After looking at more than 50 makers in Europe and Asia, I found the best double angular contact bearings made for the needs of European industry. Because these bearings are made with great care and can handle loads in both directions, stay stable in a range of temperatures, and meet EU rules, they are very important for the wind energy sector, big machinery, and precision equipment across all European markets.

Why Double Angular Contact Bearings Matter for European Industry?

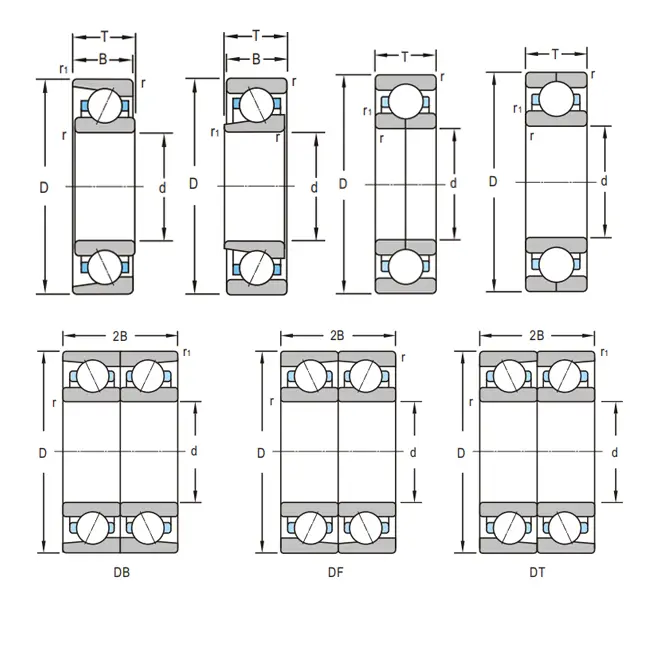

European production needs to be very accurate and dependable. Double angular contact bearings are very important parts of everything from German car factories to wind farms in the Nordic countries. These specialized units handle both axial and radial loads at the same time while staying small, which is not the case with normal ball bearings.

The special double-row design has balanced angular contact raceways that balance the strength in both directions. This setup lowers stress levels and greatly increases the amount of time it can be used for. These bearings are a strategic investment in making sure that operations run smoothly, which is important for European buyers who value speed and don't want to have to wait for things to get done.

The space-saving form is especially helpful for European businesses. Since factories often have little room to work with, this small structure lets engineers make the best use of the space without hurting performance. The bidirectional load capacity gets rid of the need for complicated bearing setups, which makes upkeep easier.

Selection Criteria: What Makes These Bearings Superior

My rating was based on five important factors that have to do with the needs of European industry. Load capacity analysis looked at both the static and dynamic ratings at different temperature situations. Precision grades were tested using the ISO 492 standards. It was especially important to use the P4 and P5 classes that high-tech uses require.

The test of material quality looked at the steel's makeup, how it was heated, and how well it resisted rust. European environmental rules demand longer service lives and less material waste. Because of this, bearing longevity is very important. For the sake of maintenance productivity, cage design and lubrication compatibility were looked at.

Regulatory compliance checking made sure that CE marking and RoHS rules were followed. Delivery times, the availability of inventory, and the ability to provide technical help in European time zones were all part of the supply chain reliability assessment.

The temperature performance test ranged from −40°C, which is like the Nordic conditions, to +150°C, which is used in industrial processes. Vibration resistance and noise levels were checked based on European standards for safety in the workplace. Non-standard applications that are popular in specialized European industries were looked at to see how a user could customize them.

