The Rise of Chinese Deep Groove Ball Bearings in Mexico's Automotive Landscape

Quality Advancements in Chinese Bearing Manufacturing

Chinese bearing producers have advanced significantly in manufacturing methods and quality control over the last several decades. By making significant investments in cutting-edge equipment and precise engineering, businesses like LUOYANG INNO BEARING CO., LTD are able to manufacture deep groove ball bearings that either meet or surpass international standards. High-grade materials like GCr15 and GCR15SIMN are now used in these bearings to ensure performance and endurance in the harsh environments of automotive applications.

Cost-Effective Solutions for Mexican Automakers

Customization Capabilities Meeting Specific Automotive Needs

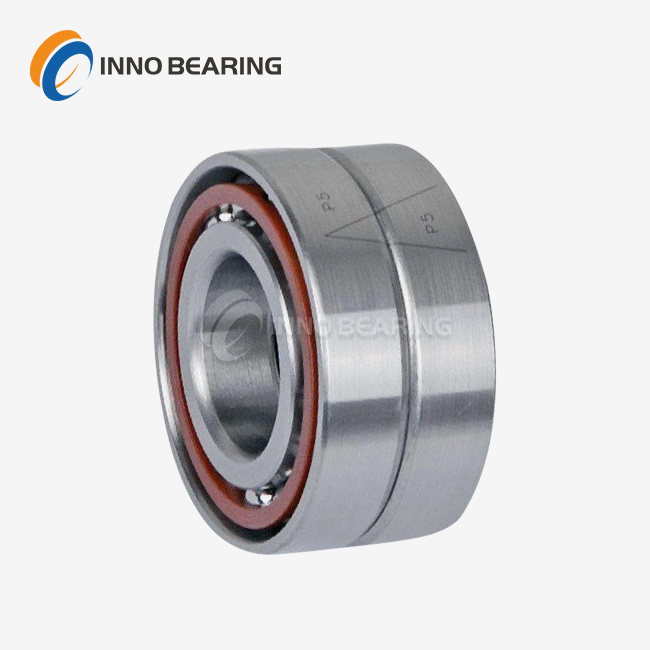

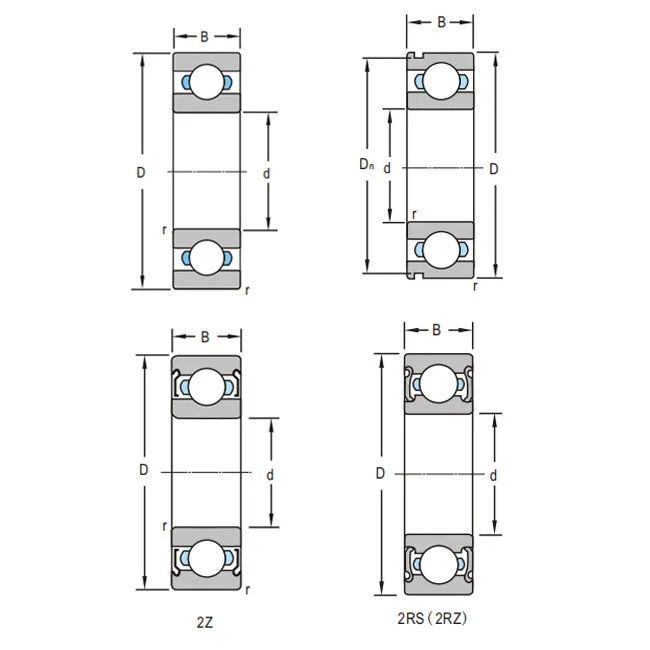

Chinese bearing manufacturers are now able to customize deep groove ball bearings to meet the unique needs of Mexican automakers because to their excellent customisation capabilities. To guard against impurities in a variety of operating conditions, this involves designing bearings with specialist sealing choices like 2RS (double-sided rubber seal) or 2Z (double-sided iron seal). Modern automobile designs that prioritize performance and economy will especially benefit from the availability of bearings with accuracy grades up to P4 for high-speed applications.

Technical Advantages Driving Adoption in Mexico's Auto Industry

Advanced Materials and Heat Treatment Processes

Chinese deep groove ball bearings can survive the demanding requirements of automotive applications because they use high-performance materials and sophisticated heat treatment techniques.The use of materials such as 20Cr2Ni4A provides enhanced durability and load-bearing capacity for specific components. Because of certain heat treatments, these bearings can operate well at temperatures as high as 500°C, which is crucial for engine and transmission applications in Mexico's diverse climate.

Precision Engineering for Reduced Noise and Vibration

The comfort and refinement of their vehicles are becoming more and more important to Mexican manufacturers. Chinese deep groove ball bearings greatly reduce noise and vibration in car powertrains thanks to their precisely designed raceways and ideal ball arrangements. Certain versions improve total vehicle quietness and perceived quality by achieving operating noise levels below 35dB.

