Conical roller bearings are very important parts of many different industries that handle both radial and axial loads. Because of their special design that allows for great load spread, these tapered roller assemblies are very important in aerospace systems, mining equipment, heavy machinery, and wind turbines. People who buy things and come up with good ways to keep them working should know how things usually go wrong. This all-inclusive guide talks about the most common bearing issues that happen in factories. It offers useful advice that lowers working downtime while extending the service life of equipment.

Identifying Common Problems in Conical Roller Bearings

Industrial processes often run into certain failure patterns that hurt the performance of bearings and put the reliability of the equipment at risk. Understanding these problems allows people to plan ahead for repair and make smart decisions about what to buy.

Surface Wear and Material Degradation

Surface wear is the slow loss of material from raceway surfaces and roller elements. This usually happens because there isn't enough lubrication or because something gets mixed in and contaminates the surface. This damage looks like cutting, pitting, or general roughness on the surface. It makes things vibrate more and lowers the amount of weight that can be carried. In mines, abrasive particles get through sealing systems, speeding up wear and greatly shortening bearing life.

Spalling and Fatigue Damage

Spalling leads to the flake-like patterns of damage that happen when cracks below the surface reach areas that are able to support weight. This happens when cyclic loading goes beyond the material fatigue limits. This is common in wind turbines where variable loads cause stress concentrations on the main shaft. Heavy machines that are always under high loads break down in similar ways due to fatigue, which can be seen in changed patterns of noise and shaking.

Corrosion and Environmental Damage

Moisture and chemicals eat away at bearing materials, which makes them weaker and stops things from working smoothly. Offshore sites face very harsh conditions where salt spray gets through protective barriers and causes quick damage. Changes in temperature make rust worse and cause thermal expansion mismatches between bearing parts.

Diagnosing and Analyzing the Causes of Bearing Problems

To solve problems the right way, you need to find the root causes and not just the symptoms. This can be done by using a systematic diagnostic method. Today's ways of tracking condition give us useful information about the health of bearings and how their performance changes over time.

Advanced Monitoring Techniques

Vibration analysis can show the state of a bearing by looking at the frequency spectrum. This can find defects in the early stages before a huge failure happens. Thermal imaging can find temperature differences that show either lubrication problems or too much weight on the machine. Oil analysis programs keep an eye on the amounts of contaminants and wear particles in lubricants. These programs are maintenance tools that help predict and extend the life of conical roller bearings.

Load Analysis and Specification Review

Proper load analysis makes sure that the right bearings are used for the job. This stops them from failing too early because of too much weight. When doing dynamic load calculations, you can't just think about the average loads. You also need to think about the conditions when the process is at its peak. Looking at the real operating conditions and the manufacturer's specifications side by side can show possible application mistakes that cause bearing problems.

Installation and Alignment Assessment

Misalignment is one of the most common causes of early bearing failure. It makes the load distribution uneven and speeds up the rate of wear. Within acceptable ranges, precision measurement tools check shaft alignment, and correct fitting methods stop damage during assembly. Training programs make sure that technicians know how to fix things correctly and use the right tools.

Proven Solutions to Conical Roller Bearing Problems

Using broad Solutions takes care of current issues while also setting up preventive steps that make long-term reliability better. These tactics include how to install things, how to manage lubrication, and how to upgrade parts.

Installation Best Practices

Proper fitting keeps parts from getting damaged during assembly and makes sure that the bearing works well throughout its lifetime. Temperature-controlled fitting methods stop thermal damage to bearing materials, and clean handling techniques get rid of contamination risks. Specialized tools apply installation forces evenly, which stops stress from building up in certain areas and creating places of failure.

Lubrication Strategy Optimization

Choosing the right lubricants for the right working conditions greatly extends the life of bearings and makes upkeep less necessary. In harsh conditions, high-temperature synthetic greases keep viscosity stable, and oil drainage systems make sure that contamination is always removed. Automated lubrication systems make sure that the right amount is applied at regular times and remove the chance of people making mistakes.

