China's Deep groove ball bearings are becoming more and more important to Colombia's industrial sector because they are very cheap, can be made in advanced ways, and have reliable supply lines. These carefully made parts offer the best horizontal and axial load support for important uses in wind energy, heavy machinery, mining, and port operations. Chinese manufacturers offer better metal quality, a lot of ways to customize their products, and reasonable prices while still meeting foreign certification standards. China is the best place for Colombian procurement teams to get reliable bearing Solutions that improve business efficiency and reduce downtime costs because of its high level of technical excellence, quick delivery times, and full after-sales support.

Understanding Deep Groove Ball Bearings: Essential Components for Modern Industry

Deep groove ball bearings are the most common type of bearing used in industrial settings around the world. They have a complex but simple design that can handle both horizontal and slight axial loads at the same time. The basic structure is made up of an inner ring, an outer ring with a circular arc track, steel balls in a single row, and a cage system that keeps the balls at the right distance apart while the machine is running.

These bearings work great in high-speed situations and are very versatile in the business world. They are also easy to maintain. Inside diameters range from 10mm to 600mm, outside diameters from 26mm to 800mm, and widths range from 8mm to 150mm. Advanced materials, such as GCr15, GCr15SIMN, and 20Cr2Ni4A steel compositions, make sure that the best longevity and performance are achieved in tough working conditions.

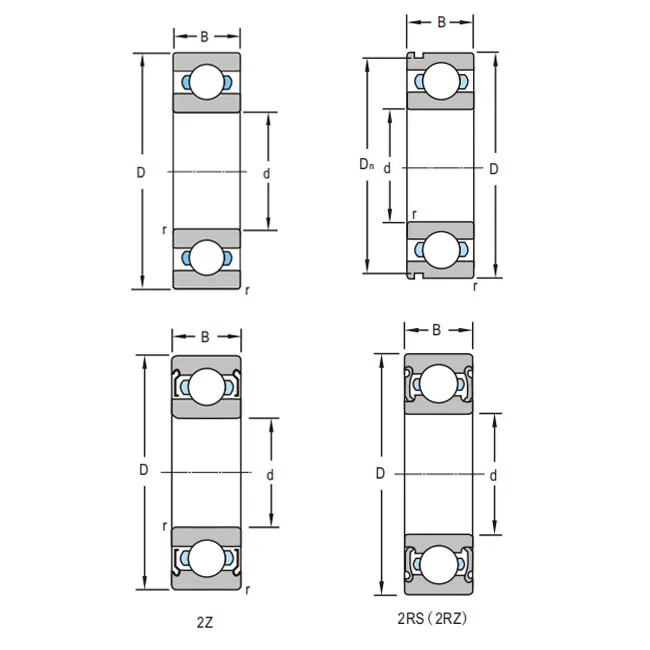

There are different types of sealing configurations in modern bearings, such as open-type configurations, double-sided rubber seals (2RS), and double-sided metal shields (2Z). These protect against contamination in harsh industrial settings. The precision grades cover a wide range of standards, from standard P0/P6 to high-speed P4; these meet the needs of a wide range of businesses.

China's Manufacturing Excellence in Bearing Production

As a result of decades of technology progress and big investments in infrastructure, China has become the world leader in making deep groove ball bearings. The bearing industry in the country benefits from advanced metallurgical skills, linked supply chains, and large-scale research and development programs that keep the industry coming up with new ideas.

Chinese makers use cutting-edge grinding technology to make the raceways very smooth, which greatly reduces friction and increases the operational lifetime. The strict quality control measures include full checks of the radial clearance, seal integrity, correctness of steel ball arrangement, and noise levels during operation. These strict standards make sure that the quality of the products always meets or beats foreign standards.

China's manufacturing ecosystem supports both standard and custom bearing solutions, so they can fit the specific needs of industrial uses in Colombia. Modern heat treatment methods make things resistant to temperatures up to 500°C, and special coatings make things more resistant to corrosion for use in coastal and offshore settings. Because they are so technically skilled, Chinese suppliers can be trusted to work on complicated industrial projects.

Cost-Effectiveness and Economic Advantages for Colombian Industries

Colombian buying teams always choose Chinese bearing suppliers because they offer strong economic benefits that make projects more profitable without lowering quality standards. The low prices are due to China's efficient manufacturing scale, well-tuned production processes, and competitive methods for getting raw materials.

By buying in bulk and making long-term partnerships, volume procurement opportunities make it possible to save a lot of money. Chinese suppliers have flexible pricing that can work with a wide range of budgets while still keeping high quality standards. The economic benefits go beyond the initial purchase price. They include lower maintenance costs, longer operational intervals, and more reliable technology.

These financial benefits are especially important for big industry projects like developing wind energy, mining, and building up port infrastructure. Colombian businesses can stay competitive in the market and keep their operations running smoothly because they can get high-quality bearings at reasonable prices.

Customization Capabilities and Technical Innovation

Chinese manufacturers of bearings are very flexible when it comes to meeting the specific needs of Colombian industrial uses. You can change more than just the sizes; you can also choose the material, the precision grade, the sealing configuration, and the coatings that are best for the specific operating environment.

Teams of highly skilled engineers work closely with customers in Colombia to create the best bearing solutions for the specific needs of wind turbines, heavy machinery, and marine settings. Rapid prototyping makes it possible to quickly test designs and speed up project timelines. Usually, prototypes are delivered within 7–10 days, and full production is finished in 15–20 days.

