Proper cleaning is essential for slewing ring bearings to last a long time. This has a direct effect on how well they work and how much it costs to maintain them in industrial settings. Effective cleaning methods can increase the life of bearings by up to 300%, which cuts down on repairs and replacement costs by a large amount. This complete guide talks about important lube methods that engineering leaders, maintenance engineers, and quality assurance teams must use for wind turbines, heavy machinery, and naval uses to work at their best.

Understanding Slewing Bearing Lubrication Fundamentals

Lubrication does a lot more important things than just reduce friction. The grease creates a protected layer between the raceways and the rolling elements. This keeps the metals from touching, which would otherwise cause them to wear out faster. This shield protects and stops rust at the same time, which is especially important for machinery in ports and remote settings where salt air can damage bearings.

Controlling the temperature is another important role. Large diameter bearings get very hot when they're working, especially when they're under heavy loads like they are in mine tools and tunnel boring machines. Good lubricants get rid of this heat well, keeping the machine running at the best temperature to protect the metal qualities of the bearing steel parts.

In tough settings, keeping contaminants out becomes very important. When greasing is done right, it forms a cushion that keeps rough particles, water, and chemical contaminants from getting into bearing surfaces. This safety is very important for wind turbine bearings that are open to the weather and for mine uses where dust is always a threat.

Selecting Optimal Lubricants for Different Applications

The choice of grease varies a lot on the factors of the job and the surroundings. Because they are very stable and don't get wet easily, lithium complex greases are perfect for use on naval cranes and offshore drilling platforms. These mixtures stay the same over a wide range of temperatures and offer better protection against rust.

Polyurea-based lubricants work great in places with high temperatures, like rotating kilns and tools used in metalworking. Their high resistance to rust and heat stability let them work continuously at high temperatures without breaking down much. The longer relubrication times cut down on the amount of upkeep that needs to be done in places that are hard to get to.

For wind turbines, you often need special oils that work better at low temperatures. Even at temperatures below zero, these formulas can still be pumped and have the right thickness for film formation. Because green energy systems are exposed to weather and changing loads all the time, anti-wear chemicals become very important.

Synthetic lubricants work better in aircraft and defense uses where precise tracking systems need to work reliably in a wide range of temperatures. Because their molecules are all the same, their viscosity properties can be predicted, which is important for radar positioning systems and equipment that tracks satellites.

Lubrication System Design and Implementation

For large-scale activities with a slew ring bearing, centralized lube devices are very helpful. These controlled systems give exact amounts of lube at set times, making sure that all of the bearing points are covered consistently. Because the pouring is managed, neither too little nor too much grease is applied, which can attract dirt and other particles.

Placement of grease fittings needs careful thought about how easy they are to get to and how likely they are to get contaminated. Maintenance crews can re-grease equipment without taking it apart, and they can do this while limiting their exposure to outdoor pollution. In tough industrial settings, protective caps and extension joints are useful.

Progressive distributors make sure that the oil is spread evenly across many grease spots. This technology is especially useful for excavators with multiple spinning bearings that need to be oiled at the same time. The graphic signs give you instant information about how the system is working and about any possible problems.

Monitoring systems use pressure monitors and flow meters to keep track of how well the greasing is working. In more advanced systems, temperature sensors are used to add extra cleaning rounds during times of high load. These smart systems make the best use of oil while keeping the thickness of the protection film.

Relubrication Intervals and Best Practices

How often you need to relubricate relies on a number of things, such as the load, the working speed, and the surroundings. Heavy-duty mining uses usually need to be oiled more often because of the high loads and risk of leakage. On the other hand, because they work in controlled settings and with less stress, precision aircraft systems may be able to run for longer periods of time.

Calculations based on load give correct relubrication timing. The best intervals are found by combining the bearing size, the loads that are being applied, and the frequency of spin. To make sure there is enough safety during tough operations, engineering teams should think about high loading situations instead of normal loads.