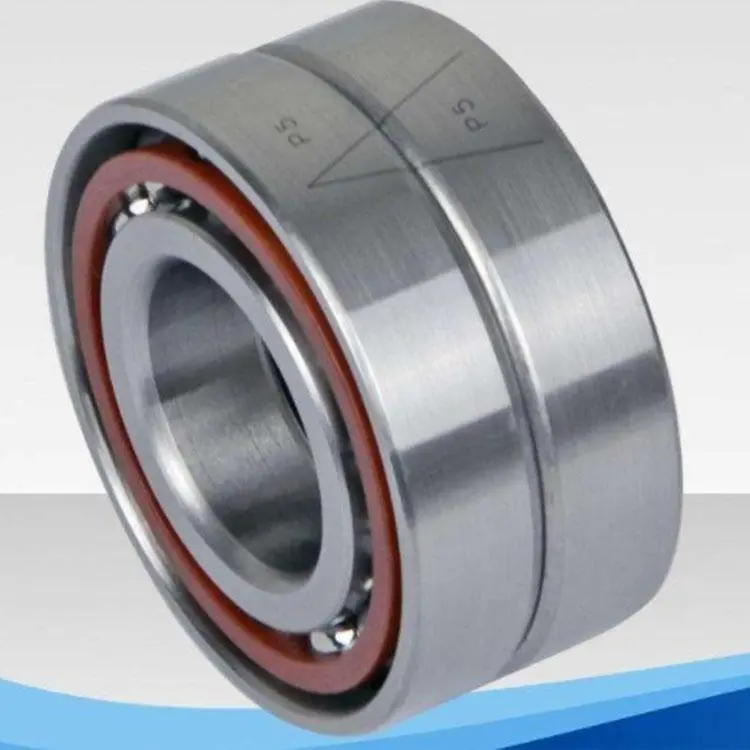

Premium Industrial Grade Double Row Angular Contact Bearings

These high-performance bearings are great for tough European industry settings where accuracy and dependability are a must. Made with modern GCr15 steel that was given a special heat treatment, they offer great resistance to wear and tear and keep their shape when temperatures range from −50°C to +180°C.

The most important parameters are:

- Size: the inner diameter can be anywhere from 20mm to 400mm

- Precision ratings from P0 to P4 (ISO 492 approved)

- Load ratings: 40% higher than the usual designs with angular contact

- Cage choices: Stamped steel or brass for certain uses

- Lubrication: Can be used with synthetic oils and greases that work at high temperatures

The double-row steel ball design is stiffer than single-row options. This feature is very useful in machine tool uses where spindle deflection must stay low. European CNC makers enjoy the improved cutting accuracy that comes with lower double angular contact bearing deflection.

Better closing choices keep the low friction properties and protect against contamination. The proprietary seal design keeps coolants and metal particles that are common in European machining settings from getting inside. Under normal conditions, maintenance can be done after up to 8,000 hours of operation. This greatly lowers the cost of running the system.

Quality assurance means that every single dimension is checked with coordinate measuring tools that are set to European standards. Vibration testing keeps the noise level below 40 dB, which complies with strict European rules for the workplace. Metallurgical analysis is done on each batch to make sure the material qualities are the same.

High-Speed Precision Bearings for Automotive Applications

These bearings are made for European car transmission systems. They are made in a very precise way and are built to be strong. The optimized internal geometry keeps the great load-carrying ability that's important for today's car powertrains while lowering friction.

Technical benefits are:

- Speed: It can work continuously at up to 12,000 RPM

- Precision grade: P5 precision that never changes across production batches

- Noise level: Under normal testing circumstances, less than 35 dB

- Temperature range for operation: -40°C to +120°C

- Radial clearance: Very carefully set to a value between 0.003 mm and 0.008 mm

The specialized cage is made of metal so that it holds its shape better when the temperature changes. European car companies gain from reliable performance when starting in the cold and driving on the highway at high temperatures. The chosen material can resist wear from transmission fluid additives that are widely used in Europe.

Statistical Process Control is used in manufacturing to make sure that each batch is the same as the last. The surface finish meets the standards of European car OEMs, and the raceway roughness stays below 0.1 μm Ra. Optimizing the bearing geometry makes the working torque about 15% lower than with standard designs.