Sealing System Enhancements

Advanced sealing technologies keep fluids in place and stop things that could cause contamination from getting in. Labyrinth seals make very complicated tracks that keep particles out without causing too much drag. Contact seals, on the other hand, are solid barriers that protect against moisture and debris. Choosing the right seal balances how much safety you need with how quickly and easily you need things to work.

Comparison of Solutions and Supplier Strategies

Evaluating supplier capabilities requires a comprehensive assessment of technical competencies, quality systems, and service support. Different manufacturers offer varying approaches to bearing design and manufacturing excellence.

Quality Certification Standards

Leading suppliers maintain multiple certifications, including ISO 9001 quality management systems and industry-specific standards like IATF 16949 for automotive applications. These certifications demonstrate commitment to consistent quality while providing audit trails for procurement verification. Third-party testing validates performance claims and ensures products meet published specifications.

Customization Capabilities

Advanced manufacturing capabilities enable custom conical roller bearing solutions for unique applications requiring non-standard dimensions or materials. Finite element analysis supports design optimization for specific load conditions, while rapid prototyping validates concepts before full production. Flexible manufacturing systems accommodate both high-volume standard products and specialized custom designs.

Technical Support Services

Comprehensive technical support includes application engineering assistance, failure analysis services, and training programs. Field service capabilities provide on-site installation support and troubleshooting expertise, reducing downtime risks during critical maintenance operations. Global service networks ensure consistent support regardless of installation location.

Preventive Measures and Long-Term Reliability Enhancement

Establishing robust preventive maintenance programs creates sustainable reliability improvements while reducing total cost of ownership. These initiatives combine proactive monitoring with systematic maintenance practices.

Environmental Control Systems

Controlling operating environments reduces bearing stress factors and extends service intervals. Filtration systems remove airborne contaminants while climate control maintains stable temperature and humidity conditions. Protective enclosures shield bearings from harsh environmental exposure in outdoor installations.

Predictive Maintenance Integration

Smart sensor technologies enable continuous condition monitoring that predicts maintenance needs before problems develop. Data analytics platforms process monitoring information to identify trends and optimize maintenance schedules. Machine learning algorithms improve prediction accuracy by analyzing historical failure patterns and operating conditions.

Training and Knowledge Management

Comprehensive training programs ensure maintenance personnel understand proper procedures and recognize early warning signs of bearing distress. Documentation systems capture institutional knowledge while providing reference materials for troubleshooting activities. Continuous improvement processes incorporate lessons learned from failure analysis into updated procedures.

INNO Bearing: Your Trusted Conical Roller Bearing Manufacturer

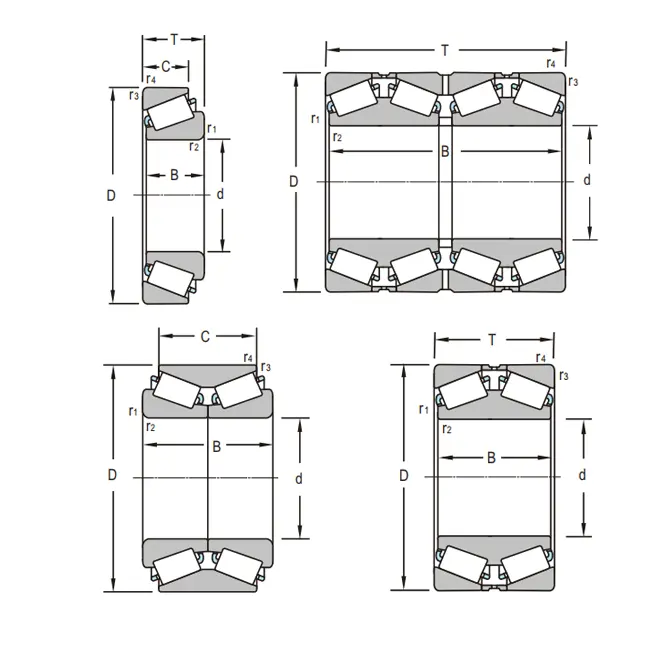

INNO Bearing specializes in manufacturing high-performance Tapered Roller Bearings designed for demanding industrial applications. Our comprehensive product portfolio includes both single-row and double-row configurations capable of handling combined radial and axial loads effectively. With inner diameters ranging from 10mm to 5000mm and precision levels from P0/P6 standard to P5/P4 ultra-precision, we serve diverse industries including wind energy, heavy machinery, mining, and aerospace applications.

