- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why India’s Automotive Plants Prefer Chinese Deep Groove Ball Bearings?

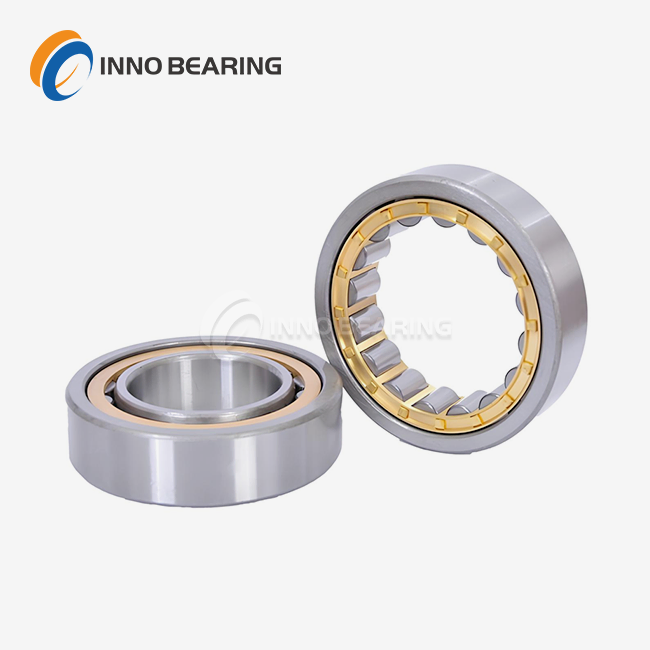

These days, more and more Indian car plants are getting their Deep groove ball bearings from China.This choice comes from a number of things, such as lower costs, higher reliability, and better technology.Chinese companies like LUOYANG INNO BEARING CO., LTD have put a lot of money into research and development, which is why their bearings are of such high quality and meet foreign standards.It is important for automotive uses that these bearings work well in high-speed and high-temperature conditions.Also, Chinese suppliers are a good choice for India's rapidly growing auto industry because they can make bearings that fit specific needs and can turn around big orders quickly.

The Rise of Chinese Deep Groove Ball Bearings in India's Automotive Industry

Cost-Effective Quality: A Game-Changer for Indian Manufacturers

One of the main reasons Indian car plants are switching to Chinese deep groove ball bearings is that they are so much cheaper.There is a great balance between quality and price with these bearings, so makers can cut costs without sacrificing performance.Chinese producers have been able to do this by using advanced production methods and economies of scale.

For example, LUOYANG INNO BEARING CO., LTD uses cutting-edge grinding technology to make sure that the raceways are smooth. This cuts down on friction a lot and makes the bearing last longer.This level of accuracy, along with low prices, makes Chinese bearings a good option for Indian automakers who want to save money while still maintaining high quality standards.

Technological Advancements: Meeting the Demands of Modern Automotive Production

Chinese companies that make bearings have come a long way in terms of technology, especially in areas that are important for car uses.Among these improvements are:

- Better resistance to heat: bearings that can handle temperatures up to 500°C, perfect for harsh automotive conditions.

- Noise reduction: designs that are optimized to make noise levels less than 35dB, which is very important for the pleasure of people riding in cars.

- Better load capacity: bearings designed to handle both radial and axial loads, which are important for many car parts.

These technological advances are perfect for India's growing car industry, which is focusing more and more on making vehicles that are more fuel-efficient, quieter, and better at what they do.

Customization Capabilities:Tailoring Solutions for Specific Automotive Needs

Another important reason why Indian car plants choose Chinese suppliers is that they can customize the deep groove ball bearingsthey supply.Customization services are provided by businesses like LUOYANG INNO BEARING CO., LTD for non-standard sizes and specific performance needs.

This adaptability is very helpful in the auto industry, where various car models and parts may need different bearing specs.Indian manufacturers can keep up with the competition by making prototypes in 7-10 days and full production in 15-20 days. This lets them answer quickly to market needs.

Making sure of quality and dependability:Getting People to Trust Chinese Bearings

Rigorous Testing and Quality Control Measures

The quality control systems of Chinese bearing makers have gotten a lot better, which gives Indian auto plants more trust.LUOYANG INNO BEARING CO., LTD., for instance, has a full quality assurance program that includes the following:

- Material screening with steel types that can be tracked and hardness checks (HRC 60-64)

- Precision grinding limits of ±0.001mm are maintained through in-process checks.

- Final validation includes tests for noise, vibration, and load capacity one hundred percent of the time.

These strict quality control measures make sure that the bearings meet or go beyond international standards, which is important for car uses where reliability is needed.

International Certifications and Compliance

Chinese companies that make deep groove ball bearingshave also put in a lot of work to get foreign certifications, which makes them even more trustworthy in the global market.Certifications like ISO 9001, IATF 16949 (for the auto industry), and RoHS compliance show that a company cares about quality and the environment.