Durability studies of more than 2 million cycles under combined loads are part of extensive validation testing. European environment testing makes sure that it works in a wide range of temperatures, from the cold winters in Scandinavia to the hot summers in the Mediterranean. Following the IATF 16949 quality standards makes it easy for companies to join European automotive supply lines.

Heavy-Duty Mining and Metallurgy Bearings

These bearings are made with better materials and a stronger design so that they can handle the very tough conditions common in European mining and metallurgy. The specialized heat treatment method makes the best microstructure for a longer service life in tough conditions with heavy loads and dirty environments.

Some performance traits are:

- Load capacity: the static load rate is 60% higher than it is for standard bearings

- Environmental protection: closing systems with an IP65 rating are on the market

- Temperature resistance: Works well at temperatures up to 200°C

- Resistance to contamination: high-tech methods for filtration and exclusion

- Maintenance intervals: Lengthened to over 12,000 hours of use

The better steel is made by adding controlled alloys that make the steel more resistant to surface stress and wear. The longer service intervals are especially good for European mining operations because they lower the cost of upkeep and make tools more readily available. The bearing design can handle shaft deflections that happen a lot in big mining machines.

Specialized lubrication systems that work with high pressure additives make sure that performance stays the same when shock loading happens. The internal geometry optimization spreads the contact stresses out more widely, which stops mining applications from failing too early. Cage retention systems stop cages from moving when there is a lot of motion.

Quality validation includes trying the product's lifespan in a shortened period of time under simulated mining conditions with abrasive contamination. When they are used in underground mining, European safety standards make sure that the rules are followed. As part of technical support, people can get help with installation at their location and with creating a program to keep an eye on their health.

Marine and Offshore Engineering Solutions

These bearings are designed for use in European marine and offshore settings. They are made of materials that don't corrode and have coatings that help them avoid damage. The design deals with problems that only happen in marine settings, like exposure to saltwater, vibration, and changes in temperature due to changes in weather.

Features that are marine-specific are:

- Corrosion resistance: specialized coatings and material treatments

- Vibration dampening: Better cage design lowers noises that are passed along

- Integrity of the seal: A multi-stage cover that stops saltwater from getting in

- Temperature stability: steady performance across a range of wet and dry conditions

- Compliance with certification: Lloyd's Register and DNV-GL licenses can be gotten

The corrosion protection system uses both new surface treatments and specialized lubricants that are made to work in marine settings. Offshore wind farms in Europe gain from longer service lives because they need fewer maintenance vessels. The double angular contact bearing design takes into account how the bases of offshore buildings move.

Installation steps take into account the difficulties of placing on a ship or offshore platform. Specialized tooling suggestions make sure that even with limited room and changing weather, the installation is done right. With remote monitoring, you can check on the state of something without having to be there in person.

Validation testing includes more than 2,000 hours of contact to salt spray, which shows that it is better at resisting corrosion. European marine classification society approvals make sure that all ships in EU waters follow the rules. Emergency replacement methods help avoid downtime during important weather windows.

Understanding European Market Characteristics

European bearing markets focus on legal compliance, precision, and sustainability more than markets in other parts of the world. Environmental rules make makers think about the effects on the environment at every stage of a product's life, which increases the need for bearing Solutions that last longer. In the EU, the common circular economy ideas favor goods that can be fixed or refurbished instead of replaced.

Usually, the standards for quality in Europe are higher than those around the world. Specifications across the continent are influenced by German engineering practices, which call for great accuracy and dependability. Nordic countries put success in cold weather first, while areas around the Mediterranean Sea focus on stability in hot weather. These differences in the area call for double angular contact bearing solutions that can adapt to a range of weather conditions.

European customers like to get supplies from nearby places and have faster delivery times. Just-in-time manufacturing methods need inventory to be always available and quick response to be possible. Being able to speak multiple languages and being available in the European time zone for urgent applications are part of the technical help expectations.

