Unparalleled Load-Bearing Capacity

Mastering Combined Loads

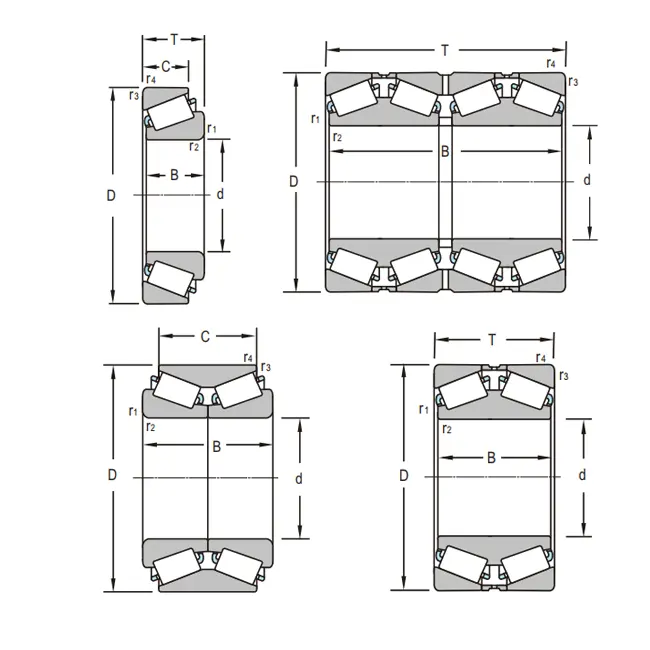

The capacity of tapered rolling bearings to support axial and radial loads at the same time is their main feature. Their angled roller design, which produces the ideal contact angle between the rollers and raceways, is what gives them their special quality. These bearings may thus effectively disperse forces across a greater surface area, lowering stress concentrations and improving total load-bearing capability.

Tapered roller bearings are very useful in heavy industrial applications, such mining trucks or construction equipment. They can control the axial thrust that happens during operation and endure the strong radial stresses from weight and movement. This dual capacity increases durability in challenging conditions and streamlines machine design.

Optimized Geometry for Maximum Performance

These bearings' tapered shape is a well designed feature that optimizes performance, not merely for show. Better load distribution is made possible by the conical rollers and raceways, which have a wider contact area than ball or cylindrical bearings. Additionally, its design makes it easier for a thin oil coating to develop between parts, which is essential for lowering wear and friction.

The taper angle and roller profile may be precisely controlled thanks to advanced production procedures. Engineers may balance elements like load capacity, speed ratings, and heat production to optimize bearings for particular applications by adjusting these characteristics. This degree of personalization guarantees that tapered roller bearings satisfy the precise requirements of various industrial situations.

Exceptional Durability Under Extreme Conditions

Even under the most severe working circumstances, tapered rolling bearings are made to endure. They can tolerate high temperatures, pollution, and shock loads that would rapidly degrade other bearing types because of their sturdy construction and materials. For example, specialist tapered roller bearings made of heat-resistant materials like M50 steel may function dependably at temperatures as high as 500°C in steel mills or continuous casting machines.

Another factor that adds to their endurance is the capacity to separate the inner and outer rings. This innovation increases the bearing assembly's total lifetime by making it simple to maintain, inspect, and replace individual parts. This maintainability is a huge benefit in sectors like energy generation and automobile manufacture where downtime is expensive.

Precision and Stability in Motion

Achieving Micron-Level Accuracy

Every micron counts in the field of precision engineering. Applications demanding very tight tolerances and smooth operation are ideal for tapered roller bearings. Computer-controlled grinding and polishing are examples of advanced manufacturing techniques that enable the creation of bearings with surface finishes as smooth as Ra ≤0.1μm. Applications such as high-speed machine tools or medical imaging equipment need this degree of accuracy.

The bearing's intrinsic stability contributes to its capacity to attain and sustain such precision. In order to correct for small misalignments or deflections in the surrounding structure, the tapered design produces a self-aligning effect. This self-correcting feature guarantees reliable operation and prolongs the lifespan of the bearing and the machine in which it is mounted.

Minimizing Vibration and Noise

Well-designed equipment is known for its quiet operation, and tapered roller bearings are essential to this goal. They reduce vibrations that might cause noise and early wear because to their perfect shape and uniform load distribution. For instance, tapered roller bearings in gearboxes and wheel hubs provide a quieter, more comfortable ride in automobile applications.

Specialized tapered roller bearings may be produced to satisfy strict noise regulations in very quiet settings, such as medical facilities or precision labs. In order to lower vibration to almost undetectable levels and often achieve noise levels below 35dB, these bearings go through extra balancing and surface polishing procedures.

