By using a new design with two pathways, double thrust ball bearings are great at handling axial forces going in both directions because they spread the weight across two sets of steel balls. This thrust ball bearing design lets machines deal with axial forces from both sides at the same time. This makes them necessary for tasks that need exact control of the rotation when the load changes. The symmetrical structure spreads the force evenly, which lowers areas of high stress and increases the operational lifetime in difficult industrial settings.

Understanding Double Thrust Ball Bearings and Their Design

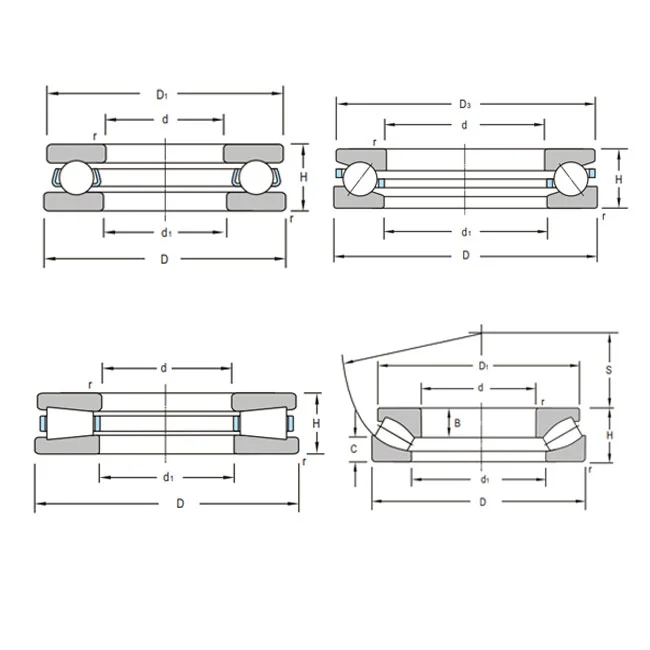

Double Thrust ball bearings are a new and advanced way to manage axial loads. This exact part has a middle washer between two shaft washers. This makes two "raceways" that let steel balls move in both directions. Unlike designs that only have a shaft washer and a housing washer, the bidirectional design has double-row steel balls that are separated by cages that have been carefully designed.

Key Parts of the Structure

The basic architecture is based on three main elements that work together. The middle washer is the main part, and it's made of high-quality GCr15, GCr15SIMN, or 20Cr2Ni4A steel so it can handle being loaded over and over. Dual shaft washers that are made like this provide the same hardness and wear resistance. Rolling elements use steel balls made of GCr15 or GCr15SIMN that are ground with great care. Cages made of stamped steel or brass keep the balls from touching each other and getting damaged.

How Load Distribution Works

The bearing can transfer axial forces through two separate load paths, which gives it bidirectional capability. When a machine pushes or pulls something, the raceway that matches that direction turns on to spread the force over several points of contact. This design rule keeps smooth rotation while lowering the stress on each ball. The symmetrical geometry guarantees the same ability to carry a load no matter the direction of the thrust, which gives steady performance over the whole range of operational cycles.

Types and Variations of Thrust Ball Bearings for Bi-Directional Loads

A wide range of thrust bearing options that are suited to different needs must be used in today's factories. Buyers can choose the best parts that balance performance, longevity, and cost-effectiveness if they know about all the different kinds that are out there.

Standard and High-Precision Setups

Standard thrust ball bearings work within P0 and P6 tolerance grades, which are good for general industrial uses that don't need to be very precise. The high-precision versions get P5 grade accuracy, which makes them smoother when rotating and less shaky. These exact models are used in very important ways in precision pumps, machine tool spindles, and other delicate devices where the exact size of each part affects how well the machine works.

The effect of choosing materials

The performance of bearings in a range of working environments is greatly affected by the steel used in them. GCr15 steel is very durable under normal industrial conditions, but GCr15SIMN is even tougher and better for situations where shock loading happens. The high-quality 20Cr2Ni4A steel has much better resistance to corrosion and temperature changes. This makes it perfect for the tough conditions of marine and metallurgical uses.

