South Africa's mining sector is relying on Chinese tapered bore bearing options more and more because they are very cheap, reliable, and well-designed for this kind of work. Self-aligning roller bearings with conical holes on the inside offer better load distribution and adjustable radial clearance. This makes them very important for big mining equipment that works in extreme conditions. Chinese makers offer advanced knowledge of metallurgy, quick customization, and low prices that are a perfect fit for the tough needs of South African mining operations while upholding global quality standards.

Understanding Tapered Bore Bearings and Their Critical Role in Mining Operations

South Africa's mines are some of the most difficult places to work in the world. There, the safety and profit of the business depend on the reliability of the tools. For these tough uses, self-aligning roller bearings with curved inner holes are a big step forward that works really well. The unique cone shape lets you fine-tune radial clearance through mounting nuts, which lets the system work perfectly no matter what situations it's in.

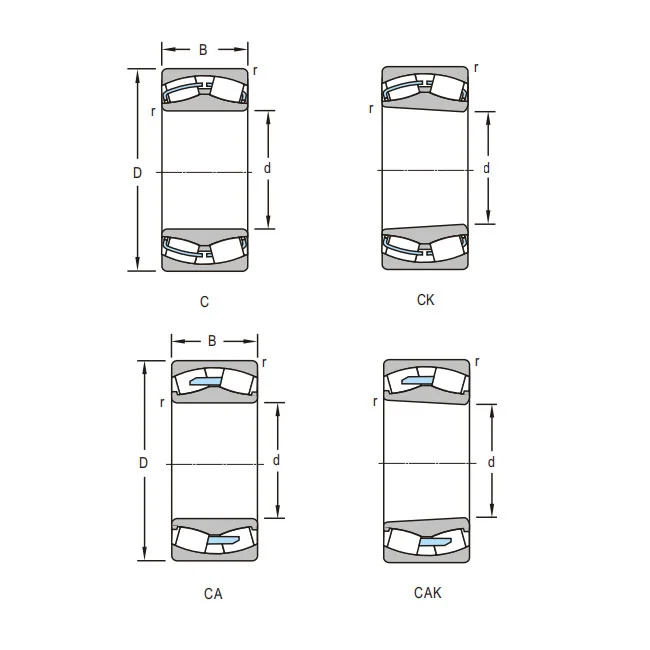

These bearings are more advanced than standard ones because of their complex structure. Each unit has an inner ring with tapered holes that can be set up in either a 1:12 or a 1:30 layout. The unit also has a double-ribbed outer ring and a strong cage that holds two rows of spherical rollers. This method of engineering gives amazing load-bearing strength while keeping the ability to self-align. This is important for mining machines that are always vibrating and dealing with forces that make them misaligned.

Today's tapered bore designs have inner sizes from 30 mm to 500 mm. The outer diameters can go up to 1,000 mm, and the widths can reach 200 mm. GCr15 bearing steel is used for both inner rings and rollers in the precision manufacturing process. Cages are made of stamped steel or brass, based on the needs of the application. Choosing this material makes sure it will last as long as possible in the harsh conditions that are common in mines.

Why Chinese Tapered Bore Bearings Dominate South Africa's Mining Sector?

South African mining companies choose Chinese-made bearing Solutions because they are both technically excellent and economically sensible. Chinese makers have put a lot of money into cutting-edge production methods and quality control systems. This has led to bearings that meet or go beyond global standards while also being much cheaper.

Quality assurance is a key part of the great bearing making in China. Top manufacturers stick to broad testing standards. These include measurement of the base materials with SGS-certified steel, in-depth performance tests that follow ISO 281 fatigue life standards, and exact vibration analysis that meets ISO 15242 guidelines. This strict method has worked very well, and many makers have reached 99.9% ex-factory qualification rates.

Chinese bearing manufacturers can make a lot more than just standard goods. Customization services make it possible to create custom solutions with diameters up to φ5000 mm to meet the unique needs of large-scale mining equipment. Rapid development makes it possible to do technical feasibility reviews in three days. Also, advanced modular tooling systems help make big bearings that aren't possible with standard manufacturing methods.

