It is important to choose the right slewing ring bearing for heavy equipment. You need to think about the load needs, the environment, and the application's specific needs. The deciIt affects how well businesses run, how much it costs to keep equipment working, and how long equipment lasts in industries from wind energy to tomining. This complete guide gives procurement managers, engineers, and equipment makers the information they need to pick the right bearings. This will make sure they work well and get the best value for their money.

Understanding Slewing Ring Bearings: Fundamentals and Working Principles

Slewing ring bearings are advanced parts of machinery that can handle difficult loading conditions and make sure that everything can turn smoothly in any direction. These bearings with large diameters have five important parts: a fixed ring, a rotating ring, rolling elements, cages, and protective seals. The integrated design lets radial forces, axial loads, and tilting moments happen at the same time, which would be too much for most bearing systems.

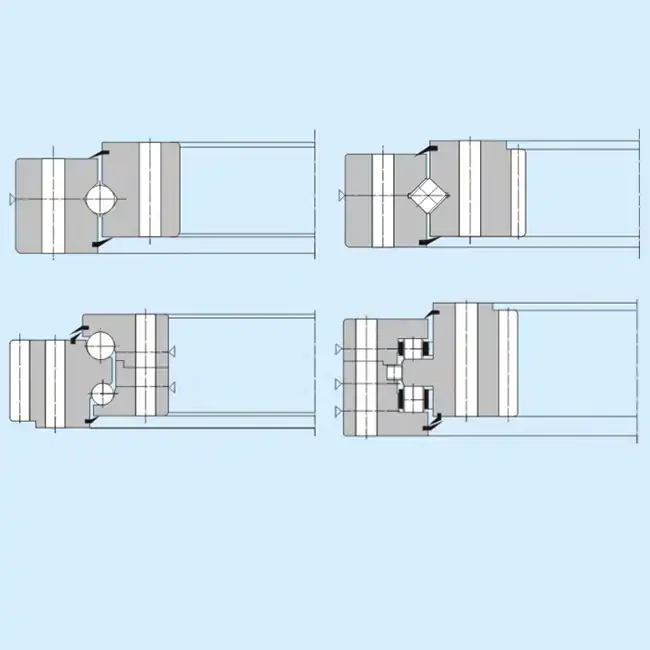

Structural Parts and Design Ideas

The basic structure has rollers set up in either a single- or double-row configuration, which depends on how the load needs to be spread out. Single-row designs take up less space, making them good for applications where space is limited. Double-row designs are better for tough working conditions because they are more stable and can hold more weight. The cage system keeps the rolling parts from hitting each other and makes sure that the right amount of space is between them. This guarantees that the bearing rotates smoothly for its entire lifetime.

Ways to Distribute the Load

Slewing Bearings are better than standard radial or Thrust bearings at handling compound loading situations. This is because radial and thrust bearings can only handle loads going in certain directions. This ability comes from the raceway geometry and large contact area that are designed to spread forces across multiple contact points. The design lets wind turbine nacelles follow the direction of the wind while holding up the very large rotor parts, or it lets excavators turn while carrying full buckets of dirt without losing strength.

Critical Factors to Consider When Selecting Slewing Ring Bearings for Heavy Equipment

A successful bearing choice needs a deep study of the operational parameters that affect performance and longevity. The first step in this evaluation process is to figure out the load capacity. This requires a deep understanding of the maximum forces that can be applied during operations and how those forces can move in different directions.

Configuration and Load Capacity Analysis

To find the right load ratings, you need to figure out the peak radial, axial, and moment loads while the equipment is running. Today's slewing ring bearings can handle axial loads of up to 15,000 kN and radial loads of up to 9,000 kN. Choosing bearings with enough of a safety margin will keep them from failing too soon. When making equipment, manufacturers must think about changing loading conditions, like shock loads from moving materials or wind gusts in turbine applications.

There are different benefits to using ball-type and roller-type configurations depending on the situation. Ball bearings allow things to rotate smoothly while only being able to handle a moderate amount of weight. This makes them a good choice for precision positioning equipment and moderate-duty applications. Roller bearings are better at handling loads, especially when it comes to heavy machinery that has to work under very stressful conditions all the time.

