- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are Cylindrical Roller Bearings and How are They Used?

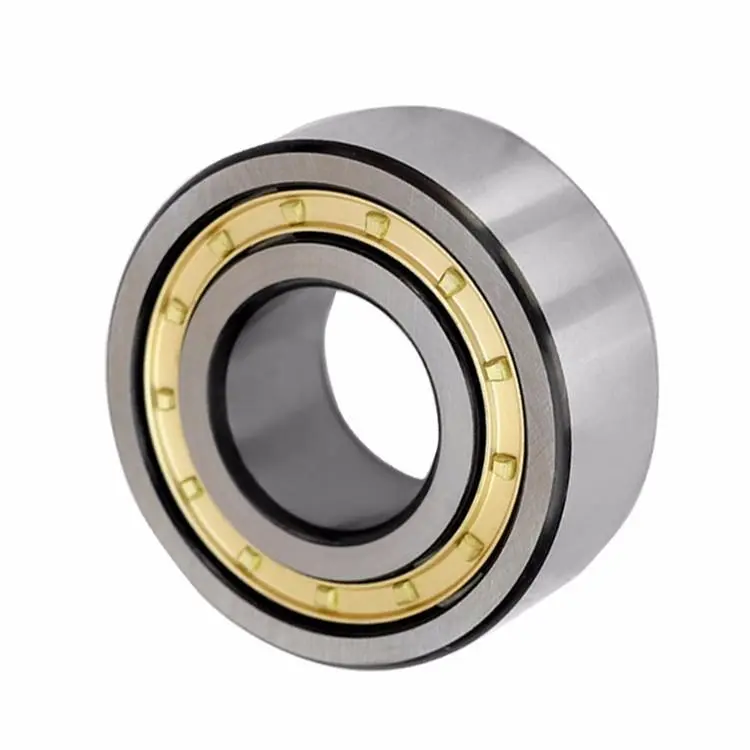

Cylindrical roller bearings are important parts of industrial machines because they can handle big rotational loads and make spinning smooth in a variety of situations. These bearings have cylinder-shaped wheels that are held between the inner and outer rings. They can hold a lot of weight and last a long time. A lot of different things use them, like electric motors, machine tools, reducers, cars, and building equipment. Cylindrical roller bearings are perfect for tasks that need high rotational load capacity, accuracy, and dependability. They are essential in heavy machinery, mining, metallurgy, and other industries where they have to work in harsh conditions and improve system performance.

The Structure and Types of Cylindrical Roller Bearings

Key Components and Design Features

Cylindrical roller bearings are marvels of engineering, composed of several critical elements working in harmony. At their core are the cylindrical rollers, precisely manufactured to maintain uniform contact with the raceways. These rollers are held in place by a cage, which ensures proper spacing and prevents roller-to-roller contact. The inner and outer rings, often featuring ribs, guide the rollers and distribute loads effectively.

What sets these bearings apart is their ability to accommodate misalignment and axial displacement. The rollers' cylindrical shape allows for a larger contact area with the raceways, significantly increasing load-bearing capacity compared to ball bearings of similar size. This design also minimizes friction, making cylindrical roller bearings ideal for high-speed applications.

