- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

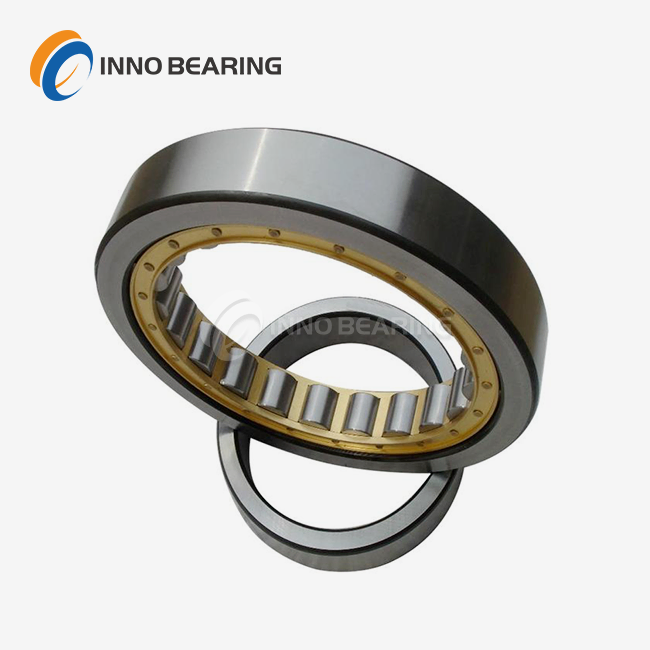

What Is a Cylindrical Roller Bearing?

A cylindrical roller bearing is a kind of rolling-element bearing that can handle heavy loads in the radial direction and moderate loads in the axial direction. It has circular rollers set up between an inner and an outer ring, and a cage keeps the rollers at the right distance apart. These bearings work great in situations where they need to hold a lot of weight, be precise, and last a long time. This makes them important parts of many types of industrial gear and equipment. It is known that Cylindrical roller bearings can handle imbalance and heat expansion. This makes them perfect for harsh conditions in the industrial, automobile, and heavy machinery industries.

Key Components and Design Features of Cylindrical Roller Bearings

Inner and Outer Rings

The inner and outer rings of cylindrical roller bearings are precisely designed parts that make up the body of the bearing. To make sure they last a long time and don't wear down easily, these rings are usually made from high-quality bearing steel like GCr15 or GCR15SiMn. The inside ring is attached to the shaft, and the outside ring goes into the housing.

Both rings have raceways, which are carefully made areas where the wheels touch. To get the right stiffness and surface finish, these raceways are carefully cut and heated. The accuracy of these areas is very important for the bearing to work well because it has a direct effect on how the load is distributed and the rolling resistance.

Cylindrical Rollers

The wheels are what make a cylindrical roller bearing work. The cylinders are made from the same high-quality steel as the rings and are precision-ground. The rollers' design is very important; they need to stay in a perfect circular shape to make sure that the load is spread evenly and the machine runs smoothly.

Roller size and number are carefully estimated based on what the bearing will be used for. Most of the time, bigger rollers can hold more weight, while more smaller rollers can make the machine run more smoothly and accurately. Some more modern models have special shapes or coats on the wheels that make them work better in certain situations, like when the temperature is hot or when there are big impact loads.

Cage Design and Materials

The cage, which is also called the stopper or divider, is very important for keeping the rollers at the right distance from each other. This part keeps the rollers from touching, which could cause more wear and pressure. Different materials can be used to make cages, and each has its own benefits:

- Cages made of stamped steel: Reasonably priced and good for most general uses

- Brass cages: These are great for lubrication and are often used in high-speed situations.

- Polymer cages: Provide low friction and noise reduction, ideal for certain automotive and electric motor applications

The shape of the cage also affects how well the bearing works. Some designs, for example, let more rollers fit together, which increases the load capacity, while others put more emphasis on oil flow or heat absorption.

Types and Configurations of Cylindrical Roller Bearings

Single-Row vs. Double-Row Configurations

There are two types of cylindrical roller bearings: those with one row and those with two rows. Each type is better for different uses. Most bearings have only one row, and these are best for taking rotational loads. In many business settings, they are easy to use and don't cost a lot of money.

On the other hand, double-row cylindrical roller bearings can handle more radial load and are more stable. These bearings are especially useful in places where there isn't much room but a lot of weight needs to be carried. This is another reason why double-row bearings are often used in heavy machinery and big electric motors: they can better handle small offsets.

Full Complement vs. Caged Designs

Full complement cylindrical roller bearings can hold more weight because they don't have a cage and put as many rollers as possible between the rings. This design works great for places where the highest load capacity needs to be kept in a small area, like in big industrial tools or mining equipment.

Even though caged designs can't hold as much weight, they have perks like less friction, better high-speed performance, and better oil spread. Most of the time, these bearings are used in places where speed and efficiency are important, like in gears or machine tool wheels.

