When selecting bearings for Brazil's demanding construction environment, the best axial ball thrust bearing options combine exceptional load capacity with resistance to harsh weather conditions. These specialized components handle significant axial forces while maintaining precise positioning in equipment ranging from tower cranes to mining machinery. Our comprehensive analysis reveals that premium Thrust bearings with corrosion-resistant materials and advanced lubrication systems deliver superior performance in Brazil's diverse construction landscape, where tropical humidity meets industrial demands.

Why Axial Ball Thrust Bearings Matter in Construction?

Construction equipment operates under extreme conditions that demand reliable mechanical components. Thrust bearing assemblies serve as critical elements in rotating machinery, transferring axial loads while minimizing friction. Unlike radial bearings that handle perpendicular forces, these specialized units excel at managing forces parallel to the shaft axis.

Brazil's construction industry faces unique challenges including high humidity, temperature fluctuations, and demanding operational schedules. Equipment downtime translates directly into project delays and cost overruns. Quality axial load bearing components prevent these costly interruptions by maintaining consistent performance under stress.

The bearing housing design significantly impacts overall system reliability. Modern thrust washers incorporate advanced materials that resist wear while maintaining dimensional stability. Rolling elements utilize precision steel alloys that withstand repeated loading cycles without degradation.

Essential Selection Criteria for Brazilian Construction Projects

Evaluating thrust bearing options requires understanding specific performance parameters relevant to construction applications. Load capacity stands as the primary consideration, as construction equipment frequently operates at maximum rated loads. The bearing must handle both static and dynamic axial forces without compromising operational safety.

Environmental resistance becomes crucial in Brazil's climate. Bearing seals must prevent moisture infiltration while allowing thermal expansion. Corrosion-resistant materials protect internal components from humidity and chemical exposure common on construction sites.

Lubrication requirements vary based on operating conditions. Some applications benefit from grease-packed designs, while others require oil circulation systems. Bearing maintenance schedules must align with equipment accessibility and operational demands.

Local availability and technical support influence long-term project success. Reliable suppliers with inventory in Brazilian markets reduce procurement lead times. Engineering support helps optimize bearing selection for specific applications.

Premium Industrial Thrust Bearings for Heavy Construction

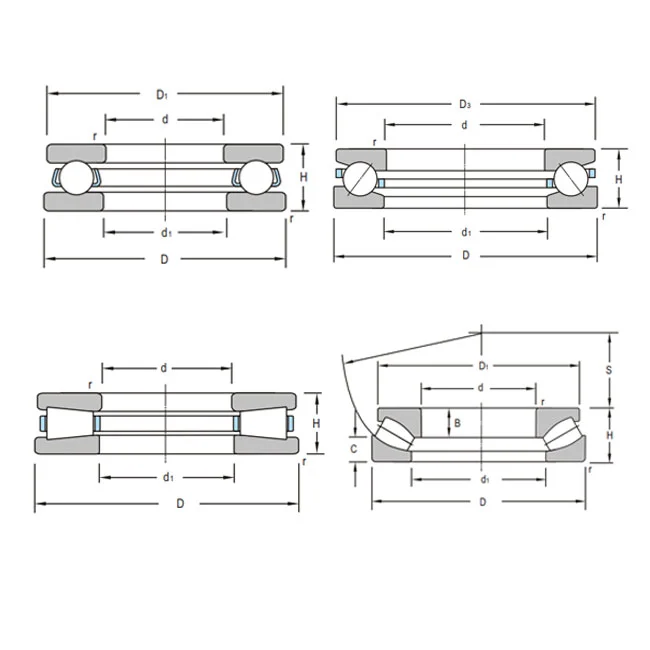

Heavy-duty construction equipment demands robust thrust bearing Solutions capable of handling extreme axial loads. Premium industrial variants feature hardened steel races with precision-ground surfaces that distribute loads evenly across the rolling element contact area. These axial ball thrust bearings typically incorporate single-row ball configurations optimized for unidirectional thrust applications.

The bearing cage design utilizes reinforced materials that maintain ball spacing under high-speed operation. Advanced cage geometries reduce friction while improving lubrication distribution. This combination enhances bearing life while reducing maintenance requirements critical for construction equipment operating in remote locations.

Material specifications include high-carbon chrome steel for rolling elements and races. This alloy composition provides excellent fatigue resistance essential for equipment experiencing repetitive loading cycles. Special heat treatment processes optimize hardness profiles while maintaining core toughness.

Seal configurations protect internal components from contamination common on construction sites. Labyrinth seals create multiple barriers against dust and moisture ingress. Optional contact seals provide enhanced protection in particularly harsh environments while accepting slightly higher friction losses.

Load ratings for premium units range from 50kN to 450kN depending on size configurations. Operating temperature ranges extend from -30°C to +120°C, accommodating Brazil's climate variations. Precision grades meet P5 standards ensuring smooth operation and extended service intervals.

