A carb bearing is a unique cylindrical roller bearing that doesn't have the inner or outer rings that are standard in most designs. Instead, it is built to handle radial loads and compensate for deviations in the installation with flexible mounting options. These one-of-a-kind bearings are now very important to industrial machines because they work better in situations that need to be able to hold a lot of weight and can be installed in many different ways. Unlike traditional bearings that depend on stationary ring structures, carb bearings use a new design with ring rollers and cages that are placed right next to the shaft and bearing housing. This gives them amazing operational benefits in tough industrial settings.

Understanding Carb Bearings: Definition, Function, and Types

Unlike most bearings, carb bearings don't have rings. This keeps great load-bearing capabilities while getting rid of the need for separate inner and outer rings. With this new method, the bearing assembly can work as a whole, and the ring rollers and cages work together to make sure that rotation happens smoothly, even when there are strong forces pushing out from the center.

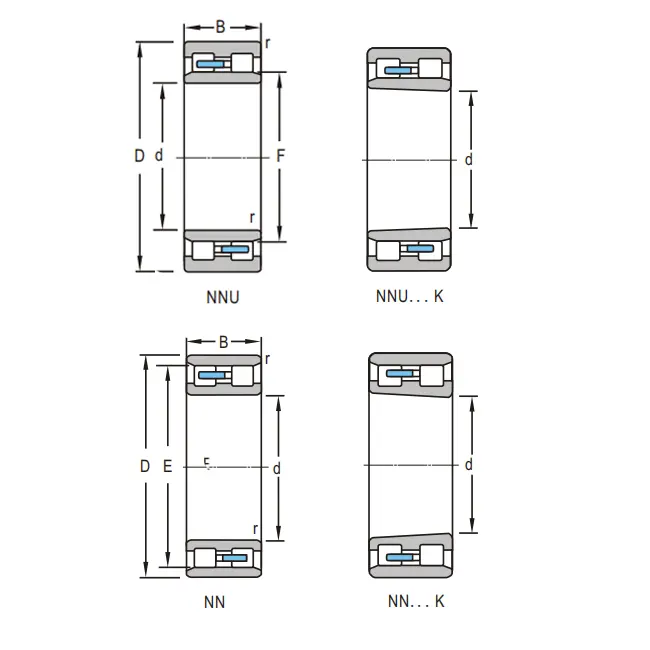

Key Design Rules and Building Parts

Ring rollers, cages, and contact seals are the three main parts that make up carb bearings. The ring rollers are made of high-quality materials like GCr15, GCr15SiMn, or 20Cr2Ni4A steel and provide a surface that can hold weight. The cage system keeps the rollers spaced and aligned correctly. Contact seals are made of nitrile rubber or fluororubber, depending on what the application needs. They keep the inside parts clean and hold the lubricants in place.

These bearings have inner diameters from 50 mm to 500 mm and outer diameters from 100 mm to 800 mm. Their widths range from 20 mm to 100 mm. Engineers can choose the right bearing specifications for a range of machinery needs in a number of different industries thanks to this dimensional flexibility.

Groups of materials and how they work

Choosing the right material is very important for bearing performance. Different types of steel have different levels of hardness, fatigue resistance, and environmental tolerance. Cage construction uses either stamped steel or brass, each with its own benefits depending on how it will be used. Cages made of stamped steel have great strength-to-weight ratios, and cages made of brass resist corrosion better in tough conditions.

The levels of precision range from the standard P0 and P6 grades to the high-precision P5 classes. These are used for applications that need very high precision and low vibration. These precision grades make sure that the parts are the same size and that the machine runs smoothly, which is important for delicate tasks.

Why Carb Bearings Are Unique: Functional and Material Advantages

The unique features of carb bearings come from their ability to make up for mistakes in how they are put together while keeping the best load distribution across the bearing surface. This compensation feature lowers the stress levels in places where they usually build up and make bearing systems fail early. This extends the system's lifespan and lowers the need for maintenance.

Managing Load and Flexible Operations

Carb bearings are great for radial load applications because they spread the force over several contact points. This keeps the bearing from wearing out quickly and extends the time between services. Since there is no ring in the design, it can handle thermal expansion. This means that when the temperature changes, the design won't bind or get too loose. This thermal compensation is especially useful when the temperature changes or when it is necessary for the system to work all the time.

Another big benefit is that the bearing assembly can be installed in different ways. It can adapt to minor shaft or housing issues without affecting how well it works. This adaptability lowers the machining tolerances that are needed and makes it easier to put things together, which lowers the costs and time needed for manufacturing and assembly.

Monitoring Performance and Maintenance Signs

Key factors that show how good carb bearings are are the roundness of the rollers, the way radial clearance is measured, and how well the seals contact the bearings. Roller roundness affects how weight is spread out and how vibrations behave, and radial clearance affects how smoothly it runs and how much weight it can hold. Seal contact performance makes sure that the seal works properly. This keeps the bearing safe from dirt and keeps the lubricant in place, both of which are very important for the bearing's lifespan.

Early warning signs of bearing deterioration include higher vibration levels, unusual noise generation, higher operating temperatures, and visible seal degradation. Keeping an eye on these parameters helps schedule maintenance before it is needed. This avoids total failures that would require expensive repairs after a long downtime.

Selecting the Best Carb Bearing for Your Needs: Procurement and Performance Considerations

Choose the best carb bear by considering operational parameters, environmental conditions, and performance expectations. Purchasers must consider technical specs, costs, and whether the new equipment will work with existing equipment and be easy to maintain.

