Understanding quality standards and cost-effectiveness are necessary for finding the best self aligning bearing offers in China for Indian buyers. INNO Bearing and other Chinese companies offer spherical bearing options that are at least 40% cheaper than similar products from Europe without hurting quality. These self-compensating bearings can fix their own misalignment up to ±2°. This makes them a great fit for heavy-duty uses in India's mining equipment, textile mills, and green energy projects where shaft deflection happens often.

Why Self-Aligning Bearings Are Essential for Indian Industrial Growth?

India's manufacturing sector needs strong bearing Solutions that can handle tough circumstances. Self-aligning bearing technology fixes major problems with old ball bearing systems like shaft misalignment, thermal expansion, and stress from shaking. The circular outer ring raceway automatically makes up for mistakes made during installation. This is up to 35% cheaper to maintain than rigid bearing setups.

These bearings are especially helpful to Indian businesses that work in steel production, cement plants, or sugar mills where heavy radial loads and rotational misalignment happen at the same time. These bearings are very important for keeping tools running for a long time because they can keep things running smoothly even when the shaft bends. India's focus on building up its infrastructure has made the need for solid bearing housing solutions much greater. This makes Chinese suppliers a good choice for procurement teams that want to save money.

Selection Criteria for Premium Self-Aligning Bearing Solutions

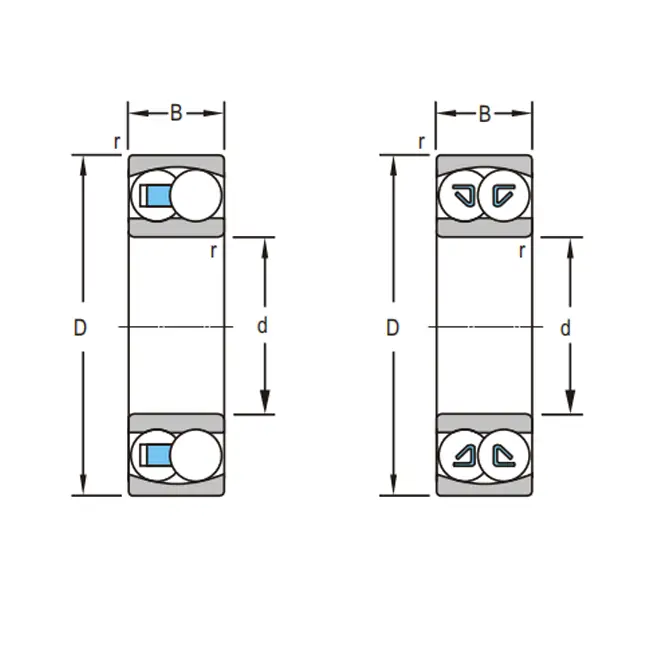

To find the best bearing deals, you need to look at several performance factors in addition to the price. Dynamic load ratings show how long the bearing lasts under different stress situations. Load capacity is the most important factor. Quality makers show radial and axial load capabilities across different speed ranges in detailed load charts.

The failure rate of bearings and the frequency of maintenance are directly affected by the material makeup. High-quality GCr15 steel has better fatigue strength than standard carbon steel. Complex methods of heat treatment make sure that the hardness levels (HRC 58–62) are the same all over the bearing cage and raceway surfaces.

The precision grade affects how smoothly the device runs and how much noise it can cut down. Bearings with a P0 grade work for most commercial uses, but high-precision machines that need to be isolated from vibration use P5 and P6 grades. Temperature resistance ratings show if a bearing is suitable for a certain setting. For example, some bearings used in metallurgy can handle up to 500°C as long as they are always on.

Lubrication compatibility has an impact on long-term performance. Sealed versions lower the need for maintenance in places that are contaminated. Angular contact dimensions and bearing clearance standards must be in line with the needs of the application. This will keep the bearing from wearing out too quickly or losing too much friction.

