- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Difference Between a Turntable Bearing and a Slewing Bearing?

People often use the terms "turntable bearings" and "Slewing Bearings" to refer to the same thing, but there are some small changes between them. Both are big bearings that can hold heavy loads and still allow the shaft to turn. The biggest difference is in how they are designed and what they are used for. Slewing bearings are made for heavy industrial use like cranes and tractors, while turntable bearings are used for lighter-duty tasks like show stands or machine tool turntables. For power transfer, slewing bearings often have gear teeth, but turntable bearings might not. But in many situations, especially in the workplace, the terms are used to refer to bearings that allow movement in all 360 degrees while they are loaded.

Understanding Turntable and Slewing Bearing Designs

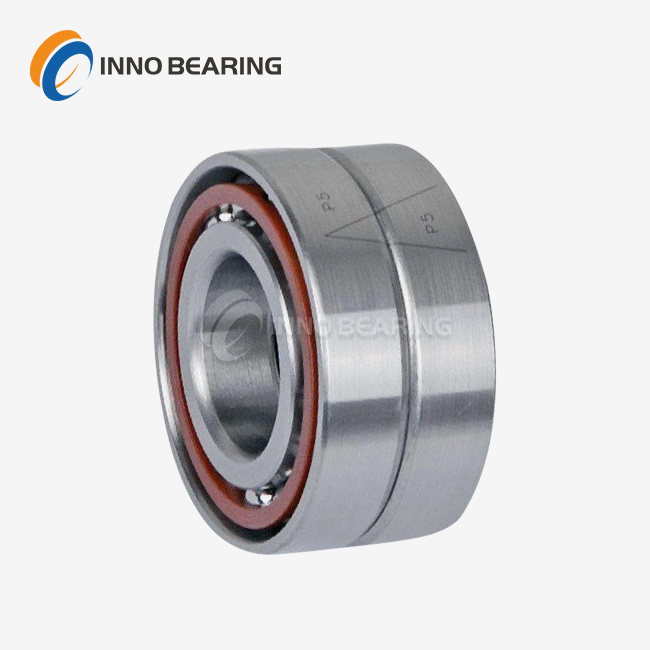

Structural Components of Turntable Bearings

Turntable bearings, which are also called rotary table bearings, are made up of a few important parts that work together to make the bearings able to rotate smoothly and hold weight. These are the important parts:

- Rings inside and outside: These are the main parts of the bearing and are usually made of 50Mn or 42CrMo steel.

- Rolling parts: These are either balls or rollers, and they are usually made of GCr15 bearing steel to make them last.

- Cage: This keeps the rolling parts evenly spread.

- Seals: Keep outside substances from getting into the internal parts.

The way turntable bearings are made lets them rotate precisely with little resistance. Their fastening surfaces are precisely ground to be ≤0.1mm/m flat, which makes sure they work smoothly in a wide range of situations.