Tech Details Review

Bearing load capacity calculations must account for static and dynamic loading. To ensure performance margins, engineers must consider maximum expected loads, duty cycles, and safety factors. Spinning speed is rotational speed. Because faster rotational speeds require more precise bearings and specialized lubrication systems, acceleration profiles and operating speeds affect bearing selection.

Temperature, pollution, and other environmental factors that degrade materials affect seal requirements. Metallurgical tools need high temperatures and strong seals.

Listed below are trusted brands and certifications.

Carb bearing manufacturers offer technical support, quality certifications, and reliable supply chains to their customers. ISO 9001 guarantees consistent, functional products. ISO 14001 companies aim to make things sustainably.

Special bearings improve performance but cost more and take longer to make. Normal bearings are cheaper and easier to get, but demanding applications may require modification.

How to Procure Carb Bearings Efficiently: Market Insights and Buying Guide

When you know the market and manage your relationships with suppliers, you can get the best prices, quality, and delivery. Understanding market dynamics and supplier capabilities makes it possible to source strategically. This supports the goals of the business and keeps costs down.

Supplier Assessment and Market Routes

For high-volume needs, the best technical support, prices, and quality assurance often come from direct manufacturers. Authorized distributors offer more products and local support, but specialized bearing suppliers might offer unique Solutions for certain uses.

It is usually much cheaper to buy a lot of bearings with the same size and specifications. Volume commitments let suppliers make the best use of their production time and scheduling when they need to buy raw materials. This helps cut costs, which can be passed on to customers.

Quality Control and Long-Term Management of the Supply Chain

Supplier quality certifications, inspection procedures, and testing capabilities make sure that products always work well and can be counted on. Quality management systems that are already in place make it possible to trace everything that happens during production. This makes it possible to quickly deal with any issues that affect quality and to always look for ways to improve.

Being able to bounce back in the supply chain requires a variety of suppliers and inventory management plans that find a balance between the costs of carrying inventory and the risks of running out of stock. Regional supplier networks give you backup sources for important bearing needs, cut transportation costs and lead times, and give you more options for getting supplies.

Company Introduction and Our Product & Service Offerings

For almost thirty years, Luoyang INNO Bearing Co., Ltd. has been making high-precision carb bearings for very difficult industrial applications. Our wide range of products includes standard and custom bearing solutions with diameters from 50 mm to 5000 mm. These products are used in many different industries, such as heavy machinery, mining, metallurgy, and power generation.

Our factory has high-tech production tools and strict quality control systems that make sure the products always work well and can be counted on. Custom engineering services make the best bearing designs for special uses, and rapid prototyping helps with custom projects' development and market times.

Technical support services include application engineering consultation, installation guidance, and maintenance training programs that are meant to get the most out of bearings and make them last longer. Our global network makes sure that products are delivered on time and support services are available in major industrial markets.

Conclusion

Carb bearings are a big step forward in bearing technology. Their ringless design and great load compensation make them stand out. Engineers can get the best performance out of their machines while keeping maintenance costs low by knowing how to choose and buy the right parts based on their unique features and how they will be used. Carb bearings are a great option for tough industrial uses that need top performance and a long service life because they are easy to install, have a high load capacity, and are reliable.

FAQs

Why are carb bearings durable?

Carb bearings last different amounts of time depending on their location, weight, care, and grease. If load calculations are correct, lubricants are chosen, and bearings are checked regularly, they will last. Product lifespan depends on installation location, temperature range, and pollution level.

Is this carb bearing compatible with my machines?

Consider load requirements, shaft and housing sizes, operating speeds, and environmental conditions to determine suitability. If you allow enough room, the technical specs should meet application needs. Talking to bearing experts helps make the right choice for unique or difficult applications.

How can carb bearings be protected from premature failure?

Temperature, seals, and vibrations are checked during preventive maintenance. It also requires frequent temperature and lubrication checks. Store properly, avoid contamination, and follow manufacturer instructions to reduce failure. Condition indicators or operating hours can determine replacements. This keeps things running smoothly.

Partner with INNO Bearing for Superior Carb Bearing Solutions

With almost 30 years of experience in manufacturing and cutting-edge engineering skills, INNO Bearing provides great carb bearing solutions. Our promise to high quality and customer satisfaction guarantees the best performance of bearings for your most difficult applications. Our technical team fully supports you with everything from the initial design to ongoing maintenance, whether you need standard setups or specially designed options.

Enjoy the benefits of working with a trustworthy carb bearing supplier that knows the problems you face in your business and offers dependable answers. We help you meet your procurement goals while keeping the quality high with our fast delivery and competitive prices. To talk about your bearing needs and learn how our knowledge can help your machinery run better, email us at sales@inno-bearing.com.

References

American Society of Mechanical Engineers. "Bearing Design and Application Guidelines for Industrial Machinery." ASME Standards Publication, 2023.

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2022 Technical Standard.

Society of Tribologists and Lubrication Engineers. "Bearing Technology and Lubrication Practices in Heavy Industry." STLE Technical Paper Series, 2023.

National Institute of Standards and Technology. "Materials Science and Engineering for Advanced Bearing Applications." NIST Special Publication 1200-27.

Bearing Industry Council. "Industrial Bearing Selection and Application Guide." BIC Technical Manual, Fourth Edition, 2022.

International Bearing Manufacturers Association. "Quality Standards and Performance Metrics for Cylindrical roller bearings." IBMA Technical Report TR-2023-05.