Picking out the right conical roller bearing for automotive wheel hubs takes a lot of thought.ing about performance specs, load needs, and environmental factors. These parts were thought out very carefully to deal with the complicated forces that come from different directions.swhile keeping the rotation smooth, even when the system is under a lot of stress. For modern cars, it is very important for engineers and buyers to be able to trust conical roller bearings because the tapered shape of these bearings makes sure that loads coming from the center and the axle are spread out more evenly.

Understanding Conical Roller Bearings in Automotive Wheel Hubs

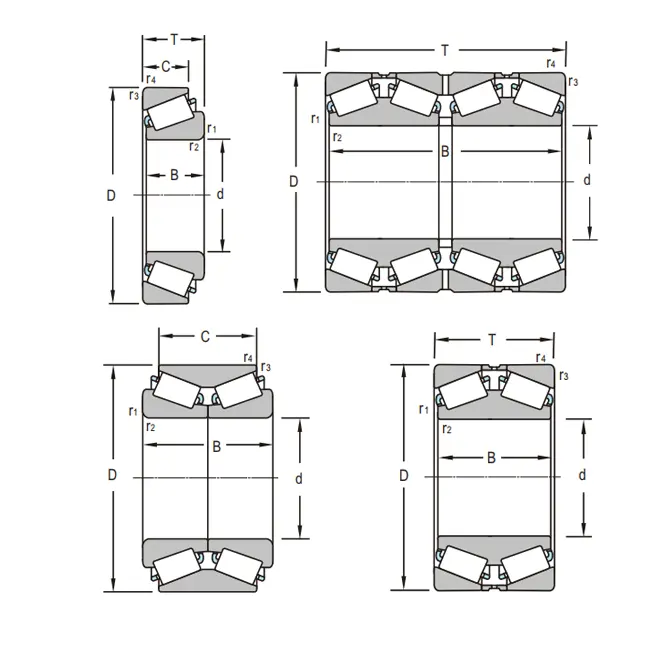

Conical roller bearings are a complex engineering solution that can handle both radial and axial loading at the same time, which is a condition of automotive wheel hub applications. The basic architecture has an inner ring with a tapered raceway, an outer ring (which can be taken apart for single-row setups or be fixed for double-row versions), precision-made rollers, and retention cage assemblies that keep the rollers at the right distance from each other while they are working.

Structural Design and How the Load Is Spread

The tapered shape makes a contact angle that spreads out the weight better than cylindrical or ball-shaped bearings. This benefit of the design is especially clear in wheel hub applications where bearings have to be able to handle different load vectors caused by the weight of the vehicle, cornering forces, and how braking works. The inner diameter usually lies between 10 mm and 1000 mm, and the outer diameter lies between 26 mm and 2000 mm. This gives a wide range of sizes that can be used for different car types.

The Standards for Material Composition and Manufacturing

High-performance conical roller bearings use high-quality steel mixtures like GCr15, GCr15SiMn, and 20Cr2Ni4A for important parts. Special heat treatments are used on the inner rings, outer rings, and rollers to get the best hardness and fatigue resistance. Stamped steel and brass are both used to make cages. The type of material used depends on the temperature range and the need for protection from the environment. Standard P0/P6 grades are used for most precision manufacturing, but very picky applications use P5/P4 specifications for ultra-precision.

Things to think about for sealing and lubrication

Road debris, moisture, and changing temperatures can make automotive wheel hubs very dirty. While sealed bearings keep dirt and dust out more effectively, open-type bearings make it easier to do maintenance and add new lubricant. Choosing the right lubricant is very important for the lifespan of conical roller bearings. Synthetic greases work better than petroleum-based greases in a wider range of temperatures.

Critical Criteria to Consider When Selecting Conical Roller Bearings

The only way to be sure that automotive wheel hub bearings will work well and last a long time is to carefully test the conditions under which they will be used. Engineers have to look at a lot of different things that are connected and affect how bearings work in the real world.

Analysis of Load Capacity

When dynamic load ratings are used, both the size and direction of the forces that happen while the vehicle is being used are taken into account to see if the bearing is suitable for that type of vehicle. Radial loads from the weight of the vehicle combine with axial loads that happen when the vehicle turns and brakes. To avoid failing too soon, the selection process has to take peak loading situations into account instead of just the average ones. Load calculations should include safety factors that are right for the expected length of time and severity of the application.

Factors that affect the environment and the way a business runs

Thermal expansion characteristics must be carefully thought about since temperature changes affect bearing clearances and how well lubrication works. The operating temperature range for most cars is between −40°C and +150°C. This means that materials and lubricants must be able to work well across this range. It is important for car parts to be resistant to contamination when they are exposed to road salt, water, and dust.