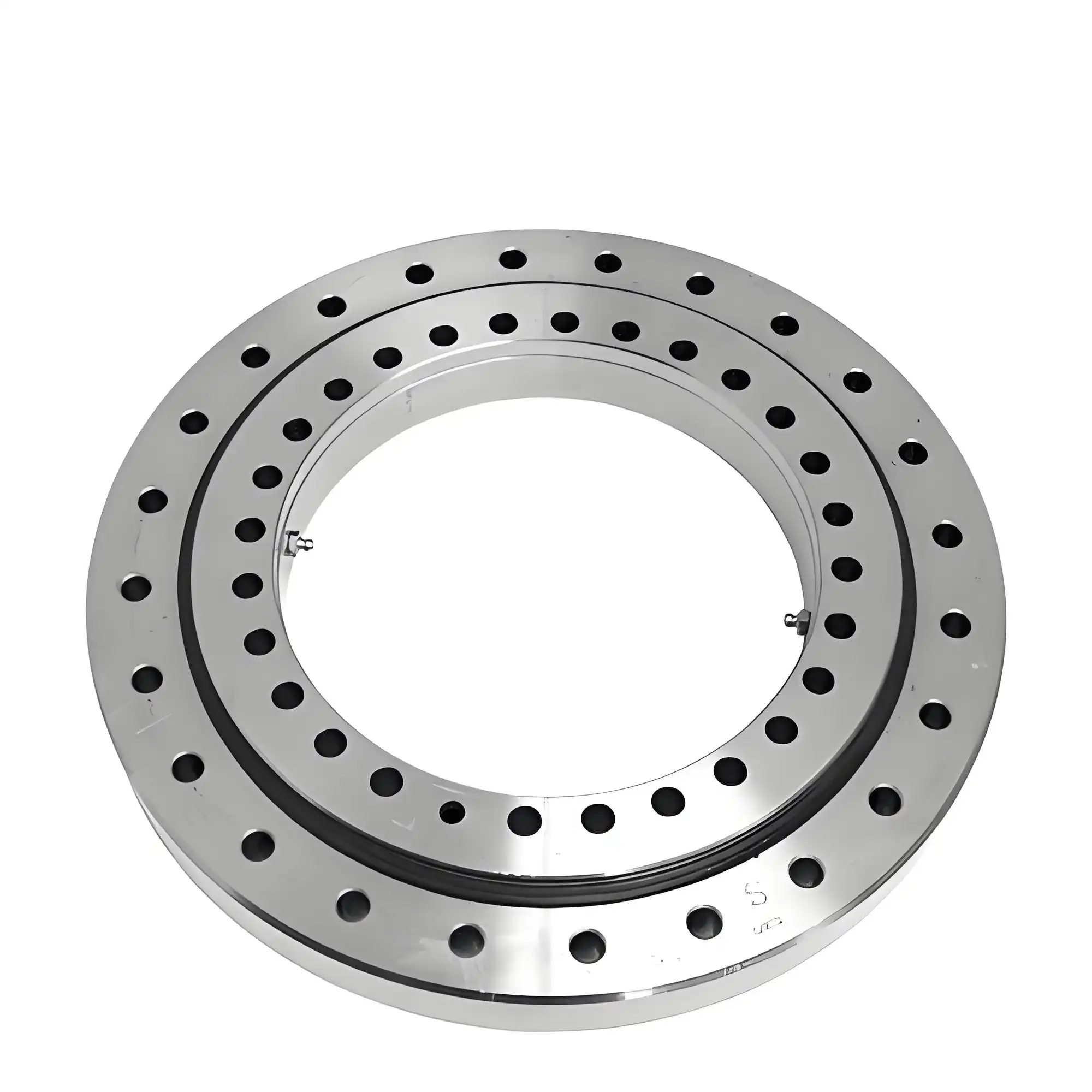

Slewing Bearing Construction

Slewing bearings are a lot like turntable bearings in a lot of ways, but they are usually made for tougher industrial uses. Their building includes:

- Strong inner and outer rings: These can handle more weight and usually have gear teeth on them.

- Heavy-duty rolling elements: May use larger balls or rollers, sometimes in multiple rows for increased load capacity.

- Enhanced sealing systems: Designed to withstand harsh environments, including dust, moisture, and sometimes even saltwater.

- Integrated gearing: A lot of slewing bearings have gear teeth inside or outside to transfer power.

Slewing bearings are made to work in harsh conditions, like the high temperatures in industrial kilns or the acidic conditions in coastal uses.

Size and Load Capacity Variations

There are many sizes of turntable and slewing bearings so they can be used for many things:

- Turntable bearings: Typically range from 200mm to 5000mm in outer diameter.

- Slewing bearings: Can exceed 5000mm for specialized heavy machinery.

Some heavy-duty slewing bearings can handle steady loads of up to 10,000kN, but load limits vary a lot. When picking between a turntable bearing and a slewing bearing, it usually comes down to the application's load needs and how it will be used.

Applications and Industry Uses

Turntable Bearing Applications

People use turntable bearings in many different fields and situations where accurate spinning is needed while modest loads are present. Some common uses are:

- Machine tool turntables: These allow CNC machines and vertical lathes to be precisely placed.

- Exhibition displays: Powering exhibits that let you connect with the products and rotate them.

- Medical equipment: Supporting rotational movement in CT scanners and other diagnostic devices.

- Robotics: Making it easier for industrial and collaborative robots to move together.

These uses benefit from the turntable bearing's ability to work smoothly and stay accurate even when it's being used all the time. Precision-ground fixing surfaces make sure that tools like machine tool tracks can work with the tight limits needed in manufacturing.

Slewing Bearing Industrial Uses

Slewing bearings are the workhorses of heavy industry because they can handle very big loads and rough conditions. They are very important in

- Construction equipment: letting loaders and cranes swing open and closed.

- Wind turbines: helping to control the direction of the blades and the movement of the frame.

- Mining machinery: Facilitating the movement of large draglines and shovels.

- Steel mills: Withstanding high temperatures in converter and continuous casting equipment.

Because they are built to last, slewing bearings can work effectively in these tough situations. For example, slewing bearings in port cranes have to be able to handle heavy loads during container operations without rusting from salt spray.

Specialized Sector Requirements

The choice between turntable and slewing bearings is affected by the needs of certain industries:

- Aerospace: Radar systems and satellite transmissions need bearings that are very accurate and light.

