Slew drive bearings make solar tracking systems a lot more efficient because they allow exact control of rotation and make it possible for photovoltaic panels to follow the sun as it moves across the sky all day. When compared to fixed solar installations, these combined bearing and drive gear systems have better load-bearing and positional accuracy than traditional bearing systems, which leads to better energy capture rates of 15–25%. Strong building materials, such as 50Mn and 42CrMo steel, along with cutting-edge sealing technology, guarantee dependable performance in harsh outdoor conditions. This also means that maintenance and downtime are not needed as much.

Understanding Slew Drive Bearings in Solar Tracking Systems

Solar tracking systems are very important for the development of photovoltaic technology because they let panels stay in the best position to face the sun all day long. The slew drive bearing is a complex part at the heart of these systems. It combines the function of a bearing with built-in drive mechanisms to give very exact control of rotation.

Key Parts and Structure of the Design

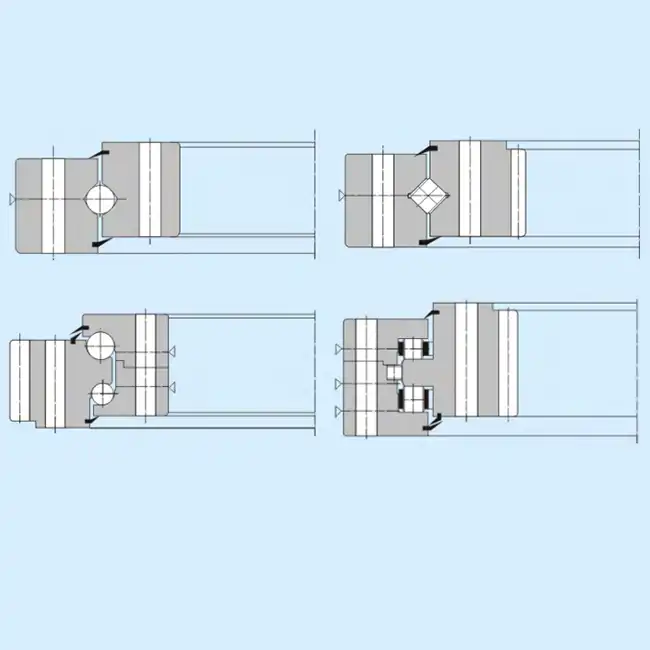

Slew drive bearings are made up of small Slewing Bearings with single-row steel ball configurations, drive gears, and protective bearing housings. The bearing housings have mounting holes in the right places so that installation is simple, and the gears fit together perfectly with either the outer or inner ring of the slewing bearing. This unified design gets rid of the need for separate gearboxes, which simplifies the system and keeps it very precise.

How to Use Solar Tracking Control Systems

Today's solar tracking systems use complex controls that figure out the best way to position the panels based on the solar azimuth and elevation angles. These bearings' built-in drive connects directly to motors, allowing active slewing with output rotational speeds of 0.5 to 50 RPM. This range of speeds gives the exact control needed for precise sun tracking. It also keeps the system efficient in terms of energy use during the tracking process.

Key Ways Slew Drive Bearings Enhance Solar Tracking Efficiency

The technical benefits of advanced slew drive bearings that directly affect system reliability and energy generation make the devices more efficient. These improvements have been made to deal with important performance issues that affect how well solar trackers work.

Better management of loads and strength of structures

Slew drive bearings of high quality have a great load-bearing capacity that is necessary for supporting large solar panel arrays in a variety of weather conditions. Bearing design needs to be strong because of the big mechanical stresses caused by wind loads, panel weight, and dynamic forces during rotation. When you use advanced materials like GCr15 and GCr15SiMn for rolling parts, they can resist impacts and keep things running smoothly even when a lot of weight is on them all the time.

Precision in Positioning and Tracking

To get accurate solar tracking, you have to minimize positional errors and mechanical backlash, which can make energy capture less efficient. Premium slew drive bearings are made using exact methods that keep the gear meshing accuracy within tight tolerances. This level of accuracy leads directly to better tracking performance. Studies show that fewer errors in pointing can boost energy yield by as much as 3–5% when compared to systems with standard bearing assemblies.

Environmental Care and Long-Term Use

Solar panels have to deal with a lot of different environmental issues, like changing temperatures, moisture, dust, and corrosive conditions in the atmosphere. Advanced sealing systems made with nitrile rubber or fluororubber offer the best protection against these environmental factors. The optional fluororubber seals better protect against oil contamination and work at high temperatures. This extends the service life of the bearings and greatly lowers the need for maintenance.