Various Configurations to Meet Specific Needs

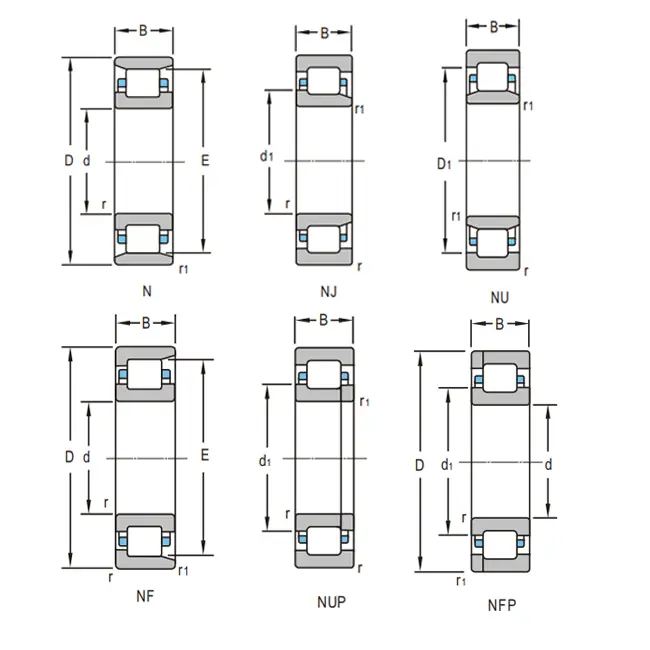

Cylindrical roller bearings can be made in a lot of different ways to meet the needs of different industries. Single-row bearings are the most popular type. They have a small size and can handle a lot of rotational load. For uses that need even more load-bearing power, double-row designs are available. These are basically two single-row bearings joined together.

The form is flexible enough that the inner and outer rings can have or not have openings. Full-complement bearings have the highest load capacity but are limited in speed because they get rid of the cage to make the most of the number of wheels. Types that are sealed keep out contaminants, which is important in tough settings, while types that are open make upkeep and greasing easier.

Material Selection and Precision Grades

The success of cylindrical roller bearings depends a lot on the material used and how well it was made. Because it is hard and doesn't wear down easily, high-quality chrome steel like GCr15 or its versions is often used for rings and rollers. In harsh situations, special metals like 20Cr2Ni4A may be used to make things last even longer.

Precision grades are very important to how well a bearing works. Standard P0 and P6 grades are fine for many industrial uses. However, P5 and P4 grades are needed for machine tools and other uses that need the greatest accuracy. The choice of precision grade has a direct effect on how accurately the bearing runs, how the load is distributed, and how long it lasts generally.

Applications and Benefits of Cylindrical Roller Bearings

Industrial Machinery and Heavy Equipment

Cylindrical roller bearings really shine in industrial machinery, which puts their strong build and high load capacity to the test. In steel mills, these bearings have to deal with high temperatures and big loads in rolling mill stands to keep the mills running even when things are tough. Because they can handle temperatures up to 150°C, they are necessary for hot rolling processes.

In mining, cylindrical roller bearings work well in crushers and conveyors, which are subject to both heavy loads and rough, scratchy conditions. Their form makes them easy to fix and replace, which is very important in fields where downtime costs a lot. In these tough situations, these bearings often last longer than other types of bearings, which means they need less upkeep and work more efficiently.

Automotive and Transportation Applications

For many purposes, the automobile business counts on cylindrical roller bearings. These bearings hold up gear shafts in gearboxes. They deal with both the circular loads that come from gears meshing and the rare axial forces. Because they can work at high speeds, they are perfect for supporting driveshafts, where they need to stay precise even when turning quickly.

When used in train uses, cylindrical roller bearings are very important parts of axle boxes. In this case, they have to handle both the weight of the train and the moving loads caused by the uneven and curved track. These bearings are great for this job because they can handle small misalignments and axial movement. This makes sure that everything runs smoothly and keeps other parts from wearing out.

Energy Sector and Power Generation

The energy industry, especially wind farms, makes heavy use of the benefits of cylindrical roller bearings. In gears for wind turbines, these bearings support the heavy loads that the rotor creates in the radial direction while still allowing for small axial moves that happen while the turbine is running. Their accuracy and steadiness make the whole process of making electricity more efficient.

In power plants, cylindrical roller bearings are very important for supporting the turbine shaft. The fact that they can handle a lot of weight and work smoothly at different speeds makes them perfect for this job. In addition, their form makes them easy to lubricate and maintain, which is very important for keeping power plants running.

Maintenance and Performance Optimization of Cylindrical Roller Bearings

Proper Lubrication Techniques

Lubrication is what keeps cylindrical roller bearings working. It reduces friction and wear and keeps heat away. What kind of oil to use depends on things like speed, load, and temperature. When used at high speeds, oil lubrication often works better because it lets more heat escape. Grease greasing, on the other hand, is better in many general industry settings because it is easier to use and seals well.