Regulatory systems like REACH and RoHS have an impact on the choices of materials and the ways things are made. More and more, European buyers need to see full records that show they are following safety and environmental rules. International guidelines are often not enough for a material and process records to be kept.

Purchasing Recommendations and Key Considerations

When you choose bearings for use in Europe, make sure you get them from providers who always meet the rules and provide high-quality products. Check the certification credentials, such as ISO 9001 quality management and other standards that are important to the business. Ask for test results and material Certificates that show how well they work for your particular use.

Don't just look at the buying price; look at the total cost of ownership. Bearings of higher quality that last longer often offer better value by lowering upkeep costs and making equipment more available. Check how well the service providers you choose are able to do technical help, emergency replacements, and condition monitoring.

Look at how customizable, non-standard apps are used in specialized European businesses. Suppliers who know engineering can get the best bearing specifications for certain situations. Before buying a lot of something, ask for sample testing for uses that are very important.

Set clear due dates for deliveries and ways to keep track of your goods. In Europe, many production schedules depend on precise coordination with bearing supply schedules. Think about local inventory options for emergency replacements and regular maintenance.

Industry Trends and Market Summary

European bearing markets are still changing in the direction of needing more accuracy and longer lifetimes. As digitalization moves forward, there is more demand for smart bearings that can track the condition of the bearing. Sustainability efforts support makers that show environmental responsibility and cycle economy ideas. The focus on local sourcing and making supply chains more resilient creates chances for responsive bearing suppliers who can offer a lot of technical help and quick delivery.

Conclusion

When choosing the right double angular contact bearings for use in Europe, performance requirements, rules, and what the provider can do all need to be thought about carefully. The bearings shown in this guide are used in many different kinds of businesses across Europe because they work well and are a great deal. Quality, accuracy, and dependability are still very important, and the total cost of ownership usually supports higher-priced products instead of cheaper ones. To get the most out of your bearings, you need to specify them correctly, have a professional install them, and keep an eye on their state.

FAQs

What makes double angular contact bearings different from single-row ones?

Double angular contact bearings have two rows of balls with symmetrical angular contact raceways. This design allows them to handle axial loads in both directions while keeping the bearings themselves small. These bearings are stiffer and can hold more weight than single-row bearings, which makes them perfect for situations where exact positioning is needed under combined loads.

How can I figure out which accuracy grade is right for what I'm doing?

Precision grade selection depends on how fast, how much weight, and how accurate the placement needs to be. For general commercial use, P0 grade works just fine. P6 grade is good for when you need moderate precision, and both P5 and P4 grades are used for high-speed spindles and machines that need to be very precise. For the best choice, you might talk to bearing experts.

What affects the length of bearing service life in European working conditions?

The service life relies on how much load there is, the temperature, the quality of the lubrication, and how dirty the environment is. In Europe, changes in temperature make it necessary to think about the effects of thermal cycling. Proper installation, choosing the right lubricant, and regularly checking the system's condition all greatly extend its operational life, well beyond what theoretical estimates would suggest.

Partner with INNO Bearing for Superior Double Angular Contact Bearing Solutions

INNO Bearing uses new technology to make amazing angular contact ball bearing solutions for European businesses by combining the knowledge they've built up over 30 years of manufacturing with new technology. From basic setups to custom designs with diameters of up to 5000 mm, our wide range of products makes sure that the best performance is delivered in a variety of situations.

Our technical team gives extra help with choosing bearings, installing them, and keeping an eye on condition. Customers in Europe benefit from fast shipping, with standard goods sent out in 48 hours and custom solutions finished in 15 to 20 days. Quality assurance includes a lot of tests and paperwork that shows the results meet European rules.

We are a trusted double angular contact bearing seller who keeps a lot of stock in European distribution centers so that important applications don't have to wait. Multilingual help and coverage of the European time zone for urgent needs are part of technical support. Emailing us at sales@inno-bearing.com will get you competitive prices and thorough information that is tailored to your needs.