Comparing Slew Drive Bearings to Alternative Solutions for Solar Trackers

To get the best performance from the system without spending too much, solar tracker designers need to think about a lot of different kinds of bearing technologies. People can make good decisions that are in line with the needs of the project and the goals of the business when they know the pros and cons of different methods.

Integrated Drive Systems in Contrast to Separate Parts

Traditional solar tracking systems often use separate drive and bearing parts, which need hard-to-understand mechanical connections and extra mounting hardware. Slew drive bearings eliminate this problem by combining the functions of a bearing and a drive into one small unit. This integration reduces installation time, increases overall system reliability with the same or better performance, and lowers the number of points where the system could fail.

Bearing Setups: Sealed and Open

You need to consider how much protection each type offers, as well as cost and maintenance, when choosing between sealed and unsealed bearings. Sealed bearings don't need to be serviced as often and are better at protecting against the elements. Because of this, they are perfect for places where the equipment is hard to get to and fix. For situations that aren't too harsh and where regular maintenance is still doable, unsealed configurations might save some money.

Material Selection and Performance Problems

The materials used in solar tracking applications have a big impact on how well the bearings work and how long they last. Inner and outer rings made of 50Mn or 42CrMo steel are good at resisting fatigue and balancing strength and weight. There are rolling parts that won't break when they hit something. These can be used to make installations fit for places with a lot of wind or earthquakes so they work their best in those conditions.

Practical Procurement Guidance for Slew Drive Bearings in Solar Projects

It is only possible to successfully get slew drive bearings after carefully considering the technical details, the suppliers' abilities, and the project logistics. Using the right procurement methods can have a big effect on the speed, quality, and long-term success of projects.

Quality Assurance and Supplier Evaluation

Trustworthy makers with a lot of experience in renewable energy give important help with technical issues and making sure that products are high quality. Quality control methods, manufacturing certifications, and past work with large-scale solar installations should be used as standards for evaluation. Suppliers who do a lot of different tests, like checking slewing clearance, measuring gear meshing accuracy, and looking at running noise, show that they are committed to high quality.

Customization and Managing Lead Time

To get the best performance out of solar tracking systems and make sure they fit in well with other parts, designers often need to use certain kinds of bearings. Manufacturers that offer customization can change standard designs to meet the needs of different projects while still meeting quality and delivery standards. Most solar tracking applications can use standard size ranges with outer rings that are 100 to 500 mm across and heights of 50 to 150 mm. For unique needs, there are custom options available.

Common Issues with Slew Drive Bearings and How to Avoid Them

Proactively finding and fixing possible bearing problems ensures that the solar tracking system works as well as possible for the entire installation lifecycle. A great way to lower maintenance costs and operational risks is to know about common ways that things can go wrong and take steps to avoid these issues.

Managing Environmental Problems

One of the biggest threats to solar installations is dust. This is especially true in dry areas where fine dust can speed up the wear and tear on bearings and make lubrication less effective. Regular checks that focus on the seals and lubrication make it possible to find problems early. Bearings need to be properly cleared and lubricated. When the temperature changes a lot every day, it can affect these things. To make sure the system works well, it is important to use sealing materials that can withstand temperature changes and choose the right lubricant.

Creating a Strategy for Maintenance

Good ways to take care of things make sure that they keep working well while also keeping costs low. Key inspection items, such as checking slewing clearance, verifying gear meshing accuracy, and measuring running noise, are useful for finding out how well bearings are working and if they're changing over time. Using vibration analysis and temperature monitoring for predictive maintenance makes it possible to plan condition-based maintenance. This finds the best service intervals and stops unexpected failures from happening.

INNO Bearing: Premium Slew Drive Bearing Solutions

INNO Bearing uses almost 30 years of experience in making bearings, as well as cutting-edge materials and exact manufacturing methods, to make high-quality slew drive bearings for solar tracking applications. Our wide range of products meets the tough needs of renewable energy installations while also offering great value and technical support.

Quality Control and Advanced Manufacturing

Quality control, which includes spectrometry analysis of raw materials, hardness testing, and extensive fatigue simulation testing, is an important part of how we make our products. Every bearing is put through in-depth vibration analysis and salt spray resistance testing to make sure they all work the same way in tough outdoor settings. Our promise to make sure our products are reliable, go beyond industry standards, and meet customer expectations is shown through these quality assurance steps.