Choosing Materials and Environmental Factors

The performance of bearings in a wide range of conditions depends greatly on the material used to make them. Standard setups use 50Mn or 42CrMo steel for the inner and outer rings. These steels have great strength-to-weight ratios and are easy to work with. For normal use, rolling parts usually use GCr15 bearing steel, but there are GCr15SiMn options for when they need to be resistant to impacts.

Environmental factors make it necessary to be careful when choosing seals and checking to see if materials are compatible. Nitrile rubber seals work for most industries, but fluororubber seals are better if you need to protect against very high temperatures or chemicals. Specialized corrosion-resistant treatments help port machinery and offshore applications last longer in tough marine conditions.

Comparing Slewing Ring Bearings: Making Informed Decisions

When it's time to buy bearings, think about the total cost and find a supplier that can meet your needs. This method of testing helps find the best long-term Solutions for the business by considering both cost and value.

Size Range and Change-Making Ability

The inner and outer diameters of a standard slewing bearing range from 80 mm to 3,800 mm and 100 mm to 4,000 mm, respectively. It can be anywhere from 8 mm to 150 mm tall. This wide range can be used for anything from little machines to very big tools used in factories. Custom solutions make these settings more flexible to meet specific needs, which allows you to do things that aren't possible with regular products.

Quality Control and Performance Evaluation

The system runs well and the parts last a long time when manufacturing is done with precision. In the quality assessment process, the inspection process depends on dimensional accuracy, slewing flexibility, and rolling element noise levels. Quality manufacturers are able to achieve noise levels below 35dB and runout tolerances of 0.05mm. This keeps things running smoothly in places where noise is a concern.

After compliance certification, quality assurance is stepped up even more. The product meets international quality and safety standards as shown by the ISO 9001, CE, API 6A, and DNV-GL standards. These Certificates are very important for getting jobs in regulated fields, such as aerospace or offshore engineering.

Procurement Considerations for Slewing Ring Bearings

When you use strategic procurement, you look at what suppliers can do beyond just the basic details of their products. The length of time it takes to get something done, how much it can be customized, and support after buying can have a big effect on the success of a project and the long-term cost of running it.

Supplier Assessment and Risk Management

Well-known slew ring bearing manufacturers usually have to do a lot of tests and quality control on their products to make sure they always work the same way. The ability to make things, provide technical support, and cover a wide area should be part of the evaluation criteria. Suppliers that offer rapid prototyping and custom engineering services make it easier to meet the needs of different applications.

Sample testing, quality verification procedures, and clear warranty terms are all ways to manage risk. Suppliers that can be trusted give performance validation data and material traceability documentation that help with maintenance planning and following the rules.

Managing Logistics and Your Stock

Large-diameter bearings need to be shipped in a certain way and carefully handled so they don't get damaged in transit. Suppliers with global distribution networks can manage regional inventory to get things to you faster and for less money. Understanding volume pricing structures and minimum order quantities helps keep the procurement budget in good shape while making sure there are enough spare parts on hand.

Best Practices to Maximize Slewing Ring Bearing Lifespan in Heavy Equipment

Proper installation, upkeep, and monitoring of bearings greatly extend their useful life and help avoid unexpected costs due to downtime. These steps must be done carefully and according to the manufacturer's instructions for the entire life of the equipment.

Installation and Starting-Up Steps

With the right tools and methods, precise installation keeps bearings from failing too early because of bad mounting or alignment problems. To make sure the best performance is achieved, surface preparation, bolt torque sequences, and alignment checking must follow the manufacturer's instructions. Professional installers have a lot of knowledge and use special tools that lower the risk of installation errors.

Condition Tracking and Maintenance Planning

Regular inspections make it possible to spot early on changes in lubrication, wear patterns, and seal breakdown. Recommended maintenance intervals depend on how heavily and in what conditions the equipment is used, but usually there are detailed checks once a year and visual checks every three months. Lubrication methods that use greases specified by the manufacturer keep the thickness of the film and stop contaminants from getting in and making the wear rate faster.