Lubrication needs are greatly affected by environmental factors. Marine settings with a lot of humidity make lubricants break down faster and need to be changed more often. Extreme changes in weather can also make lubricants less stable, so plans need to be changed when the seasons change.

Grease cleaning keeps dirt and grime from building up inside bearing systems. In this process, new oil is put on until the old grease drains out of the release holes. When you purge properly, you get rid of any built-up contaminants and replace any protection additives that may have been used up during service.

Contamination Prevention and Seal Maintenance

Integrity of the seal has a direct effect on how well the grease works and how long the bearing lasts. Wear patterns, cracks, or movement that weaken security can be found through regular checking. Replacing seals quickly stops pollution from getting in, which quickly breaks down oil qualities and speeds up bearing wear.

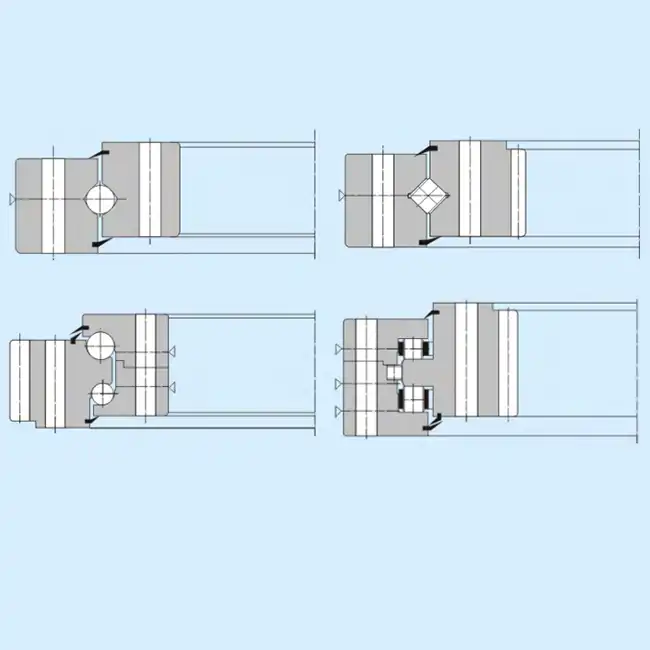

Labyrinth seals for a slewing ring bearing are great at keeping out contaminants without making touch that causes friction. These designs work especially well for heavy-load, slow-speed tasks that are common in port gear and industry equipment. The multiple stages make winding tracks that stop particles from getting through.

Contact seals protect better against small particles and water getting in. As wear happens, lip covers with spring energizers keep the contact pressure constant. Choosing the right seal materials is important to make sure they can handle the temperatures and chemicals that are used in each application.

Positive pressure devices push air outward, which stops pollution from getting in. Using dry air or nitrogen to pressurize keeps the inside clean while still letting heat expand. In precise situations where there isn't much room for error, this method works well.

Monitoring and Diagnostic Techniques

Vibration research finds worn-out bearings before they fail in a big way. Specialized tools check for frequency patterns that show problems like damaged raceways, broken rolling elements, or not enough oil being used. Trending research finds small changes that point to the need for upkeep.

Thermography can find strange changes in temperature that are linked to greasing issues. High temps can be easily seen by infrared cameras when there isn't enough lubrication. On the other hand, too much grease leads to spinning losses that show up as heat traces. Regular temperature scans let you plan repair ahead of time.

Lubricant analysis shows the amount of pollution, the loss of additives, and the breakdown products. A lab test measures the amount of water, particles, and acid that are formed to show what needs to be replaced. By plotting these factors over time, condition-based lubricant instead of time-based plans can be used.

Ultrasonic tracking picks up high-frequency sounds that are linked to bearing problems. Acoustic leaks are made when there isn't enough grease, which forms unique fingerprints. Portable tools make it easy to quickly evaluate things during regular checks.

