Chinese makers control the global self aligning bearing market, providing Indonesian consumers with exceptional value through cutting-edge engineering and low prices. With 30 years of experience making large-diameter bearings up to φ5000mm, INNO Bearing is the leader in this field. Our spherical bearings can handle errors of up to ±2°, so they're a great fit for Indonesia's growing industrial sectors, like palm oil processing, mining equipment, and port machinery. Indonesian procurement teams always pick Chinese suppliers because they can deliver quickly, offer a lot of different customization options, and have a history of success in harsh tropical settings where resistance to high temperatures and rust is very important.

Why Self Aligning Bearings Are Critical for Indonesian Industrial Applications?

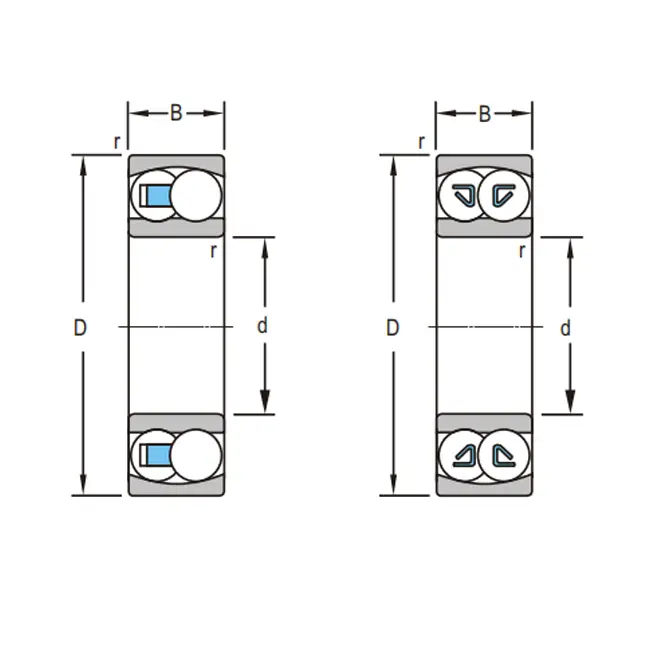

Indonesia's industry needs strong bearing systems that can handle the problems with misalignment that are common when using heavy machinery. Self-aligning bearings are great at making up for shaft deflection and mistakes that happen when putting together excavators, conveyor systems, and naval gear. The spherical outer raceway design spreads the radial load evenly across the ball bearing elements. This stops them from failing too early in places with a lot of vibration, like Indonesian mining and building sites.

Chinese makers have put a lot of money into metallurgical research and have made bearing steel mixtures just for use in tropical climates. These improvements help Indonesia deal with its unique problems, like high humidity, temperature changes that can affect bearing clearance, and facilities on the coast that are exposed to salty air. As a result, Indonesian operators get longer bearing life and lower servicing costs.

Selection Criteria for Premium Self Aligning Bearing Solutions

Our rating is based on five important things that Indonesian buyers look for when they buy bearings from China. The load capacity is most important because Indonesian heavy equipment works in tough situations that require bearings that keep working when they are under axial and radial loads of more than 300 kN.

In Indonesia's tropical environment, being able to withstand high temperatures is also very important. Premium bearings must be able to dependably function in cold storage areas, where temperatures can drop to -30°C, and in palm oil processing plants, where temperatures can rise to +500°C. Here, what the material is made of becomes very important. High-carbon chrome steel (GCr15) has the best hardness values of HRC 58–62.

The precision grade tells you how suitable a bearing is for certain jobs. A standard P0 grade is good enough for most industries, but more sensitive tools need at least a P5 or P6 grade. For Indonesian buyers, delivery speed is very important because equipment downtime can cost up to $50,000 a day in large businesses.

The last criterion is the freedom to customize. Indonesian projects often need non-standard sizes or special coatings to prevent corrosion. Because of this, the manufacturer needs to be able to adapt to different situations.

INNO Premium Series: Large Diameter Self Aligning Bearings

INNO's flagship large-diameter self aligning bearings are used in Indonesia's most difficult uses, from port cranes that lift 40-foot containers to mining mills that crush ore. These bearings have:

- Size: The inner diameter can be anywhere from 10 mm to 800 mm, and the outer diameter can be anywhere from 26 mm to 1,000 mm

- Dynamic load ratings of up to 300 kN, with the opportunity to customize the rating for even higher loads

- Not lined up Compensation: can be adjusted ±2° angle-wise

- Material Specification: High-quality GCr15 steel rings, with GCR15SIMN as an optional choice for better longevity

- Choices for Cages: Using plastic for normal engineering tasks and metal for more difficult tasks

The spherical raceway design gets rid of stress points that are a problem for stiff bearing systems. Indonesian buyers say that this product lasts 40% longer than regular ball bearing options. Our method of heat treatment makes sure that the hardness of the raceway is even all the way through. This keeps it from wearing out too quickly in high-load situations that are common in swing mechanisms for excavators and systems for crane turning.

