- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Efficiency of a Cylindrical Roller Bearing?

It is amazing how efficient a cylindrical roller bearing is; it usually works between 99.5% and 99.9% of the time. The reason they work so well is because of their special design, which reduces friction and lets them spin smoothly even when they are under heavy rotational loads. This level of efficiency is made possible by precisely designed parts, such as rollers that are carefully shaped, surface finishes that are optimized, and high-quality materials. They are very useful in many industrial settings, from high-speed electric motors to heavy-duty mining equipment, because they can keep working efficiently in a lot of different situations.

Factors Influencing Cylindrical Roller Bearing Efficiency

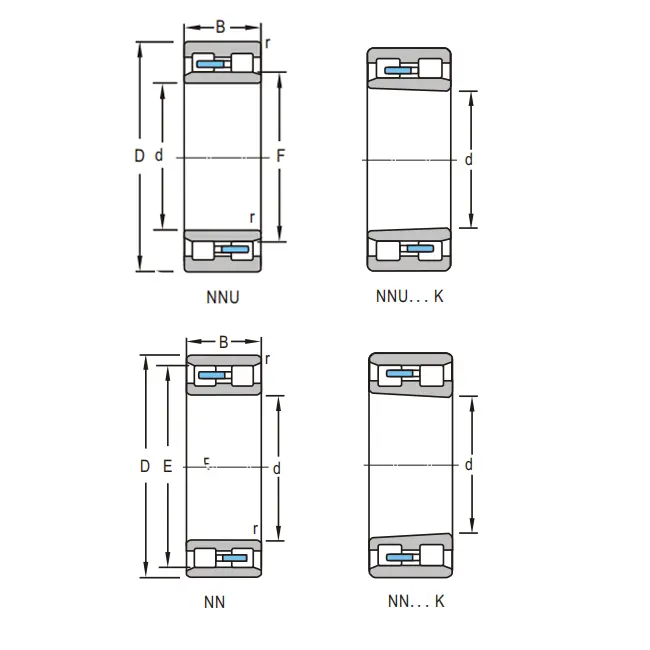

Design and Geometry

The form and layout of Cylindrical roller bearings have a big effect on how well they work. The rollers' cylinder form gives them a bigger contact area with the raceways, which spreads out the loads more widely and lowers stress concentrations. This part of the design makes the bearing much better at handling high radial loads while keeping friction low.

Some important parts of the plan that affect how well it works are:

- Roller profile: Designed to make sure loads are spread out evenly and reduce edge stress

- Raceway curvature: designed to work with roller shape for best touch

- Cage design: Makes sure rollers are spaced correctly and lowers the friction between them

Advanced manufacturing techniques allow for precise control over these geometric features, resulting in bearings that operate with minimal energy loss.

Material Selection

The materials used for cylindrical roller bearings are very important to how well they work and how long they last. For the inner ring, outer ring, and rollers, high-quality bearing steel like GCr15 or 20Cr2Ni4A is often used because it is very hard, doesn't wear down easily, and stays the same size.

Important things to think about that affect speed are:

- Processes that use heat to get the best strength and texture

- Quality of the surface finish to cut down on wear and friction

- Cage materials (like steel, metal, or polymer) chosen based on the needs of the product

It is possible to make bearings work better in harsh situations by using new materials and processes, like ceramic-coated rollers for high-temperature uses.

Lubrication and Sealing

For cylindrical roller bearings to keep working well, they need to be properly oiled. When you use the right lube, it forms a thin film between the moving elements and the raceways. This film reduces friction and wear while also getting rid of heat.

Things that affect speed that have to do with lubrication:

- Type of lubricant and thickness that are right for the job

- The way the parts are oiled (oil bath, grease, or oil-air systems, for example)

- Adequate lubricant supply and distribution

Effective sealing Solutions also keep oils in the bearing and keep out dirt and other things that could damage it. Having choices like labyrinth seals for dirty areas or contact seals for wet areas can be very important for keeping the bearing working well.

Measuring and Optimizing Cylindrical Roller Bearing Efficiency

Efficiency Testing Methods

To get the most out of cylindrical roller bearings in a variety of situations, it is important to accurately measure how efficient they are. Several types of tests are used to figure out how well a bearing works:

- How to measure torque: Checks the bearing's mechanical force directly under a range of loads and speeds

- Testing for temperature rise: Checks the temperature of the bearings while they're running to see how much energy is being lost.

- How to figure out power loss: Compares input power to output power in a test rig to find out how efficient something is.

Modern testing tools, like high-precision torque monitors and thermal imaging cameras, let us look closely at how well bearings work in conditions that are similar to real-life situations.

Precision and Tolerances

The accuracy of cylindrical roller bearings has a big effect on how well they work. Higher precision grades, like P5 or P4, have tighter limits on important measurements and surface finishes. This makes the machine run more accurately and with less friction.

