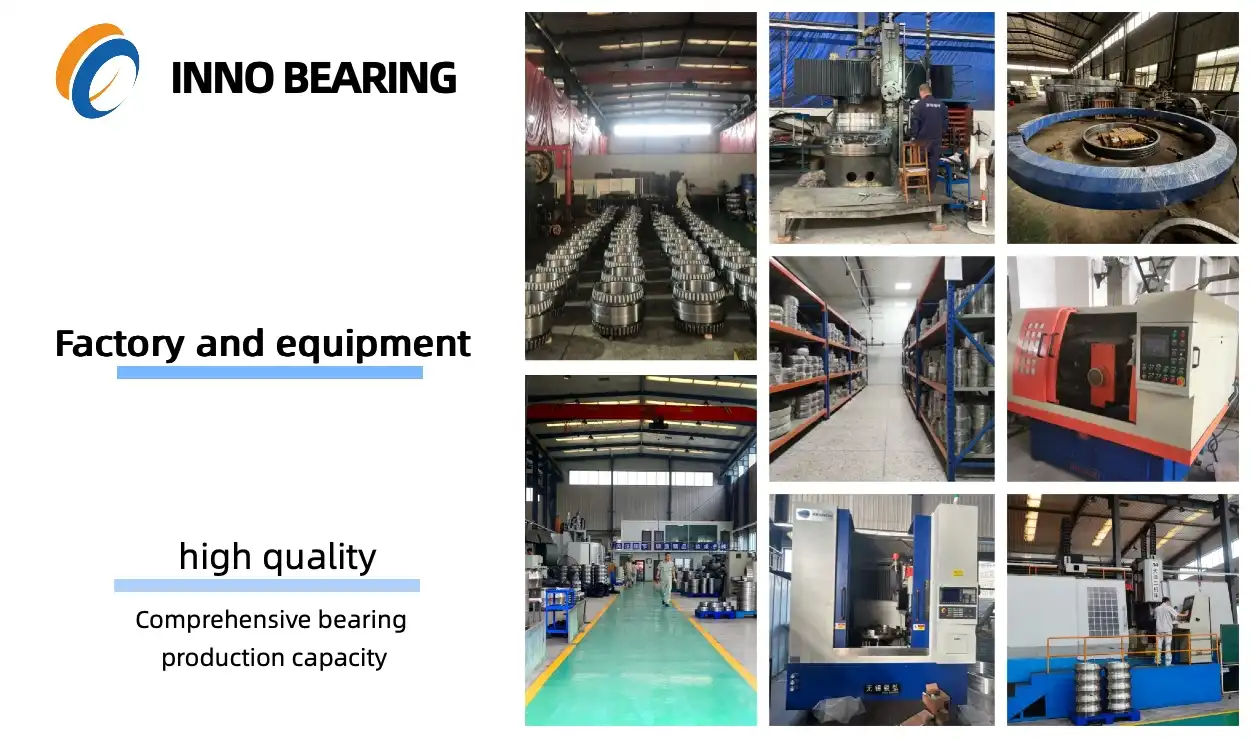

When it comes to reliable suppliers of double thrust ball bearing parts, China is the world's manufacturing giant. They offer great quality at low prices. In almost 30 years of specialized experience making big and non-standard bearings up to φ5000mm, INNO Bearing has become one of the best makers in the country. Because the company does research, development, and production all in one, it is a chosen partner for businesses that need precision-engineered axial load bearing Solutions.

The world market for bearings is still growing very quickly. This is because more people are buying them for use in wind energy, big machinery, mining, and ocean engineering. China's industrial environment has changed a lot over the years, going from simple production skills to high-level tech excellence. Because of this change, Chinese companies are now important providers for important tasks that need high-performance bearing systems.

Manufacturing Excellence: China's Competitive Edge in Thrust Ball Bearing Production

Advanced Manufacturing Infrastructure

China has spent decades investing in modern factories and tools that help its bearing manufacturing business. Chinese companies today use cutting edge CNC machine centers, automatic production lines, and precise grinding tools. This infrastructure makes it possible to consistently make high-quality bearing parts with tight specs and smooth surfaces.

Adding Industry 4.0 technologies has changed the way things are made in a big way. Smart production systems keep an eye on the performance factors of bearings in real time to make sure they are properly lubricated, have the right amount of space, and meet general quality standards. There is much less noise from bearings now that these technical improvements have made them last longer.