Advanced monitoring systems keep an eye on temperature changes, vibration patterns, and rotational resistance. These can show that problems are developing before they cause a failure. This method of prediction finds the best time to replace bearings and plans maintenance with as little effect on production as possible.

INNO Bearing: Your Trusted Partner for High-Performance Slewing Solutions

For almost thirty years, Luoyang INNO Bearing Co., Ltd. has been making high-quality slewing ring bearings for difficult industrial needs. Our full range of services includes R&D, custom design, manufacturing, and technical support that is tailored to the needs of heavy equipment in a variety of industries.

We offer standard bearings and engineered-to-order bearings with outer diameters up to 5000 mm. We use advanced materials and manufacturing methods that make our products very reliable. We focus on customization, repairs, and import substitution. These services provide affordable options to high-end brands while addressing the unique challenges of each business.

Advanced testing tools and strict quality control methods make sure that all of the bearings meet high performance standards. Our fast delivery and full technical support make it easy for projects to go smoothly from the first meeting to ongoing service support. Our knowledge is important for rotating applications in industries like heavy machinery, mining, power generation, and wind energy.

Conclusion

It is important to carefully consider the amount of load, the environment, the material specifications, and the capabilities of the supplier when choosing the best slewing ring bearing. Success depends on knowing the needs of each application and finding a balance between the cost and the value of the operation in the long term. Proper installation, upkeep, and monitoring of bearings will make them last longer and make sure the equipment is reliable. When you work with experienced manufacturers who offer a lot of technical support and customization options, you can be sure that your heavy equipment will work well for a variety of different tasks.

FAQs

How do I figure out the right load capacity for me?

Find the maximum radial, axial, and moment loads when your machine is working at its highest capacity. Then, pick bearings that can take at least 25% more than these loads. Think about how your kind of equipment will change over time and how much force you need to safely use it and keep things safe when you use it.

How often do you need to take care of the slewing bearings on your heavy equipment?

Check the tools every three months. Do a more thorough check once a year and grease it the way the maker says to. The best performance intervals may need to be changed based on the conditions, the weight of the load, and the setting.

Can you make slewing bearings that will work with any kind of equipment?

Yes, experienced makers offer custom designs with choices like size, material, built-in gearing, and unique mounting setups. If standard products don't meet the right standards, customization makes sure that applications can still work perfectly.

Partner with INNO Bearing for Superior Slewing Ring Bearing Solutions

INNO Bearing's precision-engineered slewing ring bearings can help your heavy machinery work better. Our skilled engineers will help you choose the right bearings for your application by talking with you about your needs and providing ongoing support. No matter if you need standard setups or custom solutions, our manufacturing and technical knowledge ensure dependable performance that gets the most out of your equipment.

Find out how our high-tech materials, strict quality checks, and ability to deliver quickly can help make your projects more successful. To talk about your bearing needs and look at customization options that can help with specific operational issues, get in touch with our technical specialists. As a top slewing ring bearing manufacturer, we offer customers low prices, long warranties, and continued support that lowers total ownership costs.

Ready to get the most out of your heavy equipment? For professional advice and good prices on goods that meet the needs of your project, email us at sales@inno-bearing.com.

References

Harris, T.A. & Kotzalas, M.N. "Rolling Bearing Analysis: Essential Concepts of Bearing Technology." CRC Press, 2007.

Schaeffler Technologies AG & Co. "Large Size Bearings Technical Handbook." Industrial Engineering Publication, 2019.

American Society of Mechanical Engineers. "ASME B3.17-2019: Design Guidelines for Slewing Bearings." ASME Standards Committee, 2019.

International Organization for Standardization. "ISO 12043:2007 Rolling Bearings - Single Row Slewing Bearings." ISO Technical Committee, 2007.

Burton, P.D. "Heavy Equipment Maintenance and Reliability Engineering." McGraw-Hill Professional, 2018.

Wind Power Engineering & Development. "Bearing Technology Advances for Wind Turbine Applications." Industrial Press Technical Review, 2020.