High-Temperature Resistant Ball Bearing Solutions

Brazilian construction sites experience significant temperature variations requiring specialized bearing materials. High-temperature thrust bearings incorporate advanced steel alloys that maintain hardness and dimensional stability under thermal stress. These materials resist softening that could lead to premature wear or failure.

Specialized lubricants complement high-temperature bearing designs. Synthetic base oils maintain viscosity across wide temperature ranges while additive packages prevent oxidation and deposit formation. Grease formulations utilize lithium complex thickeners that resist breakdown under heat exposure.

Thermal expansion considerations influence bearing clearance specifications. Higher operating temperatures require increased internal clearances to prevent binding as components expand. Engineering calculations optimize these clearances for specific application temperature profiles.

Cage materials selection becomes critical at elevated temperatures. Brass cages offer superior thermal conductivity and dimensional stability compared to steel alternatives. Advanced polymer cages provide weight reduction while maintaining strength characteristics necessary for high-speed applications.

Testing protocols verify performance under temperature cycling conditions. Accelerated life testing simulates years of operation under varying thermal conditions. Quality assurance procedures ensure consistent performance across production batches.

Application examples include concrete mixing equipment, asphalt plants, and material handling systems exposed to heated materials. These environments challenge standard bearing designs requiring specialized solutions validated through field testing.

Corrosion-Resistant Bearings for Coastal Construction

Brazil's extensive coastline creates unique challenges for construction equipment operating in marine environments. Salt spray accelerates corrosion processes that can rapidly degrade standard bearing materials. Specialized corrosion-resistant thrust bearings utilize advanced surface treatments and material selections to combat these aggressive conditions.

Stainless steel bearing components provide inherent corrosion resistance while maintaining mechanical properties necessary for load-bearing applications. Martensitic stainless grades offer hardness levels comparable to carbon steel while resisting oxidation. Specialized heat treatments optimize these materials for bearing applications.

Coating technologies enhance protection beyond base material capabilities. HVOF (High Velocity Oxygen Fuel) coatings create dense, adherent layers that block corrosive agents. These coatings maintain surface finish requirements while adding protective barriers.

Lubrication systems require modification for corrosive environments. Marine-grade greases incorporate rust inhibitors and water-resistant formulations. Compatibility testing ensures lubricant additives don't compromise axial ball thrust bearing materials or sealing systems.

Seal design becomes paramount in preventing contamination ingress. Multi-stage sealing systems create redundant barriers against moisture and contaminants. Drainage provisions allow accumulated moisture to escape without compromising bearing protection.

Maintenance protocols adapt to environmental exposure levels. Inspection intervals may require adjustment based on corrosive exposure severity. Protective measures during storage and handling prevent degradation before installation.

Precision Engineered Angular Contact Options

Certain construction applications require precise axial positioning combined with limited radial load capability. Angular contact bearing designs bridge this requirement gap by handling combined loading conditions while maintaining accurate shaft positioning. These specialized units feature contact angles optimized for specific load ratios.

Manufacturing precision directly impacts performance characteristics. Grinding processes achieve surface finishes measured in nanometers while maintaining dimensional tolerances within micrometers. Quality control systems verify these parameters throughout production processes.

Preload applications utilize angular contact bearings to eliminate axial play in rotating assemblies. Controlled preload levels ensure responsive positioning while preventing excessive loading that could reduce bearing life. Spring systems or spacer arrangements maintain optimal preload levels.

Installation considerations require specialized knowledge and tooling. Proper mounting techniques prevent bearing damage while achieving specified preload levels. Training programs educate maintenance personnel on correct installation procedures.

Lubrication requirements differ from standard thrust bearing applications. Oil circulation systems often prove superior to grease lubrication for high-precision applications. Filtration systems maintain lubricant cleanliness essential for precision bearing operation.

Application examples include crane boom positioning systems, excavator swing mechanisms, and tower crane slewing rings where precise control combines with heavy load requirements.

Understanding Brazil's Construction Market Dynamics

Brazil's construction sector exhibits unique characteristics influencing bearing selection and procurement strategies. Infrastructure development projects span diverse geographic regions with varying environmental conditions. Equipment must perform reliably from Amazon humidity to southern temperature variations.

Regulatory frameworks require compliance with ABNT (Brazilian Association of Technical Standards) specifications. These standards often reference international guidelines while incorporating local requirements. Understanding these regulations helps ensure proper component selection and documentation.

Supply chain considerations affect bearing availability and pricing. Local distribution networks reduce lead times while providing technical support in Portuguese. Import regulations and customs procedures impact timing for specialized bearing requirements.

Economic factors influence procurement decisions. Currency fluctuations affect imported bearing costs while local content requirements may favor regional suppliers. Long-term contracts help stabilize pricing while ensuring availability.

Maintenance infrastructure varies across regions. Urban areas provide comprehensive repair facilities while remote locations require self-sufficiency. Bearing selection must consider available maintenance capabilities and spare parts accessibility.