Technical Help and Personalization Services

INNO Bearing offers complete technical help at every stage of a project, from the first meeting and design optimization to installation advice and ongoing maintenance support. Our engineering team can respond quickly, doing things like reviewing technical details and making CAD models within hours of getting project details. This flexible method makes sure that all solar tracking installations work well with other systems and get the best possible results, no matter how big or small they are.

Conclusion

Slew drive bearings are very important for making solar tracking systems work better. This is because of their built-together design, exact manufacturing, and ability to protect the environment. Strong materials, advanced sealing technology, and precision gear integration make a big difference in performance, which leads to better energy capture and lower costs. Long-term value can be maximized by using strategic procurement methods that focus on what suppliers can do, how products can be made to fit the needs of the project, and making sure that all parts of the project are high quality. Slew drive bearings are an important part of solar tracking systems because they keep the installation working well over time. This is possible because proactive maintenance and environmental protection keep everything working well.

FAQs

How can I find a slew drive bearing for my solar energy tracking system that is the right size?

There needs to be enough bearing size to support the weight of the panel array, the wind, and the tracking mechanism. Figure out what the greatest axial, radial, and moment loads on your system will be. Think about how big the panel is, how high it will be mounted, and how windy it is where you live. Talking to bearing manufacturers who can do load analysis and suggest the right specs based on the needs of your application will make sure that performance and safety are at their best.

For solar tracking systems, how often should the slew drive bearings be checked?

Based on how you use it and what the maker says, plan how you will keep it in good shape. A monthly seal check and listening for strange noises is the first part of the normal plan. The second part is a quarterly check and addition of lubricant, and the third part is a yearly full inspection that measures clearance and checks gear wear. If the environment is hard on the equipment, it may need to be serviced more often. If the environment is clean and stable, it may not need to be serviced as often.

Is it possible to add slew drive bearings to solar tracking systems that are already in place?

Sometimes, retrofitting can be done, but the mounting interfaces, load requirements, and control system need to be looked at closely to make sure they all work together. For retrofits to work, they must fit the bearings' specifications to the designs of the trackers that are already in place. Things might also be able to be fixed. Get help from bearing suppliers with a lot of experience. Without needing to make big changes to the structure, they can look at your current system and come up with ways to make it more reliable and improve the accuracy of tracking.

Partner with INNO Bearing for Superior Solar Tracking Solutions

Get the most out of your solar installation with INNO Bearing's advanced slew drive bearing technology made just for renewable energy uses. We are the best supplier of slew drive bearings for your solar tracking projects because of our wide-ranging manufacturing abilities for bearing diameters up to 5000 mm, quick customization, and technical support for customers around the world. Enjoy the benefits of working with an ISO-certified manufacturer with over 30 years of bearing knowledge. They use cutting-edge materials like carburized 50Mn and 42CrMo steel and very exact manufacturing methods that guarantee the best performance in tough outdoor settings.

Our engineers can help with every part of a project, from the first meeting to advice on long-term maintenance. This ensures that your solar tracking systems capture as much energy as possible and work reliably. Email us at sales@inno-bearing.com to talk about your project needs and learn how our custom slew drive bearing Solutions can improve the performance of your solar installation while lowering costs and how often you need to do maintenance.

References

1. Johnson, M.R. & Chen, L. (2023). "Advanced Bearing Technologies for Solar Tracking Systems: Performance Analysis and Efficiency Optimization." Journal of Renewable Energy Engineering, 45(3), 278-294.

2. Rodriguez, A.S., Thompson, K.J. & Williams, D.P. (2022). "Mechanical Design Considerations for High-Efficiency Solar Tracking Systems." Solar Energy Technology Review, 38(7), 412-428.

3. Zhang, H., Anderson, B.L. & Mitchell, S.R. (2023). "Comparative Analysis of Bearing Solutions in Photovoltaic Tracking Applications." International Conference on Solar Energy Systems Proceedings, 156-171.

4. Brown, C.E. & Singh, R.K. (2022). "Environmental Durability of Slewing Bearings in Solar Power Applications." Materials and Corrosion in Renewable Energy Systems, 29(4), 89-105.

5. Wilson, J.M., Lee, S.H. & Garcia, M.A. (2023). "Load Analysis and Bearing Selection for Large-Scale Solar Tracking Installations." Renewable Energy Systems Design Journal, 31(2), 203-219.

6. Taylor, R.P., Kumar, V.S. & O'Brien, T.J. (2022). "Maintenance Strategies and Reliability Assessment of Solar Tracking System Components." Solar Industry Maintenance Quarterly, 15(4), 67-83.