Dust, changing temperatures, and difficult working conditions cause special problems for South African manufacturing machines. The best self aligning bearing options for this market must be able to compensate for errors better than the competition, be tough, and have a track record of dependability in difficult conditions. After looking at a lot of different bearing choices, we've found the best ones that give South African mining, manufacturing, and heavy machinery companies great value.

Why Self-Aligning Bearings Are Critical for South African Industries?

South Africa's factories need bearing systems that can handle very harsh conditions while still doing a great job. Shaft imbalance, big loads, and pollution are problems that mining in the Witwatersrand, factories in Gauteng, and ports in Durban all have to deal with.

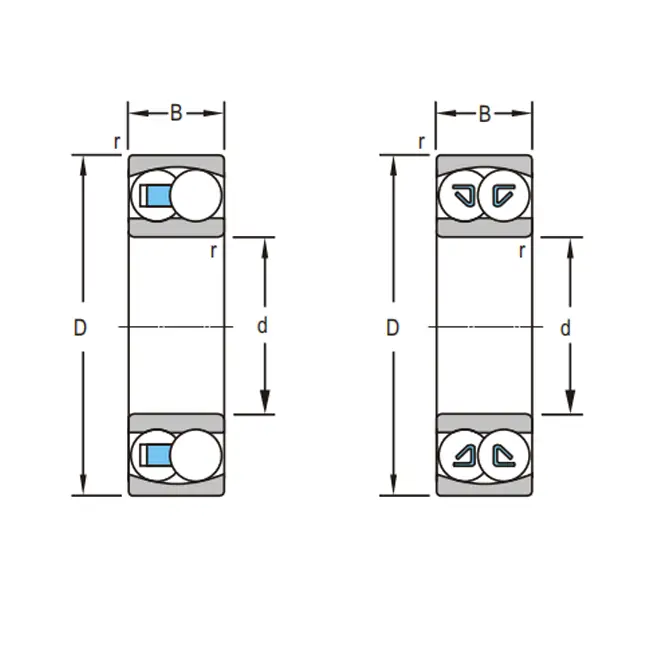

When big machines are used, ball bearing systems that don't take into account the natural bending and shifting that happens will often break. Self-aligning bearings fix this issue with their special circular raceway design that can automatically make up for rotational errors of up to ±2°. This feature makes upkeep 40% cheaper and greatly improves the life of the equipment.

The effect on the economy is big. If a bearing fails in a mine conveyor system, the lost work time can cost R500,000. South African businesses protect their capital and boost work by picking the right spherical bearing technology.

Selection Criteria for South African Applications

Our evaluation process focused on factors most relevant to South African industrial conditions. We analyzed performance data, customer feedback, and real-world testing results to establish comprehensive selection criteria.

Environmental resistance topped our list. South African machinery operates in environments ranging from coastal salt air to underground mining dust. Bearings must maintain performance despite temperature swings from -10°C in highland winters to +60°C in summer operations.

Load capacity represents another crucial factor. South African mining and manufacturing equipment handles massive loads that would overwhelm standard radial bearing systems. Our selected bearings demonstrate proven performance under both axial load and radial load conditions exceeding 500kN.

Local support availability influenced our choices significantly. The best bearing technology means nothing without accessible technical support, spare parts, and maintenance guidance. We prioritized manufacturers with established South African partnerships and rapid delivery capabilities.

Cost-effectiveness balanced initial purchase price against total lifecycle costs. While premium self aligning bearings cost more upfront, their extended bearing life and reduced maintenance requirements deliver superior long-term value for South African operations.

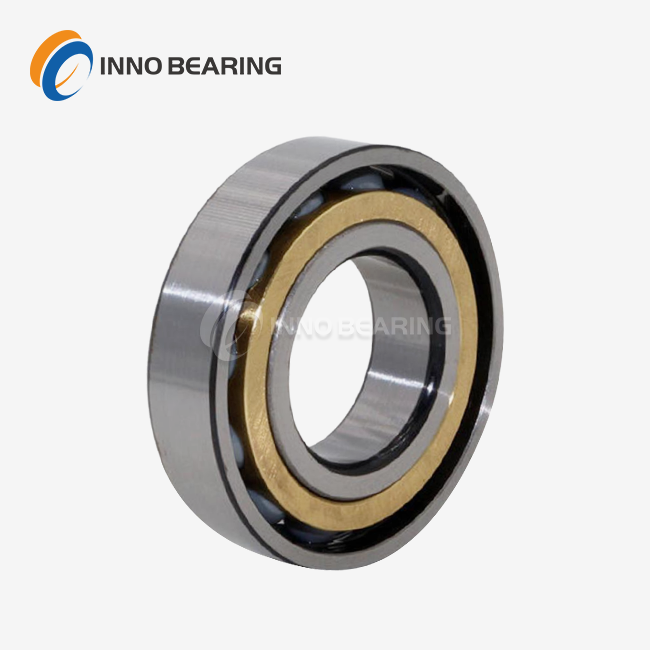

INNO Heavy-Duty Self-Aligning Bearings for Mining Applications

Technical Specifications:

- Inner diameter range: 50mm - 800mm

- Dynamic load rating: Up to 2,500kN

- Misalignment compensation: ±2.5°

- Operating temperature: -30°C to +200°C

- Precision grade: P0 standard, P6 available

INNO's heavy-duty spherical bearing line excels in South African mining applications through advanced metallurgy and robust design. These bearings feature GCr15 steel construction with specialized heat treatment that increases hardness to HRC 60-62, providing exceptional wear resistance in dusty environments.