Choices for Lubrication and Sealing

Open designs make it easier to re-lubricate and inspect, but they need to be protected from the environment. Sealed configurations include protective shields that keep dirt out and lower the need for maintenance. The severity of the operational environment, how easy it is to get to maintenance, and how often service is needed all affect the choice between these options.

Advantages of Double Thrust Ball Bearings in Industrial Applications

Double thrust ball bearings provide outstanding performance benefits that make the operation more efficient and save money. Their uniquely designed features solve a number of engineering problems at once, making them a useful choice in a range of industries.

Better at Moving Heavy Things

The dual-raceway design lets these bearings handle heavy axial loads while keeping the right control of rotation. For very tough uses, like rolling mill gearboxes, conveyors for smelting furnaces, and heavy press machines, load capacities up to 200 kN are needed. This strong performance keeps the system from failing too early and cuts down on the need for maintenance that wasn't planned.

Benefits of Operational Efficiency

It takes less energy to use ball bearings because they have a low friction coefficient that lets them move easily. The smooth rolling action lowers the amount of heat that is made, which keeps the lubricant working longer and lowers the need for cooling. Noise levels below 35 dB allow installation in places where noise is a concern without lowering the level of performance.

Benefits of Maintenance

The easy-to-use design makes it easier to do routine inspections and lubrication. Clear signs of wear on the surface make it possible to use predictive maintenance plans that stop failures before they happen. Standardizing parts across different sizes makes it easier to manage inventory and buy things.

Procurement Guide: Selecting and Buying Double Thrust Ball Bearings

When buying ball Thrust bearings, you need to think about the operational needs, the suppliers' abilities, and the total cost of ownership. This all-inclusive method picks the best parts while staying within budget and meeting delivery times.

Judging the Technical Parts

Load analysis is the first step in properly choosing bearings. The load ratings that are needed are based on the changing sizes and directions of the dynamic cycling patterns. Ball cages are made in different ways and need to be lubricated differently depending on the range of operating speeds. In very hot or cold weather, it's important to use the right materials and ways of sealing. Pollution, moisture, and how well the chemicals work with each other are some of the environmental factors that affect the protective feature needs.

In the Size Range, Things to Keep in Mind

Thrust ball bearings are usually between 10 mm and 300 mm wide on the inside, 30 mm and 400 mm wide on the outside, and 8 mm and 50 mm tall. For special uses, the outer diameter may need to be as large as φ5000 mm. This needs special skills in manufacturing and more time to get started.

Test Suppliers Against These Standards

The best suppliers stand out from the others because they have quality certifications, can make a lot of products, and can be counted on to deliver on time. Technical support, customization, and global logistics networks can help projects succeed. Cost competitiveness has to do with the short-term and long-term costs of a product. The benefits of a longer service life and less need for maintenance are the long-term costs.

Maintenance Best Practices for Optimal Performance

Proactive maintenance methods extend the life of bearings and keep operations running smoothly. Setting up regular inspections, correct lubrication, and early warning systems keeps equipment available and prevents expensive breakdowns.

Rules for Checking and Keeping an Eye on

Regularly checking the key performance indicators helps you find problems before they get worse. Steel ball clearances show how much wear there is, and raceway surface tests show whether there is dirt or too little lubrication. Vibration monitoring finds imbalances that are developing, and temperature tracking shows when lubrication breaks down or loading conditions are too high.

Managing Lubrication

Choosing the right lubricant and knowing how often to apply it have a big effect on how long bearings last. Special greases that keep their thickness even when hot are needed for applications with high temperatures. Lubrication cycles that flush debris from rolling contact surfaces often help dirty places. Automated lubrication systems make sure that the lubricant is applied evenly and they don't have to be manually adjusted by a person very often.

Methods for protecting the environment

In tough conditions, standard bearing design features aren't enough. Extra protective measures have to be used. Better sealing technologies stop things that might hurt the product from getting inside, and better materials make corrosive substances less effective. If you install something correctly, it will work well even when the conditions are tough.

Conclusion

The advanced dual-raceway design of double thrust ball bearings gives important two-way load support to difficult industrial applications. A deep knowledge of performance characteristics, material specifications, and structural parts lets you make smart purchasing choices that maximize the dependability of your equipment. Proper selection criteria including load requirements, environmental conditions, and precision needs make sure that it can be used in a wide range of industries. Good maintenance extends the useful life of equipment, keeps it operational, and provides a better total cost of ownership than other options.