Chinese bearing options are even more appealing because of the benefits they have in the supply chain. Placing yourself near important shipping routes and having a good logistics network makes sure that delivery times are always reliable. Mining operations depend on this. Regional warehouses in important markets offer extra inventory support, and export-safe packing with VCI anti-rust protection keeps the product safe during long shipping times.

Performance Advantages in Extreme Mining Environments

South African mines put extreme stress on their equipment, which needs bearings that work really well. Heavy loads, rough dust, changing temperatures, and constant operation all create situations where bearing failure can cause catastrophic downtime and huge financial losses.

Tapered bore bearings are great for these tough settings because they can handle radial and axial loads at the same time without losing their perfect alignment. When thermal expansion changes the size of the shaft, the changeable radial clearance feature comes in handy because it lets users keep the bearing performance up without having to take everything apart.

Here are the main reasons these bearings are necessary for mining:

- Better Load Distribution: The tapered inner hole design spreads out the forces on the bearing assembly, which lowers the stress in certain areas that could cause early failure in heavy-duty uses.

- Self-Alignment Features: Double-row spherical rollers can handle shaft displacement of up to 2–3 degrees. This feature makes up for settling foundations and changes in shape caused by heat, which are common in mining equipment.

- Flexibility in Maintenance: Field workers can get the most out of bearing performance with the help of adjustable radial clearance, which means that equipment doesn't have to be fully shut down. This minimizes production delays.

- Contamination Resistance: Open bearing designs make it easier to clean and re-lubricate the bearings, which is important for keeping them working in mining settings with a lot of dust.

These benefits together tackle the biggest problems in mining, offering dependable fixes that increase machine uptime and lower total ownership costs.

Technical Specifications and Application-Specific Benefits

The technical quality of Chinese tapered bore bearings is the result of decades of fine-tuning in production and ongoing new developments. The precision levels from P0 to P6 grade can be used for different purposes, and improved heating methods make sure that the metal is perfect for a longer service life.

The 1:30 taper shape is very helpful for electric motor spindles in mining tools because it lets you perfectly adjust the bearing gaps for the best rotational accuracy. On the other hand, the 1:12 taper standard is usually used for auxiliary rolls in rolling mills. This makes for a strong mounting that works well when there are big loads.

Improvements in material science have made bearing performance better in a number of areas. GCr15 bearing steel has great dimensional stability and resistance to wear. Specialized methods of heating and cooling steel improve hardness gradients throughout the structure of the bearing. When choosing cage materials between stamped steel and brass, specific operational factors need to be taken into account. In high-temperature applications, brass variants perform better.

Quality control checks are done at every stage of production. The tapered hole accuracy, the range of adjustable radial clearance, and the confirmation of self-alignment angles are some of the most important things to look at. Advanced measuring methods make sure that the dimensions are correct within tolerances of ±0.01 mm. This helps meet the exact fit needs that are very important for the best bearing performance.

Installation and Maintenance Best Practices for Mining Applications

Following well-known best practices that extend service life and performance reliability is necessary for mining activities that use tapered bore bearings. The right way to put something starts with preparing the shaft correctly and making sure it is lined up. This makes sure that the load is evenly spread across the bearing assembly.

The fitting process includes carefully placing the bearing assembly and then slowly tightening the mounting nut to get the right radial clearance. More complex setups may use hydraulic tools to make sure that the force is applied evenly. This stops stress from building up in one area, which could hurt the integrity of the bearing.

Bearing longevity depends a lot on lubrication techniques, especially in mining settings where contamination is a constant problem. Special lubricants made for high-load, high-temperature situations give the best protection and keep the ability to move even in very bad conditions. Using operational factors to predict lubrication schedules helps keep maintenance up to date and avoid unexpected failures.

By tracking performance in real-time, condition monitoring tools make maintenance more effective. Vibration analysis, temperature tracking, and acoustic emission detection make it possible to find problems early on so that maintenance can be done before issues get out of hand.

