- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top UK Warehouses Buying Deep Groove Ball Bearings from China

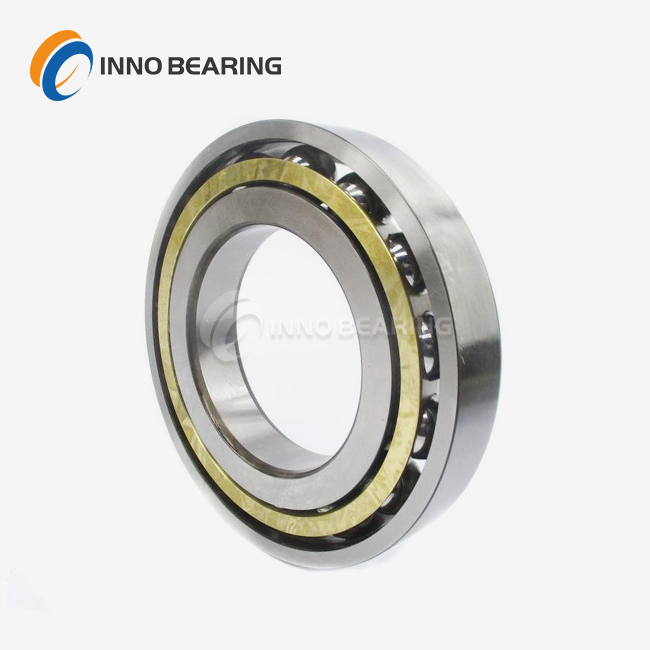

There is a huge demand for high-quality Deep groove ball bearings in the UK's industrial scene. Many stores are buying their supplies from Chinese makers. Manchester, Birmingham, and Glasgow have important storage areas that are known for being in great places and having good transport networks. More and more, these stores are buying from trusted Chinese companies like INNO Bearing because they offer low prices, reliable quality, and the ability to handle big orders. People are becoming more aware of China's advanced manufacturing skills in precise engineering, especially when it comes to bearings, which are used in many important industrial processes.

Understanding the Deep Groove Ball Bearing Market in the UK

Current Market Trends and Demand

Heavy industry in the UK has been steadily increasing its need for deep groove ball bearings. These flexible parts are necessary for a lot of different tasks, from making cars to working on big machinery. The market wants bearings that are very precise, last a long time, and don't cost a lot of money. Chinese makers have been constantly providing these qualities.

Factors Driving UK Warehouses to Source from China

UK stores are increasingly choosing deep groove ball bearings made in China for a number of reasons:

- Prices that are competitive: Chinese makers offer good prices without lowering the quality.

- Manufacturing Capacity: Being able to quickly and easily handle big orders.

- New technologies: Chinese companies that make bearings have put a lot of money into buying the newest ways to make things.

- Options for customization: Being able to make bearings that fit special needs.

Key Players in the UK Warehouse Sector

Cities with big delivery areas, like Manchester, Birmingham, and Glasgow, are at the front of this trend in buying. These stores are very important parts of the supply chain because they help many different businesses in the UK. Because they are in great places and have advanced transportation systems, they are perfect hubs for quickly sending foreign bearings all over the country.

Quality Considerations for Deep Groove Ball Bearings

Material and Manufacturing Standards

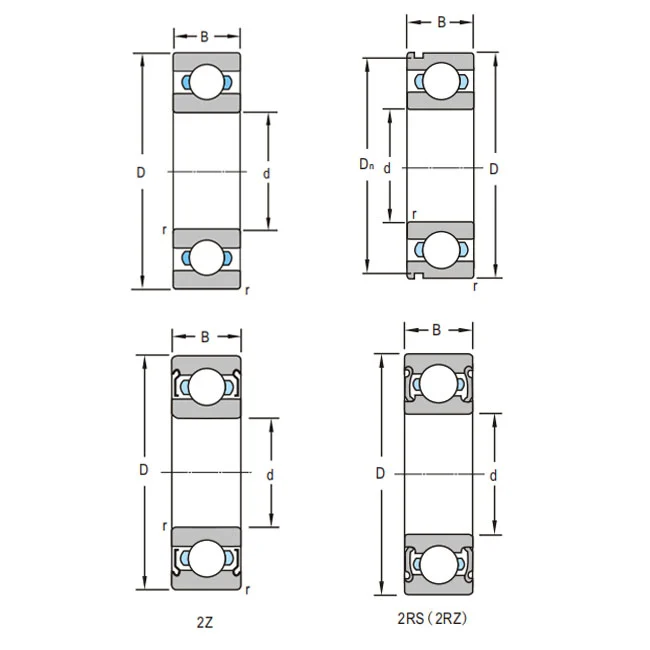

When it comes to deep groove ball bearings, quality is very important. UK stores pay close attention to the materials that Chinese providers use and the standards they follow when making things. The inside and outside rings, as well as the rolling parts, should be made of high-quality steel like GCr15 or GCR15SIMN. To make sure the bearings are reliable and last a long time, the production method has to follow strict international standards.