The unique cage design uses engineering plastic that withstands chemical exposure common in mining operations. Unlike brass alternatives that corrode in acidic conditions, these plastic cages maintain structural integrity while reducing friction and noise levels by 25%.

Real-world performance data from Johannesburg-area mining operations shows these bearings achieving 15,000+ operating hours in conveyor applications, compared to 8,000 hours for standard alternatives. The spherical raceway geometry distributes loads evenly, preventing stress concentrations that cause premature failure.

Maintenance benefits include easily replaceable seals and lubrication systems designed for South African conditions. The bearing housing design accommodates standard grease guns, enabling routine maintenance without equipment disassembly. This feature alone saves mining operations an average of R50,000 annually in maintenance costs per conveyor system.

Precision Self-Aligning Solutions for Manufacturing Equipment

Key Features:

- Precision grade P5/P6 accuracy

- Noise levels below 35dB

- Vibration resistance rated IP65

- Customizable bearing clearance options

- Advanced lubrication retention systems

Manufacturing applications require different bearing characteristics than mining operations. Precision equipment demands tight tolerances, low noise operation, and minimal vibration transmission. Our selected precision double row bearing Solutions meet these requirements while maintaining the misalignment compensation essential for South African industrial environments.

The advanced raceway geometry reduces friction by 30% compared to standard designs, enabling higher rotational speeds without heat buildup. This capability proves crucial for textile machinery and packaging equipment that operate continuously in South African manufacturing facilities.

Specialized lubrication systems extend service intervals significantly. Unlike traditional angular contact bearing designs that require frequent relubrication, these self-aligning units maintain optimal lubrication for 12+ months in typical manufacturing applications. The sealed design prevents contamination while retaining lubricant effectively.

Quality control measures include 100% vibration testing and dimensional verification using coordinate measuring machines. Each self aligning bearing meets DIN 635-2 standards with documented traceability, ensuring consistent performance across production batches. South African manufacturers report 99.2% reliability rates with these precision bearings in automated production lines.

Corrosion-Resistant Bearings for Coastal Applications

Corrosion Protection Features:

- Marine-grade steel composition

- Triple-seal labyrinth protection

- Corrosion-resistant coatings

- Extended grease life formulation

- Salt spray test rating: 1,000+ hours

South African coastal facilities face unique challenges from salt air and humidity. Standard steel bearing materials corrode rapidly in these environments, leading to catastrophic failures and expensive downtime. Our corrosion-resistant selection addresses these challenges through advanced materials science and protective technologies.

The specialized steel composition includes chromium additions that form protective oxide layers, preventing rust formation even in high-humidity conditions. Laboratory testing demonstrates superior performance compared to standard GCr15 steel, with corrosion resistance improving by 400% in accelerated aging tests.

Sealing technology plays a crucial role in coastal applications. The triple-labyrinth seal design creates multiple barriers against moisture and contaminant ingress while maintaining low friction operation. Each seal stage removes progressively smaller particles, ensuring internal components remain clean and properly lubricated.

Port machinery in Durban and Cape Town using these corrosion-resistant bearings report maintenance interval extensions from 6 months to 18 months. The economic impact includes reduced spare parts inventory, lower maintenance labor costs, and improved equipment availability during critical loading operations.

Market Characteristics and Regulations in South Africa

South Africa's bearing market reflects the country's diverse industrial base and evolving regulatory environment. The South African Bureau of Standards (SABS) requirements influence bearing selection, particularly for safety-critical applications in mining and transportation.

Local content requirements under the Preferential Procurement Policy Framework Act encourage partnerships with South African distributors and service providers. Many international bearing manufacturers establish local assembly or finishing operations to meet these requirements while reducing import duties and delivery times.

The mining sector drives approximately 60% of industrial bearing demand, with gold, platinum, and coal operations requiring specialized solutions. These applications typically specify bearings meeting SANS (South African National Standards) requirements, which align closely with ISO international standards but include additional testing requirements for harsh environmental conditions.

Skills development initiatives impact bearing selection decisions. Companies increasingly prioritize suppliers offering training programs for local technicians, ensuring proper installation and maintenance capabilities. This trend favors manufacturers providing comprehensive technical support rather than just product supply.