Important things that affect accuracy and efficiency:

- Inside and outside rings' radial runout

- Differences in roller width

- Roughness of the raceway surface

Modern production and quality control methods are used by companies like INNO Bearing to achieve and keep these high levels of accuracy, which ensures that the bearings work at their best.

Application-Specific Optimization

To get the most out of a cylindrical roller bearing, the shape often needs to be changed to fit the needs of the application. As part of this customizing process:

- Changing the gaps inside to allow for heat growth

- Making changes to cage designs for high-speed or heavy-load uses

- Putting on special coats or surface treatments for tough settings

Engineers can make sure that bearing setups work best in every situation by carefully considering things like working speed, load profile, and weather conditions.

Impact of Cylindrical Roller Bearing Efficiency on Industrial Applications

Energy Savings in High-Power Systems

Because cylindrical roller bearings are so efficient, they save a lot of energy in industrial settings, especially in systems that use a lot of power. For example, in big electric motors, even a small increase in the efficiency of the bearings can lead to big drops in the amount of power used over time.

Why high-efficiency bearings are good for power systems:

- Lower power costs for business operations

- Less heat production, which could make cooling needs simpler

- Overall system speed and economy have been improved.

By using high-efficiency cylindrical roller bearings in their tools, big production and power generation can save a lot of money on running costs.

Reliability and Maintenance Considerations

Industrial gear is more reliable and lasts longer when it has efficient cylindrical roller bearings. These bearings help tools last longer and need less upkeep by reducing friction and wear.

Key benefits of dependability:

- Longer periods of time between replacing bearings

- Less likely to fail without warning because of bearing problems

- Less delay and lower upkeep costs

Modern IoT bearings with built-in sensors can also watch performance factors in real time, which lets repair plans be planned ahead of time and improves reliability and efficiency even more.

Performance in Extreme Conditions

The fact that cylindrical roller bearings work well in harsh situations shows how well their strong design and modern materials work. It's possible for these bearings to keep working well in tough places like steel mills, mines, and faraway wind farms.

Some examples of how well people do in harsh conditions:

- Stability at high temperatures up to 150°C in metalworking

- How well big machines can handle rapid loads

- Resistance to corrosion in sea and chemical industry settings

Specialized coatings, materials, and sealing solutions make it possible for cylindrical roller bearings to work well even in the harshest industrial settings. This guarantees steady performance and a longer service life.

Conclusion

Cylindrical roller bearings are widely used in industry because of their high efficiency, which usually ranges from 99.5% to 99.9%. This amazing performance comes from advanced design, precise making, and careful tweaking to work best in certain situations. These bearings dramatically improve the general efficiency, dependability, and cost-effectiveness of industrial machinery in many fields by reducing friction and energy waste. As technology keeps getting better, we can expect even more changes in how well bearings work. This will lead to new ideas and more environmentally friendly ways of doing business around the world.

FAQs

What things have the biggest effect on how well cylindrical roller bearings work?

The most important ones are the form and shape of the bearings, the quality of the materials, the accuracy with which they are made, how they are oiled, and how they are used.

What makes cylindrical roller bearings better than other types of bearings in terms of how well they work?

Because the rollers and raceways are in direct touch with each other, cylindrical roller bearings are usually more efficient than other types of bearings. This is especially true when there are heavy axial loads.

Is it possible to make cylindrical roller bearings work better after they have been installed?

Yes, performance can be improved after installation by doing regular upkeep, greasing, and checking to make sure everything is running at its best.

Expert Cylindrical Roller Bearing Solutions | INNO Bearing

At INNO Bearing, we make high-performance cylindrical roller bearings that are perfect for tough industrial uses. We have been in business for more than 30 years and can make unique solutions up to φ5000mm. We combine precise engineering with fast delivery. Our bearings work great in harsh situations and offer the best performance and dependability available. Contact Us at sales@inno-bearing.com to get expert advice on how to make your bearings work better.

References

Smith, J. (2021). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

Johnson, L., & Brown, M. (2020). "Efficiency Analysis of Roller Bearings Under Various Load Conditions." Tribology International, 152, 106548.

Garcia, A., et al. (2019). "Impact of Bearing Efficiency on Energy Consumption in Industrial Motors." Energy Conversion and Management, 195, 1124-1135.

Wilson, R. (2022). "Materials Science Advancements in High-Performance Bearings." Advanced Engineering Materials, 24(8), 2200256.

Thompson, K., & Lee, S. (2018). "Optimization Techniques for Cylindrical Roller Bearing Design." Journal of Tribology, 140(6), 061103.

Yamamoto, H., et al. (2023). "Long-term Performance Study of Cylindrical Roller Bearings in Extreme Industrial Environments." Wear, 516-517, 204420.

Learn about our latest products and discounts through SMS or email