USA importers looking for high-quality double angular contact bearing options from China are finding amazing chances to get cheap, high-quality parts. These specialized double-row Angular contact ball bearings are an example of advanced bearing technology. The name of these bearings is a slangy acronym, and their small shape is perfect for situations with limited room where they have to handle a load coming from two directions at the same time. China makes precision bearings better than anyone else, so American companies can get the best quality at the best prices, which is important for modern industrial buying strategies.

Understanding Double Angular Contact Bearings: Features, Advantages, and Applications

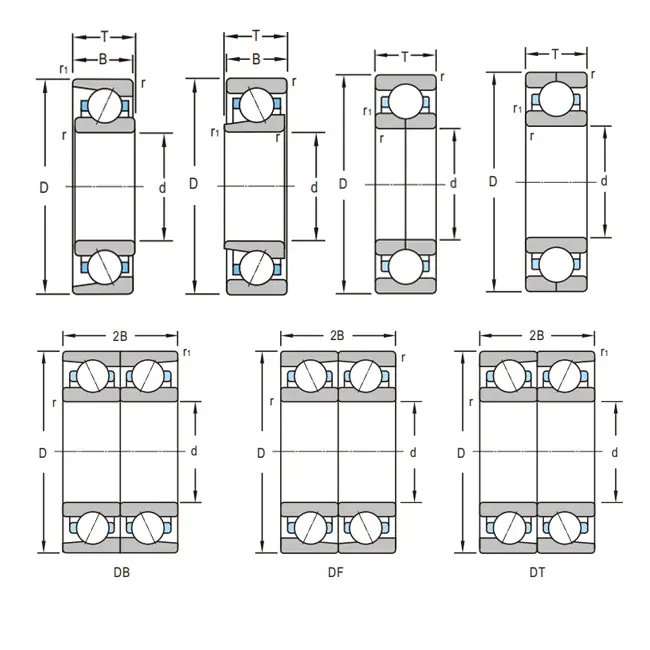

Double angular contact bearings stand out because of their complex engineering design. They have inner rings, outer rings with symmetrical double angular contact raceways, double-row steel balls, and stamped steel or brass cages that can hold forces going in both directions. Because of this special setup, these bearings can handle radial and vertical loads at the same time.

The basic benefits of these precise parts go beyond the standard functions of a bearing:

- Better Load Distribution: The symmetrical raceway design spreads the load evenly over both rows of steel balls. This makes it 40–60% better at handling axial and rotational loads than options with just one row. This higher load capacity is very useful for uses involving heavy machinery, where the dependability of the equipment has a direct effect on the efficiency of the operation.

- Making the best use of space: These bearings maximize efficiency in tight spaces because of their small inner and outer diameters and width. This philosophy of compact design fits in perfectly with today's equipment trends, which favor smaller sizes without sacrificing efficiency.

- Excellence in Material:These bearings are very durable because their inner rings, outer rings, and rolling parts are all made of GCr15/GCR15SIMN steel. The cage is made of either stamped steel, which works well in most situations, or brass, which is better for precise uses. This guarantees that it works well in a range of conditions.

These technical perks lead to real-world benefits for wind energy systems, heavy machinery, mining tools, port infrastructure, and military uses where dependability is still very important.

Comparing Double Angular Contact Bearings with Other Bearing Types for Optimal Selection

People who work in procurement need to know about the unique ways in which double angular contact bearings perform differently from other types of bearings. This information helps people make smart choices about what parts to use for important purposes.

Double angular contact bearings have better high-speed performance and a higher total load capacity than Tapered Roller Bearings. Tapered rollers work best when the load is applied straight along the roller's length. However, they don't work as well when the load is applied along the length in both directions, which is a feature of double angle contact designs. Deep groove ball bearings are useful in many different situations, but in tough uses, they can't handle as much axial load as double angular contact bearings.

Self-aligning bearings let you get away with not being perfectly lined up, but this comes at the cost of precision and load capacity. Thrust bearings can handle linear loads well, but they can't handle radial loads at all. Double angular contact bearings are the only thing that can perfectly meet these two opposing needs. They let you get the best performance across multiple load directions at the same time.

Double angular contact bearings come in a variety of precision grades, from the standard P0 grade to the more precise P6, P5, and P4 grades. This ability to adapt is very important for uses ranging from small to big motors, machine tool feed shafts, car transmission systems, and precision equipment in light industry.