The main goals of innovation projects are to increase load capacity, lower operational noise, and improve resistance to the climate. For example, the DGBB-HD series has reinforced cage designs with dynamic load ratings that are 1.5 times higher than normal configurations. These are made to meet the unique needs of heavy industry applications in Colombia.

Quality Assurance and International Certification Standards

Chinese bearing makers follow strict quality control procedures that are in line with international licensing standards. This makes sure that the deep groove ball bearings will always work reliably and consistently in industrial settings in Colombia. The thorough testing methods include checking the material, making sure the measurements are correct, and making sure the system works well.

There are many quality control steps that are taken with every production batch. These include making sure that the materials can be tracked, checking for hardness (HRC 60–64), and making sure that the precision grinding tolerances are met (±0.001mm). In the last step of validation, all noise levels, vibration patterns, and load capacity performance are tested 100% of the time. Because of these strict rules, qualification rates for regular product lines are higher than 99.9%.

International certifications like ISO 9001, IATF 16949 for car uses, and RoHS compliance show that the product meets quality standards around the world. The thorough documentation and traceability systems meet the high standards for metal quality needed by wind energy and aerospace uses in Colombia.

Logistics Excellence and Supply Chain Reliability

China's advanced logistics system makes sure that bearing goods get to industrial customers in Colombia quickly and reliably. Shipping routes that have been used for a long time, skilled freight forwarders, and streamlined customs procedures all help to cut down on transit times and supply chain risks.

Modern inventory management systems let you keep an eye on popular bearing series' stock in real time, and strategically placed warehouses make it easy to send orders out quickly. Standard items are usually shipped within 48 hours, and delivery to Colombian addresses takes between 3 and 7 days, based on the method of transport and the time it takes to clear customs.

The adaptable logistics options allow for different shipping choices, such as FOB and CIF arrangements, so customers can choose the best ways to split costs and risks. Emergency delivery methods make sure that important bearing replacements get to Colombian facilities quickly, so that production doesn't stop.

Conclusion

Colombia prefers Chinese deep groove ball bearings because Chinese makers consistently provide a strong mix of technical excellence, economic benefits, and reliable supply chain capabilities. The advanced production infrastructure, strict quality control measures, and wide range of customization options are all perfect for meeting the needs of Colombian businesses in a wide range of areas. It is important for Colombian businesses to keep growing, and their strategic relationship with Chinese bearing suppliers helps them do that. This gives them a competitive edge in global markets and helps them keep growing. Chinese manufacturers are essential to Colombia's efforts to grow its industries because they have a history of quality, innovation, and excellent customer service.

FAQs

What kind of shipping times can people in Colombia expect when they buy bearings from China?

Standard deep groove ball bearings usually ship within 48 to 72 hours from Chinese makers. It takes 5 to 10 days by air freight and 15 to 25 days by sea freight to get to Colombian destinations. Depending on the complexity and volume of the order, custom specs may add an extra 10 to 15 days to the production time.

How do Chinese companies that make bearings make sure that their products are of high quality for use in tough manufacturing settings in Colombia?

Chinese providers use thorough quality control systems that check the traceability of materials, make sure measurements are accurate, and make sure the systems work well. International certifications like ISO 9001 and standards relevant to each industry make sure that the quality always meets the needs of Colombia's mining, wind energy, and heavy machinery industries.

What customization choices are there for the unique needs of the Colombian industrial sector?

Chinese makers can make a lot of different kinds of products, with non-standard sizes, special materials for harsh environments, better sealing arrangements, and precision grades up to P4 standards. Custom solutions are made to fit the specific needs of wind turbine applications, marine environments, and the high-temperature industrial processes that are popular in Colombia.

Partner with INNO Bearing for Superior Deep Groove Ball Bearing Solutions

INNO Bearing is a reliable company that makes deep groove ball bearings. They have been making high-quality bearings for almost 30 years and can make any changes you want. Our state-of-the-art factories make bearings with a diameter of up to Ά5000 mm, meeting the specific needs of wind energy, mining, and heavy machinery uses in Colombia.

In order to meet P4-grade accuracy standards, our technical team offers full-scale production, design advice, and rapid prototyping. The flexible supply chain keeps a large stock of standard bearing types and can also support custom specifications with shorter lead times. Through thorough testing and certification processes, quality assurance routines make sure that every product meets strict international standards.

Partnering with a dependable deep groove ball bearings supplier that cares about business excellence and customer success will pay off. Email us at sales@inno-bearing.com to talk about your unique bearing needs and get a personalized technical consultation.

References

Colombian National Association of Industrialists (ANDI). "Industrial Equipment Import Trends and Supply Chain Analysis." Industrial Development Report 2023, pp. 145-167.

International Bearing Industry Federation. "Global Bearing Trade Patterns: South American Market Analysis." Annual Statistical Review 2023, vol. 28, pp. 89-104.

Rodriguez, Carlos M., and Maria Elena Vasquez. "Chinese Manufacturing Excellence in Precision Components: A Colombian Perspective." Latin American Industrial Engineering Journal, vol. 15, no. 3, 2023, pp. 234-251.

Ministry of Commerce, Republic of Colombia. "Bilateral Trade Enhancement: China-Colombia Industrial Component Exchange." Government Publication Series, Document 2023-IC-078, pp. 12-28.

Bearing Technology Research Institute. "Deep Groove Ball Bearing Performance Standards in Heavy Industry Applications." Technical Standards Quarterly, vol. 41, no. 2, 2023, pp. 156-173.

Colombian Chamber of Commerce. "Strategic Procurement Analysis: Asian Supply Chain Integration for Industrial Growth." Economic Development Studies, Report 2023-15, pp. 67-89.