- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Do Turntable Bearings Work?

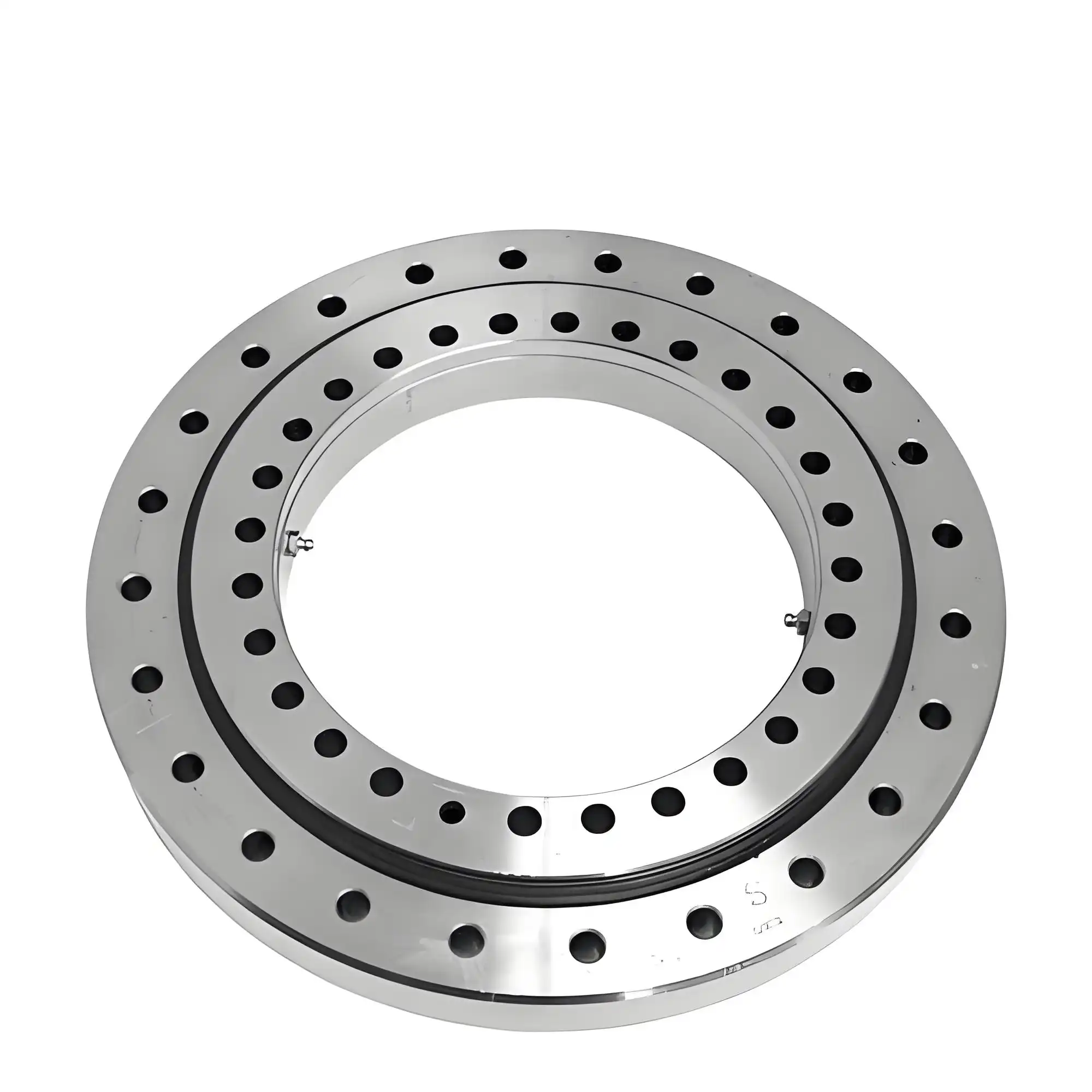

There are interesting mechanical parts called turntable bearings that allow smooth, 360-degree turning in many industry settings. These highly precise machines work by using a circle of moving parts, usually balls or rollers, that are positioned between two rings. One ring stays still while the other spins. This reduces friction and spreads the load evenly, making it possible to move easily even when big things are on it. Because of their special shape, turntable bearings are used in a wide range of machines, from building tools to green energy systems. They make it possible for many machines that shape our modern world to rotate.

The Anatomy of Turntable Bearings

Core Components

Turntable bearings are made up of a few important parts that work together to make the turning smooth and strong. The important parts are the following:

- Outer ring: A big, round piece of steel that makes up the outside of the bearing

- Smaller ring that fits inside the bigger ring is called the inner ring.

- Rolling elements: Balls or rollers that facilitate rotation between the rings

- Cage or separator: A structure that keeps the rolling elements evenly spaced

- Seals: Protective barriers that keep lubricants in and contaminants out

Tight specs are used to make these parts, which are usually made of high-quality materials like 50Mn or 42CrMo steel for the rings and GCr15 bearing steel for the rolling elements. The materials and production methods used have a big effect on how well and how long the bearing lasts.

Design Variations

There are different types of turntable bearings for different uses:

- Single-row vs. double-row: Designs with two rows can hold more weight.

- Roller vs. ball: Roller bearings can hold more weight, but they may have more friction.

- Geared vs. not-geared: Some bearings have gears inside or outside to transfer power.

- Split vs. not split: It is easy to put split patterns in some situations.

The form that is chosen relies on things like how much weight needs to be carried, how much room is available, and whether extra features like gear teeth or fixing holes are needed.

Size and Load Capacity

There is a big range of sizes and weights for turntable Slewing Bearings. As an example:

- The outside widths can be anywhere from 200 mm to an amazing 5000 mm.