Material Science and Metallurgical Expertise

Chinese companies have created complex technologies for bearing materials by using high-quality steel types and advanced heat treatment methods. Careful choice of bearing cage materials and bearing seal parts guarantees the best performance in a range of working situations. These changes have a direct effect on how temperature is managed in bearings and how often they fail.

Efforts to improve bearing speed while keeping the structure's stability under high rotational load bearing situations are the major focus of research and development. Chinese producers can compete with foreign names by making their products better and more affordable thanks to ongoing progress in material science.

Strategic Supplier Selection: Essential Criteria for Choosing Double Thrust Ball Bearing Manufacturers

Technical Capabilities Assessment

To judge a manufacturer's technical ability, you need to look at their engineering skills, production capacity, and quality control systems. Leading providers show they know how to create special bearings, machine them precisely, and test them thoroughly. Professional skill is shown by being able to provide thorough technical documents and bearing care instructions.

Manufacturers should have high-tech testing tools that can check how well bearings work in settings that are similar to real-life situations. This includes checking for vibrations, trying the load, and making sure the greasing system works right. These features make sure that goods meet strict performance standards in a wide range of settings.

Industry Experience and Specialization

Manufacturers with a lot of experience in double thrust ball bearing production know how to deal with the unique problems that come up in each business application. Applications that use wind energy need to be very resistant to tiredness, while mining equipment needs to be very durable in tough environments. For marine uses, bearing seals need to be more resistant to rust and work reliably.

Top makers are different because they have specialized knowledge in designing angular contact bearings and using them in two directions. This knowledge leads to better product designs that make operations run more smoothly and need less upkeep.

Quality Management Systems

Strong quality control systems make sure that the quality of the product stays the same and that it can be tracked all the way through the production process. Leading manufacturers use a wide range of quality control methods, from checking the raw materials to testing the finished product. You can be sure that these methods will make the product reliable and work well for a long time.

International standards should be used for documentation and Process Control methods. This will make sure that everything is clear and that people are held accountable. Commitment to quality greatness is shown by regular internal checks and efforts to make things better all the time.

Customization and Engineering Support

The ability to offer unique solutions is what sets exceptional makers apart from average sellers. In complicated situations, bearing assembly setups need to be changed, bearing cage designs need to be customized, and bearing clearance requirements need to be made clear. Manufacturers that offer full tech help can come up with the best answers for unique operating needs.

As part of technical consulting services, there should be application analysis, advice on choosing bearings, and suggestions on how to improve performance. This joint method makes sure that the best products are chosen and that the implementation goes smoothly.

Supply Chain Reliability

Consistent shipping performance and clear communication throughout the supply chain are very important when choosing a provider. Reliable makers keep the right amount of goods on hand, set up strong transportation systems, and give correct delivery dates. These skills make sure that work keeps going and that projects stay on schedule.

Being close to important shipping ports and having well-established international transportation networks makes global distribution more efficient. Manufacturers that have a history of doing well in foreign markets show that their operations are mature and reliable.

Quality Certifications: International Standards and Compliance Requirements

ISO Quality Management Standards

ISO 9001 approval is a basic sign of quality management system compliance. It makes sure that processes are always the same and that practices for ongoing growth are used. For companies that make bearings, ISO/TS 16949 certification meets the needs of the car industry, and ISO 14001 certification shows a commitment to environmental management.

Leading makers often get extra licenses, like ISO 45001 for managing health and safety at work. These Certificates give you peace of mind that your operating success and risk management skills are complete.

Industry-Specific Certifications

IEC 61400 standards for a double thrust ball bearing must usually be followed for wind energy applications, while classification society approvals from groups like DNV GL or ABS are needed for naval purposes. Aerospace uses need AS9100 approval, which makes sure that strict quality control and tracking rules are followed.

For mining and heavy machinery use, certain regional standards may need to be met, like ATEX approval for use in dangerous environments or CE marking for entry to the European market. Knowing these standards helps you find makers who can meet the needs of a certain product.

Environmental and Safety Compliance

RoHS compliance makes sure that goods meet safety standards for dangerous chemicals in the environment. Following the REACH rules shows that you care about product safety and protecting the environment. As environmental laws around the world get stricter, these certificates become more important.

Material safety data sheets and environmental effect studies should be full and available from manufacturers. This paperwork shows that the company is responsible and meets the needs of the customers.

Effective Sourcing Strategies: Platforms and Channels for Bearing Procurement

B2B E-commerce Platforms

Online platforms make it easy to connect with many providers and compare their skills, qualifications, and prices. A lot of the time, these platforms have services that check the reliability of suppliers, customer reviews, and ways to keep transactions safe. But careful due diligence is still needed for important uses.

