Identifying Common Turntable Bearing Problems

Excessive Noise and Vibration

Unusual noise or vibration when the turntable is operating is one of the most obvious indicators of bearing problems. This may show up as rumbling, squeaking, or grinding noises, often accompanied by audible wobbling or trembling of the spinning machinery. These signs might point to a number of issues, such as poor lubrication, misalignment, or bearing component breakage.

To diagnose vibration and noise problems:

- Examine the bearing and its surroundings visually.

- Utilize vibration analysis instruments to pinpoint certain frequency trends.

- Look for structural problems or loose mounting bolts that might increase vibrations.

- Look for any indications of pollution or damage to the bearing's seals.

Irregular Rotation or Sticking

The rotation of a turntable bearing should be steady and smooth. During operation, jerky motions, brief sticking, or resistance might be signs of a number of possible problems:

- uneven deterioration of the rolling parts or bearing races

- contamination by foreign particles or debris

- Poor or deteriorated lubrication

- misalignment of the bearing or its attached parts

To deal with erratic rotation:

- Look for obvious indications of wear or damage on the bearing.

- If contamination is detected, clean the bearing and oil it again.

- Verify and correct the turntable's alignment with the related equipment.

- To find any variations from the requirements, measure the runout of the bearing.

Excessive Clearance or Play

Increased play or clearance in turntable bearings over time may compromise the accuracy and stability of the spinning machinery. Applications needing great precision, such radar systems or machine tool turntables, may find this problem especially troublesome. Excessive clearance might be caused by:

- Typical deterioration after prolonged usage

- Impact damage or overloading

- Initial installation or modification done incorrectly

- Preload loss in preloaded bearing designs

In order to resolve clearance concerns:

- Use dial indicators or specialist instruments to measure the axial and radial play.

- Examine the measured values in relation to the manufacturer's guidelines.

Examine any instances of overloading or impact that could have resulted in early wear, and if necessary, adjust the preload. If wear is considerable, think about replacing the bearing.

Diagnosing Lubrication-Related Problems

Insufficient Lubrication

Turntable bearing lifetime and smooth operation depend on proper lubrication. Wear, increased friction, and perhaps catastrophic failure may result from inadequate lubrication. The following are indicators of insufficient lubrication:

- A higher operating temperature

- audible grinding or squeaking sounds

- Metal-to-metal contact that is visible on bearing surfaces

- Decreased fluidity of rotation

To fix problems with lubrication:

- Examine and abide by the manufacturer's recommended lubrication regimen.

- Check for obstructions in the distribution channels and grease fittings.

- Use lubricants that are suitable for the particular working circumstances (temperature, load, and speed).

- Install a dependable lubrication monitoring system, including automatic grease dispensers or oil analysis.

Contamination of Lubricant

Just as harmful as inadequate lubrication might be contaminated lubricant. Dust, water, and metal particles are examples of contaminants that may accelerate wear and lead to early turntable bearing failure. The following are signs of tainted lubricant:

- Discoloration or an odd oil or grease consistency

- Observable dirt or particles in the lubricant

- Elevated noise levels or bearing temperatures

- Patterns of increased wear on bearing surfaces

To prevent contamination of the lubricant:

- Examine and clean the vicinity of the bearing seals on a regular basis.

- Use premium seals that are suitable for the working environment.

- Use the right handling and storage techniques for lubricants.

- For crucial applications, think about using filtered lubrication systems.

- Over-Lubrication

Although it's often disregarded, excessive lubrication may be just as harmful as little lubrication. Higher operating temperatures, greater energy consumption, and even seal damage might result from using too much grease or oil. Over-lubrication symptoms include:

- leaking of lubricant from mounting surfaces or seals

- Operating temperatures that are abnormally high

- Using more power to get beyond churning resistance

- Excessive pressure might cause seal damage or failure.

To avoid and deal with excessive lubrication:

- Observe the manufacturer's recommendations about the amount and frequency of lubrication.

- Establish a monitoring system to keep tabs on bearing performance and temperature

- use precise lubrication equipment to regulate the quantity of grease applied.

- Educate maintenance staff on appropriate lubrication methods and the dangers of overgreasing.

