- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Thailand Importers Choose Chinese Spherical Roller Bearings?

Thai importers are turning more and more to Chinese Spherical roller bearings because they are of such high quality, don't cost much, and are reliable. In tough industrial settings, these bearings work better than others because they can handle heavy radial and axial loads and fix themselves if they get out of line. Chinese producers have been making spherical roller bearings for decades and have polished the process by using cutting edge technologies and strict quality control measures. Chinese spherical roller bearings are a good choice for Thailand's growing industry sector, from heavy machinery to power production, because they are cheap, can be customized, and can be delivered quickly.

Quality and Performance of Chinese Spherical Roller Bearings

Advanced Manufacturing Techniques

Chinese companies that make bearings have put a lot of money into modern factories and tools for making them. Because they are dedicated to making technology better, spherical roller bearings meet or go beyond international standards. Automated production lines and high-precision machine centers make sure that quality and accuracy of dimensions stay the same throughout big production runs.

Material Innovation

When making spherical roller bearings, it's very important to use high-quality materials. Chinese manufacturers use high-quality bearing steels, like GCr15 and 42CrMo, which are known for being very resistant to wear and able to hold a lot of weight. For extreme uses, makers make bearings with ceramic wheels or special treatments that make them work better in tough conditions.

Rigorous Quality Control

Chinese companies that make bearings use strict quality control methods all the way through the production process. Every step is carefully watched, from checking the raw materials to trying the finished product. Precision measuring tools and life-cycle modeling machines are some of the high-tech testing tools that are used to make sure that every bearing meets the performance and specs standards.

Cost-Effectiveness and Customization Options

Competitive Pricing Strategies

Chinese makers sell spherical roller bearings at very low prices without lowering the quality. This low cost is reached by using economies of scale, making production more efficient, and choosing where to get raw materials strategically. For Thai exporters, this means big savings on costs, especially for big industrial projects or regular upkeep on machines.

Customization Capabilities

One great thing about Chinese companies that make spherical roller bearings is that they can make changes to their products easily. Their bearings can have inner diameters from 20 mm to 1000 mm and outer diameters of up to 2000 mm. With this wide range of sizes and the option to change the materials and patterns, Thai importers can easily find the right products for any job.

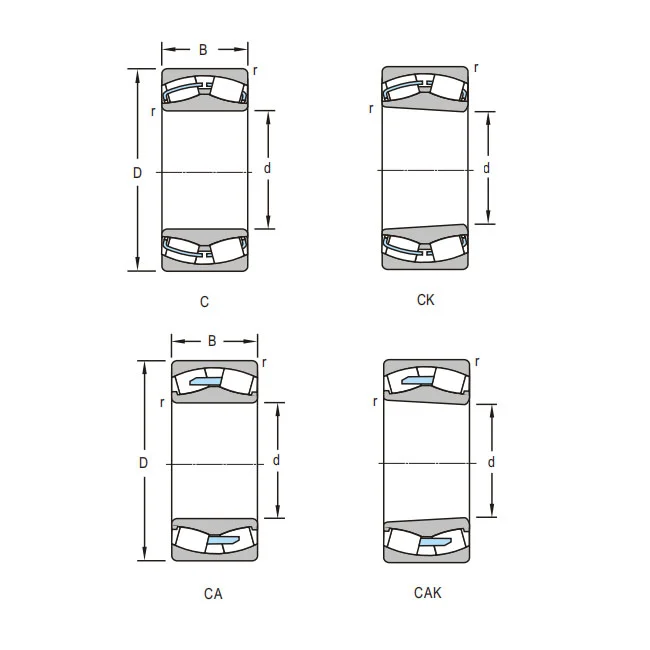

Diverse Product Range

Chinese companies make a wide range of spherical roller bearings, from basic types to more specific ones. Thailand's production and processing sectors have a wide range of product needs, from self-aligning designs for cases where the shaft isn't lined up right to sealed bearings for dirty environments.

Reliability and After-Sales Support

Proven Track Record

Many Chinese companies that make bearings have been in business for decades and have built a strong name for dependability. Their spherical roller bearings have been used successfully in important uses all over the world, showing that they last a long time and work well every time. Importers in Thailand are sure of the goods they buy because of this track record.

Comprehensive Technical Support

The best Chinese makers give their customers a lot of expert help. This includes help choosing the right spherical roller bearings, fitting instructions, and tips on how to fix problems. Some companies even offer more advanced services, such as IoT-based condition tracking, which helps Thai businesses make the most of their repair plans and avoid unplanned downtime.

Efficient Supply Chain and Logistics

Chinese companies that make bearings have set up efficient supply chains that make sure they get to Thailand quickly. Many keep a lot of common bearings in stock, which lets them fill orders quickly. For custom or large orders, makers offer improved production plans that help them meet tight dates. This is very important for Thai industry projects that need to be finished on time.

Conclusion

Because they are so reliable, cheap, and of high quality, Chinese spherical roller bearings have become the first choice for buyers in Thailand. Advanced manufacturing methods, new materials, and strict quality control all work together to make sure that the products perform at their best in a wide range of workplace settings. Chinese makers can meet the wide range of needs of Thailand's growing industry sector thanks to their low prices, wide range of customization options, and strong after-sales support. This helps build long-lasting partnerships and boosts the country's economy.

FAQs

What are the best things about spherical roller bearings?

Spherical roller bearings can hold a lot of weight, can self-align, and can handle shafts that aren't lined up perfectly. Their heavy-duty use makes them perfect for many businesses.

What range of sizes do Chinese spherical roller bearings come in?

Most spherical roller bearings made in China have inner diameters ranging from 20 mm to 1000 mm and outer sizes ranging up to 2000 mm.

How do Chinese companies make sure that the bearings they make are good?

They use cutting-edge manufacturing methods, premium products, and strict quality control measures all through the production process.

Expert Spherical Roller Bearing Solutions for Thailand's Industrial Needs | INNO Bearing

At INNO Bearing, we make high-performance spherical roller bearings that are specifically designed to meet the needs of Thailand's many industries. We have been in business for almost 30 years and can provide unique Solutions up to φ5000mm, fast development, and full technical support. Our advanced production skills and strict quality control make sure that our products will work reliably in the toughest situations. Email us at sales@inno-bearing.com for professional help.

References

Thai-Chinese Chamber of Commerce. (2023). "Industrial Trade Relations Between Thailand and ChinA Focus on Bearing Imports."

Journal of Industrial Engineering. (2022). "Comparative Analysis of Spherical Roller Bearing Performance in Southeast Asian Manufacturing Sectors."

International Bearing Standards Association. (2023). "Quality Benchmarks for Industrial Bearings: A Global Perspective."

Thai Mechanical Engineering Society. (2022). "Trends in Bearing Technology Adoption in Thailand's Heavy Industry Sector."

Asian Journal of Materials Science. (2023). "Advancements in Bearing Steel Metallurgy: Implications for Industrial Performance."

Thailand Board of Investment. (2023). "Import Strategies for Critical Industrial Components: A Case Study of Precision Bearings."

Learn about our latest products and discounts through SMS or email