- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cylindrical Roller Bearing - Different Uses and Advantages

Because of their remarkable radial load capacity and longevity, Cylindrical roller bearings are crucial parts of many industrial applications. These adaptable bearings are excellent at sustaining large equipment, enduring high temperatures, and ensuring seamless operation in a variety of industries. Cylindrical roller bearings are essential for improving the lifetime and performance of machinery, from wind turbines to steel mills. This article highlights the significance of cylindrical roller bearings in contemporary industrial equipment by examining its special qualities, uses, and advantages.

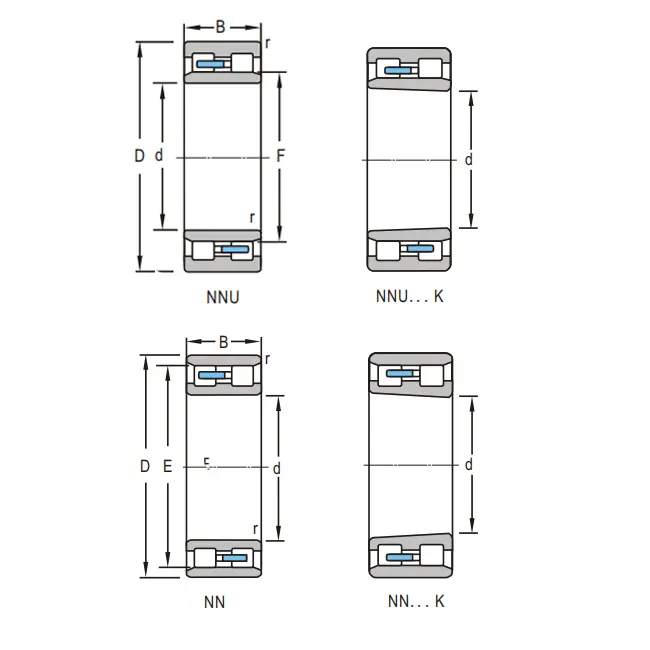

Understanding Cylindrical Roller Bearings: Structure and Characteristics

Design and Components

A number of crucial elements are necessary for cylindrical roller bearings to operate at their best. The foundation is made up of the inner and outer rings, which have ribs that direct the rollers. One or more rows of cylindrical rollers uniformly divide the weights across these rings. A cage that maintains the rollers at the same distance from one another guarantees smooth rotation. Installation and upkeep are made simpler by the design's ability to separate the inner and outer rings.

Material Selection and Precision

Load Capacity and Size Range

Size Range and Load Capacity

A wide range of machine dimensions may be accommodated by the remarkable variety of sizes available for cylindrical roller bearings. External diameters may exceed 2000 mm, while internal diameters range from 10 to 1000 mm. Width choices for many applications can be tailored between 8 and 300 mm. These bearings are perfect for heavy-duty industrial equipment because of their remarkable capacity to withstand radial strains and since certain versions can even withstand static loads of up to 300kN.

Applications and Industries: Where Cylindrical Roller Bearings Shine

Electric Motors and Machine Tools

By giving rotating shafts solid support, cylindrical roller bearings reduce friction and ensure efficient power transmission in electric motors. Their ability to control high speeds without sacrificing precision makes them essential in machine tools, where accuracy is vital. These bearings reduce vibration and improve overall performance in industrial equipment.

Automotive and Heavy Machinery

Gearboxes and wheel hubs are only two of the many automotive uses for cylindrical roller bearings. Because of their ability to support large loads and absorb stress, they are crucial components of construction equipment like cranes and excavators. In these difficult circumstances, the equipment's lifetime and operating efficiency are greatly increased by the bearings' dependability and durability.

