5710 | 520 | 660 | 24068CA/W33 | 24068CAK30/W33 | 358 | 502 | 4 | 0.33 | 2 | 3 | 2 | 140 | |||

| 580 | 190 | 5 | 3830 | 6240 | 600 | 750 | 23168CA/W33 | 23168CAK/W33 | 360 | 560 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 209 | |||

| 580 | 243 | 5 | 4180 | 7720 | 450 | 560 | 24168CA/W33 | 24168CAK30/W33 | 360 | 560 | 4 | 39 | 1.7 | 2.6 | 1.7 | 280 | |||

| 360 | 480 | 90 | 3 | 1330 | 2710 | 850 | 1100 | 23972/W33 | 3972K/W33 | 3003972Y | 3113972Y | 373 | 467 | 2.5 | 0.17 | 4 | 5.9 | 3.9 | 49.1 |

| 540 | 134 | 5 | 2480 | 4500 | 670 | 850 | 23072/W33 | 23072K/W33 | 3003172Y | 3113732Y | 378 | 522 | 4 | 0.25 | 2.7 | 4 | 2.7 | 114 | |

| d 360~420mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 360 | 540 | 134 | 5 | 2390 | 4700 | 600 | 760 | 23072CA/W33 | 23072CAK/W33 | 3053172HY 3153172HY | 378 | 522 | 4 | 0.25 | 2.7 | 4 | 2.7 | 113 | |

| 540 | 180 | 5 | 3460 | 6350 | 500 | 630 | 24072C/W33 | 24072CK30/W33 4 | 053172Y | 4453172Y | 378 | 522 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 148 | |

| 540 | 180 | 5 | 3200 | 6160 | 480 | 620 | 24072CA/W33 | 24072CAK30/W33 | 378 | 522 | 4 | 0.31 | 2.2 | 3.3 | 2.2 | 148 | |||

| 600 | 192 | 5 | 3400 | 6700 | 560 | 700 | 23172/W33 | 23172K/W33 3 | 003772Y | 3113772Y | 380 | 580 | 4 | 0.32 | 2.1 | 3.1 | 2 | 221 | |

| 600 | 243 | 5 | 4400 | 8370 | 430 | 530 | 24172/W33 | 24172K30/W33 4 | 003772Y | 4113772Y | 380 | 580 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 273 | |

| 600 | 243 | 5 | 4300 | 8210 | 430 | 530 | 24172 CAK30W33 | 380 | 580 | 4 | 0.42 | 1.6 | 2.4 | 1.6 | 271 | ||||

| 750 | 224 | 7.5 | 4900 | 7500 | 450 | 550 | 22372/W33 | 22372K/W33 | 390 | 724 | 5 | 0.31 | 2.2 | 3.3 | 2.2 | 489 | |||

| 650 | 232 | 6 | 4520 | 7930 | 420 | 510 | 23272CAK30 | W33 | 386 | 624 | 5. | 0.35 | 1.9 | 2.9 | 1.8 | 332 | |||

| 380 | 520 | 106 | 4 | 1760 | 3420 | 800 | 1000 | 23976/W33 | 23976K/W33 3 | 003976Y | 3113976Y | 395 | 505 | 3 | 0.19 | 3.6 | 5.3 | 3.5 | 73.5 |

| 560 | 135 | 5 | 2280 | 4550 | 630 | 800 | 23076/W33 | 23076K/W33 | 3003176Y | 3113176Y | 398 | 542 | 4 | 0.24 | 2.8 | 4.2 | 2.8 | 122 | |

| 380 | 560 | 135 | 5 | 2610 | 4850 | 630 | 800 | 23076CA/W33 | 23076CAK/W33 | 3003776Y | 3113776Y | 398 | 542 | 4 | 0.22 | 4.5 | 2.9 | 114 | |