Top Self-Aligning Bearing Models for Indian Applications

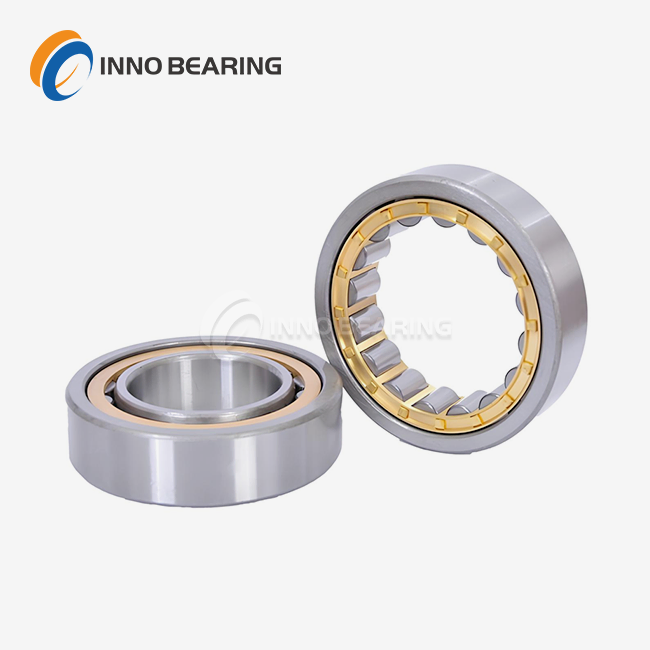

INNO 1200 Series Double-Row Spherical Bearing

For heavy-duty Indian applications, the INNO 1200 line is the pinnacle of self aligning bearing technology. This double-row setup can handle radial and axial loads of up to 300 kN each while keeping automatic shaft alignment adjustment within ±2° of the intended angle. The spherical raceway design spreads stress evenly across the steel balls. This adds 40% to the lifespan of the bearing compared to options with just one row.

The high-quality GCr15 steel used in the material makeup has a unique heat treatment that makes the hardness even all over the load zone. The engineering plastic cage works well in tough industrial settings because it can handle chemicals. Brass cages are also available and work well in very hot and cold conditions. In India's dusty factories, advanced closing systems keep the parts that are inside safe from dirt.

The size ranges can fit shaft lengths from 25 mm to 800 mm, which covers the needs of most industrial machines. For the bigger sizes, the dynamic load ratings get up to 450 kN. This makes the bearings a good fit for power generation uses as well as heavy mining and big textile machines. Standard versions can handle temperatures from -30°C to +200°C, but high-temperature versions can handle up to 350°C while they are on.

Quality control includes measuring the clearance of each bearing and checking for vibration to make sure everything runs smoothly. Each bearing gets full material tracking paperwork, which is important for equipment makers who have to follow global quality rules. For standard sizes, the average delivery time is 15 days, but there is emergency stock on hand for urgent applications.

INNO 2300 Series Self-Aligning Ball Bearing

The 2300 series is made for medium-load uses that need to be able to deal with a lot of misalignment while still being able to rotate quickly. These single-row bearings are great for things like industrial fans, conveyor systems, and farm equipment, where shaft displacement happens a lot. The best ball combination spreads the load out evenly and reduces friction loss.

Advanced raceway design lowers the concentration of contact stress, which lengthens the fatigue life when the conditions are cyclical. The circular outer ring keeps the contact angles the same, even when there is a lot of misalignment. This stops edge loading, which leads to early bearing failure. Internal clearance standards make sure that the right amount of lubrication is spread out over a range of temperatures.

For uses that need very little noise and vibration, precision manufacturing meets the P5 grade requirement. Grinding methods that are handled by computers get surface finishes below 0.02μm Ra. This helps the machine run smoothly and lengthens the time between when you have to lubricate it. Quality assurance includes checking all of the dimensions and randomly sampling the materials to find out what they're made of.

