- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

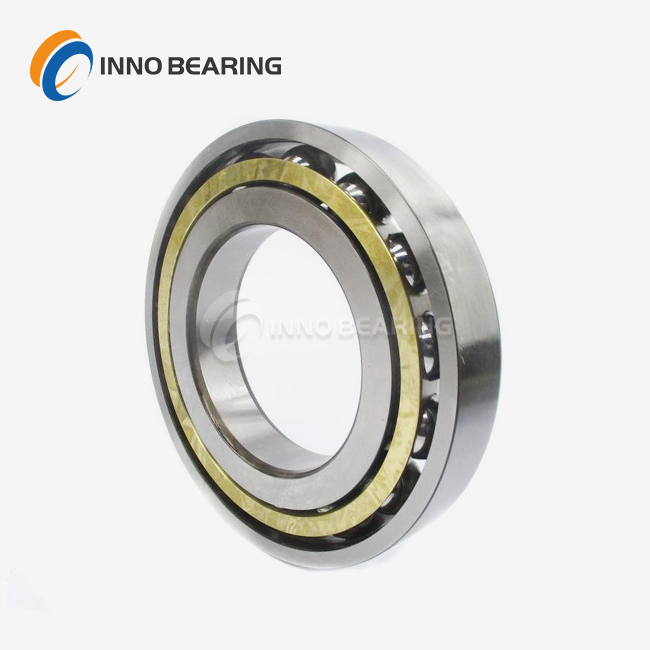

Tapered Rolling Bearings: Features, Benefits, Applications

Tapered rolling bearings are important parts in many industrial settings because they can hold both horizontal and axial loads very well. There are curved rollers between the inner and outer rings of these bearings, which makes them very useful. They can handle big loads and stay in precise line. Tapered Roller Bearings are great for situations where you need a high load capacity, better economy, and a longer service life. They can handle both rotational and push loads at the same time. Bearings are an important part of many types of machinery and equipment, from car engines to heavy machinery and accurate instruments. They make sure that everything works smoothly and reliably.

Tapered Rolling Bearings: Design and Functionality

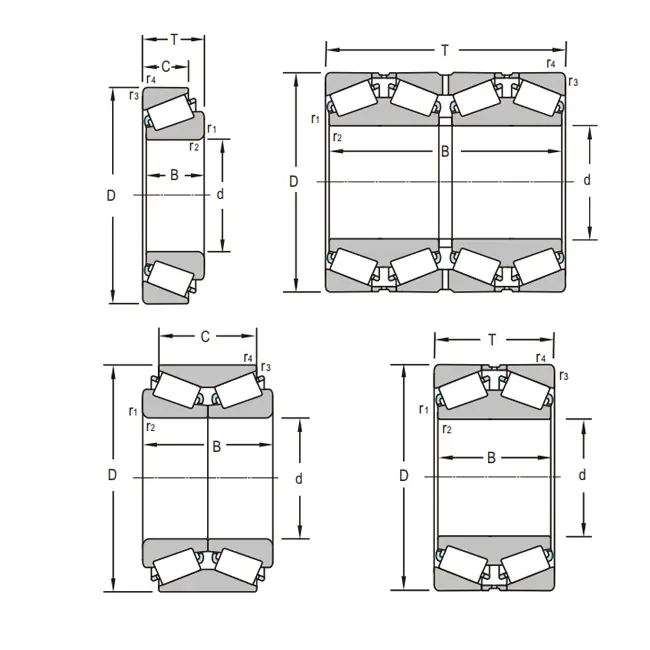

Structural Components of Tapered Rolling Bearings

There are several important parts that make up tapered rolling bearings that all work together to give the best performance. The most important parts are:

- Inner ring (cone): Features a tapered raceway to guide the rollers

- Outer ring (cup): Has a corresponding tapered raceway

- Tapered rollers: Precision-engineered elements that facilitate rolling motion

- Cage: Maintains proper spacing between rollers

Because of the way these parts are shaped, the load is spread out evenly and there is less slippage during operation. Because it is curved, the bearing can effectively handle both horizontal and axial loads, which means it can be used in many situations.