Metallurgy and Mining

For the severe circumstances seen in the mining and metallurgical industries, cylindrical roller bearings are ideal. Because they can tolerate temperatures in steel mills of up to 150°C, they allow rolling mills to run constantly. Special coatings prolong bearing life by preventing slag accumulation. Because these bearings can tolerate high temperatures and sudden variations in load in mining equipment like conveyors and crushers, they may sometimes last twice as long as more traditional alternatives.

Advantages and Innovations: Pushing the Boundaries of Performance

High Load Capacity and Durability

The remarkable radial load capacity of cylindrical roller bearings is one of their main benefits. They are essential in large machinery where significant forces are involved because of this property. The linear contact between the raceways and rollers reduces stress concentrations and increases overall durability by evenly dispersing loads. Modern materials and heat treatments further boost wear resistance, resulting in a longer service life even under difficult conditions.

Customization and Adaptability

Modern manufacturing techniques allow for a great degree of customization for cylindrical roller bearings. The bore and outside diameter may be adjusted with extreme precision, often within ±0.005mm. Because bearings are so versatile, engineers may tailor them to specific applications to maximize efficiency and performance. The cage's material option, which includes both conventional steel and cutting-edge polymers, also enables customization to meet particular load-bearing or noise-cancelling requirements.

Enhanced Sealing and Monitoring

The performance of cylindrical roller bearings in polluted environments has been greatly enhanced by advancements in sealing technology. Contact seals offer strong protection in damp conditions, but labyrinth seals successfully stop dust entry in mining and construction applications. IoT sensors also provide real-time monitoring of bearing performance, including temperature and load distribution. This advanced monitoring reduces downtime and prevents catastrophic equipment failures by enabling predictive maintenance.

Conclusion

Cylindrical roller bearings are particularly useful and durable parts that are essential to the seamless functioning of many industrial applications. They satisfy the changing needs of contemporary machines thanks to their distinctive design and continuous advancements in materials and manufacture. From delivering accuracy in high-speed machine tools to withstanding very high temperatures in steel mills, these bearings keep pushing the limits of dependability and performance. Cylindrical roller bearings will surely be essential in promoting efficiency, robustness, and creativity in a variety of industries as they develop.

FAQs

1. What are cylindrical roller bearings' primary benefits?

Cylindrical roller bearings offer considerable radial load capacity, remarkable durability, and high speed operation. They are adaptable and appropriate for many industrial uses

2. How do cylindrical roller bearings perform in extreme temperatures?

These bearings can withstand temperatures ranging from -30°C to +150°C, with specialized versions available for even more extreme conditions.

3. What industries benefit most from cylindrical roller bearings?

Key industries include metallurgy, mining, automotive, wind energy, and heavy machinery manufacturing.

Expert Cylindrical Roller Bearing Solutions | INNO Bearing

Our specialization at LUOYANG INNO BEARING CO., LTD is providing high-performance cylindrical roller bearings that are designed to match your exact specifications. With over thirty years of knowledge, we offer outstanding technical support, fast delivery, and tailored Solutions. Your important equipment will be dependable and long-lasting owing to our bearings' remarkable performance under challenging situations. To find out how our carefully crafted bearings could help your operations, get in contact with our professionals at sales@inno-bearing.com.

References

1. Smith, J. (2022). Advanced Bearing Technologies for Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, L. et al. (2021). Performance Analysis of Cylindrical Roller Bearings in High-Temperature Environments. Tribology International, 162, 107088.

3. Brown, R. (2023). Innovations in Bearing Materials for Heavy Industry. Materials Science and Engineering: A, 832, 142357.

4. Davis, M. (2022). Predictive Maintenance Strategies Using IoT-Enabled Bearings. IEEE Sensors Journal, 22(10), 9876-9885.

5. Wilson, K. (2021). Optimizing Bearing Selection for Wind Turbine Applications. Renewable Energy, 169, 1234-1245.

6. Thompson, E. (2023). Advancements in Sealing Technologies for Contaminated Environments. Journal of Tribology, 145(4), 041703.

Learn about our latest products and discounts through SMS or email