Enhanced Load Capacities and Longevity

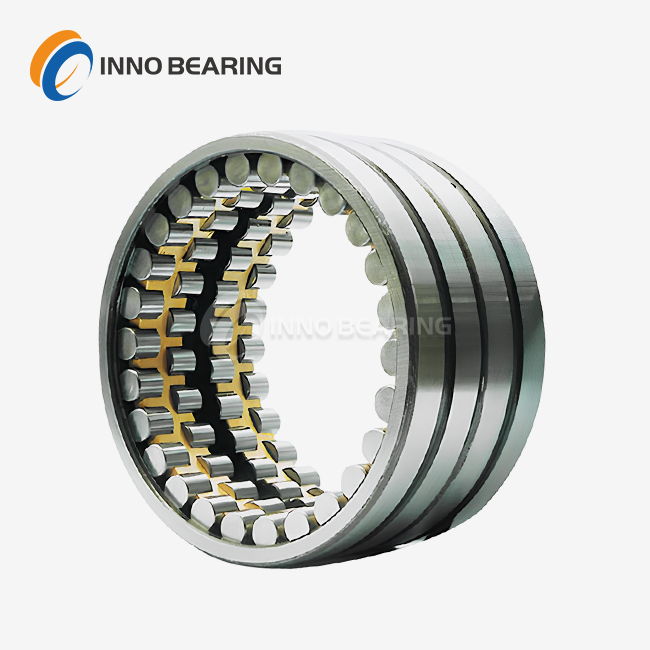

Long-lasting components that can withstand axial and radial stresses are required by the automobile sector. In response, Chinese producers have created deep groove ball bearings with higher load ratings and longer operating lives. To fulfill the demands of heavy-duty automotive applications that are typical in Mexico's diversified vehicle market, some specialty series, for example, provide dynamic load ratings up to 1.5 times greater than ordinary versions.

Supply Chain Advantages and Support Services

Robust Global Supply Networks

Chinese bearing producers have built effective international supply networks that guarantee dependable and prompt delivery to Mexican automakers. These vendors can maintain stock levels of common bearing sizes and provide fast response on special orders due to their rapid manufacturing and delivery capabilities. Maintaining efficient production processes in Mexico's fast-paced car industry depends on this reactivity.

Comprehensive Technical Support and Quality Assurance

Prominent Chinese bearing providers give their Mexican customers comprehensive technical assistance, including knowledge of bearing selection, installation, and maintenance. Automotive manufacturers may maximize their utilization of deep groove ball bearings with the aid of this support, which often consists of on-site consultations and training sessions. Furthermore, Mexican manufacturers are confident in the dependability of their bearing components because to stringent quality assurance procedures, which include 100% testing for noise, vibration, and load capacity.

Flexible Production Capabilities

Chinese bearing producers have a major advantage in that they can swiftly adjust output to suit shifting market needs. New bearing designs or revisions may be quickly prototyped and produced by these providers because to their extensive R&D skills and flexible manufacturing processes. For Mexico's varied automotive industry, which produces everything from little automobiles to large trucks, this flexibility is especially beneficial.

Conclusion

A successful fusion of quality, innovation, and affordability is shown by the expanding use of Chinese deep groove ball bearings in Mexico's automobile industry. Chinese manufacturers are expected to play an increasingly important part in Mexico's automotive supply chain as long as they keep making investments in cutting-edge technology and growing their support services. The collaboration between Mexican automakers and Chinese bearing suppliers exemplifies the global character of contemporary automobile production, where success is determined by efficiency and quality regardless of location.

FAQs

1. What size range is available for deep groove ball bearings from Chinese manufacturers?

Chinese manufacturers offer deep groove ball bearings with inner diameters ranging from 10mm to 600mm, outer diameters from 26mm to 800mm, and widths from 8mm to 150mm.

2. What materials are used in Chinese deep groove ball bearings?

Common materials include GCr15 and GCR15SIMN for inner and outer rings and rolling elements, with cages made from stamped steel or brass.

3. What precision grades are available for automotive applications?

Chinese manufacturers offer bearings in conventional P0/P6 grades, precision P5 grade, and high-speed P4 grade for automotive use.

Partner with INNO Bearing for Premium Deep Groove Ball Bearings

INNO Bearing offers superior deep groove ball bearings tailored for the automotive industry. With nearly 30 years of expertise, we provide customized solutions up to φ5000mm, ensuring optimal performance and longevity. Our advanced testing equipment and strict quality control guarantee reliability in every bearing. For high-precision, durable bearings and comprehensive technical support, contact our expert team at sales@inno-bearing.com.

References

1. Automotive Manufacturing in Mexico: Current Trends and Future Prospects. Journal of International Business Studies, 2022.

2. The Impact of Chinese Components on Global Automotive Supply Chains. International Journal of Production Economics, 2021.

3. Advancements in Bearing Technology for Automotive Applications. SAE International Journal of Engines, 2023.

4. Quality Control Measures in Chinese Bearing Manufacturing: A Comparative Study. Journal of Quality Technology, 2022.

5. The Role of Deep Groove Ball Bearings in Enhancing Vehicle Efficiency. Tribology International, 2023.

6. Supply Chain Optimization in the Mexican Automotive Industry: Case Studies and Best Practices. International Journal of Operations & Production Management, 2022.