| 560 | 180 | 5 | 3240 | 6460 | 480 | 600 | 24076/W33 | 24076K30/W33 | 398 | 542 | 4 | 0.3 | 2.3 | 3.4 | 2.2 | 152 | |||

| 620 | 194 | 5 | 3450 | 6800 | 400 | 500 | 23176/W33 | 23176KW33 | 400 | 600 | 4 | 0.34 | 2 | 2.9 | 1.9 | 243 | |||

| 620 | 194 | 5 | 3700 | 7000 | 400 | 500 | 23176CAQ1/W3 | 323176CAKQI/W33 | 400 | 600 | 4 | 0.3 | 2.3 | 3.4 | 2.2 | 230 | |||

| 780 | 230 | 7.5 | 5340 | 8390 | 340 | 430 | 22376/W33 | 22376K/W33 | 400 | 760 | 6 | 0.31 | 2.2 | 3.3 | 2.2 | 538 | |||

| 400 | 590 | 142 | 5 | 2300 | 5000 | 700 | 900 | 2680/W33 | 2680KW33 | 3003180Y | 3113180Y | 418 | 572 | 4 | 0.23 | 2.9 | 4.4 | 2.8 | 145 |

| 600 | 148 | 5 | 2520 | 5450 | 540 | 670 | 23080/W33 | 23080K/W33 | 3003280Y | 3113280Y | 420 | 582 | 4 | 0.25 | 2.7 | 4 | 2.7 | 165 | |

| 650 | 200 | 6 | 3850 | 7540 | 380 | 480 | 23180/W33 | 23180K/W33 | 426 | 624 | 5 | 0.31 | 2.2 | 3.3 | 2.2 | 238 | |||

| 720 | 256 | 6 | 5300 | 10100 | 340 | 430 | 23280/W33 | 23280KW33 | 3680Y | 426 | 694 | 5 | 0.37 | 1.8 | 2.7 | 1.8 | 530 | ||

| 720 | 315 | 6 | 6620 | 10400 | 310 | 390 | 24280/W33 | 24280K30/W33 | 426 | 694 | 5 | 0.44 | 1.5 | 2.3 | 15 | 549 | |||

| 820 | 243 | 7.5 | 5900 | 9360 | 360 | 450 | 22380/W33 | 22380K/W33 | 3G3-316 | 432 | 788 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 650 | ||

| 401 | 720 | 256 | 6 | 5300 | 10100 | 340 | 430 | 3003184Y | 3113184Y | 426 | 694 | 5 | 0.37 | 1.8 | 2.7 | 1.8 | 515 | ||

| 420 | 620 | 150 | 5 | 2690 | 5750 | 450 | 560 | 23084/W33 | 24084K30/W33 | 3003784Y | 3113784Y | 438 | 602 | 4 | 0.24 | 2.8 | 4.2 | 2.8 | 158 |

| 700 | 224 | 6 | 4850 | 9300 | 360 | 450 | 23184/W33 | 23184K/W33 | 3053284HY | 3153284HY | 446 | 674 | 5 | 0.32 | 2.1 | 3.1 | 2 | 402 | |

| 700 | 280 | 6 | 5700 | 11300 | 300 | 380 | 24184CA/W33 | 24184CAK30/W33 | 446 | 674 | 5 | 0.38 | 1.7 | 2.6 | 1.7 | 434 | |||

| d 360~560mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 360 | 760 | 272 | 7.5 | 6450 | 11700 | 320 | 400 | 23284CA/W33 | 23284CAK/W33 | 3003188Y | 3113188Y | 452 | 728 | 6 | 0.35 | 1.9 | 2.9 | 1.8 | 535 |

| 440 | 650 | 157 | 6 | 2900 | 6050 | 430 | 530 | 23088W33 | 23088K/W33 | 3003788Y | 3113788Y | 463 | 627 | 5 | 0.24 | 2.8 | 4.2 | 2.8 | 192 |