- Most inner sizes are between 160 mm and 4800 mm.

- The heights range from 20 mm to 180 mm.

Different designs can handle different amounts of weight; some heavy-duty models can hold up to 10,000kN of standing weight. Because they are so flexible, turntable bearings can be used in a wide range of situations, from small precise tools to huge industrial machines.

The Working Principle of Turntable Bearings

Rotational Mechanics

One of the main ideas behind turntable bearings is that moving touch reduces friction. As one ring moves around in relation to the other, the balls or rollers move the sliding friction into the rolling friction. This greatly lowers the force needed to start and keep the spinning going, even when heavy loads are present.

The inner and outer rings have bent raceways that are meant to move the rolling elements and spread the loads out evenly. This load allocation is very important for keeping things running smoothly and stopping them from wearing out or breaking too soon.

Load Handling

Turntable bearings are designed to handle different types of loads, such as:

- For axial loads: Straight-line forces on the axis of rotation

- Loads that span: Forces that are not parallel to the axis of spin

- Moment loads: Tilting forces that create uneven pressure distribution

How well the bearing can handle these loads relies on its size, form (single-row vs. double-row), and the kind of moving elements that are used. For example, Tapered Roller Bearings are great at handling both axial and rotational loads, which makes them perfect for use in big machines.

Lubrication and Sealing

For turntable bearings to work smoothly, they need to be properly oiled. Lubricants are used for many things, such as:

- Getting rid of friction between moving parts

- Getting rid of the heat that is made during work

- Keeping rust at bay

- It helps keep toxins out.

High-quality seals and oils work together to keep the inside of the bearing clean and well-oiled. Specialized seals, like those with an IP67 rating, can protect better against dust, water, and even saltwater damage in harsh settings.

Applications and Advancements in Turntable Bearing Technology

Industrial Applications

Turntable bearings are used in a lot of different fields and situations, such as:

- Construction: Excavators, cranes, and other heavy equipment

- Renewable Energy: Systems for yaw and pitch in wind turbines

- Making things: robotic systems and machine tool tracks

- Transportation: Railway car connections and ship-to-shore cranes

- Radar and satellite tracking devices for the air

Each use brings its own problems, which is what keeps bearing form and materials from getting old.

Technological Advancements

New developments in turntable bearing technology include the following:

- More advanced materials: Using high-performance metals and polymers to make things last longer

- Making things with precision: Tighter standards and better surface finishing make the process go more smoothly.

- Built-in sensors: The addition of tracking tools for wear and load

- Improved lubrication: making oils that last a long time and work well at high temperatures

- Computational modeling: Use of finite element analysis for design optimization

Bearings that last longer, hold more weight, and work better in harsh conditions are the result of these technical advances.

Future Trends

The future of turntable bearing technology is likely to focus on:

- Smart bearings: Adding IoT features for tracking in real time and planning repair ahead of time

- Sustainability: Making products and chemicals that are better for the environment

- Miniaturization: Creation of ultra-compact bearings for emerging applications in robotics and medical devices

- Additive manufacturing: a look at 3D printing methods for making unique bearings

As long as businesses want better performance and dependability, turntable bearing technology will change to meet these needs.

Conclusion

Turntable bearings are amazing works of engineering that make smooth spinning possible in a huge range of situations. We can understand how important these parts are to modern industry by learning about their structure, how they work, and how technology is always improving them. From huge wind machines to precise medical equipment, turntable bearings keep getting better at what they do, making things more reliable and efficient. When we think about the future, these small but important parts will definitely be a big part of how the tools that move our world forward are made.

FAQs

What's the difference between a slewing ring and a turntable bearing?

The change isn't very important. People often use the terms "turntable bearing" and "slewing ring" to refer to the same kind of large-diameter bearing that lets two buildings rotate around each other.

What is the average life span of a turntable bearing?

The amount of time a turntable bearing lasts depends on its use, the load it's under, how well it's taken care of, and its surroundings. They can last anywhere from 5 to 20 years or more if you take good care of them.

Is it possible to fix turntable bearings?

Most of the time, yes. Turntable bearings can frequently be repaired or refurbished by specialized companies, which can be cheaper than buying a new one. This is especially true for big, custom bearings.

Expert Turntable Bearing Solutions | INNO Bearing

At LUOYANG INNO BEARING CO., LTD., we make high-precision turntable bearings for commercial uses that are very strict. Our team of experts has been working together for almost 30 years and can create and make unique bearings up to φ5000mm to fit your needs. We provide dependable, long-lasting Solutions for everything from heavy machinery to green energy systems. Our solutions are backed by strict quality control and the ability to quickly adapt to new needs. Email us at sales@inno-bearing.com if you need high-quality turntable bearings that are made just for you.

References

Smith, J. (2022). "Advancements in Turntable Bearing Technology for Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

Johnson, A. & Lee, S. (2021). "Comparative Analysis of Single-Row vs. Double-Row Slewing Rings in Heavy Machinery." International Journal of Industrial Mechanics, 18(2), 112-129.

Brown, R. (2023). "The Role of Turntable Bearings in Wind Turbine Yaw Systems: A Comprehensive Review." Renewable Energy Systems, 30(4), 567-584.

Garcia, M. et al. (2022). "Materials Science Innovations in Large-Diameter Bearing Design." Advanced Engineering Materials, 24(6), 2100987.

Thompson, L. (2021). "Predictive Maintenance Strategies for Turntable Bearings in Industrial Robotics." Automation and Robotics Quarterly, 37(1), 45-62.

Wilson, K. & Chen, Y. (2023). "Computational Modeling Approaches for Optimizing Slewing Ring Performance." Computer-Aided Design and Applications, 20(5), 1034-1051.

Learn about our latest products and discounts through SMS or email