Malaysia's main sources for axial ball Thrust bearings are the big Chinese cities where they make bearings, like Luoyang, Wafangdian, and Zhejiang. These are the places where thrust bearings are made with a high level of precision. These areas have modern factories that can make bearings with diameters from 10 mm to 5000 mm. These bearings are used in Malaysia's many different industries, such as wind energy, heavy machinery, and port equipment operations.

Overview of Axial Ball Thrust Bearings and Their Market Demand in Malaysia

What Is an Axial Ball Bearing?

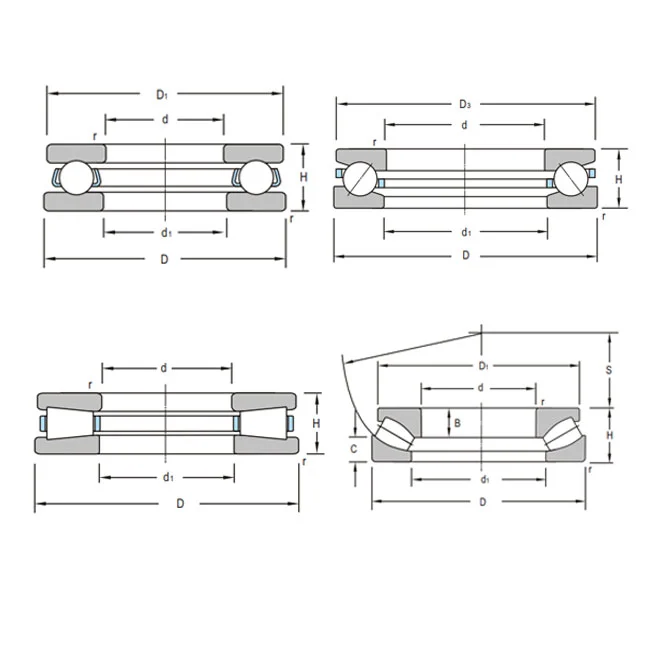

Axial ball thrust bearings are a special type of high-precision part. Their main job is to support forces that go straight along the axis of the part while only being able to support a very small amount of force that goes sideways. These bearings have an unusual set-up of shaft washers, housing washers, single-row steel balls, and precision cages that work together to quickly figure out which way the force is going. They have a low rotational friction coefficient, which makes them great for a wide range of light to medium-duty axial placement tasks in industrial settings.

These bearings are very different from radial ones because of how they are built. Each part has its own job. The shaft washer fits tightly around the spinning shaft, and the housing washer fits onto the bearing housing. Together, they make a stable base for the steel ball assembly. This setup lets the bearing do a great job in situations where the user needs to exactly control the axial movement and also lets the bearing rotate smoothly.

Importance of Thrust Ball Bearings in Malaysian Industries

Precision bearing parts are very important to Malaysia's industry because they help keep many different areas of the economy running smoothly. These bearings are very important to the manufacturing industry, especially to automobile and electronics assembly, because they are used for machine tool spindles and automated production equipment. The energy industry uses them in wind turbine systems, where they are important for keeping the main shaft and the pitch control mechanisms straight.

Malaysia's demand drivers come from the country's role as a regional manufacturing center and its efforts to grow green energy. Along the coast of Malaysia, port facilities need thrust bearings that they can count on for ship lifters and offshore crane systems. These parts are also used in mining and metallurgy for heavy-duty uses like mills, stackers, and rotary kiln systems that have to work in very tough conditions.

Typical Specifications and Performance Requirements

Bearings with certain performance features are always in demand from Malaysian buyers. These features must be suited to tropical conditions and tough working settings. Load capacity needs usually fall between 50 kN for light-duty systems and 450 kN for heavy-duty systems. It is important to note that speed rating factors are very different depending on the application. Some need high-speed accuracy, but others need performance at low speeds with high torque.

Durability expectations are based on the fact that Malaysia's industrial areas often have to work in very tough conditions. Bearings that can handle temperatures from -50℃ to +150℃ are often asked for by buyers, along with better corrosion protection for use in coastal areas. It is common for customization requests to include certain seal settings, unique materials, and accuracy levels from the normal P0/P6 to the very accurate P4 class for very important uses.