Our advanced manufacturing processes utilize premium steel grades including GCr15, GCr15SiMn, and 20Cr2Ni4A materials, ensuring exceptional durability under extreme operating conditions. Precision grinding technology achieves tolerances within 0.002mm for critical applications, while our quality assurance programs maintain 99.9% defect-free rates across all production metrics. Custom bearing solutions accommodate unique requirements up to φ5000mm diameter, with specialized coatings and treatments for harsh environmental applications.

Technical support services include application engineering assistance, failure analysis capabilities, and comprehensive documentation packages. Our global distribution network provides rapid delivery with emergency replacement options available within 72 hours for critical applications. ISO 9001 certification and industry-specific compliance ensure consistent quality standards across all product lines.

Conclusion

Understanding common issues with conical roller bearings and applying well-known fixes greatly increases the dependability of your gear and lowers the cost of running it. Systematic diagnostic methods find the root causes of problems so that tailored fixes can be used to correct certain ways that things can go wrong. Preventive maintenance strategies that include correct installation, lubrication management, and environmental controls greatly increase the life of bearings. Choosing suppliers with a lot of technical support experience guarantees that you get quality goods and professional help throughout the life of the equipment.

FAQs

What distinguishes conical roller bearings from other bearing types in heavy load applications?

Conical roller bearings feature tapered geometry that optimizes load distribution between radial and axial forces, making them superior for applications with combined loading conditions. The line contact between rollers and raceways provides higher load capacity compared to ball bearings, while the separable design facilitates installation and maintenance in large machinery applications.

How can I determine the appropriate lubrication interval for bearings in extreme environments?

Lubrication intervals depend on operating temperature, load conditions, speed, and environmental factors. Generally, high-temperature applications require more frequent relubrication, while contaminated environments may necessitate shorter intervals. Condition monitoring through oil analysis and vibration measurement provides data-driven guidance for optimizing lubrication schedules based on actual bearing condition rather than fixed time intervals.

What are the key indicators that suggest bearing replacement rather than continued maintenance?

Critical indicators include visible spalling or cracking on bearing surfaces, excessive radial or axial play, persistent noise or vibration despite proper lubrication, and contamination damage that compromises structural integrity. When repair costs approach replacement costs or when safety concerns arise from potential catastrophic failure, replacement becomes the prudent choice.

Partner with INNO Bearing for Superior Bearing Solutions

Maximize your equipment reliability with INNO Bearing's precision-engineered tapered roller bearings designed for the most demanding industrial applications. Our three decades of manufacturing excellence delivers custom solutions up to φ5000mm diameter, backed by comprehensive technical support and global service capabilities. Whether you require standard configurations or specialized designs for unique operating conditions, our expert engineering team provides application-specific recommendations that optimize performance and extend service life. Contact Us at sales@inno-bearing.com to discuss your requirements with our conical roller bearing supplier specialists and discover how our proven solutions can enhance your operational success.

References

Harris, T.A. & Kotzalas, M.N. (2020). "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press.

Sadeghi, F. et al. (2019). "A Review of Rolling Contact Fatigue." Journal of Tribology, American Society of Mechanical Engineers.

Poplawski, J.V. & Peters, S.M. (2018). "Bearing System Analysis: Failure Modes and Preventive Maintenance Strategies." Tribology International.

ISO 281:2017. "Rolling bearings - Dynamic load ratings and rating life." International Organization for Standardization.

Tallian, T.E. (2021). "Failure Atlas for Hertz Contact Machine Elements." American Society of Mechanical Engineers Press.

Bredthauer, H. & Fischer, U. (2019). "Industrial Bearing Technology: Design, Performance, and Maintenance." Springer Engineering Publications.