Operating Principles and Load Distribution

Tapered roller bearings work on the idea of rolling contact between rollers and raceways. As the bearing spins, the tapered rollers travel through the raceways, distributing loads between the inner and outer rings. The taper angle determines the bearing's load-carrying capacity and efficiency.

The geometry of tapered roller bearings optimizes the load distribution.

- Radial loads are dispersed throughout the length of the rollers.

- The tapered surfaces handle axial stresses, creating a wedging movement.

- Combined loads are successfully managed by the interplay of radial and axial forces

This excellent load distribution increases the bearing's capacity to sustain large loads while preserving accuracy and decreasing wear.

Types and Variations of Tapered Rolling Bearings

There are different shapes and sizes of tapered rolling bearings to meet the needs of different applications:

- Single-row tapered roller bearings: Most common type, suitable for moderate radial and axial loads

- Double-row tapered roller bearings: Offer increased load capacity and rigidity

- Four-row tapered roller bearings: Designed for extremely heavy loads in industrial applications

- Matched pair assemblies: Pre-adjusted sets for precise shaft positioning

In addition, tapered roller bearings can be made to have special traits like

- Designs that are sealed for dirty places

- Materials that can handle high temperatures for harsh working situations

- Precision-grade bearings for uses that need to be very accurate

Because of these differences, engineers can pick the best tapered roller bearing for each application, ensuring the best performance and durability.

Benefits and Advantages of Tapered Rolling Bearings

High Load Capacity and Durability

Tapered rolling bearings are great at carrying big loads, which is why they are essential for heavy-duty uses. Their special design lets them:

- Support horizontal and axial loads better, and some types can handle dynamic loads of more than 500kN

- Stress is spread evenly across the moving parts, which cuts down on wear and extends the life of the bearing.

- Better stiffness and stability, especially in two- and four-row arrangements

More improved materials and heat processes have made tapered roller bearings last longer. When vacuum degassing is done on high-purity steels like GCr15 and GCr15SiMn, they can become up to 20% more resistant to wear. This high level of longevity means that less upkeep is needed, and the total cost of ownership is lower for people who use the tools.

Precision and Reduced Friction

Tapered rolling bearings are very accurate, which makes them good for uses where accuracy is very important. Some important benefits of precision are:

- It is possible to achieve precision grades of P4/P5 (ISO 492), which makes it perfect for medical tools and high-precision machines;

- Surface finishes that are very smooth (Ra ≤0.1μm) and reduce friction and heat production

- Designs that can be changed while keeping measurements within ±0.001mm, even for non-standard sizes

Because tapered roller bearings have less friction, they use less energy and run at lower temperatures. This is especially helpful in situations like car gears, where speed and fuel economy are very important.

Versatility and Adaptability

One of the best things about tapered rolling bearings is that they can be used in a lot of different businesses and situations. These things show how adaptable they are:

- A lot of sizes: Inner sizes range from 10 mm to 1000 mm, and outer widths reach up to 2000 mm, so they can meet the needs of a wide range of machines.

- Resistance to heat: special materials like M50 steel or ceramic hybrids can work in temperatures as high as 500°C.

- Customization options: Fast development of non-standard designs, and 30% shorter production wait times than the norm in the industry

Because they are so flexible, tapered roller bearings can be used in a wide range of situations, from small parts for cars to huge machines in factories. Engineers in a wide range of fields choose them because they can handle a wide range of load conditions, speeds, and weather factors.

Applications and Industry Use Cases

Automotive and Transportation

Tapered rolling bearings are very important in the automotive and transportation sectors because they help vehicles work better, use less fuel, and be safer. Some important uses are:

- Wheel hubs: They hold up radial and axial stresses while letting the wheels turn smoothly.

- Transmissions: Making sure that the gears in manual and automated gearboxes are lined up correctly and that the load is evenly distributed

- Differentials: Making it easier for power to move smoothly between drive shafts

- Steering systems: Giving steering columns and connections support with less friction

- Tapered roller bearings provide a number of benefits in these situations:

- Better load capacity for larger trucks and a bigger payload

- Better fuel economy because to less friction and more accurate alignment

- Longer service life; certain sealed designs may survive more than 50,000 hours in dirty settings

- Works with new lubricants and sealing technologies for the best performance

Heavy Machinery and Construction Equipment

Tapered rolling bearings are very strong and can handle a lot of weight, which makes them necessary for heavy machinery and construction equipment. Some such uses are:

- Excavators and bulldozers: boom arms, buckets, and tracks that help them work

- Cranes: Making it easier for lifting mechanisms and stabilizers to turn smoothly

- Mining equipment: Crushers and conveyors can handle heavy loads and tough conditions.