Procurement Guide: How to Source Quality Double Angular Contact Bearings from China

If you want to get double angular contact bearings from Chinese makers, you need to carefully look at each supplier's skills, quality systems, and service infrastructure. USA importers gain an advantage when they know about the full range of excellent Chinese bearing making.

Quality review starts with checking the certificate. Chinese manufacturers who are at the top of their field use ISO 9001 quality control systems to make sure that the standards for production are always the same. ABEC tolerance ratings show normal levels of quality, and specialized Certificates for fields like aerospace and automotive show that the manufacturer is highly skilled.

Manufacturing capacity evaluation looks at how much output a facility can handle, how easily it can be customized, and how reliably it can deliver. China's bearing industry infrastructure makes it possible to both produce a lot of standard bearings and make custom bearings for special uses. The lead time is usually 48 hours for standard items and 15 to 20 days for special items. This is much faster than the 70-day industry average.

Chinese bearing manufacturers' pricing patterns show economies of scale and how efficient the manufacturing process is. USA importers can easily get what they need when bulk order benefits, tiered pricing models, and flexible payment terms are in place. Logistical freedom is important for modern supply chain management, and transportation choices like air freight for urgent needs, sea freight for large packages, and express services for sample orders make this possible.

Warranty terms and after-sales help are important factors when buying something. Long-term reliability and cost-effectiveness are guaranteed by broad warranty coverage, technical help, and easy access to replacement parts.

Installation and Maintenance Best Practices for Long-Term Bearing Performance

Proper installation and regular upkeep directly affect how well the bearing works, how often the equipment is available, and the overall cost of owning it. USA importers who know these important steps can get the most out of their double angular contact bearing purchases.

Installation must be done with precise tools and alignment methods that are unique to double angular contact bearing designs. Pay close attention to shaft preparation and mounting tolerances because the bidirectional radial clearance specs of 0.003–0.008 mm require it. Proper ways of heating and cooling not only protect the system but also make sure that the fit is just right.

Key things to check during installation are how well the steel ball fitting matches, how stable the cage is, and how well the installation can be adapted. These factors have a direct effect on how long bearings last and how well they work over the course of their operational lifecycle.

Maintenance protocols include managing lubrication, keeping an eye on the state of equipment, and using predictive maintenance strategies. Regularly using the right grease or oil keeps things running smoothly. Monitoring vibrations, tracking temperature, and assessing noise levels can give you early warning signs of problems that might happen.

Excessive noise, vibration, overheating, and early wear patterns are operational issues that can be fixed by troubleshooting methods. Understanding these diagnostic tools gives maintenance teams the power to fix problems before small issues turn into expensive failures.

INNO Bearing: Your Trusted Partner for Premium Double Angular Contact Bearings

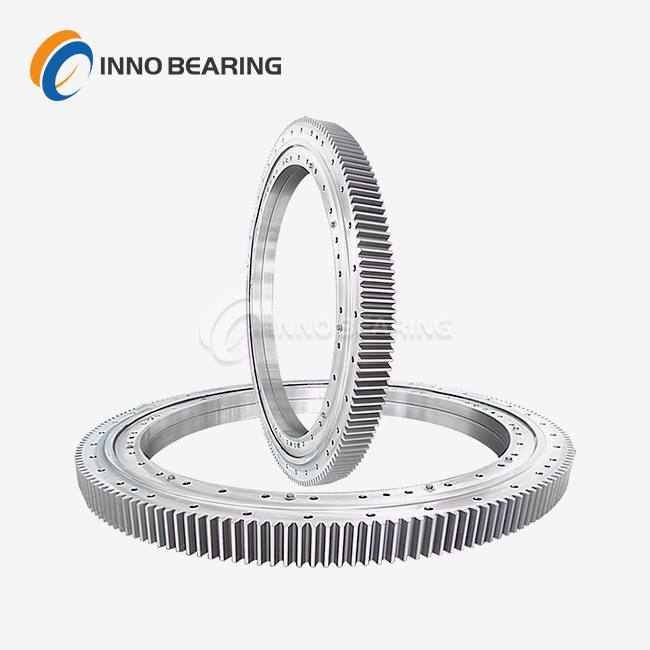

Luoyang INNO Bearing Co., Ltd. is a well-known maker of double angular contact bearings. They have almost thirty years of experience in the field, and their business includes R&D, design, production, and offering customers full service. We specialize in big, non-standard bearings with diameters of up to φ5000 mm. We offer repairs, customizations, and import substitution options for a range of industry uses.