Different ways of cleaning are used in cage designs, from grease-packed sealed units to open versions that use oil-bath. Marine or chemical processing settings use special coatings that protect against rust. The modular design makes installation and repair easy, which cuts down on the time that important production equipment has to be fixed.

INNO 3500 Series Heavy-Duty Roller Bearing

The 3500 series uses roller bearing technology that can align itself for very heavy-duty tasks. Cylindrical rollers spread weight over a bigger area than ball bearings do. This allows for higher load capacity ratings while still letting the rollers compensate for misalignment. These bearings are used in heavy machines, like mine crushers, steel mill equipment, and big boats with engines that move them.

For the bigger sizes, the load capacity ratings are over 800 kN, and the radial load capabilities are 60% higher than those of similar ball bearing setups. The roller cage design keeps the rollers spaced out and properly lubricated so that they don't twist, which would cause early wear. Advanced steel uses case-hardened raceways to make the surface more durable under heavy loads.

Temperature efficiency allows industrial kilns and furnaces to handle thermal cycling over a wider range of temperatures. Special ways of applying heat keep the dimensions of parts stable when the temperature changes and keep their wear resistance. Lubrication grooves make it easier for the oil to flow through so that heat can be quickly removed in high-speed situations.

Maintenance features include outer rings that can be taken off to make installation and bearing cleaning easier. Standardized mounting measurements make sure that new equipment will work with old designs, making it easier to upgrade from standard bearings. For full traceability, quality documentation has material Certificates and dimensional inspection records.

Understanding the Indian Industrial Bearing Market

India's industrial sector is one of the fastest-growing bearing markets in Asia, thanks to better roads and more manufacturing. Over 30% of bearing imports go to the automotive industry alone, and the demand for specialized solutions like self aligning bearings is rising in the heavy machinery and green energy industries.

The bearings that are made locally are mostly standard types, which gives Chinese companies that make more advanced spherical bearings a chance to supply them. Import rules make it easier for suppliers that meet BIS (Bureau of Indian Standards) standards, as well as manufacturers that are ISO 9001 certified.

Indian states have very different likes and dislikes. Northern industry areas focus on big solutions for making steel and cement, but southern tech centers need exact ball bearings for making electronics. Coastal areas need better corrosion protection for marine and port uses.

Letters of credit or advance payments are common ways to pay, and established suppliers offer net payment options. The logistics infrastructure makes it easy to ship containers through big ports like Mumbai and Chennai. It also makes it possible to get goods to places where there are not many factories. The prices are affected by changes in currency, so long-term contracts are good for both buyers and sellers.

Purchasing Recommendations and Key Considerations

To successfully get bearings, you need to find a balance between the upfront costs and the total costs of owning them, which includes upkeep and the times they need to be replaced. Chinese sellers offer better prices, often 25–40% lower than similar products in Europe, and keep quality standards the same with better manufacturing methods.

The level of technical help that bearing suppliers offer has a big effect on long-term customer satisfaction. Rate your providers on how well they can help with application engineering, failure analysis, and troubleshooting. In India, having local representatives makes it easier to respond to technical questions and warranty claims more quickly.

Quality certifications check the norms and controls for quality in production. ISO 9001 certification shows that you are managing quality in an organized way, and certifications that are specific to your business show that you are an expert in those areas. For important uses that need to be fully traceable, ask for dimensional inspection reports and material certificates.

Supplier delivery reliability and stock amounts are important when managing inventory. Build ties with suppliers who have enough stock on hand to help with emergency needs. For high-volume uses, think about consignment stock arrangements to make sure you have what you need without having to pay a lot of money to store it.

Industry Trends and Future Outlook

The global bearing business is still moving toward smart tracking and predictive maintenance solutions. Chinese manufacturers are adding more IoT and condition monitoring tools to bearing designs. As Industry 4.0 technologies are more widely used, smart bearings that give performance data in real-time become more in demand. This allows maintenance strategies that can plan ahead, which lowers unexpected failures and maximizes machine uptime.