- Agricultural machinery: Making sure that planting and harvesting equipment works reliably

In these tough situations, tapered roller bearings offer:

- Great durability; some bearings can hold loads of up to 80 tons.

- Advanced sealing technologies make it hard for dirt and other things to get in.

- Able to work in very hot and very humid situations

- Easy to maintain and replace, which cuts down on equipment downtime

Industrial Machinery and Precision Equipment

Tapered rolling bearings are used a lot in several industrial and precise applications, such as:

- Machine tools: Giving lathes, milling machines, and grinding machines accurate spindle support

- Steel mills: able to handle heavy loads and high temperatures in rolling mill stands

- Wind turbines: Making sure that the primary shafts and gears work smoothly

- Medical imaging equipment: CT and MRI scanners that rotate with less noise and good accuracy

Some of the advantages of tapered roller bearings in these situations are:

- Very precise; certain bearings may make noise levels below 35dB for delicate equipment.

- Very rigid and able to hold a lot of weight, which makes machining more accurate.

- Designs that can be changed to fit the needs of different industries, such electromagnetic interference. Bearings without oil for medical devices

- Long-term dependability, which cuts down on the need for maintenance and makes equipment work better overall

Conclusion

Tapered rolling bearings are strong and flexible parts that are needed in many industry settings. Because of their special design, they can handle radial and rotational loads better than other bearings. This makes them essential in the automobile, heavy machinery, and precision equipment industries. These bearings make machines work better, last longer, and be more efficient by having features like being able to handle heavy loads, reducing friction, and being able to adapt to harsh circumstances. Tapered roller bearings will definitely be very important in making technology better and meeting the strict needs of modern engineering uses as industries continue to change.

FAQs

What is the main advantage of tapered rolling bearings?

Tapered rolling bearings excel in handling combined radial and axial loads, offering high load capacity and precision in various applications.

How do tapered roller bearings differ from other bearing types?

They feature tapered rollers and raceways, allowing for better load distribution and the ability to handle both radial and thrust loads simultaneously.

What industries commonly use tapered roller bearings?

These bearings are widely used in automotive, heavy machinery, construction equipment, and precision industrial applications.

Can tapered rolling bearings operate in extreme conditions?

Yes, specialized designs can withstand high temperatures up to 500°C and operate in contaminated or humid environments.

What is the typical lifespan of a tapered roller bearing?

With proper maintenance, some tapered roller bearings can last over 50,000 hours, especially in sealed designs for challenging environments.

Expert Tapered Rolling Bearing Solutions | INNO Bearing

At Luoyang INNO bearing Co., Ltd, we specialize in manufacturing high-quality tapered rolling bearings for demanding industrial applications. With nearly 30 years of experience, our team offers customized Solutions, rapid prototyping, and exceptional technical support. From standard designs to large-scale bearings up to φ5000mm, we deliver precision-engineered products that meet the most stringent requirements. Contact our experts at sales@inno-bearing.com to discover how our tapered roller bearing solutions can enhance your equipment's performance and reliability.

References

Smith, J. (2021). Advanced Bearing Technology in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

Brown, A., & Johnson, R. (2020). Tapered Roller Bearings: Design Principles and Performance Optimization. International Journal of Tribology, 18(2), 89-104.

Chen, X., et al. (2022). Comparative Analysis of Bearing Types in Heavy-Duty Machinery. Mechanical Systems and Signal Processing, 165, 108351.

Wilson, E. (2019). Innovations in Bearing Materials for Extreme Operating Conditions. Advanced Engineering Materials, 21(8), 1900254.

Thompson, L., & Davis, K. (2023). The Role of Precision Bearings in Medical Imaging Equipment. Biomedical Engineering Journal, 52(4), 412-428.

Yamamoto, H. (2021). Bearing Selection and Design Considerations for Wind Turbine Applications. Renewable Energy, 169, 1156-1170.

Learn about our latest products and discounts through SMS or email