- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

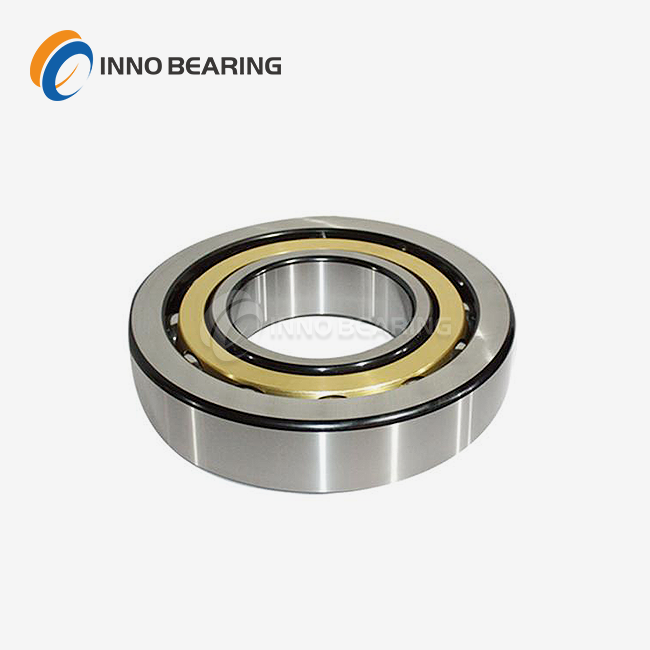

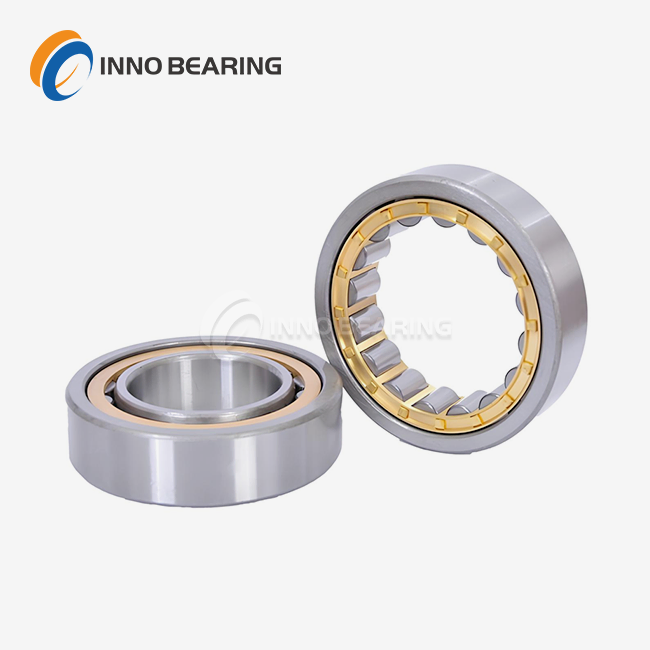

Single-Direction Angular Contact Thrust Ball Bearing

2.Structure Type: Shaft washer + housing washer + single-row angular contact steel balls + brass cage, open structure.

3.Size Range: Inner diameter: 15 - 200mm, outer diameter: 40 - 250mm, height: 12 - 40mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (angular contact steel balls): GCr15/GCR15SIMN, cage: brass.

5.Accuracy: Conventional P5 grade, ultra-precision model is of P4 grade.

6.Application Fields: Spindles of precision machine tools, turbochargers, high-end fans.

7.Key Inspection Items: Accuracy of contact angle, radial runout (≤0.003mm), running stability.

Single-Direction Angular Contact Thrust Ball Bearing: Precision Engineered for Demanding Applications

Single-Direction Angular Contact Thrust ball bearings are engineered to handle high axial loads with unmatched precision. Designed for industries where reliability under extreme conditions is non-negotiable, these bearings combine P4-grade rotation accuracy, robust materials, and adaptive designs to excel in applications like wind turbine pitch systems, robotic arms, and metallurgical machinery. With a contact angle optimized for unidirectional force (15°–25°), they ensure smooth operation even at 4,000 RPM or 150°C. Let’s explore how this component solves critical challenges across sectors.

