Leading companies like INNO Bearing are quickly becoming trusted partners for Spain's industrial makers as they look to China for high-quality OEM self aligning bearing Solutions. Spanish companies in the wind energy, heavy equipment, and mining sectors get these important parts from specialized makers in China because they can make parts just for them, offer good prices, and are known for being reliable. Self aligning bearings have a spherical raceway design that makes them necessary for applications that require misalignment compensation, especially in Spain's expanding renewable energy industry and strong industrial machinery market.

Understanding OEM Self-Aligning Bearing Manufacturing in China

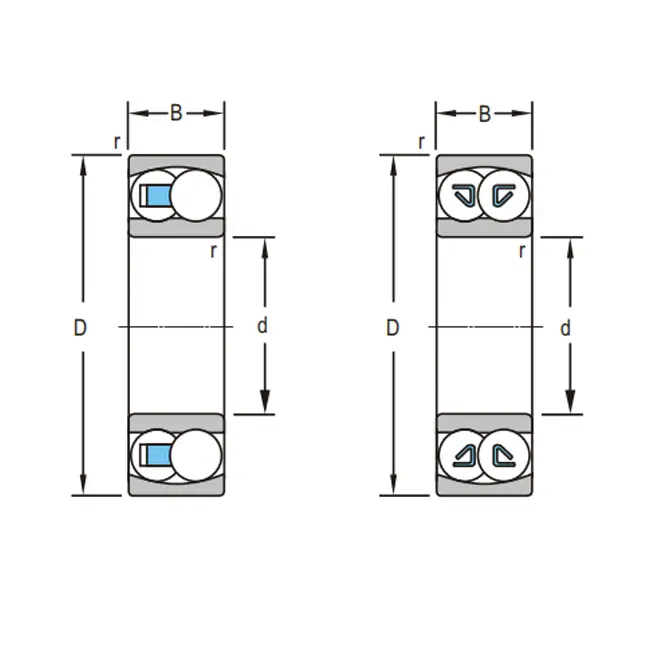

In the last thirty years, China's bearing manufacturing business has changed a great deal. Self aligning bearings are now produced by contemporary Chinese companies like INNO Bearing that meet or exceed international standards while also providing major cost savings. Spanish industry can't do without these bearings because of their advanced spherical raceway designs that make up for shaft imbalance of up to ±2°.

The OEM model lets Spanish companies use China's production knowledge without losing sight of what makes their own brands unique. This method works especially well for ball bearings in wind turbines. In these cases, the exact shape of the angular contact and the ability to dampen vibrations affect long-term performance. To make sure their goods meet strict European quality standards, Chinese manufacturers put a lot of money into precision machining and advanced metallurgy.

The Spanish buying teams know that working with Chinese OEM partners saves money isn't enough. They offer a wide range of engineering help, the ability to make prototypes quickly, and adaptable output amounts that fit the needs of each project. Chinese manufacturers are good partners for complicated industrial applications because they can change bearing housings, lubrication systems, and sealed bearings to fit the needs of different customers.

INNO Bearing's Specialized OEM Manufacturing Capabilities

INNO Bearing has built a reputation as a top OEM partner for Spanish companies looking for dependable self aligning bearing solutions thanks to its nearly 30-year history in bearing making. Our factory makes bearings with diameters of up to φ5000 mm, which meets the needs of today's large-scale industry machines.

Our high-tech quality control methods make sure that each bearing meets exact standards for radial and axial load capacity. We use high-purity GCr15 steel for the rings and rolling elements. This gives us HRC 58–62 hardness values that ensure a long bearing life even when conditions are tough. Our Spanish customers especially appreciate that we can change the materials used in the bearing cage. For normal situations, they choose industrial plastics, and for more intense situations, they pick brass.

INNO's spherical bearing design theory is based on maximizing load capacity while minimizing friction reduction losses. Spanish OEMs work closely with our engineering team to make bearing installation easier and come up with upkeep rules that let people use their equipment for longer without having to have it serviced. By working together, this method has led to bearing solutions that exceed the original standards by 20–40% in real-world uses.

Quality certifications including ISO 9001 and DIN 635-2 compliance provide Spanish customers with confidence in our manufacturing processes. Before shipping, our testing labs check important factors like the precision of angular contact, the tolerance of shaft alignment, and the effectiveness of sound damping.