Expected lifespan and upkeep needs

Expected bearing life calculations use well-known standards in the field while taking into account a vehicle's specific duty cycles and ways of keeping it in good shape. Automotive manufacturers want longer service intervals more and more. This puts more focus on bearing durability and sealed bearing designs that lower the need for maintenance. Cost-effectiveness analysis figures out how the costs of buying something and the costs of owning it (like the costs of replacing it and the time it isn't being used) compare with each other.

Comparative Analysis: Conical Roller Bearings Versus Other Bearing Types for Wheel Hubs

It's easier to pick the right bearing technology for an automotive application when you know its advantages and disadvantages. Each type of bearing has its own special features that might make it a better fit for certain tasks or budgetary constraints.

Variations Between Tapered and Conical Roller Bearings

Many people think conical roller bearings and Tapered Roller Bearings are the same thing, but they have small differences in how they are designed that change the way they work. The way conical roller bearings contact each other is optimized to lower the amount of stress at the edges. This could lengthen the amount of time the service lives under conditions of high load. A better load distribution leads to less noise and vibration. This is good for passenger comfort and part longevity.

How Does It Compare to Other Technologies in Terms of How Well It Works?

Compared to conical rollers, ball bearings can handle more speed, less friction, and less axial load. When the load is applied radially, Cylindrical roller bearings work best. They aren't strong enough to handle the combined loading conditions of wheel hubs. Single-row and double-row conical roller bearings differ in how much weight they can hold, how much space they need, and how much they cost. These must fit with the vehicle platform's limitations.

Benefits that come with using the app

When combined loading conditions are harsh, conical roller bearings work much better in heavy-duty automotive applications. These apps include business vehicles, off-road gear, and high-performance cars. Since they can handle thermal expansion and misalignment, they are great for applications with tight tolerances or that need to be able to thermal cycle.

Procurement Considerations for Automotive Wheel Hub Bearings

When you want to buy bearings, you need to build strong relationships with suppliers and look at what each vendor can do for you beyond just the cost. The difficulty of today's car supply chains means that producers need to be able to make goods for customers all over the world with steady quality and on-time delivery.

Supplier Assessment and Certification Needs

Automotive industry standards require tough supplier qualification processes that use ISO 9001 quality management systems and IATF 16949 requirements that are only used in the automotive industry. Supplier evaluation should include quality control systems, technical support resources, and manufacturing capabilities. Established bearing manufacturers with experience in the auto industry understand how to best meet the needs of their customers and are able to offer ongoing support.

Customization and Amount Considerations

Standard bearing sizes might not get the best performance out of certain kinds of vehicles. This opens up chances to make custom Solutions that either get better performance or lower costs. Volume requirements affect how suppliers are chosen and how much things cost. Usually, larger orders get better terms and direct technical help. For production planning, lead time has to be taken into account, especially when non-standard specifications that need custom manufacturing processes are involved.

Quality Control and the Ability to Trace

Automotive applications need a lot of quality documentation and material traceability to help with warranty claims and recall situations when they are needed. Supplier quality systems need to keep records of inspections, test results, and proof of materials for every lot that is made. Advanced suppliers use predictive analytics and real-time quality monitoring to spot problems before they affect the production schedule.

Troubleshooting and Maintenance Tips for Conical Roller Bearings in Automotive Wheel Hubs

Proactive maintenance and early failure detection extend the service life of bearings. This lowers unexpected downtime and the costs that come with it. Knowing how things usually go wrong helps you focus on the right problems and not just the obvious ones.

Common Mistakes and Root Cause Analysis

Early bearing failures are usually not caused by bad design. Instead, they happen because of things like not putting enough grease on them, dirt getting in, or installing them the wrong way. Making noise almost always means there is a lot of dirt that needs to be cleaned up right away or a lot of damage. If something gets very hot, it could mean that the clearances are too small, the preload is set too high, or the lubrication is not working properly. These problems need to be looked at carefully.

Preventive Maintenance: A Few Tips

When planning inspection times that work with a vehicle's maintenance schedule, you should think about how hard it's working and where it is. Oil analysis is a way to check on lubrication. Before any damage is visible, it can find particles from wear and contamination. Watching the temperature while the system is moving can help you find problems early that you might not see when the system is not moving and during inspections.

Ways to Improve Performance

In tough automotive settings, bearings can work better with the help of specialized materials and high-tech surface treatments. Anti-corrosion coatings help things last longer in places where they can get wet or come into contact with chemicals. Better synthetic lubricants and seal designs protect bearings in tough conditions. These two big changes help fix a problem that used to make bearings wear down more quickly.

