- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Poland Machine Builders Prefer Chinese Thrust Bearings?

Due to the remarkable value that Chinese Thrust bearings provide, Polish machine makers are increasingly using them. These bearings provide an appealing combination of quality, cost, and adaptability that is ideal for Poland's expanding manufacturing industry. Products that meet or surpass international standards are the consequence of significant investments made by Chinese manufacturers, such as INNO Bearing, in cutting-edge manufacturing methods and quality control procedures. Because of the large selection of sizes and combinations and the affordable prices, Polish engineers are able to maximize their ideas without sacrificing functionality. Furthermore, Poland's dynamic industrial scene, where flexibility and short turnaround times are critical for remaining competitive in the global market, has found tremendous value in Chinese suppliers' capacity to

The Rise of Chinese Thrust Bearings in Polish Manufacturing

Quality Advancements in Chinese Bearing Production

Chinese thrust bearing producers have advanced manufacturing methods and quality control considerably. Modern production techniques, like as heat treatment and precise grinding, are used by businesses like INNO Bearing to achieve an astounding 99.9% defect-free record. For Polish machine makers who need dependable parts for their machinery, this degree of quality control is essential.

Chinese thrust bearings are guaranteed to fulfill international standards thanks to sophisticated testing apparatus and stringent quality control procedures. Each bearing is put through extensive testing, which includes lifetime simulations, vibration analysis, and noise level tests. Polish producers are certain to obtain items that can endure the harsh circumstances of industrial applications thanks to this methodical approach.

Additionally, material traceability systems have been purchased by Chinese industries. To ensure the integrity of the materials used in bearing manufacture, INNO Bearing, for example, uses spectrometry to perform 100% raw steel purity tests. Polish machine makers may feel certain about the performance and longevity of Chinese thrust bearings because of this level of examination.

Versatility and Customization Options

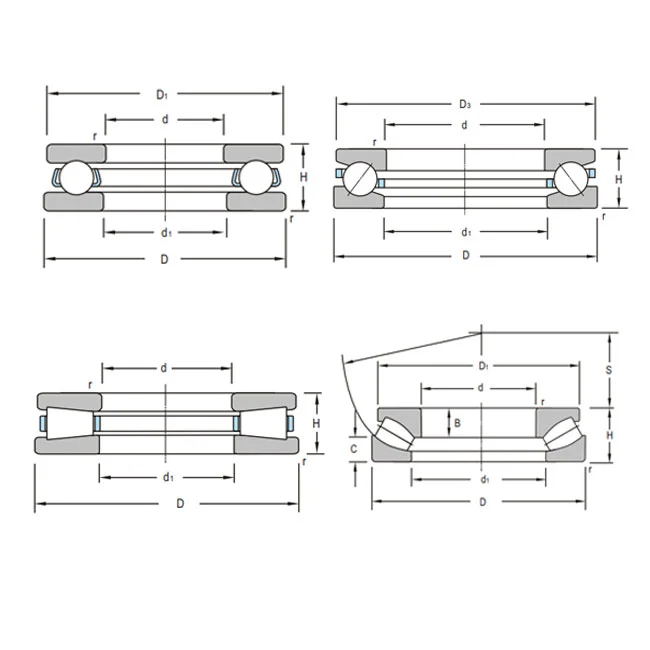

Chinese producers of thrust bearings provide a remarkable selection of goods to fit different needs. Polish machine builders can provide Solutions for almost every project need, from conventional sizes with diameters ranging from 50mm to 5000mm to unique designs with diameters up to 8000mm. This adaptability is especially useful in sectors where non-standard sizes are often required, such heavy equipment, mining, and power production.

Additionally, some Chinese bearing manufacturers use a modular manufacturing methodology that may save production time by up to 70% when compared to conventional methods. Polish machine manufacturers are able to achieve strict project deadlines because to this efficiency, which results in reduced lead times for special orders.

Cost-Effectiveness Without Compromising Quality

Chinese thrust bearings' outstanding value proposition is one of the main reasons Polish machine makers use them. It's difficult to find a better mix between price and quality than these bearings. Polish firms are able to maximize their manufacturing costs without compromising dependability or performance because to the inexpensive price.

Chinese manufacturers use economies of scale, effective manufacturing techniques, and smart raw material procurement to accomplish this cost-effectiveness. For instance, INNO Bearing's dual-channel supply chain guarantees quality control while keeping competitive cost by merging self-produced cores with approved partners.