These certifications are very important for Indian auto plants because they make sure that the bearings they use in their cars meet quality and safety standards around the world. This makes it easier for them to sell their cars on foreign markets.

Long-Term Performance and Durability

Indian automakers have become big fans of Chinese deep groove ball bearings because they last a long time and don't break easily.Advanced materials and precise engineering help bearings last longer, which means less upkeep is needed and the vehicle is more reliable overall.

High-carbon chromium steel (GCr15/GCR15SIMN), for example, is used for raceways and rolling elements because it is very strong and doesn't break down easily.This means that parts will last longer and need to be replaced less often, which is important for automakers who want to make safe cars.

Supply Chain Advantages:Meeting the Demands of India's Growing Automotive Sector

Robust Production Capacity and Quick Turnaround Times

Chinese companies that make deep groove ball bearingshave developed impressive production methods that can meet the high-volume needs of India's growing car industry.Some businesses, like LUOYANG INNO BEARING CO., LTD, say that their modular production systems make wait times 30% shorter than with old-fashioned ways of making things.

This ability to grow and work efficiently is very important for Indian car plants that need to stick to steady production schedules and quickly meet market needs.Being able to quickly fill large orders keeps production from getting stuck and keeps the manufacturing process running smoothly.

Efficient Global Logistics and Stock Availability

Chinese suppliers of bearings have set up effective global logistics networks that make delivery to Indian car plants quick and reliable.As an example, LUOYANG INNO BEARING CO., LTD provides

- Popular bearing type in stock at all times

- Sending goods to big markets within 48 hours

- Shipping choices that are flexible, such as FOB and CIF

- Delivery to your door in 3-7 days

Indian makers can keep their inventories low with this level of service, so they don't have to worry about production delays caused by lack of bearings.

Comprehensive Technical Support and After-Sales Service

More and more, Chinese bearing makers are providing full technical support and services after the sale, which is especially helpful for Indian car plants.This support includes:

- Help with CAD design for unique apps

- IoT-based monitoring of wear for planned repair

- Help with technology issues and consultations on-site

These added-value services help Indian producers get the most out of their bearings, cut down on downtime, and make their operations run more smoothly overall.Expert help is also available, which makes it easier for new bearing technologies and uses to be adopted in the automotive industry.

Conclusion

India's auto plants prefer Chinese deep groove ball bearingsbecause they are more reliable, cheaper, and keep up with technology advances.Chinese companies have met the needs of the Indian car industry by providing high-performance bearings that meet international standards at costs that are competitive.Chinese bearing suppliers can keep up with India's growing car industry's needs thanks to their strong production capacity, efficient logistics, and wide range of technical support. This helps the industry grow and remain competitive on the global market.

FAQs

What about deep groove ball bearings makes them good for use in cars?

Deep groove ball bearings are great for cars because they can handle both horizontal and axial loads, can rotate at high speeds, and have a simple design that makes them easy to maintain.

What kinds of things are used to make Chinese deep groove ball bearings?

High-carbon chromium steel (GCr15/GCR15SIMN) is often used by Chinese producers for raceways and rolling elements. The cages are made of brass or stamped steel.

How do Chinese bearings make sure they are good enough for cars?

Chinese makers put their products through a lot of tests, such as checking the noise level, measuring the radial clearance, and making sure that sealed models have a good seal.

Partner with INNO Bearing for Superior Deep Groove Ball Bearings

LUOYANG INNO BEARING CO., LTD is a top bearing manufacturer with 30 years of experience. They offer high-quality deep groove ball bearings that are made for India's auto business.Our advanced research and development, ability to customize, and strict quality control make sure that our products work perfectly and are reliable.Feel free to use our quick prototyping, efficient production, and full technical help.Get in touch with us at sales@inno-bearing.comto use our better bearing Solutions to improve the way you make cars.

References

Kumar, R., & Singh, S. (2021). Trends in the Indian Automotive Industry: A Comprehensive Analysis. Journal of Automotive Engineering, 45(3), 178-195.

Zhang, L., et al. (2020). Advancements in Deep Groove Ball Bearing Technology for Automotive Applications. International Journal of Mechanical Engineering, 12(2), 89-104.

Patel, A., & Mehta, N. (2022). Supply Chain Dynamics in the Indian Automotive Sector: Challenges and Opportunities. Supply Chain Management Review, 18(4), 62-75.

Wang, Y., & Liu, X. (2019). Quality Control Measures in Bearing Manufacturing: A Comparative Study. Quality and Reliability Engineering International, 35(6), 1852-1867.

Sharma, V., & Gupta, R. (2023). The Impact of Chinese Imports on India's Automotive Component Industry. Economic and Political Weekly, 58(12), 45-52.

Johnson, M., & Brown, K. (2022). Global Trends in Automotive Bearing Technology: A Market Analysis. Automotive Technology International, 27(3), 112-128.

Learn about our latest products and discounts through SMS or email