There are many things to think about when choosing the right slew drive bearing for robotic machines, such as how much weight it needs to hold, how precise it needs to be, and the conditions it will be working in. These built-together bearing systems add the ability to rotate to a drive function. They are an important part of any automated machinery, from AGV robots to medical PTZ systems. Engineers make good choices that guarantee robots will work well and last a long time when they understand technical specs, material qualities, and performance details.

Understanding Slew Drive Bearing Fundamentals

Today's robotic machines need precise parts that can handle complicated loads and make sure the machine turns correctly. Slew drive bearings are a new type of bearing that combines the old way of doing slewing with direct drive features. These advanced assemblies make separate motor links unnecessary, which leads to more efficient setups for automated systems.

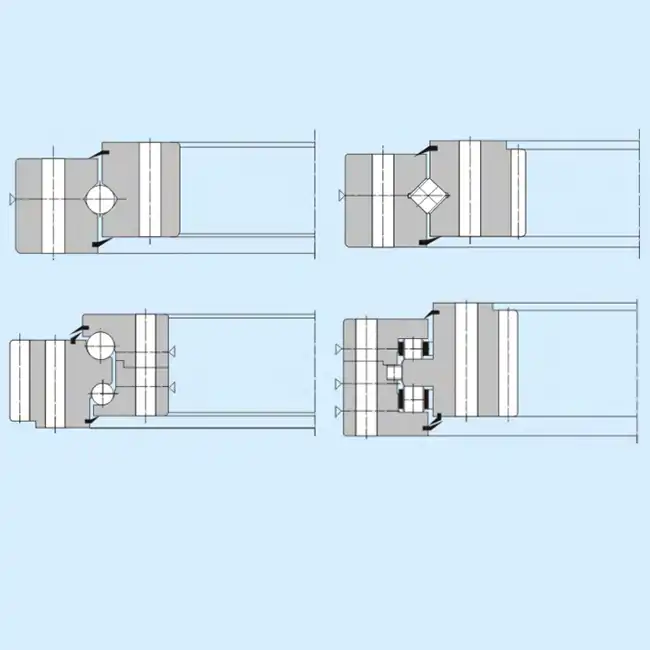

The core structure has single-row steel ball Slewing Bearings with exact drive gears inside strong bearing housings. This integration makes a straight motor connection possible, which lets the robot move its head or camera around the way it needs to. The gear system works with either the outer or inner ring. Which one it works with depends on the design needs and how much room there is.

The outer ring width is usually between 100mm and 500mm, and the height is usually between 50mm and 150mm. The output rotational speeds, which can range from 0.5 to 50 RPMs, give the controlled movement needed for precise robotic jobs. These parameters make slew drive bearing systems especially good for uses that need small designs that don't hurt performance.

Material Selection and Engineering Excellence

The choice of material has a direct effect on the performance and lifespan of slew drive bearings. Inner and outer rings use high-strength steel alloys, mostly 50Mn and 42CrMo, which were chosen because they are very durable and can hold a lot of weight. These materials are treated with special heating methods to get the best hardness grades while keeping their structure intact when stress levels change.

GCr15 steel is used most of the time for rolling elements, but GCr15SiMn can be used instead when better impact protection is needed. This choice of material makes sure that it works well and can handle the repeated loading that is common in robotic applications. The choice of materials relies on the needs of the project and the conditions in which it will be used.

Nitrile rubber or fluororubber is used in sealing systems, and the choice of material depends on how the system will be used. Fluororubber seals are great for tough industrial settings because they withstand oil and high temperatures better than other seals. Choosing the right seal keeps the bearing clean and preserves the lubrication's effectiveness during the bearing's lifetime.

Critical Performance Parameters

When choosing slew drive bearing systems for robotic machines, load ability is an important thing to think about. These bearings must be able to handle both axial and rotational loads while keeping the position exactly right. Understanding load math makes sure the right size is used and failure doesn't happen too soon because of too much weight.

The level of accuracy needed changes a lot from one robotic application to another. The amount of accuracy needed for AGV robots is different from what is needed for medical equipment or smart PTZ systems. It is important that the slew drive bearing specs match with the exact positioning tolerances needed for each case, taking into account how accurate it needs to be when it is not moving and when it is moving.

Motor choices and system design are affected by the operating speed. Most robotic uses fall within the 0.5 to 50 rpm range, but to get the best performance, speed needs should be matched to bearing capabilities. To keep precision at higher speeds, it may be necessary to improve lube systems or change gear ratios.

Temperature considerations affect material selection and lubrication choices. Different ways of managing heat are needed for different places, from controlled labs to tough industrial spaces. Proper thermal analysis makes sure that the expected temperature range will always work the same way.

Application-Specific Requirements

AGV robots make it hard to choose the right slew drive bearings. These mobile platforms need small, light tools that can move and show where they are with confidence. The bearing dimensions must fit in a small spot and still be able to turn the load so it can change direction.

For manufacturing and assembly processes, small worktables that can rotate need to be very precise and able to work smoothly. In these cases, the amount of noise made by the slew drive bearing is very important because too much shaking can lower the quality of the work. Quality control and precision machining during manufacturing make sure that the process is quiet, which is important for sensitive work settings.