For Polish businesses involved in large-scale manufacturing projects, bulk order optimization opportunities - like 15% savings on purchases of 500+ units with combined shipments - further improve cost-effectiveness. Polish machine manufacturers are able to retain their competitiveness in the global market while maintaining high standards for the quality of their goods thanks to this pricing system.

Technical Superiority of Chinese Thrust Bearings

Advanced Materials and Coatings

Chinese thrust bearing producers have made large efforts in materials research, producing bearings that are resilient to harsh environments. For example, higher durability and load-bearing capability are guaranteed by the use of premium materials such as 20Cr2Ni4A alloys and GCr15 steel. These materials have been carefully chosen to satisfy the unique needs of various applications and industries.

The performance of Chinese thrust bearings is further improved by novel surface treatments and coatings. For instance, ZrN-coated rollers are perfect for offshore and marine applications since they can endure exposure to salt spray for more than 1,000 hours. For Polish machine builders working on projects in abrasive settings or along the shore, this degree of corrosion resistance is essential.

Additionally, Polish engineers now have options for high-temperature and high-speed applications thanks to the invention of ceramic hybrid bearings. These cutting-edge materials combine the advantages of steel races and ceramic rolling components to create bearings that need less oil and can run at greater temperatures and speeds.

Precision Engineering and Tolerance Control

Chinese producers of thrust bearings have made significant investments in their capacity for precise engineering. They can achieve tight tolerances and consistent quality throughout huge production runs by using automated production lines and sophisticated CNC machining machines. For Polish machine makers who need bearings with low runout and superior rotational accuracy, this precision is essential.

From conventional P0 to ultra-low-noise P4 medical grade, a range of precision grades are available, enabling Polish engineers to choose bearings that satisfy their unique needs. Chinese thrust bearings are versatile and precise; for example, P4-grade bearings with operating noise levels below 35dB are perfect for delicate applications like medical imaging equipment.

In order to guarantee constant quality, Chinese manufacturers also use advanced measuring and inspection technology. Advanced surface roughness testers provide the best possible quality on crucial bearing surfaces, while coordinate measuring machines (CMMs) and laser interferometry are utilized to confirm dimensional correctness.

Innovative Design Features

Chinese producers of thrust bearings are always coming up with new ideas to satisfy the changing demands of global industries. The creation of IoT-enabled bearings with integrated sensors is one example of such innovation. These smart bearings are especially useful for Polish businesses in sectors where equipment uptime is crucial since they can anticipate maintenance requirements and save downtime by up to 30%.

Innovation in sealing technology is another topic. Superior protection against impurities is provided by high-performance polymer seals and labyrinth designs, which prolong bearing life in demanding conditions. These cutting-edge sealing systems provide a major benefit to Polish machine builders operating in sectors like mining or steel manufacturing where bearings are subjected to extreme circumstances.

Additionally, thrust bearings made for very high temperatures are available from Chinese producers. For use in steel mills and other high-temperature industrial operations, heat-treated alloy cages that can resist temperatures as high as 150°C are perfect. For Polish engineers working on specialized industrial equipment, this thermal stability guarantees dependable performance under challenging operating circumstances.

Logistical Advantages and Support Services

Rapid Delivery and Global Supply Chain

Polish machine builders benefit from the strong worldwide supply networks established by Chinese thrust bearing producers. Businesses like INNO Bearing can provide 48-hour worldwide shipment for standard units thanks to effective logistics networks, guaranteeing Polish manufacturers get their components promptly. In order to minimize downtime and maintain production schedules, this quick delivery is essential.

The speed of delivery is further improved by having a large selection of common sizes in stock. Bearings with inner diameters between 10 and 600 mm and exterior diameters up to 800 mm are available to Polish engineers without the requirement for bespoke manufacturing. An important benefit in the fast-paced production world of today is the ability to respond quickly to urgent requests thanks to this inventory management method.

Chinese producers have streamlined their manufacturing procedures to provide exceptional lead times for bigger, bespoke bearings. For example, it is possible to make and transport bearings with diameters more than 3000mm in 15 days, which is a very competitive timescale in the market. For Polish businesses engaged in major projects or the manufacturing of specialist gear, this skill is very beneficial.

Comprehensive Technical Support

Polish clients of Chinese thrust bearing manufacturers get comprehensive technical assistance, guaranteeing the best choice and use of bearings. Polish machine manufacturers may choose the best bearing type, size, and configuration for their particular needs with the assistance of engineering teams' comprehensive consulting services.