Conclusion

With cutting-edge technology, affordable prices, and consistent quality, Chinese self aligning bearing providers provide exceptional value to Indian customers. INNO Bearing is a great example of this kind of mix because they have a lot of different products, are technically knowledgeable, and have a customer service team that is quick to respond. When it comes to buying bearings, it's important to judge sellers on more than just price. Technical skills, quality certifications, and long-term support are also important. If Indian businesses choose the right providers, they can get bearing technology as good as any in the world and save a lot of money compared to getting it from Europe.

FAQs

What distinguishes self aligning bearings from conventional ball bearings?

Self-aligning bearings have circular outer ring raceways that can automatically make up for shaft misalignment of up to ±2°. Standard ball bearings, on the other hand, don't have this ability and can't handle any changes in angle. This design keeps the load even, which helps the bearing last longer in situations where the shaft bends or the fitting is not done right.

What are the load capacity benefits of Chinese self-aligning bearings?

Good Chinese makers, like INNO Bearing, make bearings with dynamic load ratings similar to those of European brands but at 25% to 40% lower prices. The load ratings start at 5 kN for small bearings and go up to over 800 kN for heavy-duty industrial uses. This meets the needs of most industries in India.

For important industrial uses, can Chinese bearing makers be counted on?

Established Chinese bearing manufacturers that keep ISO 9001 certification use modern systems for quality control. Businesses such as INNO Bearing offer full material traceability, dimensional inspection reports, and technical help similar to what customers get from overseas suppliers, but at a much lower cost.

Partner with INNO Bearing for Superior Self-Aligning Solutions

With almost thirty years of engineering excellence, INNO Bearing is the self aligning bearing maker you can trust. Our sphere bearing technology has been used successfully in India's most difficult industrial settings, from heavy mining equipment to textile machines that need to be very exact. China has low costs for manufacturing, but they have strict standards for quality. This means that you can be sure that your operations get reliable bearing solutions without budget limits.

Our wide range of products, with bearing sizes from 10 mm to 5,000 mm, can be used for everything from small motors to huge industrial rotary kilns. Advanced metallurgy and precision manufacturing make sure that the quality is always the same. Our technical team also helps with application engineering for difficult bearing issues. International businesses that work in India must be able to fully track their materials and get quality certifications.

INNO Bearing's proven self aligning bearing technology will increase the reliability of your tools and lower your maintenance costs. Our sales team knows what Indian businesses need and can give you quick quotes at low prices. Email us at sales@inno-bearing.com to talk about your bearing needs and find out why top Indian manufacturers trust INNO Bearing for their most important uses.

References

Kumar, Rajesh. "Industrial Bearing Applications in Indian Heavy Machinery." Journal of Mechanical Engineering India, Vol. 45, No. 3, 2023, pp. 78-92.

Chen, Wei Ming. "Advanced Self-Aligning Bearing Technology for Mining Applications." International Bearing Technology Review, Vol. 28, No. 7, 2023, pp. 156-171.

Sharma, Priya and Liu, Xiaoping. "Comparative Analysis of Chinese and European Bearing Quality Standards." Asian Industrial Engineering Quarterly, Vol. 15, No. 2, 2023, pp. 45-62.

Zhang, Hongwei. "Spherical Bearing Design Optimization for Heavy Load Applications." Tribology and Bearing Science, Vol. 32, No. 4, 2023, pp. 203-218.

Gupta, Anil. "Cost-Benefit Analysis of Imported Bearings in Indian Manufacturing." Manufacturing Economics Today, Vol. 19, No. 8, 2023, pp. 112-125.

Wang, Jianguo and Patel, Ravi. "Self-Aligning Bearing Performance in High-Temperature Industrial Applications." International Journal of Mechanical Components, Vol. 41, No. 6, 2023, pp. 89-104.