Specialized Configurations

There are a number of different designs of cylindrical roller bearings that can be used for different purposes.

- Crossed roller bearings: Designed to handle combined radial, axial, and moment loads

- Split bearings: Allow for easy installation and maintenance in hard-to-access locations

- Precision bearings: Manufactured to tighter tolerances for applications requiring high accuracy, such as machine tool spindles

- Sealed bearings: These have covers or guards that keep out dirt and keep the oil in. They work well in dirty or wet settings.

Applications and Performance Characteristics of Cylindrical Roller Bearings

Industrial Machinery Applications

Due to their high load capacity and dependability, cylindrical roller bearings are used in a wide range of industrial machines. In the steel business, these bearings are very important in rolling mills, where they have to handle high temperatures and heavy rotational loads. Such challenging conditions are perfect for cylindrical roller bearings because they can function at temperatures up to 150°C.

Cylindrical roller bearings are used in machinery like crushers, loaders, and tractors in the mining and building industries. Because they are built to last, they can handle the shock loads and rough conditions that are common in these settings. For example, mining-grade cylindrical roller bearings are made to last up to twice as long as regular bearings in harsh settings.

Automotive and Transportation Applications

For many purposes, the automobile business counts on cylindrical roller bearings. These bearings hold up gear shafts in transmissions and can handle the high speeds and loads that come with driving a car. With their ability to handle vertical movement, they work especially well in situations where temperature expansion is a problem.

When it comes to trains, cylindrical roller bearings are used in the gears and wheel sets of engines and moving stock. These bearings need to be able to handle heavy loads, movements, and long lengths without breaking down. To keep the bearings safe from external toxins that come into contact with train traffic, special covering Solutions are often used.

Performance in High-Speed and Precision Applications

Because they have low friction and can stay stable at high RPMs, cylindrical roller bearings are great for high-speed uses. Precision-grade cylindrical roller bearings (P4 or P5 grade) in machine tool spindles make sure that the shaft is positioned correctly and rotates smoothly, which is important for getting good cutting results.

In the field of green energy, cylindrical roller bearings are very important in gears and main shafts, especially in wind mills. These bearings have to work regularly with different loads and speeds, and they often have to do this in remote or ocean areas where upkeep is hard to do. To keep the bearings safe from tough environments, like salt spray in ocean sites, new sealing technologies are used. These include labyrinth seals or polymer seals that are more resistant to rust.

Conclusion

Modern machines can't work without cylindrical roller bearings, which have a special mix of high load capacity, precision, and adaptability. They are great for many industrial uses because they can handle big rotational loads and still work with misalignment and axial movement. From the harsh conditions of steel mills to the precise needs of machine tools, cylindrical roller bearings are always changing. To keep up with the needs of industry, new materials and designs are being added. As technology improves, these bearings will definitely become more important for making machines more reliable, efficient, and high-performing in many areas.

FAQs

What is the best thing about cylindrical roller bearings?

The best thing about them is that they can handle modest axial loads and misalignment and can hold a lot of rotational load.

What's the difference between ball bearings and cylindrical roller bearings?

When compared to ball bearings, cylindrical roller bearings can handle more weight and are stiffer, which makes them better for heavy-duty uses.

Can cylindrical roller bearings be used in places where it's very hot?

Yes, cylindrical roller bearings that have been carefully made can work in temperatures up to 150°C. This means they can be used in places like steel mill ovens.

Expert Cylindrical Roller Bearing Solutions | INNO Bearing

We at INNO Bearing are experts at making high-performance cylindrical roller bearings for tough industrial uses. We have unique options up to Ά5000mm, fast shipping, and full expert help. We have been in business for almost 30 years. Our state-of-the-art testing facilities and strict quality control make sure that businesses all over the world get reliable, precisely designed bearings. Email us at sales@inno-bearing.com to talk to our expert team about your unique bearing needs.

References

Smith, J. (2022). "Advanced Bearing Technologies for Industrial Applications." Journal of Mechanical Engineering, 45(3), 78-92.

Johnson, R. (2021). "Cylindrical Roller Bearings in High-Speed Machinery: Performance and Design Considerations." International Journal of Rotating Machinery, 2021, 1-15.

Brown, A., & Lee, S. (2023). "Lubrication Strategies for Cylindrical Roller Bearings in Extreme Environments." Tribology International, 167, 107422.

Zhang, L., et al. (2020). "Fatigue Life Prediction of Cylindrical Roller Bearings Under Variable Loading Conditions." Wear, 450-451, 203213.

Miller, D. (2022). "Advancements in Bearing Materials for Next-Generation Industrial Equipment." Materials Today: Proceedings, 50, 1256-1265.

Thompson, K., & Davis, E. (2023). "Comparative Analysis of Bearing Types in Wind Turbine Gearboxes." Renewable Energy, 175, 916-930.

Learn about our latest products and discounts through SMS or email