Addressing Structural and Alignment Issues

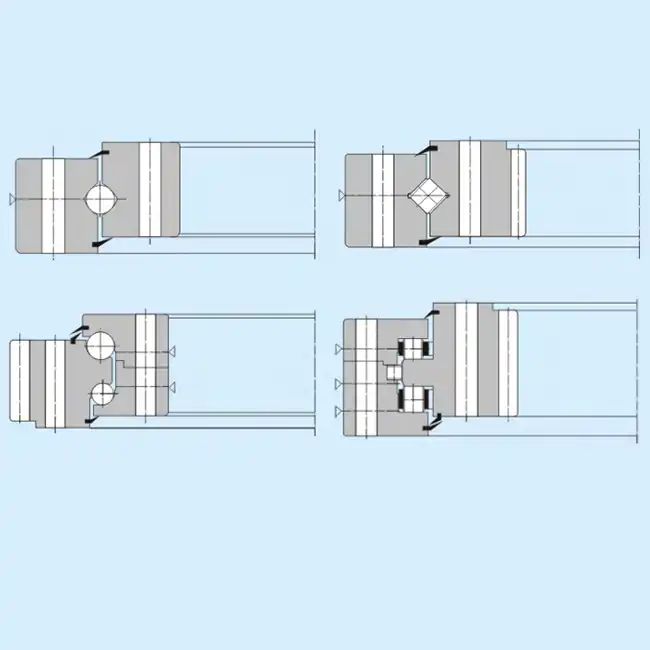

Mounting Surface Irregularities

The quality of a turntable bearing's mounting surface has a significant impact on its performance. Uneven load distribution, misalignment, and early bearing failure may result from irregularities including warping, unevenness, or inadequate flatness. Typical mounting surface problems include:

- Localized high points that result in unequal load

- deformation or warping of the underlying framework

- improper mounting surface preparation or machining

- Foreign particles or debris caught between the mounting surface and the bearing

To solve problems with the mounting surface:

- Survey the mounting surface's levelness and equality utilizing exactness estimation hardware, at that point utilize the right machining strategies to get the wanted surface quality (as a rule ≤0.1mm/m flatness).

- To fine-tune arrangement, think around utilizing shims or flexible mounting solutions.

- Prior to introducing orientation, make beyond any doubt mounting surfaces are completely cleaned and reviewed.

Misalignment Between Connected Components

For optimum performance and endurance, the turntable slewing bearing and its linked components must be properly aligned. Uneven load distribution, more wear, and less efficiency may all be caused by misalignment. Typical alignment problems consist of:

- Angle discrepancy between the mating and bearing parts

- Parallelism faults in systems with many bearings

- eccentricity between the coupled shafts' axis of rotation and the bearing center

- Misalignment caused by thermal expansion in high-temperature applications

To fix issues with alignment:

- For accurate alignment measurement and adjustment, use dial indicators or laser alignment equipment.

- Use a thorough alignment process both during installation and during significant maintenance.

- When designing, take into account the effects of thermal expansion and make allowances for high-temperature applications.

- As part of normal preventive maintenance, keep an eye on and maintain alignment.

Structural Deformation Under Load

A turntable bearing's supporting structure has to be sufficiently stiff to provide correct alignment and load distribution while in use. Reduced performance, uneven wear, and misaligned bearings may result from structural deformation. Among the elements causing structural problems are:

- Insufficient rigidity of the foundation or supporting structure

- Dynamic loads that are higher than those specified in the design

- Over time, structural components may get worn out or damaged.

- Effects of thermal expansion in big or hot applications

To lessen issues with structural deformation:

- Optimize structural stiffness throughout the design process by using finite element analysis (FEA).

- Do routine structural examinations, especially for sensitive or high-load applications.

During operation, use strain gauges or other monitoring tools to identify excessive deformation. Existing structures may need to be reinforced or retrofitted if deformation problems are found.

Conclusion

To effectively diagnose turntable Slewing Bearings, one needs a thorough grasp of bearing physics and possible failure mechanisms in addition to a methodical methodology. The lifespan and functionality of these vital parts may be greatly increased by maintenance teams by taking care of frequent problems including noise and vibration, lubrication difficulties, and structural issues. Many typical turntable slewing bearing problems may be avoided with regular inspections, good lubrication techniques, and attention to alignment and mounting surface quality. When issues do occur, timely and precise diagnosis combined with the right remedial measures may save downtime and guarantee the dependable functioning of rotating machinery in a variety of sectors.

FAQs

1. How often should turntable bearings be lubricated?

The lubrication frequency depends on the specific application, operating conditions, and manufacturer recommendations. Generally, it ranges from monthly to yearly intervals.

2. Can a damaged turntable bearing be repaired?

Minor issues can often be addressed through cleaning, re-lubrication, or adjustment. However, significant damage usually requires bearing replacement.

3. What causes premature wear in turntable bearings?

Common causes include inadequate lubrication, contamination, misalignment, overloading, and improper installation or maintenance practices.