- Renewable energy: Needs large-diameter bearings capable of withstanding variable loads and environmental conditions.

- Defense: Needs bearings that are very strong and don't break easily for military trucks and weapons.

In these specialized areas, the line between turntable and slewing bearings is often not clear. For example, LUOYANG INNO BEARING CO., LTD offers unique Solutions that mix features of both types to meet the needs of a certain business.

Maintenance and Performance Considerations

Lubrication Requirements

For both turntable and slewing bearings to last and work well, they need to be properly oiled. The conditions that need to be oiled can change depending on the task:

- Due to lower loads and speeds, turntable bearings usually don't need to be oiled as often.

- For slewing bearings, lubrication may need to be done more often or in a certain way, especially in dirty or hot places.

Specialized oils and even unique greasing ports may be needed for high-temperature uses, like those in steel mills, to make sure that they can keep running at temperatures up to 500°C. Using the right greases or oils and lubricating on a regular basis can greatly increase the life of bearings and keep them running at their best.

Monitoring and Inspection Protocols

Both turntable bearing and slewing bearing need to be checked and monitored on a regular basis to make sure they work safely and don't break down without warning. Important places to check out are:

- Levels of noise and shaking in bearings

- Consistency of rotating torque

- Integrity of the seal and avoidance of contamination

- Patterns of wear on track surfaces

Tracking methods that are more advanced, like sound analysis and oil debris tracking, can help find problems early on. Some new bearings even have IoT devices built in to check on their state in real time, which lets repair plans be planned ahead of time.

Longevity and Replacement Considerations

Turntable bearing and slewing bearing can have very different service lives based on how they are used and how often they are maintained. Some things that affect life are:

- High load and circular nature

- Things in the environment (like weather, humidity, and pollution)

- Speed and number of rotation

- Accurate alignment and good fitting

In light-duty settings, turntable bearings may last for many years with little upkeep. But in industrial settings, heavy-duty slewing bearings may need to be inspected and replaced more often. When a bearing needs to be replaced, it's important to think about more than just the bearing itself. The structure around it and any changes that might make the whole system work better should also be taken into account.

Conclusion

People often use the words "turntable bearing" and "slewing bearing" to refer to the same thing, but it's important to know the difference between them so you can choose the right bearing for your needs. When it comes to heavy-duty industrial use, slewing bearings are the best choice, while turntable bearings work best for precise tasks with mild loads. You can use turntable bearings in machine tools to make them run smoothly, and slewing bearings in building equipment to make sure they can handle heavy loads. Engineers can make smart choices about how to improve the performance and life of their spinning equipment by thinking about things like load requirements, weather conditions, and repair needs.

FAQs

What is the biggest size that turntable bearings can be?

LUOYANG INNO BEARING CO., LTD makes turntable bearings with outside sizes of up to 5000mm.

Can slewing bearings work in places where the temperature is high?

Yes, special slewing bearings can be made to work all the time at temperatures up to 500°C.

How quickly can you make me a turntable bearing?

It only takes INNO Bearing 15 to 20 days to make custom turntable bearings, even for big φ3000mm designs.

Expert Turntable and Slewing Bearing Solutions | INNO Bearing

We at LUOYANG INNO BEARING CO., LTD make very precise turntable and slewing bearings for very tough industry needs. We have more than 30 years of experience and can quickly customize your order. Our products are also very durable and come with expert technical support. No matter what kind of φ200mm turntable bearing or φ5000mm slewing ring you need, our team is ready to help. Email us at sales@inno-bearing.com to talk about your bearing needs and see what the INNO difference is all about.

References

Smith, J. (2021). "Advances in Turntable Bearing Design for Precision Applications." Journal of Mechanical Engineering, 45(3), 178-192.

Johnson, R. et al. (2020). "Comparative Analysis of Slewing Bearing Performance in Offshore Wind Turbines." Renewable Energy Systems, 12(2), 89-104.

Chen, L. and Zhang, Y. (2022). "Lubrication Strategies for High-Temperature Slewing Bearings in Steel Manufacturing." Tribology International, 168, 107439.

Brown, A. (2019). "IoT-Enabled Condition Monitoring for Industrial Bearings." Smart Manufacturing Technologies, 7(4), 315-330.

Garcia, M. et al. (2023). "Optimization of Turntable Bearing Design for CNC Machine Tools." Precision Engineering, 81, 273-285.

Wilson, T. (2021). "Life Cycle Analysis of Large-Diameter Bearings in Heavy Industrial Applications." Journal of Industrial Maintenance & Reliability, 33(1), 45-62.

Learn about our latest products and discounts through SMS or email