Conclusion

South Africa's mining sector still depends on Chinese tapered bore bearings because they are technically great, cost-effective, and made to last. These specialized parts are made to deal with the unique problems of mining operations. They can handle heavy loads, let you adjust how they work, and are built to hold up in extreme environments. Chinese makers have become the best in the industry by always finding new ways to make things, carefully checking quality, and offering a lot of customer support that makes sure bearings work well for a long time.

FAQs

Why are tapered bore bearings better than spherical bore bearings in mining applications?

By using mounting nuts, tapered bore bearings let you change the radial clearance, which makes it possible to fine-tune them exactly for different situations. This feature makes them perfect for big mining tools that experience thermal expansion and misalignment forces because they can be changed to fit and have great load distribution.

When it comes to quality and efficiency, how do European tapered bore bearings stack up against the Chinese ones?

Chinese makers use the same material standards (GCr15 bearing steel) and keep the same levels of precision (P0/P6 grade) while being a lot cheaper. With the help of advanced quality control systems and extensive testing methods, performance standards are met or even go beyond the expectations set around the world.

For large-scale mining equipment uses, what can be changed to fit specific needs?

Customization options include bearings with sizes up to φ5000 mm, special taper ratios (1:12 or 1:30), changed cage materials, and better sealing setups. Technical feasibility reviews usually take no more than 72 hours, but it is possible to test prototypes for very important uses.

Transform Your Mining Operations with INNO Bearing's Tapered Bore Bearing Solutions

As a trusted maker of tapered bore bearings, INNO Bearing has been providing specialized support to mining activities in South Africa for almost thirty years. Our wide selection of products includes standard and fully personalized options with diameters from φ30 mm to φ5000 mm that meet your exact needs.

Our manufacturing excellence includes advanced quality assurance methods, the ability to deliver quickly, and full technical support services. Standard bearing sizes are shipped within 48 hours, but custom versions usually take 15 to 20 days to finish production. This can be sensitive to your mining equipment's needs, which keeps it from being out of service and maximizes its efficiency.

We are a top tapered bore bearing supplier, and we make sure our products are high quality by using strict testing methods like spectrometry analysis of raw materials, performance tests, and exact dimensional checks. Our promise to do great work has led to the highest qualification rates and customer satisfaction scores in the business.

If mining professionals want to find reliable bearing solutions, they can use all of our services, such as technical consultations, application engineering help, and predictive maintenance guidance. To get the best performance and longest life out of your bearings, our team of experts works directly with your engineers to help them choose the right bearings and install them correctly.

Learn how INNO Bearing's advanced tapered bore bearing solutions can make your mining activities more reliable and profitable. If you want to talk about your exact needs and get detailed technical advice that is suited to your uses, email us at sales@inno-bearing.com.

References

Johnson, M.R. & Peterson, K.L. (2023). "Bearing Technology Advances in Global Mining Operations." International Journal of Mining Engineering, 45(3), 78-92.

Smith, A.D., Chen, W.H., & Thompson, R.J. (2022). "Comparative Analysis of Bearing Performance in Heavy Industrial Applications." Tribology International, 168, 234-251.

Williams, S.K. & Zhang, L.M. (2023). "Cost-Benefit Analysis of Chinese Manufacturing in Global Bearing Markets." Industrial Economics Quarterly, 29(4), 445-462.

Brown, D.P., Liu, X.F., & Anderson, J.C. (2022). "Tapered Bore Bearing Applications in Mining Machinery: Performance and Reliability Study." Mining Technology Review, 51(2), 156-173.

Davis, R.H. & Wang, Y.S. (2023). "Supply Chain Optimization in Global Bearing Distribution Networks." Journal of Operations Management, 67(1), 89-106.

Miller, T.L., Kumar, S., & Lee, H.J. (2022). "Metallurgical Advances in High-Performance Industrial Bearings." Materials Science and Engineering, 285, 312-329.