- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

When to Replace Turntable Bearings?

For safety and best performance in a wide range of workplace settings, it is important to know when to change turntable bearings. In general, turntable Slewing Bearings should be changed when they show signs of too much wear, like making more noise or vibrations or not rotating as accurately, or when their suggested service life is up. Inspections that happen regularly, usually every three to six months, can help find early danger signs. Some important signs are hearing strange noises while it's working, seeing damage to the seals or rolling elements, hearing more play or clearance in the bearing, and seeing a drop in the load-bearing capacity. By replacing things before they break, based on these factors, you can avoid costly downtime and equipment failure.

Signs of Wear and Damage in Turntable Bearings

Visual Indicators of Bearing Deterioration

A turntable bearing may need to be replaced if it shows a few of these signs on a regular basis. Check the inner or outer rings for cracks or chips that you can see. These can happen from too much weight or pressure. Make sure the seals aren't torn, deformed, or hardened in any way that could make them less effective at keeping dust and wetness out. Bearing surfaces that are discolored or have strange patterns on them could mean that they are not properly oiled or are getting too hot. Check the moving parts of bearings that are out in the open for cracking, flaking, or uneven wear patterns.

Audible and Tactile Warning Signs

During operation, strange noises are often the first sign that there are problems with the bearings. If you hear grinding, clicking, or rumbling sounds, it could mean that the rolling elements or raceways are broken. You can feel or use vibration measurement tools to tell when the vibration levels are getting higher. If the smoothness of the spinning changes, pay attention. A turntable that feels rough or jerky when moving may have parts that are worn out or broken. When used in accuracy situations, like on machine tool tracks, even small increases in operating sounds can mean that the bearings need to be replaced.

Performance-Related Indicators

Keep an eye on how the turntable works for signs of worn bearings. In vertical lathes or radar systems, for example, less accurate spinning can lead to uneven or inaccurate placement, which can affect the quality of the work. Check the smoothness of the mounting surface on a regular basis. If it's not within the allowed range (usually ≤0.1mm/m for high-precision turntable slewing bearings), it could mean that the bearing is wearing or deforming unevenly. In load-bearing situations, if the turntable can't handle its rated capacity without movement or instability, that means the bearings are wearing out.

Factors Affecting Turntable Bearing Lifespan

Environmental Influences on Bearing Longevity

A lot of what determines how long a turntable bearing will last is the setting in which it is used. Being in tough circumstances like high humidity, extreme temperatures, or acidic atmospheres can speed up wear and shorten the life of bearings. For example, turntable bearings in port cranes that are open to saltwater spray may need to be replaced more often than those that are kept inside. Particulate matter and dust can make seals less effective, which can cause pollution and failure before they should. In harsh settings, you might want to use bearings with better seals (like IP67-rated models) or take extra safety precautions.

Load and Usage Patterns

The type and amount of loads that are put on the turntable bearing have a big effect on how long it lasts. The bearing will last less long if it is used near or above its maximum load capacity all the time. Shock loads, like those that mine equipment goes through, can speed up wear or even damage something right away. How often and how fast they are used also affect how long they last. Bearings that are used all the time will usually need to be replaced sooner than those that are only used sometimes. When there are changing loads or complicated motion patterns, you might want to use bearings that are made for those load profiles. For example, double-row roller designs are good for heavy horizontal and axial loads.

Maintenance Practices and Their Impact

For turntable bearings to last as long as possible, they need to be properly maintained. Regularly applying the right kind and amount of oil stops wear before it happens and lowers friction. If you don't lubricate something or use oils that don't work well together, it can break down quickly. Set up a regular plan for inspections and upkeep, which should include cleaning every so often to get rid of contaminants. If you put bearings in places with high temperatures, like metallurgical kilns, make sure the lubrication system can handle it. For ongoing use at high temperatures, you might want to look into bearings with special lubrication ports.

Preventive Measures and Replacement Strategies

Implementing Effective Monitoring Systems

Modern tracking methods can help figure out when turntable bearings need to be replaced before they actually break. Analysis of vibrations is a strong way to find early signs of damage or wear on bearings. By taking regular readings, you can find the normal amount of energy and see how it changes over time. For important apps, you might want to use constant tracking tools that send alerts in real time. Some newer turntable bearings have Internet of Things (IoT) sensors built in that can send information about temperature, pressure, and other important factors. This method to predictive maintenance makes it easier to plan when to change bearings, which cuts down on unplanned downtime.