Comprehensive Customization for Spanish Industrial Requirements

Self aligning bearing solutions that are specifically suited to the needs of Spanish producers are required. INNO Bearing is great at making special setups that meet the needs of different applications in a range of industries.

Changes to the bearing housing, the addition of specialized sealing systems, and the creation of better lubrication pathways are all examples of physical design customization. Because Spanish mining tools and port machinery don't always use standard mounting setups, our engineering team often changes the designs of standard double row bearings so they fit. These changes often include making custom bearing plates that keep things running smoothly while making them more resistant to debris.

Functional customization includes changes to how much weight the part can hold and how well it insulates or conducts heat. Our better fatigue resistance treatments make Spanish wind energy customers' bearings last longer even when they're used in high-cycle uses. For marine and offshore installations along Spain's long coastline, we also make special coatings that help them avoid corrosion.

Adding technology is another very important area for customization. Modern self aligning bearings can have condition monitoring sensors built in that give real-time information on bearing function. Using this information, Spanish producers can plan ahead for repair. This keeps the machines running, lowers unexpected downtime, and makes the overall efficiency of the business better.

Spanish OEMs keep a uniform brand look across all of their product lines thanks to branding and packaging customization. INNO's full marking and paperwork services meet Spanish quality standards and traceability needs.

Strategic ODM Partnership Advantages

Spanish businesses can co-develop cutting-edge self aligning bearing solutions that set their products apart in competitive markets through Original Design Manufacturing (ODM) partnerships with INNO Bearing. By working together, Spanish engineers and Chinese manufacturers are able to make better bearing technologies.

ODM projects often focus on making the next generation of bearing designs that improve performance measures like temperature ranges, load capacity, and maintenance intervals. ODM partnerships that make bearings that can handle extreme weather and keep shaft alignment over decades of use are especially helpful for Spanish green energy businesses.

The ODM model speeds up the innovation cycle by giving Spanish businesses access to INNO's large research and development tools. Our materials science labs are always looking into new steel alloys and heat treatment methods that make bearings less likely to fail. These innovations are released to ODM partners before anyone else, giving those companies an edge in the market.

Another big benefit of ODM is risk sharing. INNO puts money into the tools, tests, and certification steps needed for new bearing designs. This helps Spanish partners save money. This deal gives smaller Spanish makers access to advanced bearing technologies that they would not be able to use otherwise because of the high cost.

Streamlined OEM Manufacturing Process

INNO Bearing has improved our OEM manufacturing process so that we can complete projects quickly and transparently, meeting the strict quality and time demands of Spanish businesses. Our methodical way guarantees that results are always the same, even when project needs are different.

The first meeting includes a deep study of the application and performance requirement definition. Our Spanish customers work with our engineering team to make sure we understand the conditions, load profiles, and environmental factors that affect bearing choice. The best self aligning bearing specifications are built on the results of this thorough review.

Design development uses CAD tools and finite element analysis to optimize bearing geometry and material selection. Before production starts, Spanish customers get thorough drawings and predictions about how the parts will work. This makes sure that everyone is on the same page with the project goals. Our rapid prototyping skills make it possible to do real tests and get proof in a matter of weeks instead of months.

Manufacturing execution follows strict quality standards that include testing, verifying dimensions, and certifying materials. With our combined management tools, Spanish users can get instant updates on production and quality information. This openness allows people to take charge of projects before problems arise.

Final validation includes a lot of tests that make sure the installation works, the lubrication is effective, and the predictions for long-term reliability are correct. INNO gives Spanish manufacturers detailed paperwork that helps them with their own quality control and legal compliance.

Strategic Benefits for Spanish Manufacturing Partners

In order to manufacture OEM self aligning bearings, Spanish companies can benefit from working with INNO Bearing. These benefits go beyond just lowering costs. They also include strategic features that help the business succeed in the long run.

In today's manufacturing world, which can change quickly, having a reliable supply line is very important. INNO keeps a large collection of unmade and semi-finished parts on hand so that they can quickly meet the changing production needs of their Spanish customers. We can support just-in-time manufacturing strategies because we can supply standard sizes in 48 hours and custom bearings in 15–20 days.