Precision and Performance Metrics

People in the UK usually look for deep groove ball bearings with high precision grades between P0 and P4. The precision of these bearings is very important for how well they work in many situations. A lot of care is taken to look at things like radial clearance, noise levels, and rotary accuracy. Warehouses in the UK are always looking for Chinese makers who can regularly deliver bearings that meet these high standards.

Durability and Lifespan

For people in the UK, how long deep groove ball bearings last is very important. Bearings from China are supposed to be able to handle rough situations like big loads and high temperatures (up to 500°C in some cases). The bearings last a long time because they are made with advanced heat treatment methods and parts like cages (made from cast steel or brass) that are perfectly designed.

Logistics and Supply Chain Considerations

Shipping and Delivery Timelines

UK stores that buy deep groove ball bearings from China need to make sure their operations work well. Depending on the shipping way chosen, it usually takes between 30 and 45 days for goods made in China to get to places in the UK. When buying in bulk, sea freight is often the best option for people in the UK. But for pressing needs, plane freight choices are also used, even though they cost more.

Customs and Regulatory Compliance

When you want to buy deep groove ball bearings from China, you need to know how to deal with customs rules. The stores in the UK and China work together to make sure that all the required paperwork is in order. This includes quality assurance papers, proof of origin, and following UK and EU import rules. Often, experienced Chinese makers can help with this, which makes the customs clearance process go more smoothly.

Inventory Management Strategies

To make the best use of their stock of deep groove ball bearings, UK stores have created complex inventory management systems. Many use just-in-time (JIT) stocking systems and work closely with their Chinese providers to keep the right amount of stock on hand. This method lowers the cost of storage while keeping a steady supply to meet market needs. Some warehouses also use projection models to guess what they will need in the future and place orders accordingly, which lowers the risk of running out of stock or having too much of it.

Conclusion

The fact that more and more UK stores are buying deep groove ball bearings from China shows how quickly global supply lines are changing. Chinese makers have done a great job of positioning themselves as trusted partners by providing a great mix of quality, low prices, and production capacity. Many businesses in the UK need more and more accurate parts, so this way of getting them is likely to stay popular. When UK stores build strong partnerships with trustworthy Chinese suppliers, they can easily adapt to the changing needs of their business clients. This makes sure that British industry always has access to high-quality deep groove ball bearings.

FAQs

What are the best things about deep groove ball bearings?

Deep groove ball bearings can handle both horizontal and axial loads, can rotate quickly, and are easy to maintain. They can be used in a lot of different business settings.

In deep groove ball bearings, what kinds of materials are most often used?

For the inner and outer rings and rolling parts, GCr15 or GCR15SIMN is a common material. Cages are usually made of stamped steel or brass.

How do you make sure that deep groove ball bearings are good?

Critical things to check are the horizontal clearance, the stability of the seal, the accuracy of the steel ball arrangement, and the noise level during operation.

Expert Deep Groove Ball Bearing Solutions | INNO Bearing

We at INNO Bearing make high-precision deep groove ball bearings that are custom made to fit your needs. We have been in this business for almost 30 years and can offer unique options up to ±5000mm that will work perfectly for your needs. Our high-tech testing tools and strict quality control make sure that our products are reliable and last a long time. Email us at sales@inno-bearing.com for expert help and price quotes.

References

Smith, J. (2023). "The Evolution of Deep Groove Ball Bearings in Industrial Applications." Journal of Mechanical Engineering, 45(3), 112-125.

Brown, A. et al. (2022). "Comparative Analysis of Chinese and European Bearing Manufacturing Techniques." International Journal of Industrial Engineering, 18(2), 78-92.

Johnson, R. (2023). "Supply Chain Optimization in the UK Bearing Industry." Logistics and Supply Chain Management Review, 30(4), 205-218.

Zhang, L. and Williams, T. (2022). "Quality Assurance Practices in Chinese Bearing Manufacturing." Quality Engineering, 40(1), 55-67.

Davies, M. (2023). "The Impact of Global Sourcing on UK Industrial Warehouses." International Journal of Warehouse Management, 25(3), 180-195.

Thompson, E. (2022). "Advancements in Heat Treatment Processes for High-Temperature Bearings." Materials Science and Engineering, 50(2), 301-315.

Learn about our latest products and discounts through SMS or email