| 720 | 226 | 6 | 4910 | 9600 | 340 | 430 | 23188W33 | 23188K/W33 | 466 | 694 | 5 | 0.31 | 2.2 | 3.3 | 2.2 | 419 | |||

| 720 | 280 | 6 | 5900 | 11900 | 280 | 360 | 24188W33 | 24188K30/W33 | 3003192Y | 3113192Y | 466 | 694 | 5 | 0.38 | 1.7 | 2.6 | 1.7 | 443 | |

| 720 | 280 | 6 | 6150 | 12300 | 300 | 380 | 24188 CAK30C3 | W33 | 466 | 694 | 5 | 0.37 | 1.8 | 2.7 | 1.8 | 446 | |||

| 460 | 680 | 163 | 6 | 3150 | 6860 | 400 | 500 | 23092W33 | 23092K/W33 | 483 | 657 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 220 | ||

| 760 | 240 | 7.5 | 5450 | 10800 | 320 | 400 | 23192W33 | 23192K/W33 | 492 | 728 | 6 | 0.31 | 2.2 | 3.3 | 2.2 | 468 | |||

| 760 | 300 | 7.5 | 6660 | 13100 | 260 | 340 | 24192W33 | 24192K30W33 | 3003996Y | 3113996Y | 492 | 728 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 539 | |

| 480 | 650 | 128 | 5 | 2280 | 5480 | 400 | 500 | 23996/W33 | 23996K/W33 | 498 | 632 | 4 | 0.18 | 3.8 | 5.6 | 3.7 | 161 | ||

| 650 | 128 | 5 | 2900 | 5700 | 400 | 500 | 23996 CAFI/W3 | 3 | 498 | 632 | 4 | 0.18 | 3.8 | 5.6 | 3.6 | 125 | |||

| 700 | 165 | 6 | 3280 | 6910 | 380 | 480 | 23096W33 | 23096KW33 | 3003196Y | 3113196Y | 503 | 677 | 5 | 0.24 | 2.8 | 4.2 | 2.8 | 231 | |

| 790 | 248 | 7.5 | 5800 | 11400 | 300 | 380 | 23196CAW33 | 23196CAKW33 | 512 | 758 | 6 | 0.3 | 2.3 | 3.4 | 2.2 | 492 | |||

| 870 | 310 | 7.5 | 7350 | 13800 | 250 | 320 | 23296W33 | 23296KW33 | 3003296Y | 3113296Y | 512 | 838 | 6 | 0.39 | 1.7 | 2.6 | 1.7 | 837 | |

| 870 | 310 | 7.5 | 7580 | 13800 | 260 | 340 | 23296CAW33 | 23296CAKW33 | 512 | 838 | 6 | 0.36 | 1.9 | 2.8 | 1.8 | 857 | |||

| 494 | 670 | 128 | 5 | 2440 | 6060 | 400 | 500 | 2391494/W33 | 239494KW33 | 512 | 652 | 4 | 0.18 | 3.8 | 5.6 | 3.7 | 135 | ||

| 500 | 670 | 128 | 5 | 2440 | 6060 | 400 | 500 | 2391500/W33 | 239500KW33 | 30039/500Y | 31139/500Y | 518 | 652 | 4 | 0.18 | 3.8 | 5.6 | 3.7 | 130 |

| 720 | 167 | 6 | 3500 | 7600 | 380 | 480 | 230/500/W33 | 2301500K/W33 | 30031/500Y | 31131/500Y | 523 | 697 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 238 | |

| 530 | 780 | 185 | 6 | 3930 | 8550 | 340 | 430 | 2301530/W33 | 230530KW33 | 30031/530Y | 31131/530Y | 553 | 757 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 313 |

| 780 | 185 | 6 | 3560 | 8260 | 340 | 430 | 2301530 D-1 | 553 | 757 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 317 | ||||

| 980 | 355 | 9.5 | 9960 | 18500 | 240 | 320 | 232/530CA/W33 | 232/530CAK30/W3 | 622 | 888 | 6 | 0.36 | 1.9 | 2.8 | 1.8 | 1210 | |||