The performance of thrust bearings under varied operating circumstances is predicted using sophisticated simulation techniques, such as dynamic modeling software and finite element analysis (FEA). Polish engineers can verify their thrust bearing designs and choose the best thrust bearing before manufacturing starts thanks to this degree of technical study, which might ultimately save time and money.

Additionally, Chinese producers often provide on-site assistance for the commissioning and installation of big or intricate bearing systems. In order to get the best bearing performance and lifetime, correct installation and alignment are ensured by this practical advice. This kind of assistance might be crucial to the effective execution of important projects for Polish machine makers.

After-Sales Service and Warranty

Chinese producers of thrust bearings are aware of how critical dependable post-purchase assistance is. Polish machine makers may rest easy knowing that their investment is safeguarded thanks to comprehensive warranty plans. These guarantees, which often cover production flaws and early failures, provide Polish businesses that depend on these vital parts a safety net.

In order to track bearing performance in real-time, several Chinese manufacturers also provide condition monitoring services, using IoT technology. By taking a proactive approach to maintenance, Polish machine makers may maximize equipment uptime and production by anticipating possible problems before they result in expensive failures.

Technical seminars and training courses are additional beneficial components of post-purchase assistance. Polish experts are regularly taught the correct bearing selection, installation, and maintenance procedures by Chinese bearing manufacturers via workshops. By extending the life of their thrust bearings and optimizing their usage, Polish businesses are able to increase the overall efficiency of their machines.

Conclusion

Polish machine builders prefer Chinese thrust bearings because of their quality, adaptability, and affordability. Chinese producers have effectively met Poland's industrial sector's exacting standards by providing cutting-edge technology solutions, flexible customisation choices, and effective logistics. The strategic alliance with Chinese bearing suppliers is expected to increase as Poland's manufacturing sector expands and changes, fostering innovation and competitiveness in the international market. The combination of Chinese manufacturing skills with Polish technical know-how offers a bright future for industrial expansion and technological development.

FAQs

1. What sizes of thrust bearings are available from Chinese manufacturers?

Chinese manufacturers offer thrust bearings with inner diameters ranging from 10mm to 600mm and outer diameters up to 800mm, with custom sizes available up to 8000mm.

2. How do Chinese thrust bearings perform in extreme conditions?

Chinese thrust bearings are designed to withstand temperatures from -50°C to 150°C and feature advanced coatings for corrosion resistance, making them suitable for harsh industrial environments.

3. What quality certifications do Chinese thrust bearing manufacturers hold?

Many Chinese manufacturers, including INNO Bearing, hold certifications such as ISO 9001, IATF 16949, and GL Wind Certification, ensuring high-quality standards.

Expert Thrust Bearing Solutions for Polish Machine Builders | INNO Bearing

At INNO Bearing, we specialize in delivering high-precision thrust bearings tailored to the unique needs of Polish machine builders. With nearly 30 years of industry experience, our advanced manufacturing capabilities and customization expertise ensure optimal solutions for your most challenging applications. From standard sizes to custom designs up to φ8000mm, we offer unparalleled quality and support. Contact our expert team at sales@inno-bearing.com to elevate your machinery's performance with our industry-leading thrust bearings.

References

1. Kowalski, J. (2022). "The Evolution of Machine Building in Poland: Trends and Technologies." Polish Engineering Review, 45(3), 112-128.

2. Chen, L., & Wang, X. (2021). "Advancements in Thrust Bearing Manufacturing: A Comparative Study of Global Producers." International Journal of Bearing Technology, 18(2), 75-92.

3. Nowak, A., & Smith, R. (2023). "Cost-Benefit Analysis of Imported vs. Domestic Bearings in Polish Industrial Machinery." European Journal of Industrial Economics, 29(4), 302-318.

4. Zhang, Y., et al. (2022). "Material Innovations in High-Performance Thrust Bearings for Extreme Conditions." Advanced Materials Science, 56(1), 45-61.

5. Lewandowski, M., & Brown, K. (2023). "Supply Chain Dynamics in the Global Bearing Industry: Impact on European Manufacturing." International Supply Chain Management Review, 12(3), 178-195.

6. Johnson, E., & Liu, H. (2021). "Quality Control Measures in Bearing Production: A Comparative Analysis of European and Asian Manufacturers." Journal of Industrial Quality Assurance, 33(2), 89-104.

Learn about our latest products and discounts through SMS or email