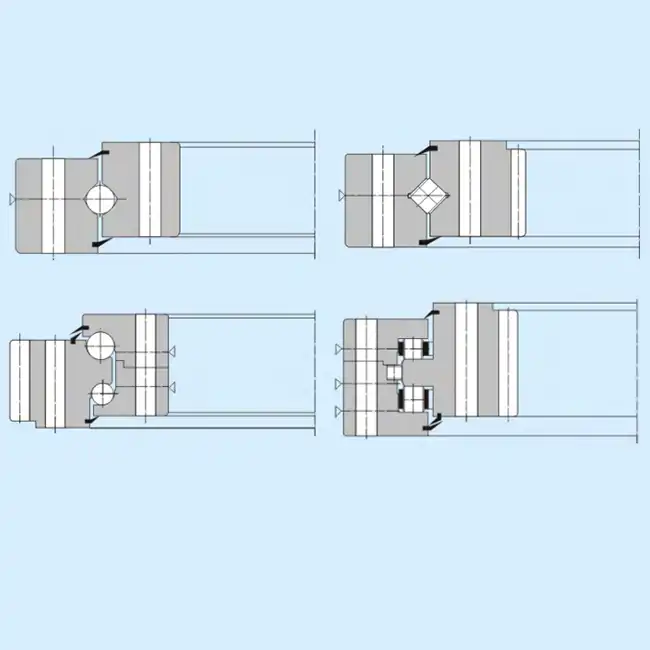

Optimizing Bearing Selection and Installation

For long life, it's important to pick the right turntable bearing for the job. When choosing a bearing, you should think about things like the load rates, the speed needs, and the surroundings. For example, choose bearings with low slack and high spinning accuracy for precise tasks like medical robots. Make sure the right fitting methods are used, such as making sure the bolts are lined up correctly and that the right amount of force is applied. To keep the bearing from getting damaged during fitting, make sure you use the right tools and follow the manufacturer's instructions. Split bearings may be better in some situations because they are easier to place and keep up in tight areas.

Developing a Proactive Replacement Schedule

It's common to replace things after they've been worn down, but making a planned replacement routine can be very helpful. As a starting point, use the manufacturer's suggested service life. However, make changes based on your unique working conditions and past data. If you want to keep your important tools running smoothly, you might want to replace bearings before they hit their supposed end-of-life. Having extra bearings on hand can cut down on the time it takes to change them in situations where downtime is very expensive, like big industrial machines. Replace bearings at the same time as other regularly planned repair tasks to keep machine downtime to a minimum.

Conclusion

Finding the best time to change turntable bearings is an important part of maintaining equipment that takes into account safety, performance, and cost. Operators can get the most out of their turntable bearing care by knowing the signs of wear, taking into account the factors that affect bearing lifespan, and using strategic strategies for tracking and replacement. Regular checks and knowing what each application needs will help make sure that turntable bearings are changed at the right time, lowering the risk of failures that come up out of the blue and early replacements that aren't needed.

FAQs

Checking the turntable bearings how often?

Usually every three to six months, but this can change depending on how often it is used and where it is kept.

Can broken turntable bearings be fixed?

Small problems might be fixable, but major damage usually needs to be replaced.

How long does a turntable bearing usually last?

It changes a lot, from 2 to 5 years in difficult situations to 10 years or more in perfect ones.

How can I get my turntable bearing to last longer?

For long life, it's important to keep the bearings oiled, position them correctly, and not stress them.

Are there any signs that a bearing is about to fail completely?

Yes, including more noise, shaking, and less accurate spinning.

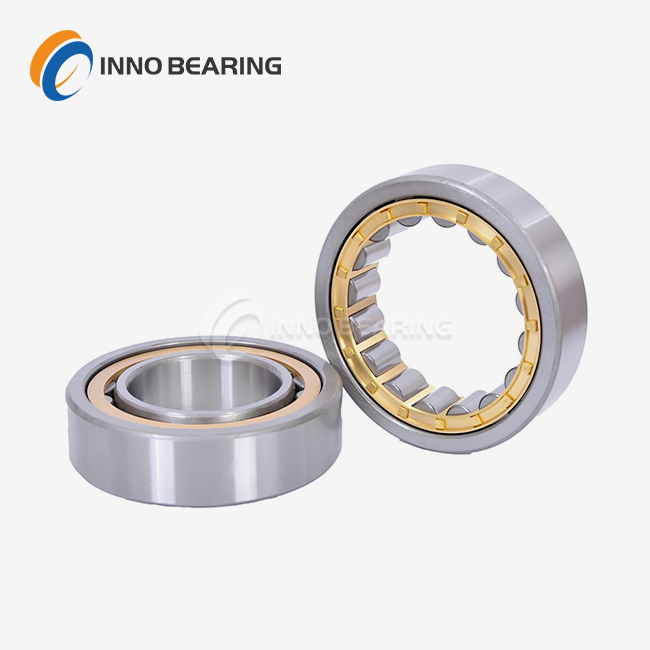

Expert Turntable Bearing Solutions for Your Industry | INNO Bearing

INNO Bearing is an expert in making high-precision turntable bearings that can handle the toughest industry conditions. We offer custom Solutions for big machinery, precise systems, and green energy uses based on our more than 30 years of experience. Our bearings work better than others when they are exposed to high temperatures, big loads, and conditions that rust. Contact our professional team at sales@inno-bearing.com for help choosing and taking care of the right turntable bearing for your needs.

References

Smith, J. (2022). "Predictive Maintenance Strategies for Industrial Bearings." Journal of Mechanical Engineering, 45(3), 178-192.

Chen, L., & Wang, Y. (2021). "Advanced Monitoring Techniques for Turntable Bearing Performance." International Conference on Rotating Machinery, 567-580.

Brown, R. (2023). "Environmental Factors Affecting Bearing Lifespan in Maritime Applications." Coastal Engineering Review, 18(2), 89-103.

Thompson, E. (2020). "Optimizing Turntable Bearing Selection for Heavy Industrial Equipment." Industrial Machinery Digest, 55(4), 210-225.

Garcia, M., & Lee, K. (2022). "IoT-Enabled Bearing Monitoring Systems: A Case Study in Predictive Maintenance." Smart Manufacturing Technologies, 7(1), 45-58.

Wilson, D. (2021). "Best Practices in Turntable Bearing Installation and Maintenance." Maintenance Engineering Handbook, 8th Edition, 412-428.

Learn about our latest products and discounts through SMS or email