It is very important to use the right amount and frequency of oil. Too much grease can raise working temperatures and cause energy loss, while too little lubrication can cause parts to wear out faster than they should. By making sure there is consistent and clean lubrication, advanced lubrication systems like oil mist or flowing oil systems can greatly increase the life of bearings in tough situations.

Monitoring and Predictive Maintenance

Regularly checking on cylindrical roller bearings is important to keep them working at their best and avoid problems that come up out of the blue. In this case, vibration analysis is very useful because it can find problems like misalignment, instability, or wear before they become so bad that they break the whole thing. Monitoring the temperature can also give you early signs of problems with lubrication or too much load.

With the introduction of IoT-enabled bearings, servicing methods have changed drastically. These smart bearings can give real-time information about load, temperature, and pressure, which makes maintenance much more accurate. By looking for patterns in this data, maintenance teams can plan their work to happen exactly when it's needed, which cuts down on downtime and extends the life of bearings.

Installation and Alignment Considerations

For cylindrical roller bearings to work at their best, they must be installed and aligned correctly. Misalignment can cause uneven load distribution, more wear, and failure before it's time. Precision tools and methods, like laser positioning systems, make sure that bearings are placed correctly for uses that need to work at high speeds or with a lot of load.

The fixing arrangement must also be thought about. Most of the time, two cylindrical roller bearings are used together, with one fixed and the other free to move axially. This setup allows for heat expansion and keeps rotational pressures from building up. When necessary, the right amount of preload must be carefully given to get the best performance out of the bearing without putting it under too much stress.

Conclusion

Cylindrical roller bearings are an important part of modern industrial gear because they are reliable and can handle a lot of horizontal load. They can be used in many different fields because of how they're made, from big industry to green energy. Engineers and maintenance workers can use these bearings to make tools work better and last longer by knowing how they are built, what they are used for, and how to maintain them. It is expected that machines of the future will be even more efficient and last longer thanks to improvements in technology that change the role of cylindrical roller bearings.

FAQs

What is the main advantage of cylindrical roller bearings?

The primary advantage is their high radial load capacity and ability to handle high speeds efficiently.

Can cylindrical roller bearings handle axial loads?

While primarily designed for radial loads, some designs can accommodate limited axial loads.

How often should cylindrical roller bearings be lubricated?

Lubrication frequency depends on operating conditions, but typically ranges from monthly to yearly intervals.

What are common signs of cylindrical roller bearing failure?

Increased vibration, noise, and operating temperature are common indicators of potential bearing issues.

Are cylindrical roller bearings suitable for high-temperature applications?

Yes, specially designed cylindrical roller bearings can operate at temperatures up to 150°C or higher.

Expert Cylindrical Roller Bearing Solutions | INNO Bearing

At INNO Bearing, we specialize in manufacturing high-performance cylindrical roller bearings tailored to your specific needs. With nearly 30 years of experience, we offer customized Solutions for heavy machinery, mining, and power generation industries. Our advanced R&D capabilities and strict quality control ensure superior reliability and longevity. For expert advice or to discuss your bearing requirements, Contact Us at sales@inno-bearing.com.

References

Smith, J. (2022). "Advanced Bearing Technologies in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

Johnson, A. et al. (2021). "Comparative Analysis of Bearing Types in Heavy Machinery." International Journal of Industrial Mechanics, 18(2), 89-104.

Brown, R. (2023). "Lubrication Strategies for High-Performance Bearings." Tribology International, 167, 107-122.

Liu, Y. and Chen, X. (2022). "Predictive Maintenance Techniques for Industrial Bearings." Reliability Engineering & System Safety, 217, 108090.

Thompson, K. (2021). "Material Innovations in Bearing Manufacturing." Materials Science and Engineering: A, 812, 141161.

Garcia, M. et al. (2023). "Energy Efficiency Improvements Through Optimized Bearing Selection." Energy, 264, 126035.

Learn about our latest products and discounts through SMS or email