Technical Specifications: Built to Perform

- Axial Load Capacity: 50 kN to 3,000 kN (static) | Customizable for higher demands

- Speed Limits: 1,500–4,000 RPM (dependent on lubrication and material)

- Temperature Range: -30°C to +150°C (stainless steel or hybrid ceramic options available)

- Precision: Standard P4 (ABEC 7), upgradeable to P2 for micron-level accuracy

- Materials: High-purity GCr15/SAE 52100 steel | Ceramic balls for reduced friction

- Lifespan: 80,000+ hours under ISO 281 testing protocols

Industry-Specific Solutions

1. Wind Energy: Surviving Harsh Environments

Designed for turbine yaw/pitch systems, our bearings withstand salt spray, -40°C Arctic cold, and sudden load shifts. Key features:

-

Corrosion-resistant coatings (1,000+ hours salt spray tested)

-

IoT-ready sensors for predictive maintenance, reducing downtime by 30%

-

DNV GL & IEC 61400 certifications for offshore compliance

2. Robotics: Precision in Motion

Meet surgical and semiconductor automation demands with:

-

≤2μm radial runout for error-free robotic joints

-

FDA-approved greases or dry-film lubrication for cleanrooms

-

25,000 RPM capability with hybrid ceramic balls

3. Metallurgy: Enduring Extreme Heat

Optimized for rolling mills and blast furnaces:

- 500°C heat-treated raceways to resist deformation

- Triple-cage reinforcement for impact loads up to 3,000 kN

Customization Made Simple

Need a Single-Direction Angular Contact Thrust Ball Bearing with a non-standard size or specialized performance? Our workflow ensures precision:

1. Requirement Analysis: Share your load, speed, and environmental data.

2. 3D Simulation: We optimize stress distribution digitally.

3. Prototyping & Testing: Validate with accelerated lifespan trials.

4. Batch Production: Modular assembly cuts lead times by 30%.

Example: A European wind OEM needed φ1200mm bearings with embedded temperature sensors. Delivered in 18 days.

Quality You Can Trust

- 100% Material Traceability: MTC-certified steel batches.

- 3-Stage Inspections:

- Dimensional accuracy (±2μm)

- Hardness (60–64 HRC)

- Vibration analysis (Z1–Z4 grades)

- 10,000-Hour Validation: Simulated 20-year operational stress in 12 weeks.

Fast Global Delivery

- 48-Hour Shipping: 1,000+ standard models in stock.

- Regional Warehouses: EU/US/ASEAN hubs enable 72-hour regional delivery.

- Custom Orders: 15–20 days even for φ3000mm sizes.

Beyond the Product: Lifelong Support

- Free Mounting Guidance: Get FEA-based fit optimization reports.

- 24/7 Emergency Replacements: Critical failure? Parts arrive in 72 hours.

- IoT Integration: Monitor bearing health via our cloud platform.

Why Choose Us?

✅ 30+ Years Expertise: Trusted by 50+ metallurgical giants.

✅ 30% Faster Customization: Modular designs reduce wait times.

✅ 99.9% On-Time Delivery: Since 2020.

FAQs

1. How do your bearings handle 500°C environments?

Our metallurgical-grade bearings use SAE 52100 steel with specialized heat treatment, retaining hardness above 500°C.

2. Can you make bearings for corrosive settings?

Yes! We offer stainless steel races or ceramic balls paired with sealed lubrication.

3. What certifications do you hold?

ISO 9001, ABEC 7, IEC 61400, and REACH compliance.

4. How fast can you deliver to remote wind farms?

Through regional hubs, we guarantee 72-hour delivery to most global sites.

Contact Us

Need a Single-Direction Angular Contact Thrust Ball Bearing That Matches Your Exact Needs?

Email our engineers at sales@inno-bearing.com for a free technical consultation.

Learn about our latest products and discounts through SMS or email