Advanced Manufacturing Capabilities and Quality Assurance

State-of-the-Art Production Facilities

Chinese companies have made large investments in cutting-edge production facilities that use the latest bearing manufacturing technologies. These advanced arrangements enable the production of high-precision spherical roller bearings that meet demanding international standards. Computer-controlled machinery and automated production lines provide accuracy and consistency in every bearing produced, reducing the likelihood of defects and raising overall quality.

Rigorous Quality Control Measures

Leading Chinese bearing manufacturers use stringent quality control measures at every stage of the production process. Every stage is meticulously monitored, from selecting the raw ingredients to assessing the final result. Advanced testing equipment, including load simulation systems and accurate measuring instruments, is used to evaluate the bearings' lifetime and performance. Because of this commitment to quality control, Turkish importers have more faith in the reliability of spherical roller bearings manufactured in China.

Compliance with International Standards

Chinese producers use internationally accepted standards for quality management systems, such ISO 9001. Additionally, several follow certifications specific to the oil and gas industry, such API 610. Because of this dedication to international standards, the spherical roller bearings that Turkey imports are certain to meet or beyond the requirements required for a variety of industrial applications, from heavy machinery to precision equipment.

Cost-Effectiveness and Economic Advantages

Competitive Pricing Strategies

One of the primary attractions for Turkish importers is the low prices offered by Chinese manufacturers. Chinese manufacturers are able to provide spherical roller bearings at prices that are often more appealing than those of other international providers because to a combination of labor cost reductions, economies of scale, and effective manufacturing methods. For Turkish companies trying to reduce operating costs without sacrificing quality, this cost advantage is very important.

Reduced Total Cost of Ownership

After the initial purchase price, Chinese-made spherical roller bearings often provide a lower total cost of ownership. Longer service intervals and lower maintenance costs might result from these bearings' dependability and durability when purchased from reliable vendors. Because of its endurance, Turkish industrial processes eventually need fewer replacements, which reduces total expenses.

Flexible Payment and Shipping Terms

Diverse Product Range and Customization Options

Comprehensive Size and Type Availability

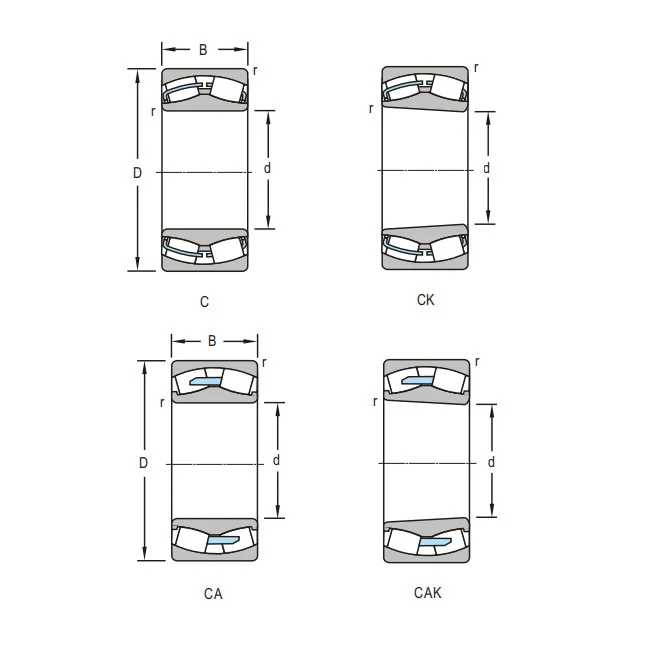

A wide variety of spherical roller bearings are available from Chinese producers to meet different industrial requirements. The range of possibilities is extensive, ranging from basic sizes to large-scale bearings with outer diameters up to 2000mm and inner diameters up to 1000mm. Whether it's for rolling mills, electric motors, reducers, or construction equipment, Turkish importers may get the precise specs they need thanks to our extensive assortment.

Customization Capabilities

Adjustment to Particular Industry

Adaptation to Specific Industry Needs

Chinese producers have mastered the art of creating spherical roller bearings for a range of industrial applications. For instance, they offer heat-treated models that can withstand temperatures of up to 150°C for metallurgical applications or sealed designs with IP66 certifications for dusty mining situations. Thanks to our industry-specific approach, Turkish importers may find bearings designed for their particular operational challenges, whether in port equipment, steel production, or other challenging industries.

Conclusion

Turkey imports spherical roller bearings from China due to a number of factors, including cost-effectiveness, product variety, and superior production capabilities. Turkish businesses find Chinese manufacturers to be a desirable supplier due to their capacity to create high-quality bearings that satisfy international requirements at cheap prices. China's status as a favored supplier is further cemented by the variety of alternatives available, including customisation possibilities. The strategic alliance with Chinese bearing makers will probably be essential to Turkey's economic development and technical progress as it expands its industrial base.

FAQs

1. What are the key features of spherical roller bearings?

Spherical roller bearings are self-aligning, capable of handling heavy radial loads, and can compensate for shaft misalignment. They typically have a double-row roller structure and are available in various sizes and materials.

2. What industries commonly use spherical roller bearings?

These bearings are widely used in industries such as electric motor manufacturing, construction machinery, rolling mills, and port equipment.

3. What precision levels are available for spherical roller bearings?

Precision levels typically range from P0 to P6, with higher precision grades available for critical applications.

Expert Spherical Roller Bearing Solutions for Turkish Industries | INNO Bearing

We at LUOYANG INNO BEARING CO., LTD provide premium spherical roller bearings designed to meet Turkey's industrial requirements. With over 30 years of experience, we provide customized Solutions up to φ5000mm, guaranteeing peak performance even in challenging circumstances. We are the perfect supplier for Turkish companies because of our cutting-edge production skills, strict quality control, and affordable prices. To find out how our bearings may improve your operations, send us an email at sales@inno-bearing.com.

References

1. Turkish Statistical Institute. (2022). Import Statistics on Industrial Components.

2. World Bearing Association. (2023). Global Bearing Market Analysis Report.

3. Journal of Industrial Engineering. (2021). Comparative Study on Spherical Roller Bearing Performance.

4. International Trade Center. (2023). Trade Map - Bilateral trade between Turkey and China.

5. Turkish Ministry of Industry and Technology. (2022). Industrial Sector Growth Report.

6. China Bearing Manufacturers Association. (2023). Annual Export Data and Market Trends.