Direct maker websites have a lot of scientific information, specs for products, and background on the company. This straight access makes it easier to get a fuller picture of a company's producing skills and technical know-how.

Trade Shows and Industry Events

At international trade shows, you can meet manufacturers in person, which lets you have in-depth professional conversations and build relationships. Major events in the bearing business show off the newest technologies and advances and give people the chance to network with experts in the field.

Local companies that are better at competing in certain market areas often show up at regional trade shows. These events give people information about new tools and business trends.

Industry Associations and Networks

Professional groups keep lists of suppliers and share information about trustworthy makers with the market. A lot of the time, these groups evaluate suppliers and keep quality standards files. Being a member of a known group shows that you are committed to using the best methods in your field.

These organizations have technical panels and working groups that give members access to experts in the field and information about new technologies. This information helps people make smart choices when choosing a source.

OEM Partnership Excellence: Key Considerations for Collaborative Manufacturing

Intellectual Property Protection

Complete intellectual property deals for a double thrust ball bearing keep secret ideas and new technologies safe. These contracts should cover things like privacy, sharing technology, and having the sole right to make the product. Clear paperwork stops disagreements and protects everyone's valuable intellectual property.

Partners can trust each other more when they sign non-disclosure agreements that cover things like technology specs, manufacturing methods, and market knowledge. These legal rules make it possible for everyone to work together while protecting competitive benefits.

Design Collaboration and Engineering Support

For OEM partnerships to work, makers need to work together on the planning process and share their technical knowledge and production ideas. When people work together, they often come up with better ideas that are cheaper, work better, and are easier to make.

Regular reviews of the design and testing of prototypes make sure that goods meet quality and performance standards. During the creation process, manufacturers should give full testing results and proof data.

Production Scaling and Capacity Management

For OEM agreements to work, output ability and growth needs to be in sync. Manufacturers should show that they can increase production levels while still meeting quality standards and delivery dates. Changes in market demand can be met by manufacturing systems that are flexible.

Long-term conversations about capacity planning make sure that relationship growth will last. In these talks, people talk about what technologies will be needed in the future, how to grow the market, and how to best use resources.

Smart Procurement: MOQ and Pricing Optimization Strategies

Minimum Order Quantity Considerations

Understanding a manufacturer's MOQ standards can help you make the best decisions about what to buy and how to handle your goods. When compared to customized options, standard goods usually have lower MOQ needs. To find the right balance between stocking costs and bulk prices, you need to carefully look at how demand changes over time and how much space you have.

Most of the time, lower MOQ needs are possible with long-term deals that guarantee supply and keep prices stable. These agreements are good for everyone because they make planning easier and operations run more smoothly.

Value-Based Pricing Negotiations

When negotiating prices, it's better to focus on the total value than just the unit costs. Product quality, shipping dependability, expert help, and guarantee terms are some of the things that should be thought about. Life-cycle cost analysis often shows that expensive goods with longer bearing lives and less upkeep need are the best buys.

Payment terms and volume promises have a big effect on how prices are set. Long-term contracts and savings for early payments can help you save money and build better relationships with your suppliers.

Market Intelligence and Benchmarking

Doing regular market study gives you information about how prices compare and what the latest tech trends are. This information helps with smart tactics for negotiating and judging the performance of suppliers. Knowing how the global supply chain works helps you plan for changes in prices and the market.

Comparing different sources through benchmarking activities helps find the best ways to do things and find ways to make things better. Along with price, these evaluations look at technical skills, high performance, and service levels.

Quality Assurance: Factory Audit and Control Recommendations

Pre-Audit Preparation and Documentation Review

A full factory audit starts with a careful look at all the paperwork, like quality guides, process methods, and certification records. This first look finds possible problems and places that need more attention during the audit. Standardized audit forms make sure that all providers are evaluated using the same criteria.

Checking a supplier's financial health and business survival planning can help you figure out how reliable they are and how long they will be around. These ratings help with risk management and choosing which suppliers to work with.

Production Process Evaluation

On-site checks for a double thrust ball bearing should look at how the products are made, how well the equipment works, and the quality control methods. Seeing real production activities can help you figure out how consistent the process is and how skilled the operators are. The way materials are handled and stored affects the quality of the result, so these factors should be carefully considered.

Calibration records for testing tools and study of measurement systems show a dedication to precision and accuracy. These methods make sure that the design standards for deep groove bearings and other important factors are met.