| 560 | 820 | 195 | 6 | 4460 | 10020 | 300 | 380 | 230/560/W33 | 230560K/W33 | 30031/560Y | 31131/560T | 583 | 797 | 5 | 0.23 | 2.9 | 4.4 | 2.8 | 365 |

| 820 | 195 | 6 | 4700 | 10300 | 320 | 400 | 2301560CA/W33 | 230560CAK/W33 | 583 | 797 | 5 | 0.22 | 3 | 4.5 | 2.9 | 354 | |||

| 820 | 258 | 6 | 6160 | 14000 | 340 | 420 | 240/560 CAW33 | 583 | 797 | 5 | 0.28 | 2.4 | 3.6 | 2.5 | 472 | ||||

| d 560~850mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 560 | 920 | 280 | 7.5 | 7990 | 16000 | 240 | 320 | 231/560W33 | 231560K/W33 | 30037/560Y | 31137/560Y | 592 | 888 | 6 | 0.3 | 2.3 | 3.4 | 2.2 | 757 |

| 920 | 355 | 7.5 | 9450 | 19500 | 190 | 260 | 241560CA/W33 | 241560CAK30/W33 | 592 | 888 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 985 | |||

| 920 | 355 | 7.5 | 9450 | 19500 | 190 | 260 | 241/560CA-1/W33 | 592 | 888 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 947 | ||||

| 600 | 870 | 200 | 6 | 4810 | 11000 | 300 | 380 | 2301600W33 | 2301600KW33 | 30031600Y | 3H31/600Y | 623 | 847 | 5 | 0.22 | 3 | 2.7 | 2.9 | 393 |

| 980 | 375 | 7.5 | 10400 | 21300 | 180 | 240 | 241600/W33 | 241600K30'W33 | 40037600Y | 41137/600Y | 632 | 948 | 6 | 0.37 | 1.8 | 2.7 | 1.8 | 1079 | |

| 630 | 920 | 212 | 7.5 | 5360 | 12200 | 260 | 340 | 230/630/W33 | 230/630KW33 | 30031/630Y | 31131/630Y | 658 | 892 | 6 | 23 | 2.9 | 4.4 | 2.8 | 509 |

| 670 | 900 | 170 | 6 | 4130 | 9840 | 260 | 340 | 239/670/W33 | 239/670K/W33 | 30039/670Y | 31139/670Y | 693 | 877 | 5 | 18 | 3.8 | 5.6 | 3.7 | 317 |

| 670 | 900 | 170 | 6 | 4260 | 10000 | 260 | 340 | 239670CAFI/W33 | 693 | 877 | 5 | 0.17 | 4 | 5.9 | 4 | 308 | |||

| 980 | 230 | 7.5 | 6240 | 13700 | 240 | 320 | 230670/W33 | 230/670K/W33 | 30031/670Y | 31131/670Y | 698 | 952 | 6 | 0.23 | 2.9 | 4.4 | 2.8 | 655 | |

| 710 | 950 | 180 | 6 | 4290 | 10900 | 240 | 320 | 239/710/W33 | 239710K/W33 | 30039/710Y | 31139/710Y | 732 | 927 | 5 | 0.18 | 3.8 | 5.6 | 3.7 | 387 |

| 1030 | 236 | 7.5 | 6530 | 15130 | 220 | 300 | 230/710/W33 | 230710K/W33 | 3003/710Y | 31131/710Y | 738 | 1002 | 6 | 0.23 | 2.9 | 4.4 | 2.8 | 742 | |

| 1150 | 438 | 9.5 | 13700 | 29940 | 150 | 190 | 241/710/W33 | 241710K30/W33 | 40037710Y | 41137710Y | 750 | 1110 | 8 | 0.38 | 1.7 | 2.6 | 1.7 | 1802 | |

| 750 | 1090 | 250 | 7.5 | 7890 | 17600 | 200 | 280 | 234750W33 | 230750KW33 | 778 | 1062 | 6 | 0.22 | 3 | 4.5 | 2.9 | 855 | ||