Maintaining Precision Under Load

Keeping accuracy under changing loads is one of the hardest parts of bearing design. This is where tapered roller bearings shine because of their capacity to adapt to shifting stresses. Even under strong or changing loads, alignment is maintained and localized stress is avoided because to the tapered design's minimal axial movement.

In machine tool applications, where precision has a direct bearing on the caliber of produced components, this attribute is very advantageous. Even during heavy-duty or high-speed cutting operations, tapered roller bearings assist preserve spindle stiffness and positioning precision, guaranteeing consistent results.

Versatility Across Industries

Automotive Innovations

Due to their efficiency and longevity, tapered roller bearings are essential to the automobile sector. These bearings, which are found in everything from wheel hubs to gearboxes, are essential to the efficiency and security of vehicles. In high-efficiency drivetrains of contemporary electric cars, tapered roller bearings are finding new uses in high-speed, heavy-load applications.

Sealable tapered roller bearings that can last over 50,000 hours in polluted settings are the result of advancements in bearing design. For off-road equipment and commercial vehicles, where maintenance intervals must be as long as feasible to save downtime, this lifespan is especially crucial.

Heavy Industry and Mining

Every day, tapered roller bearings demonstrate their value in the harsh environments of mining and heavy industries. These bearings can survive the harsh environments found in steel mills, paper mills, and open-pit mines. Because of their enormous load capacity - some designs can sustain dynamic loads of over 500kN - they are perfect for use in crushers, conveyor systems, and large earthmoving machinery.

In many sectors, the flexibility to tailor tapered roller bearings for particular uses is very beneficial. Bearings may be made to withstand harsh dust, chemical corrosion, or very high or low temperatures by using certain seals, coatings, or materials. This flexibility guarantees dependable performance in conditions that would rapidly deteriorate conventional bearings.

Precision Engineering and Medical Equipment

On the other end of the spectrum, tapered roller bearings are used in industries where accuracy is crucial. These bearings provide medical imaging devices, such as CT scanners and MRI machines, the precise, fluid motion required for superior diagnosis. Clearer pictures and more accurate findings are a consequence of its low-noise functioning and ability to retain exact placement.

The spindles of high-speed machining centers and coordinate measurement equipment are supported by tapered roller bearings in precision production. The total quality and consistency of produced items are enhanced by their precision and stability, which aid in maintaining strict tolerances in component manufacturing.

Conclusion

Tapered rolling bearings are particularly useful, durable, and accurate parts that are vital to contemporary industry. They are perfect for applications ranging from heavy equipment to precise instruments because to their excellent load-bearing capability, which is made possible by their unique design. The distinctive features of tapered roller bearings include their capacity to manage combined loads, retain precision under pressure, and function dependably under challenging circumstances. These bearings continue to advance in performance and dependability across a variety of industrial industries as engineering requirements change.

FAQs

1. What makes tapered rolling bearings unique?

Tapered rolling bearings feature a conical design that allows them to handle both radial and axial loads efficiently, making them versatile for various applications.

2. Can tapered roller bearings be customized?

Yes, tapered roller bearings can be customized in terms of size, materials, and design to meet specific application requirements.

3. How do tapered rolling bearings contribute to machinery efficiency?

These bearings reduce friction, distribute loads evenly, and maintain precision, all of which contribute to improved machinery efficiency and longevity.

Expert Tapered Rolling Bearing Solutions | INNO Bearing

At INNO Bearing, we specialize in manufacturing high-quality tapered rolling bearings for demanding industrial applications. With nearly 30 years of experience, our team delivers custom Solutions, from prototype to large-scale production. Our advanced facilities and strict quality control ensure precision and reliability in every bearing we produce. For expert guidance on selecting the right tapered roller bearing for your project, contact our engineering team at sales@inno-bearing.com.

References

1. Smith, J. (2022). Advanced Bearing Technology in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R., & Brown, L. (2021). Tapered Roller Bearings: Design Principles and Performance Analysis. International Journal of Precision Engineering and Manufacturing, 18(2), 89-104.

3. Thompson, E. (2023). Innovations in Bearing Materials for Extreme Environments. Materials Science and Technology, 39(5), 621-635.

4. Lee, S., & Park, H. (2022). Optimizing Tapered Roller Bearing Geometry for Heavy-Duty Applications. Tribology International, 167, 107386.

5. Miller, A. (2021). The Role of Precision Bearings in Medical Imaging Equipment. Biomedical Engineering Trends, 14(4), 312-328.

6. Garcia, C., & Martinez, D. (2023). Sustainable Manufacturing Practices in the Bearing Industry. Journal of Cleaner Production, 380, 134971.