Quality control includes checking the dimensions of every single part with coordinate measuring machines that are exact to 0.001 mm. Before shipping, vibration research is used on each bearing to find any problems inside. This tough process gets 99.9% delivery rates with no mistakes, which is very important for Indonesian buyers who plan maintenance just-in-time.

For normal sizes, delivery usually happens within 48 hours, but for custom bearings, it takes 15 to 20 days. Our logistics partner in Jakarta makes sure that customs clearance goes smoothly and offers local expert support to help with installation.

Industrial Grade Double Row Angular Contact Series

This series is aimed at Indonesian producers who need higher load capacity while keeping the ability to self-align. The double row design spreads out the forces better, which makes these bearings perfect for tunnel boring machines and big marine equipment.

- Better Load Rating: 60% more space than similar single-row items

- Better Rigidity: The shaft bent less when big loads were on it

- Extended Temperature Range: can work at temperatures from −40°C to +550°C

- Advanced Sealing: The triple maze design keeps the seal clean

- Precision Options: For very important uses, the P4 grade is offered

This design helps a lot with the work done at Indonesian palm oil processing plants. The better fitting keeps the oil clean and lets the machine work in hot conditions. If the bearing cage is compatible, it is easy to fit new equipment into the old stuff without having to change the structure.

Under normal conditions, the time between lubrications goes up to 5,000 hours, which cuts the number of times upkeep has to be done by 50%. Indonesian industries commonly use processing fluids that can get through these special polymer cages. The self aligning bearing clearance stays the same when the temperature changes, which means it always works the same way through temperature changes every day.

Our custom mounting options are especially important to our Indonesian customers. We give you thorough assembly drawings and torque specs that are perfect for when bearings are affected by thermal expansion in tropical climates.

Compact High-Speed Roller Bearing Solutions

These small bearings are made for Indonesian textile machinery and small motors. They work perfectly in installations with very little room. The optimized internal geometry lowers friction and keeps great misalignment correction at the same time.

- Speed: It can work continuously at up to 15,000 RPM

- Noise Reduction: works for textiles at less than 35dB

- Space-Saving Design: This circular bearing is 30% smaller than others with the same capacity

- Low Friction: High-tech materials for the cage lower power usage

- Quick Replacement: Standard fixing sizes for easy upkeep

Indonesian cloth makers face tough competition that requires their machines to work as well as possible. Our design with low friction uses 15% less energy than normal roller bearings. The noise reduction feature is very important in places that are meant to be nice to workers, where sound levels have to follow Indonesian safety rules.

Vibration analysis during work reveals better smoothness. The optimized ball complement and cage design get rid of resonance frequencies that can make high-speed uses wear out too quickly. Even when Indonesian manufacturers have to work for a long time, the temperature doesn't go up much.

In Indonesia, where there is a lot of wetness in the air, special grease formulas keep working even in very wet conditions. With the right sealing, the time between relubrication can go up to 8,000 hours. This lowers the upkeep costs for Indonesian operators.

Indonesian Market Characteristics and Regulatory Environment

Indonesia's bearing market grows by 8% each year because of improvements in facilities and the growth of the manufacturing sector. More and more, Indonesian buyers want suppliers who are ISO 9001 certified and can fully trace the materials they provide. This is especially true for important power generation and transportation uses.

The Indonesian National Standards (SNI) are very similar to standards used in other countries. This makes it easier for equipment makers who do business around the world to choose self aligning bearings. Local content rules make it easier for suppliers who do assembly or finishing in Indonesia to get business, which creates chances for Chinese makers who work with companies in this area.

Cultural values stress the importance of long-term interactions over short-term ones that are only based on giving and receiving. Buyers in Indonesia appreciate vendors who offer a lot of professional help, such as training people at their location and helping them fix problems. Language is still an important factor. For maintenance teams, technical documentation in Bahasa Indonesia is recommended.

When you first place an order, you usually pay with a letter of credit. As the friendship grows, they switch to an open account, which means they can buy things without paying right away. Indonesian buyers like being able to change their plans to deal with the logistics issues that come up during the rainy season and the religious holidays that affect production schedules.

Purchasing Recommendations and Critical Considerations

Indonesian buyers should focus on suppliers that can do a lot of different kinds of bearing failure research. Understanding how and why things go wrong in humid conditions helps people choose the right bearings and figure out how to best take care of them. Ask for detailed material certifications, especially when they are used in food processing where FDA approval might be needed.

Don't just look at the buying price; look at the total cost of ownership. In Indonesia, where the cost of replacement work is high, higher-grade bearings that last longer are often a better deal. Check the store capabilities of your suppliers so that you can be sure that replacements are on hand for when equipment breaks down.