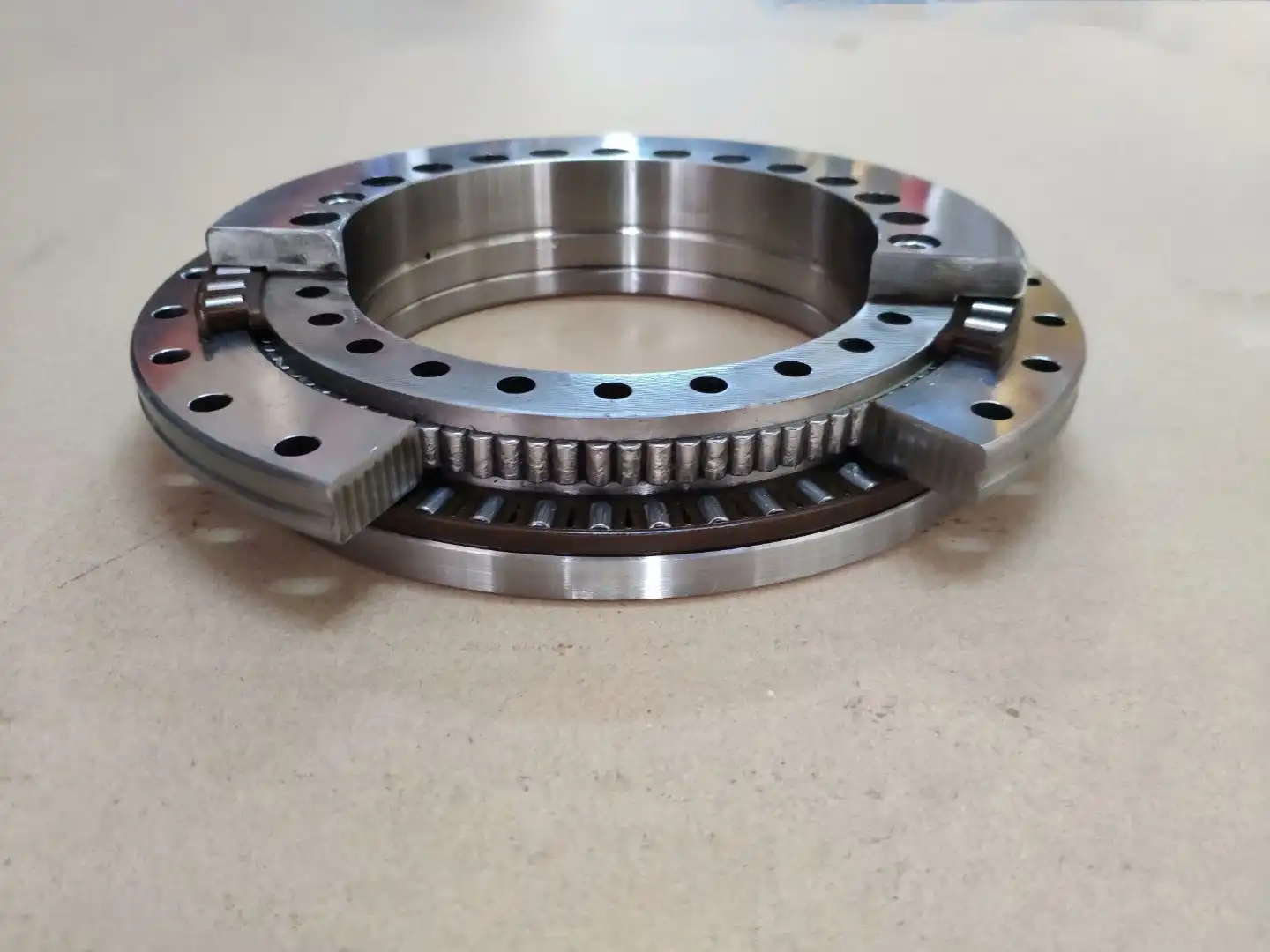

Expert Turntable Bearing Solutions for Industrial Applications | INNO Bearing

At INNO Bearing, we specialize in high-precision turntable bearings designed to withstand extreme industrial demands. Our custom solutions, ranging from φ200mm to φ5000mm, are engineered for heavy loads, high temperatures, and ultra-low noise operations. With rapid 15-20 day delivery and global technical support, we're your trusted partner for all turntable bearing needs. Contact Us at sales@inno-bearing.com for expert assistance and tailored solutions.

References

1. Smith, J. (2022). "Advanced Turntable Bearing Design for Heavy Industry Applications." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R. & Lee, S. (2021). "Lubrication Strategies for Extended Turntable Bearing Life." Tribology International, 162, 107088.

3. Zhang, Y. et al. (2023). "Structural Analysis of Large-Diameter Slewing Bearings Under Dynamic Loads." Engineering Failure Analysis, 140, 106560.

4. Brown, T. (2020). "Predictive Maintenance Techniques for Industrial Turntable Bearings." Reliability Engineering & System Safety, 203, 107085.

5. Garcia, M. & Patel, K. (2022). "Thermal Effects on Precision Turntable Bearing Performance." Journal of Tribology, 144(6), 061701.

6. Wilson, E. (2021). "Noise and Vibration Analysis in Turntable Bearing Systems: A Comprehensive Review." Mechanical Systems and Signal Processing, 161, 107950.