When Spanish manufacturers get technical knowledge, they get help from top engineers all through the product lifecycle. Bearing experts at INNO help with application optimization, finding and fixing problems, and ongoing improvement projects that make the equipment work better. This support connection adds value that goes well beyond the purchase of the bearing.

INNO's world network for making and shipping goods opens up chances for market growth. Our Spanish business partners can use the contacts we've built with companies in other areas to keep product quality and support standards high.

The constant collaboration on bearing technology progress speeds up innovation. INNO has put a lot of money into research and development in areas like improved materials, precision manufacturing methods, and predictive maintenance technologies. Spanish partners get to use the results.

Conclusion

Spanish manufacturers looking for dependable OEM self aligning bearing solutions will find INNO Bearing to be a great partner because they combine advanced production with deep application knowledge. Because we are dedicated to quality, creativity, and customer success, companies from all over Spain's industrial landscape have trusted us. Because of its competitive prices, great expert support, and proven reliability, INNO is the smart choice for your bearing needs. With our wide range of customization options and simple production methods, we can help your business grow and do well in global markets.

FAQs

Why are INNO's self aligning bearings suitable for wind energy uses in Spain?

Our self aligning bearings are made with a unique metal that can withstand high-cycle wear and work well in temperatures from -30°C to +500°C. The spherical raceway design makes up for shaft misalignment of up to ±2° on its own. This is very important for wind turbines because tower flex and base settling make it hard to keep everything in line.

How does INNO make sure that the standard of OEM bearing orders is always the same?

ISO 9001 certification is something we keep, and DIN 635-2 norms are something we follow in all of our manufacturing. Before they are sent out, each bearing is checked for size, hardness, and function. Our method for managing quality allows full traceability and paperwork that meets the rules in Europe.

For Spanish industry uses, what can be changed to fit specific needs?

INNO offers a lot of customization options, such as changing sealing systems for marine settings, adding better corrosion resistance coatings, changing bearing cage materials, and changing lubrication systems. We can also add condition tracking features and make application-specific mounting setups to meet your unique needs.

Partner with INNO Bearing for Your Self-Aligning Bearing Solutions

With the exact engineering and manufacturing quality that Spanish industrial businesses require, INNO Bearing is prepared to become your reliable OEM self aligning bearing manufacturer. We are the best choice to meet your bearing needs because of our three decades of knowledge, state-of-the-art production, and dedication to quality.

INNO's Spanish manufacturers profit from our all-encompassing method to bearing design and production. We come up with ways to help Spain's industries work better, because we know how hard it can be for them to meet the needs of the real world. Our engineering team knows how to get the best work done, whether you need basic setups or very specially designed bearings.

Thanks to the high-tech tools in our manufacturing plant, we can make bearings of all shapes and sizes, from small, precise units to very large assemblies with diameters over 5000 mm. Because of this, INNO can help Spanish companies in a wide range of businesses, from renewable energy and mining to marine equipment and aerospace.

Are you ready to learn how superior self aligning bearing options from INNO Bearing can improve your product line? Our team of bearing experts is ready to talk with you about your needs and make tailored suggestions that will help you meet your technical and business goals. To start working with China's top self aligning bearing provider, email us at sales@inno-bearing.com.

References

Spanish Wind Energy Association. "Industrial Component Sourcing Trends in Renewable Energy Sector." Madrid: AEE Publications, 2023.

European Bearing Manufacturers Association. "Quality Standards and Procurement Guidelines for Industrial Bearings." Brussels: EBMA Technical Report, 2023.

Institute of Mechanical Engineers. "Bearing Technology Advances in Heavy Industrial Applications." London: IMechE Press, 2022.

Spanish Ministry of Industry. "Strategic Analysis of Manufacturing Supply Chains and International Partnerships." Madrid: Government Publications Office, 2023.

International Organization for Standardization. "Precision Bearing Manufacturing Standards and Global Compliance Requirements." Geneva: ISO Standards Publication, 2023.

Maritime Equipment Manufacturers Council. "Bearing Solutions for Offshore and Port Infrastructure Applications." Barcelona: MEMC Technical Bulletin, 2022.