INNO Bearing: Your Trusted Partner for Automotive Wheel Hub Bearings

INNO Bearing's high-performance conical roller bearings are designed for use in automotive wheel hubs where performance is critical. Our wide range of products includes both standard and custom bearing solutions that are designed to meet the needs of today's changing vehicle platforms. With almost thirty years of bearing manufacturing experience, we use advanced metallurgy, exact manufacturing, and strict quality control to make bearings that are better than the performance standards in our field.

Our automotive bearing solutions use high-quality steel alloys and specialized heat treatment processes that can make the service life up to 40% longer than standard options. With diameters from 10mm to 5000mm, the manufacturing capabilities make it possible to find solutions for everything from small cars to big commercial trucks. Every bearing is tested fully with vibration analysis, dimensional verification, and performance validation to make sure that the quality and reliability are always the same.

The business keeps its ISO 9001 certification and IATF 16949 automotive quality standards. It helps car makers around the world by giving them trustworthy supply chain partnerships. Our technical support team helps with application engineering to make sure customers get the best bearings for their needs. The ability to quickly make prototypes helps create custom bearing solutions with shorter development times to meet tight schedules for launching products.

Conclusion

Choosing the best conical roller bearings for wheel hubs in cars needs a full study of the performance specs, load needs, and environmental conditions. Tapered roller bearings are especially good for tough automotive applications where reliability and longevity are very important because tapered roller geometry spreads the load better than other shapes. Successful bearing selection balances the need for technical performance with the need to keep costs down. It also makes sure that the supplier's abilities match the quality and delivery expectations. Knowing the pros and cons of different bearing technologies helps people make smart purchasing decisions that improve vehicle performance and lower overall costs. Proactive maintenance and early failure detection extend bearing service life while cutting down on unexpected downtime and the costs that come with it.

FAQs

How do car conical and tapered roller bearings differ?

Conical roller bearings' shape improves contact. This reduces edge stress and improves load distribution. These words mean the same thing, but they differ: This design change usually improves stability and quietness. It may last longer under heavy loads than other tapered roller designs.

How do I choose a wheel hub bearing size?

Consider the vehicle's weight, space, load conditions, and performance when choosing a bearing size. The inner diameter must match the shaft, the outer diameter must fit the housing bore, and the width must accommodate axial space limits. You should consider a vehicle's weight when moving and stopped, as well as its turning and braking forces, to determine its weight capacity.

How can you prolong your car's wheel hub conical roller bearings?

A bearing works best when properly installed, slick, and covered to prevent dirt from entering. Check for noise, temperature changes, and wear during regular inspections. Sealed bearings need less grease, but when they reach their service limits, they may need to be replaced.

Partner with INNO Bearing for Superior Automotive Bearing Solutions

For tough automotive wheel hub applications, INNO Bearing provides the best conical roller bearings in the industry. We can make a wide range of standard and custom bearing designs up to φ5000mm. This makes us the best conical roller bearing supplier for difficult automotive projects. We can help you with either standard replacement bearings or custom-made solutions for new vehicle platforms. Our technical knowledge and promise to deliver quality will make sure everything works well and is dependable.

Our global supply chain can help car manufacturers around the world by making sure that they always get good prices and on-time deliveries while keeping quality high. We have over thirty years of experience making bearings. To talk about your needs, please email us at sales@inno-bearing.com. Our technical team offers full application support to help you choose the best bearing solution while also getting the best performance and value for your automotive wheel hub applications.

References

1. Harris, T.A. & Kotzalas, M.N. (2007). "Essential Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, Automotive Bearing Applications Chapter.

2. Society of Automotive Engineers (2019). "SAE J692: Automotive Wheel Bearing Performance Standards and Testing Procedures." SAE International Technical Standards.

3. International Organization for Standardization (2018). "ISO 281:2007 Rolling Bearings - Dynamic Load Ratings and Rating Life." Automotive Applications Supplement.

4. American National Standards Institute (2020). "ANSI/ABMA Standard 7: Shaft and Housing Fits for Metric Radial Ball and Roller Bearings." Automotive Wheel Hub Applications.

5. Johnson, R.M. & Anderson, K.L. (2021). "Advanced Materials and Manufacturing Processes for Automotive Bearing Applications." Journal of Automotive Engineering, Volume 235, Issue 8.

6. European Automotive Bearing Manufacturers Association (2020). "Technical Guidelines for Automotive Wheel Hub Bearing Selection and Application." EABMA Technical Publication Series.