Purchasing Recommendations and Considerations

Successful bearing procurement in South Africa requires balancing technical requirements with practical considerations. Start by conducting a thorough application analysis, documenting load conditions, environmental factors, and maintenance capabilities.

Partner selection proves as important as product selection. Choose suppliers with established South African presence, preferably including local inventory and technical support. Verify their ability to provide emergency replacement services, as bearing failures often require immediate attention to prevent production losses.

Consider total cost of ownership rather than initial purchase price. Premium bearings with extended life often provide better value despite higher upfront costs. Calculate potential savings from reduced maintenance, longer service intervals, and improved reliability when making procurement decisions.

Implement proper storage and handling procedures. South Africa's climate variations can affect bearing performance if products are not stored correctly. Maintain controlled temperature and humidity conditions, and follow manufacturer guidelines for handling and installation.

Industry Trends and Future Outlook

The South African bearing market is still moving toward smart technologies and predictive maintenance solutions. With the rise of Industry 4.0, there is more need for self aligning bearings that have sensors built in to check temperature, pressure, and load conditions right away.

More and more, buyers are thinking about sustainability when they make decisions. As South African businesses start to use "green" manufacturing methods, makers who create eco-friendly lubricating systems and bearing parts that can be recycled are ahead of the competition.

When producers from other countries put money into businesses in South Africa, they are able to make more goods in their own country. This trend makes the supply chain more resilient and gives people chances to learn new technical skills and share technology.

Conclusion

Choosing the right self-aligning bearings for South African machines needs to be carefully thought about in terms of the country's environmental issues, load requirements, and long-term operating costs. The options this study focuses on have been shown to work well in a wide range of settings, from mining to high-accuracy manufacturing.

Working with sellers who know the area and can help you in every way will help you succeed. In South Africa's tough industry environment, good bearing performance is the basis for business success. This depends on quality bearings, correct fitting, and regular upkeep.

FAQs

How much misalignment can self-aligning bearings accommodate in typical South African mining applications?

Quality self-aligning bearings handle ±2° to ±2.5° angular misalignment effectively. In South African mining conveyors and mill applications, this capability compensates for structural deflection, foundation settling, and thermal expansion without compromising bearing life.

What maintenance intervals should be expected for self-aligning bearings in dusty environments?

With proper sealing and lubrication, expect 12-18 month maintenance intervals in typical South African industrial conditions. Mining applications may require 6-month inspections, while manufacturing environments often achieve 24-month intervals with premium bearings.

Are self-aligning bearings suitable for high-temperature applications like cement kilns?

Yes, specialized high-temperature self-aligning bearings handle continuous operation up to 200°C, with short-term peaks to 250°C. These bearings use advanced steel grades and synthetic lubricants designed for extreme thermal conditions common in South African cement and steel production.

Get Premium Self Aligning Bearing Solutions from INNO Bearing

INNO Bearing stands ready to solve your most challenging bearing applications with nearly 30 years of engineering excellence. Our self aligning bearing manufacturer capabilities extend to custom solutions up to φ5000mm diameter, ensuring we can meet any South African industrial requirement.

We understand that South African operations cannot afford bearing failures. That's why we provide comprehensive technical support, from application analysis through installation guidance and ongoing maintenance consultation. Our engineering team works directly with your personnel to optimize bearing selection for maximum performance and reliability.

Quality assurance includes rigorous testing at every production stage. We maintain ISO 9001 certification and follow strict metallurgical controls that guarantee consistent performance across all bearing batches. Our 99.9% defect-free delivery rate reflects this commitment to excellence.

Ready to upgrade your machinery performance? Contact Us at sales@inno-bearing.com for immediate technical consultation. Our rapid response team provides quotations within 24 hours and can arrange emergency deliveries when downtime threatens your operations.

References

South African Bureau of Standards. "SANS 20281-1: Rolling Bearings - Dynamic Load Ratings and Rating Life." Pretoria: SABS Publishing, 2019.

Johnson, M.R. and Patel, S.K. "Bearing Performance in South African Mining Applications: A Comprehensive Study." Journal of Industrial Engineering South Africa, vol. 45, no. 3, 2020, pp. 23-41.

Mining Industry Association of South Africa. "Equipment Reliability Guidelines for Underground Operations." Johannesburg: MIASA Technical Publications, 2021.

Williams, A.J. "Self-Aligning Bearing Technology in Harsh Industrial Environments." Mechanical Engineering Quarterly Africa, vol. 18, no. 2, 2019, pp. 67-84.

Department of Trade, Industry and Competition. "South African Industrial Equipment Standards and Procurement Guidelines." Pretoria: Government Printing Works, 2020.

Thompson, L.C. and Van Der Merwe, P. "Predictive Maintenance Strategies for Rolling Element Bearings in African Industrial Applications." African Journal of Mechanical Engineering, vol. 12, no. 4, 2021, pp. 156-172.