Supplier Development and Continuous Improvement

For partner relationships to work well, they need to be constantly developing and improving. Reviewing performance on a regular basis helps find ways to improve and solve quality issues. Improvement projects that involve more than one person often have big benefits for all involved.

Training programs and efforts to share technology make suppliers better at what they do and make relationships stronger. These efforts in developing suppliers give businesses a competitive edge and make the supply chain more stable.

Industry Leadership: Characteristics of Premier Bearing Suppliers in 2026

Technological Innovation and Digital Transformation

It is common for top makers to use digital technologies like IoT devices, AI, and predictive analytics. These technologies make it possible to track the performance of bearings in real time and plan ahead for repair. Digital twin technologies make it easier to try and improve things virtually before they are made in real life.

Advanced modeling tools help with the creation of new products and the study of how they are used. With these tools, you can improve the general performance, bearing clearance, and lubricant systems while cutting down on development time and costs.

Sustainability and Environmental Responsibility

As the need for world survival grows, caring for the environment becomes more and more important. Leading producers have complete environmental management systems that deal with things like recycling, reducing trash, and using less energy. Most of the time, these projects cut costs while still meeting the green goals of the customers.

Using green energy, saving water, and starting programs to cut down on emissions are all examples of sustainable production practices. Life-cycle studies help people understand how their purchases will affect the world and help them make smart buying decisions.

Global Service Networks and Technical Support

International service networks let you get professional help locally and respond quickly. These networks make it possible for effective emergency repair services and help for bearing care. Regional service centers make customers happier while cutting down on reaction times and transportation costs.

Full expert training programs make sure that service standard is the same everywhere in the world. Digital help systems give users access to technology resources and expert advice 24 hours a day, seven days a week.

Conclusion

To find the best double thrust ball bearing maker in China, you need to look at their professional skills, quality processes, and customer service. The Chinese bearing business has changed a lot over the years, now making world-class goods and giving them an edge in many market areas. To be successful, you need to carefully evaluate suppliers, make sure that your needs are understood, and work together with them to reach your long-term goals.

INNO Bearing is a great example of how quality, creativity, and customer service can work together to make a business great. They are the best at what they do because they have been in business for almost 30 years and specialize in large-scale bearing solutions. They are dedicated to always getting better and making sure their customers are happy, which makes them a great partner for tough uses in many different fields.

FAQs

How do I choose a double thrust ball bearing maker in China? What should I look for?

Pay attention to the company's technical skills, quality certifications (ISO 9001 or industry-specific standards), output capacity, ability to make changes, and track record in the application area you're looking for. Check their testing tools, technical help, and supply chain dependability to make sure they can meet your long-term needs.

How can I be sure that Chinese bearing makers meet quality standards?

Ask for all the paperwork you can get, like test results, quality licenses, and process control methods. Do workplace surveys to look at how things are made and how quality control is handled. To make sure that performance claims are true, look at customer references and case studies from related apps.

What is the smallest amount of unique double thrust ball bearings that I can order?

MOQs change a lot depending on how complicated the design is and how much the maker can do. Standard changes may need 50 to 100 units, while fully customized designs usually need at least 200 to 500 units. You could lower the MOQ standards and get better prices by talking about long-term deals.

Partner with INNO Bearing for Superior Double Thrust Ball Bearing Solutions

INNO Bearing is ready to be your reliable double thrust ball bearing maker in China. They have years of experience and the most up-to-date technology. We have a lot of experience making big and non-standard bearings, and we have strict quality control methods in place to make sure they work perfectly in your important uses. Our engineering team is here to help you with any technical questions you have throughout the whole process, whether you need standard goods or completely unique solutions. See what a difference skilled knowledge and committed service can make. Email us at sales@inno-bearing.com to talk about your unique needs and find out how we can help your business succeed.

References

International Organization for Standardization. "Quality Management Systems - Requirements for Automotive Production and Service." ISO/TS 16949:2016.

American Bearing Manufacturers Association. "Bearing Industry Standards and Best Practices Manual." 2024 Edition.

Chinese Mechanical Engineering Society. "Technical Guidelines for Large Diameter Bearing Manufacturing." Beijing: Mechanical Industry Press, 2023.

Wind Power Engineering & Development. "Bearing Technologies for Next-Generation Wind Turbines." Annual Technical Review, 2024.

International Electrotechnical Commission. "Wind Energy Generation Systems - Design Requirements." IEC 61400-1:2019.

Society of Tribologists and Lubrication Engineers. "Bearing Lubrication and Maintenance Guidelines for Industrial Applications." STLE Technical Paper, 2024.