FAQs

What are the most important things that affect the weight that a double thrust ball bearing can hold?

The bearing's weight limit relies on its size, quality, and ball count, along with the design's overall craftsmanship. Raceways and rolling parts made of higher-quality steel will be able to hold more weight at their maximum load rating. At the same time, careful manufacturing makes sure that the weight is spread out evenly at all points where it touches.

Can you use double thrust ball bearings in areas that get really hot?

Yes, ceramic hybrid balls and other materials that can handle temperatures above 150°C are used in some special cases. Using better ways to seal and the right lubricant makes sure that metallurgical applications can be used in very hot or very cold weather.

How do you take care of double thrust ball bearings that are sealed and those that aren't?

Sealed bearings might not be as fast, but they don't need to be cleaned as often and keep dirt out. If designs that aren't sealed get dirt and dust in them, it's fine; you can just add more lubricant and look inside. But, they need more care to keep working well.

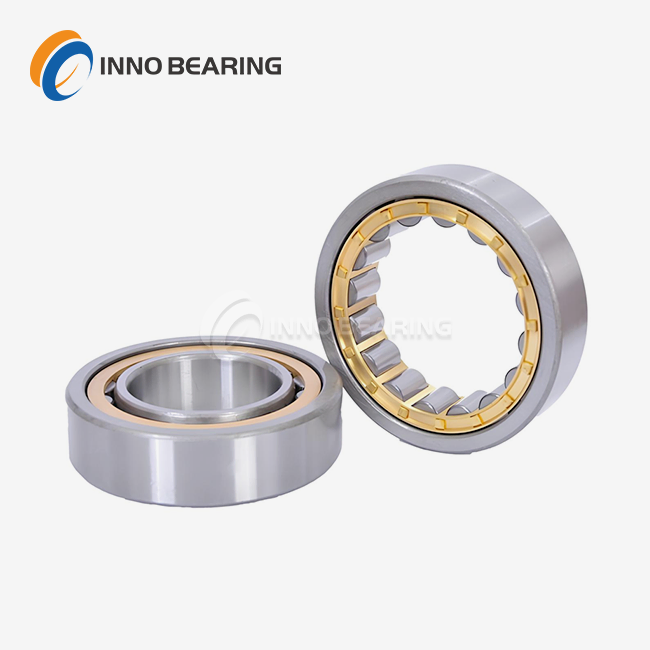

Partner with INNO Bearing for Superior Thrust Ball Bearing Solutions

For tough applications with bi-directional loads, INNO Bearing provides the best thrust ball bearings on the market. Having worked in the field for almost three decades, we are able to make custom bearings with a diameter of up to φ5000mm and a load capacity 25% higher than the norm. We have more than 1,000 standard models on hand for immediate delivery, and our custom Solutions go into production 30% faster than those of our competitors. Through very careful manufacturing methods and tough tests, our broad quality assurance program makes sure that 99.9% of products have no mistakes. If you want to talk about your exact needs with our technical team, please email us at sales@inno-bearing.com. As a trusted thrust ball bearing manufacturer, we offer full engineering support from the first meeting to installation help. This is backed by our technical hotline available 24/7 and predictive maintenance capabilities.

References

Harris, T.A. & Kotzalas, M.N. (2019). Essential Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, Taylor & Francis Group.

Hamrock, B.J., Schmid, S.R., & Jacobson, B.O. (2018). Fundamentals of Fluid Film Lubrication in Thrust Bearings. McGraw-Hill Education.

Tallian, T.E. (2020). Failure Atlas for Hertz Contact Machine Elements: Thrust Ball Bearing Applications. ASME Press.

Eschmann, P., Hasbargen, L., & Weigand, K. (2017). Ball and Roller Bearings: Theory, Design and Application in Industrial Machinery. John Wiley & Sons.

Jones, A.B. (2018). A General Theory for Elastically Constrained Ball and Radial Roller Bearings Under Arbitrary Load and Speed Conditions. Journal of Basic Engineering Transactions.

Palmgren, A. (2021). Ball and Roller Bearing Engineering: Principles and Applications in Heavy Industrial Equipment. SKF Engineering & Research Centre Publications.