Industry-Specific Lubrication Strategies

Wind energy uses have their own problems, such as changing loads, bad weather, and limited access. When turbine pitch bearings are constantly rotating, the grease is moved away from areas that are under a lot of stress. Specialized greases with better binding qualities can stand up to rotating forces that could starve important areas.

When mining with a slew ring bearing, lubricants need to be able to handle high pressure loads and pollution. Stackers and reclaimers work in dusty places where rough bits speed up wear. High-performance chemicals make the film stronger, and high pressure formulas keep it safe from being loaded suddenly.

Marine uses need better resistance to rust and the ability to move water. Offshore cranes and people who load ships are exposed to salt spray, which damages bearing surfaces. Marine-grade oils have agents that stop rust and move water around so that they keep protecting in tough conditions.

Aerospace standards stress stability and dependability over a wide range of temperatures. Satellite tracking systems need lubricants that can work in both cold places like the arctic and hot places like the desert. Formulations that are "space-qualified" go through a lot of tests to make sure they work well in important situations.

Troubleshooting Common Lubrication Problems

When base oils separate from binder systems, they leave behind hard residues that make it hard for bearings to turn. This is called grease hardening. This situation is usually caused by chemicals or temperatures that are too high. Completely removing the grease and applying it again restores the proper greasing. Getting to the root causes of the problem stops it from happening again.

When there isn't enough lubricant, working temperatures and tremor levels rise. This happens when there isn't enough, when delivery lines are stopped, or when there are too many cleaning times. Re-greasing right away stops damage from becoming permanent while a system check finds the root causes.

Too much oil leads to high running temperatures and damage to the seals from too much internal pressure. Churning losses lower effectiveness, and the grease that is released into the air brings in dirt and other pollutants. With the right amount estimates and controlled application, this useless and possibly harmful situation can be avoided.

Adding water to a grease quickly breaks down its qualities and makes rust more likely. This ongoing issue can be fixed by regularly checking the seals, keeping the drainage system in good shape, and using methods to keep water out. Water-displacing additives offer short-term security while long-term options get rid of sources of contamination.

Conclusion

When you handle grease well, you can change the performance of slewing ring bearings from reactive maintenance to proactive asset optimization. Choosing the right oil, applying it in a planned way, and keeping an eye on it all the time can increase the life of bearings and lower their total purchase costs. Comprehensive lubrication programs pay for themselves by increasing downtime, lowering the cost of replacements, and making operations more reliable. When engineering teams use these tactics, their operations are set up to stay ahead of the competition because their equipment works better and repair problems happen less often.

Partner with INNO Bearing for Expert Lubrication Solutions

INNO Bearing has been making bearings for 30 years and offers full professional support to help you get the most out of your slewing ring bearing. Based on your specific working needs and the factors in the surroundings, our engineering team makes lube suggestions that are just right for you. Get in touch with us at sales@inno-bearing.com to talk about your slewing ring bearing supply needs, whether you need high-performance bearings for wind turbines or custom options for naval use.

References

Harris, T.A. & Kotzalas, M.N. (2019). "Essential Concepts of Bearing Technology: Lubrication and Performance Optimization." CRC Press, Fifth Edition.

Budinski, K.G. (2018). "Tribology in Heavy Industry: Advanced Lubrication Strategies for Large Diameter Bearings." ASME Press.

International Organization for Standardization (2020). "ISO 281:2020 Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO Publications.

Johnson, R.P. & Williams, M.T. (2021). "Wind Turbine Bearing Lubrication: Best Practices for Extended Service Life." Renewable Energy Engineering Quarterly, Vol. 15, No. 3.

National Lubricating Grease Institute (2019). "NLGI Guide to Bearing Grease Selection and Application." NLGI Technical Publication.

Peterson, A.L. & Chang, S.K. (2020). "Marine Bearing Lubrication: Corrosion Protection and Performance Enhancement." Marine Technology Society Journal, Vol. 54, Issue 2.