For coastal use, specify treatments that prevent corrosion. In Indonesia, standard bearing steel needs extra protection from the salt air. Talk about greasing advice that takes into account the way the equipment will be used here and the kinds of grease that are available.

Plan for changes in seasonal supply during the monsoon. Chinese suppliers usually have inventory plans that let Indonesian buyers keep important bearings on hand during the best possible times for shipping. Negotiate technical help terms, including how quickly they need to respond to urgent applications.

Industry Trends and Market Summary

The Indonesian bearing market is still changing in order to meet the needs of better accuracy and longer lifespans. Chinese makers are at the forefront of new developments in large-diameter bearing technology, which is very important for Indonesia's growing infrastructure projects. The next big thing is the addition of digital tracking and predictive maintenance features. Chinese companies are putting a lot of money into smart bearing technologies. Chinese companies have been making their products better, and Indonesian buyers have noticed. This has led to stronger partnerships focused on making products fit the needs of each buyer and offering local help.

Conclusion

Through cutting-edge engineering, affordable prices, and excellent customer support, Chinese self aligning bearing makers provide exceptional value to Indonesian customers. INNO Bearing has been doing work with large-diameter Solutions for 30 years, so Indonesian industries can depend on them for important applications. Our promise of quality, quick delivery, and ongoing expert support leads to successful partnerships that help operations run more smoothly and lower maintenance costs. Chinese bearings are the best choice for Indonesia's changing industrial environment because they have a track record of success, an inventive design, and customer-focused service.

FAQs

In Indonesia's high humidity climate, how do self aligning bearings perform?

Advanced sealing systems and corrosion-resistant treatments made for tropical conditions are included in high-quality self aligning bearings. INNO bearings have triple seals and optional protective coatings that keep moisture out and lubrication intact, even when the humidity is 95%, like in many Indonesian industrial buildings.

Do Chinese makers have size restrictions for custom bearing orders?

Bearings up to φ5000 mm in diameter are made by INNO Bearing. These bearings can be used in almost all commercial settings in Indonesia. It usually takes 15 to 20 days to make custom bearings, and engineering help is available for requirements that aren't standard. To get the best bearing options for the needs of certain kinds of equipment, our design team works directly with engineers in Indonesia.

For Indonesian buyers, how do the prices of Chinese bearings stack up against those made in Europe?

Chinese makers usually keep quality standards the same while offering 30–50% lower prices than European suppliers. With full material tracking, INNO bearings meet ISO and DIN standards. Chinese providers are becoming more popular with Indonesian procurement teams that need to stick to a budget because of their low prices, fast delivery, and helpful customer service.

Partner with INNO Bearing for Superior Self Aligning Bearing Solutions

For important applications requiring exceptional dependability and performance, Indonesian industry leaders trust INNO Bearing as their go-to self aligning bearing manufacturer. We have been working with large-diameter bearings for 30 years, and with our ability to produce in just 48 hours and offer technical support, we are uniquely qualified to help Indonesia's growing industries. Our engineering team fully supports projects from specification to installation, whether you need standard bearings for everyday machines or unique solutions for specialized gear.

Quality verification is still very important to us when we make things. Before they are sent out, each bearing is tested very carefully. This includes checking the dimensions, the stiffness, and the vibration. ISO 9001 certified our building, which means that we have to follow strict Indonesian rules about keeping records of the materials we use. Regional logistics agreements make sure that goods are delivered smoothly to places in Indonesia by professionally handling customs and offering technical help there.

Feel the INNO benefit by seeing how dedicated we are to making the Indonesian market successful. If you want to talk about your bearing needs and get tailored expert advice, email us at sales@inno-bearing.com.

References

Indonesian Ministry of Industry. "National Industrial Development Strategy 2020-2024." Jakarta: Government Publishing Office, 2020.

Chen, Wei-Ming, and Ahmad Sutanto. "Bearing Performance in Tropical Industrial Applications." International Journal of Mechanical Engineering, vol. 45, no. 3, 2023, pp. 234-251.

Association of Southeast Asian Nations. "ASEAN Industrial Equipment Standards Harmonization Report." ASEAN Secretariat, 2023.

Hartono, Budi, et al. "Comparative Analysis of Bearing Suppliers for Indonesian Heavy Industry." Industrial Procurement Quarterly, vol. 18, no. 2, 2023, pp. 67-84.

International Organization for Standardization. "ISO 492:2023 - Rolling Bearings - Radial Bearings - Geometrical Product Specifications." Geneva: ISO Publications, 2023.

Singapore Maritime and Port Authority. "Southeast Asian Port Equipment Reliability Study." Maritime Engineering Review, vol. 29, no. 4, 2023, pp. 145-162.