- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

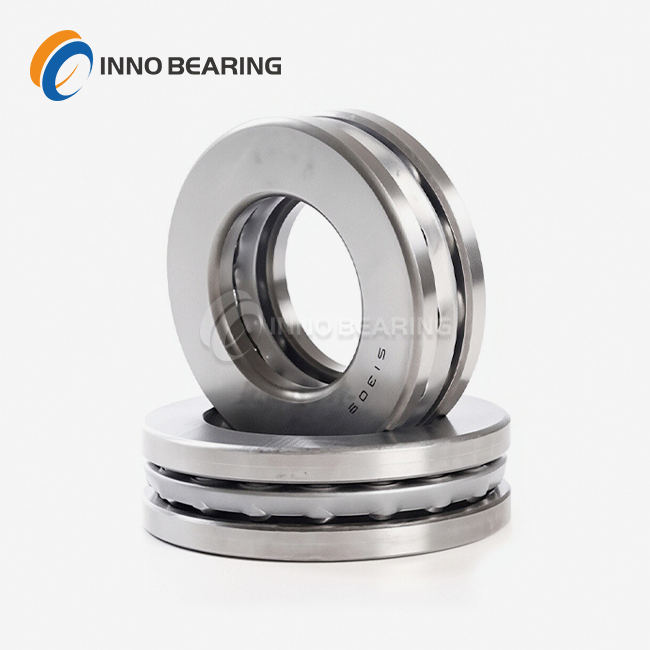

small slewing bearing

2.Structure Type: It has a thin-wall annular shape. The inner and outer rings are made of medium carbon steel, with built-in single-row small-diameter steel balls, engineering plastic cages, and small-diameter mounting holes evenly distributed. Some are without seals (suitable for clean environments).

3.Size Range: Outer ring diameter: 80 - 400mm, inner ring diameter: 60 - 360mm, height: 8 - 35mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Medical devices (turntables of operating tables), intelligent PTZ (monitoring cameras), small amusement equipment (mini turntables), household intelligent machinery.

6.Key Inspection Items: Deformation amount of thin walls, slewing flexibility.

Compact Precision: Small Slewing Bearings Engineered for Medical & Robotics Innovation

When your medical devices or robotics demand small Slewing Bearings that combine microscopic accuracy with whisper-quiet operation, LUOYANG INNO BEARING delivers. Our ultra-compact slewing rings (80–400mm diameter) are precision-machined to P4-grade tolerances, achieving noise levels under 35dB for MRI systems, surgical robots, and automated PTZ cameras. With 18+ years of expertise in miniature bearing design, we solve space-constrained motion challenges while meeting ISO 13485 and FDA compliance.

Why Precision-Critical Industries Trust Our Compact Slewing Solutions?

1. Medical-Grade Performance in Miniature Packages

-

Silent Rotation: ≤35dB operation ensures patient comfort during MRI scans or robotic surgeries.

-

Biocompatible Materials: Stainless steel 440C/fluororubber seals resist sterilization chemicals.

-

Zero Backlash: Micron-level radial clearance (<0.005mm) maintains surgical tool accuracy.

2. Robotics-Optimized Agility

- High-Speed Stability: Smooth operation at 50–100 RPM for collaborative robot joints.

- Ultra-Light Design: 30% weight reduction vs. standard bearings through thin-wall engineering.

- Custom Mounting Kits: Pre-drilled holes match KUKA/ABB/FANUC robot interfaces.

Technical Specifications: Precision Where It Matters

| Parameter | Specification |

|---|---|

| Outer Diameter | 80mm – 400mm |

| Material | 42CrMo/50Mn steel, GCr15 balls |

| Precision Grade | P4 (ABEC-7 equivalent) |

| Noise Level | <35dB @ 30 RPM |

| Load Capacity | Up to 12kN dynamic / 25kN static |

| Certifications | ISO 13485, RoHS, ISO 10993-5 biocompatible |

Solving Critical Challenges in Medical & Robotic Systems

A. MRI Machine Rotational Consistency

Our small slewing bearings eliminate image distortion by maintaining <0.01mm axial runout under 0.5T magnetic fields. Fluoropolymer-coated cages prevent RF interference.

B. Surgical Robot Lifetime Durability

Hybrid ceramic balls (Si3N4) and 58–62 HRC raceways extend service life to 200,000 cycles – 2× industry average for arthroscopic tools.

C. Legacy Equipment Modernization

Reverse-engineered replacements for discontinued bearings in Da Vinci Surgical Systems and GE MRI units, with 95% dimensional accuracy.

6 Reasons to Partner with INNO BEARING

1. Certified Compliance: Full documentation for FDA/CE submissions.

2. 15-Day Custom Lead Time: Modify bore sizes, seals, or gear teeth rapidly.

3. No MOQ Constraints: Order 1 prototype or 500+ production units.

4. Sterilization-Ready: Pass autoclave (135°C) and ethylene oxide tests.

5. 24/7 Technical Support: On-call engineers for emergency replacements.

6. Global Stock Hubs: 48-hour delivery to EU/NA robotics OEMs.

FAQs

Q: How do you achieve <35dB noise in medical-grade products?

A: Precision grinding (Ra 0.2μm finish) and nylon cages dampen vibration – tested per ISO 8579-2 standards.

Q: Can you match legacy bearing specs in obsolete surgical robots?

A: Yes! Share samples or blueprints for reverse engineering with 95%+ dimensional accuracy.

Q: What certifications support biocompatibility?

A: ISO 10993-5 tested materials with full traceability from melt to final assembly.

Q: Lead time for φ200mm custom bearings with gear teeth?

A: 12–15 days – 70% faster than competitors through modular production.

Contact Us

Elevate Your Medical/Robotics Equipment with Precision-Certified Bearings

📧 Email sales@inno-bearing.com for:

- Free legacy bearing analysis

- Custom design consultations

- Emergency replacement coordination

INNO BEARING – Where microscopic precision meets macroscopic reliability in small slewing bearing innovation.

Learn about our latest products and discounts through SMS or email