Medical equipment uses have strict needs for cleanliness and reliability. Slewing devices for diagnostic tools must work all the time without the risk of getting dirty. Giving extra attention to how seals are designed and what materials are used makes sure that they can be safely used in healthcare settings and keep working correctly for long periods of time.

For tracking and surveillance uses, smart PTZ systems need to be exactly in place and move smoothly. The performance of the slew drive bearing has a direct impact on the stability of the picture and the accuracy of the tracking. For things that are installed outside and will be subject to extreme weather conditions, resistance to weather damage and long-term reliability are very important.

Quality Control and Inspection Standards

Slewing clearance measurements make sure that the bearing can rotate smoothly and that the parts fit together correctly. Too much clearance makes setting wrong, and not enough clearance makes binding and early wear happen. During manufacturing, precise gap control keeps the best performance levels.

The accuracy of gear meshing affects the noise level and efficiency of torque transfer. Precision production makes sure that the teeth of the gears are properly aligned. This makes sure that the weight is evenly spread across the surfaces of the gears. Before the final assembly, advanced checking methods check the accuracy of the meshing. This avoids early failure and guarantees smooth operation.

Noise testing finds possible problems with bearings before they get to the places where they are used. Standardized noise measurement methods find problems with bearings and make sure they meet the needs of the application. A low noise level is especially important for medical and lab work where sound levels have to be kept low.

Quality documentation lets you see where something came from and how well it works, which is important for key applications. If problems come up during operation, comprehensive testing records show that the standards are met and can help fix the problems. Each bearing comes with a detailed testing report that shows the part is reliable.

Installation and Maintenance Considerations

Proper slew drive bearing installation requires careful attention to mounting surfaces and bolt torque specifications. Surface flatness and bolt hole alignment directly affect bearing performance and lifespan. Installation procedures must follow manufacturer guidelines to ensure warranty compliance and optimal operation.

Lubrication requirements vary based on application demands and environmental conditions. Initial lubrication ensures proper break-in operation, while maintenance schedules prevent premature wear and extend bearing life. Lubrication type and quantity specifications must match operational requirements and manufacturer recommendations.

Maintenance intervals depend on operational conditions and application requirements. Regular inspection schedules identify potential issues before they cause system failures. Preventive maintenance approaches prove more cost-effective than reactive repairs, particularly for critical robotic systems.

Replacement planning considers lead times and inventory management for critical applications. Having spare bearings available minimizes downtime when maintenance or unexpected failures occur. Strategic inventory management balances carrying costs against production continuity requirements.

Cost Analysis and Value Engineering

Initial purchase price represents only one component of total ownership costs for slew drive bearing systems. Operating expenses including maintenance, energy consumption, and replacement parts significantly impact long-term economics. Value engineering approaches consider total cost of ownership rather than focusing solely on upfront expenses.

Performance specifications must balance capability requirements against cost constraints. Over-specification increases unnecessary costs, while under-specification leads to premature failure and higher total expenses. Proper specification development ensures optimal value while meeting application requirements.

Supplier selection criteria include technical capability, quality systems, and delivery performance in addition to pricing considerations. Reliable suppliers provide consistent quality and support that reduce total ownership costs through improved performance and reduced downtime.

Custom versus standard Solutions require careful economic analysis. Standard bearings offer lower costs and shorter delivery times, while custom designs provide optimized performance for specific applications. The decision depends on volume requirements, performance needs, and cost sensitivity.

Conclusion

Selecting the optimal slew drive bearing for robotic machinery requires thorough understanding of application requirements, material properties, and performance specifications. Success depends on matching bearing capabilities with specific operational demands while considering long-term maintenance and cost factors. Quality suppliers provide the technical expertise and manufacturing capabilities necessary for reliable, high-performance solutions. Proper specification, installation, and maintenance ensure maximum return on investment while supporting critical robotic operations across diverse industrial applications.

Partner with INNO Bearing for Superior Slew Drive Solutions

INNO Bearing delivers precision-engineered slew drive bearing systems backed by nearly three decades of manufacturing excellence. Our comprehensive customization capabilities and rapid delivery ensure your robotic machinery achieves optimal performance while meeting strict quality standards. As a trusted slew drive bearing manufacturer, we provide technical support throughout your project lifecycle. Ready to discuss your specific requirements? Contact Us at sales@inno-bearing.com today.

References

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007. Geneva: ISO Press, 2007.

Harris, Tedric A., and Michael N. Kotzalas. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis." 5th ed. Boca Raton: CRC Press, 2006.

Mechanical Engineering Society. "Slewing Bearing Applications in Industrial Automation." Journal of Mechanical Design 142, no. 8 (2020): 081405.

Robotics Industries Association. "Bearing Selection Guidelines for Automated Machinery." Detroit: RIA Technical Publications, 2019.

American Bearing Manufacturers Association. "Load Ratings and Fatigue Life for Ball and Roller Bearings." ABMA Standard 9-1990. Washington DC: ABMA, 2018.

Deutsche Norm. "Slewing Bearings - Dimensions, Geometric and Run-out Tolerances." DIN 628-4:2018. Berlin: Beuth Verlag, 2018.