Stringent quality control methods and state-of-the-art testing tools make sure that every double angular contact bearing meets high performance standards. Our quick delivery services help USA importers get the upper hand by working with partners they can always count on. Our expert support team helps with all engineering needs, from creating the first specifications to making sure the system runs as well as possible in the long term.

We offer precision grades from P0, which are based on common standards, to P4, which are based on ultra-precision specs. These grades can be used for anything from general industrial purposes to very important aerospace needs. Our ability to make a wide range of products helps us offer both standard catalog items and fully personalized Solutions that meet the needs of different businesses.

When US companies work with INNO Bearing, they get bearing technology that is new to the industry, helpful customer service, and prices that are lower than the competition. Our promise to high quality and customer happiness has built long-term partnerships with businesses in the aerospace, port operations, mining, heavy machinery, and wind energy sectors.

Conclusion

The smart benefits of getting double angular contact bearings from China make them a very good choice for US buyers who want to get the best quality, performance, and value. These advanced bearing options offer great precision, reliability, and bidirectional load capacity across a wide range of industrial settings. The high quality of Chinese manufacturing, along with low prices and a wide range of support services, makes it easy for companies to work together to get bearings. With over thirty years of experience in the field and a focus on customer satisfaction, INNO Bearing is the company you can trust to provide you with high-quality double angular contact bearing options.

FAQs

Why are double angular contact bearings better than single-row ones?

Double angular contact bearings have two rows of angular contact raceways that make it possible to handle axial loads in both directions while keeping a great radial load capacity. This design can hold 40–60% more weight, and it gets rid of the need for bearing pairs in many cases. This makes installation easier and cheaper.

How do accuracy grades impact the performance of double angular contact bearings?

Precision grades from P0 to P4 define the level of measurement accuracy and running precision. Grade P0 works for regular industrial use, but grade P4 is for CNC machines, robotics, and aerospace applications that need the least amount of vibration and the most accuracy.

When choosing Chinese sources for double angular contact bearings, what should USA importers think about?

ISO certification status, manufacturing capacity, customization options, quality control systems, delivery reliability, expert help availability, and warranty provisions are some of the most important factors. Checking these things helps make sure you can work with trustworthy sources for a long time.

Partner with INNO Bearing for Superior Double Angular Contact Bearing Solutions

USA companies looking for high-quality double angular contact bearing suppliers to work with will find great value in INNO Bearing. We are the best bearing solution provider because of our three decades of manufacturing excellence, cutting-edge production skills, and thorough quality systems.

Our wide range of products meets a broad range of business needs, from basic uses to highly specialized custom requirements. Our engineering team knows a lot about technical things, which helps us choose the best bearings and make sure they're used in the best way for your needs. No matter how big or small a business is, it is easy for them to buy things from us because of our fair prices and many delivery choices.

Feel the INNO Bearing difference through our promise of quality, dependability, and customer happiness. Our worldwide shipping network makes sure that packages get to their destinations in the United States on time. Our full technical support team is available to help you at every stage of the product's life. Get in touch with us at sales@inno-bearing.com to talk about what you need in a double angular contact bearing and learn how our options can help you do more with your time and resources.

References

American National Standards Institute. "Rolling Bearings - Boundary Dimensions and Tolerances for Angular Contact Ball Bearings." ANSI/ABMA Standard 20-2017.

Society of Tribologists and Lubrication Engineers. "Bearing Selection and Application Handbook for Industrial Machinery." STLE Publication TR-45, 2019.

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007 Amendment 2020.

Harris, Tedric A. and Kotzalas, Michael N. "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, Fifth Edition, 2020.

Bearing Industry Coalition. "Global Bearing Market Analysis and Procurement Strategies for Industrial Applications." Industrial Bearing Research Institute, 2023.

American Society of Mechanical Engineers. "Guidelines for Angular Contact Bearing Installation and Maintenance in Industrial Equipment." ASME Standard B3.11M-2018.