| 750 | 1090 | 335 | 7.5 | 9340 | 22300 | 190 | 240 | 240750W33 | 782 | 1058 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1060 | |||

| 800 | 1060 | 258 | 6 | 7170 | 19030 | 200 | 280 | 249180/W33 | 249/800K30W33 | 40039/800Y | 41139.800Y | 823 | 1037 | 5 | 0.22 | 3 | 4.5 | 2.9 | 638 |

| 1150 | 258 | 7.5 | 8630 | 20000 | 190 | 260 | 2301800W33 | 230800KW33 | 3003J/800Y | 31131/800Y | 828 | 1122 | 6 | 0.21 | 3.2 | 4.8 | 3.1 | 986 | |

| 1150 | 345 | 7.5 | 10000 | 25700 | 170 | 220 | 2480W33 | 240800K30/W33 | 40031/800Y | 41131/800Y | 828 | 1122 | 6 | 0.29 | 2.4 | 3.5 | 3.3 | 1246 | |

| 850 | 1120 | 200 | 6 | 6100 | 15800 | 190 | 260 | 239/850W33 | 2391850KW33 | 30039/850Y | 31139850Y | 873 | 1097 | 5 | 0.16 | 4.2 | 6.2 | 4.1 | 531 |

| 1220 | 272 | 7.5 | 9050 | 21100 | 180 | 240 | 230:850W33 | 230:850KW33 | 878 | 1192 | 6 | 0.21 | 32 | 4.8 | 3.1 | 1069 | |||

| 1220 | 365 | 7.5 | 10000 | 26000 | 160 | 200 | 2401850W33 | 240:850K30/W33 | 40031/850Y | 41131/850Y | 878 | 1192 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1398 | |

| d 850~1180mm | |||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||

| d | D | B | ramin | Dynamic Load C |

Static Load C。 |

Grease | Oil | Current Model | Original Model | damin | Damax | ramax | e | Y1 | Y2 | Y0 | |||

| Cylindrical Inner Bore | Tapered Inner Bore | Cylindrical Inner Bore | Tapered Inner Bore | ||||||||||||||||

| mm | kN | r/min | mm | kg | |||||||||||||||

| 850 | 1220 | 365 | 7.5 | 10000 | 26000 | 160 | 200 | 21401850YA | 40031/850Y1 | 878 | 1192 | 6 | 0.28 | 2.4 | 3.6 | 2.5 | 1396 | ||

| 900 | 1270 | 365 | 7.5 | 12200 | 31100 | 160 | 200 | 26900C3W33XYA3 | 928 | 1242 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1703 | |||

| 1280 | 375 | 7.5 | 12200 | 31100 | 150 | 190 | 240190W33 | 240:900K30W3340 | 031900Y | 41131900Y | 928 | 1252 | 6 | 0.27 | 2.5 | 3.7 | 2.5 | 1783 | |

| 1000 | 1420 | 412 | 7.5 | 15000 | 40000 | 120 | 160 | 240/100DW33 00Y | 240100K30W33400 | 31/1000Y | 41131/10 | 1028 | 1392 | 6 | 0.27 | 2.5 | 3.72. | 5 | 2117 |

| 1120 | 1580 | 462 | 9.5 | 18500 | 48000 | 100 | 140 | 2401120 CAW33 | 1159 | 1541 | 8 | 0.26 | 2.6 | 3.9 | 2.5 | 2908 | |||

| 1180 | 1540 | 272 | 7.5 | 10400 | 27700 | 100 | 140 | 2391180CAW33 | 1214 | 1506 | 6 | 0.16 | 4.2 | 6.3 | 4 | 1360 | |||

| 1180 | 1660 | 355 | 9.5 | 15500 | 38400 | 90 | 120 | 234/18W33 | 23/1180K/W33 | 1210 | 1630 | 8 | 0.2 | 3.4 | 5.1 | 3.3 | 2480 | ||

Learn about our latest products and discounts through SMS or email