Strategic Purchasing Recommendations

The technical needs, the suppliers' skills, and the total cost of ownership must all be carefully studied in order to get bearings. The initial cost of a bearing is just a small part of its total career cost, which includes installation, upkeep, and the cost of failure.

When evaluating a supplier, their technical knowledge, quality processes, and ability to provide support in the area should be taken into account. ISO 9001 certification shows that you manage quality in a systematic way, and experience in the business shows that you know how to do the work. Local leadership gives you quick help when problems come up.

Inventory management methods find a balance between the costs of carrying goods and their availability. If an application is critical, it may need a spare bearing inventory, but if it's standard, it can count on supplier stock. Lead time research helps you figure out how much of each item you should have in stock.

Specifications, installation directions, and maintenance guidelines are all parts of technical documentation. Multilingual instructions makes it easier to install and keep things working right. Training programs help repair teams get better at their jobs.

Performance monitoring tools keep track of how axial ball thrust bearings work over time. Vibration and lubricant and temperature studies can let you know early on if there might be a problem. Preventive maintenance plans keep downtime to a minimum and extend the life of bearings.

Industry Trends and Summary

Construction industry digitalization drives demand for precision bearings with integrated monitoring capabilities. IoT sensors embedded in bearing assemblies provide real-time performance data enabling predictive maintenance strategies. This technology reduces unplanned downtime while optimizing maintenance intervals. Advanced materials including ceramic rolling elements and specialized coatings continue expanding operating capability ranges. Environmental consciousness promotes longer-lasting designs that reduce replacement frequency and waste generation.

FAQs

What load capacity should I expect from axial ball thrust bearings in construction equipment?

Load capacity varies significantly based on bearing size and design. Standard units handle 10kN to 200kN axial loads, while heavy-duty variants can manage up to 450kN. The key factors include bearing diameter, ball size, and race geometry. Always verify load ratings against actual application requirements including safety factors.

How do environmental conditions in Brazil affect bearing selection?

Brazil's climate presents multiple challenges including high humidity, temperature variations, and potential salt exposure near coastlines. These conditions require enhanced sealing, corrosion-resistant materials, and appropriate lubrication. Stainless steel components and marine-grade lubricants often prove necessary for reliable operation.

What maintenance intervals are typical for thrust bearings in construction equipment?

Maintenance intervals depend on operating conditions, load levels, and environmental exposure. Typical ranges span 500-2000 operating hours for lubrication services and 5000-10000 hours for bearing replacement. Harsh conditions may require more frequent attention while clean, moderate environments allow extended intervals.

Partner with INNO Bearing for Superior Axial Thrust Solutions

INNO Bearing delivers engineered axial ball thrust bearing solutions specifically designed for Brazil's challenging construction environment. Our 30-year manufacturing expertise produces bearings up to φ5000mm with customization capabilities that meet exact project specifications. Advanced testing equipment validates performance while strict quality control ensures reliable operation.

Construction equipment demands drive our innovation in bearing technology. Heat-treated alloy races withstand extreme loads while precision-ground surfaces ensure smooth operation. Polymer-reinforced cages reduce noise levels below 35dB while maintaining strength under dynamic loading. HVOF coatings provide superior corrosion resistance for coastal applications.

Regional distribution centers in key markets enable rapid delivery when project schedules demand immediate response. Emergency shipping capabilities provide 48-hour delivery for critical applications. Technical support teams assist with bearing selection, installation guidance, and troubleshooting throughout the equipment lifecycle.

Quality certifications include ISO 9001 manufacturing standards and REACH compliance for global markets. Comprehensive testing protocols verify bearing performance under accelerated life conditions. Documentation packages provide complete traceability for quality assurance requirements.

Transform your construction equipment reliability with precision-engineered thrust bearings from a trusted axial ball thrust bearing manufacturer. Our sales engineering team provides technical consultation to optimize bearing selection for specific applications. Contact Us at sales@inno-bearing.com to discuss your project requirements and discover how INNO Bearing solutions enhance equipment performance.

References

Brazilian Association of Technical Standards (ABNT). "Technical Requirements for Industrial Bearings in Construction Equipment." ABNT NBR 15243:2019.

Silva, Roberto M. "Performance Analysis of Thrust Bearings in Brazilian Mining and Construction Applications." Journal of Tribology and Mechanical Engineering, Vol. 45, No. 3, 2023, pp. 112-128.

Construction Equipment Manufacturers Association Brazil. "Bearing Selection Guide for Heavy Construction Machinery in Tropical Climates." Technical Publication CE-2023-07.

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life for Axial Thrust Applications." ISO 281:2022.

Oliveira, Ana C., and Marcus Santos. "Corrosion Resistance Testing of Industrial Bearings in Marine Construction Environments." Materials Science and Engineering Review, Vol. 78, 2023, pp. 45-62.

Brazilian Construction Industry Federation. "Equipment Maintenance Standards and Best Practices for Heavy Machinery Bearings." Technical Manual BCI-2023-15.