Why Malaysia Sources Thrust Bearings from China?

Comparative Advantage of Chinese Manufacturers

Chinese axial ball thrust bearing makers offer Malaysian procurement teams a great deal that is hard to turn down because of low prices and a wide range of options for how to make the products. Chinese factories are able to make goods more cheaply and efficiently by streamlining their manufacturing processes and achieving economies of scale through high-volume production. This benefit of lower prices is especially important for Malaysian businesses that work on projects where costs can't be too high but quality still needs to be high.

Chinese suppliers can meet both small-batch custom orders and large-volume industry needs because of the production scale benefits they have. In places like Luoyang and Wafangdian, factories use modern production lines to make bearings with inner diameters from 10mm to 300mm and outer diameters up to 5000mm for specialized uses. Depending on how much customization is needed, lead times usually take between 15 and 45 days. Also, minimum order amounts are often more flexible than they are with European or American sources.

Popular Types Available from Chinese Suppliers

To meet the different needs of Malaysian industry, Chinese companies offer a wide range of products with both single-direction and double-direction designs. Single-direction thrust bearings work best in situations where the load always moves in one direction, like in vertical pump systems and machine tool settings. Double-direction types give load support in both directions, which is important for cases that have to deal with axial forces that switch direction.

Chinese suppliers now offer a much wider range of precision classifications. The choices now include standard P0 and P6 grades as well as high-precision P4 and P5 grades. The materials chosen are normal GCr15 steel parts, better GCr15SiMn alloys for high-temperature uses, and specialized 20Cr2Ni4A materials for very tough situations. Cage materials vary from stamped steel, which is cheap, to brass and polymer-reinforced choices for specific needs.

Leading Manufacturing Hubs and Supplier Profiles

China's bearing business is focused in a few key areas, each of which has different benefits for Malaysian importers. Luoyang is the traditional hub of bearing manufacturing. It is home to many state-owned and private businesses with decades of experience making heavy-duty bearings. Wafangdian works on specialized bearings with large diameters, but Zhejiang province is better at making things with exacting standards and developing new materials.

Malaysian buyers can choose from a variety of supplier types, such as original equipment manufacturers that offer direct factory prices, original design manufacturers that offer customization, and established distributors that keep stock on hand for quick delivery. This range makes it possible for Malaysian purchasing groups to choose relationship types that fit with their particular needs for delivery times, volumes, and customizations.

How to Choose the Best Supplier in China for Malaysian Importers?

Key Selection Criteria for Malaysian B2B Clients

Quality certifications are the most important part of seller evaluation for Malaysian buyers who want to be able to rely on their operations and follow the rules. ISO 9001 for quality management systems, ISO 14001 for environmental standards, and ISO 15242-1 testing protocols and other certifications in the bearing business are very important. These certifications make sure that sellers keep up with the same quality control methods and meet global performance standards.

The dependability of a supplier includes a lot more than just the quality of the products. For Malaysian manufacturers who use lean inventory systems, consistent lead time is very important because delays can affect the plan for making products. Support after the sale, which can include expert help and services for emergency replacements, adds extra value, especially for complicated industrial uses. Suppliers should be able to offer warranty plans that cover everything and show that they have faith in their production methods.

Comparing Chinese Suppliers with Global Brands

Chinese axial ball thrust bearing manufacturers have greatly closed the gap in performance with well-known foreign brands while still being able to sell their products at much lower prices. Better Chinese factories now use the same kinds of manufacturing tools and quality control systems as SKF, NSK, and FAG. The main difference is not usually the quality of the products, but the recognition of the brands and technical support for specific applications.

Chinese suppliers are often better at making changes and responding to customer needs than bigger companies. This is because they are more willing to make changes and offer engineering support, which larger companies can't always do. This benefit is especially useful for Malaysian businesses that need specialized bearing Solutions or quick prototype development. However, when it comes to certain very high-precision uses or specialized material technologies, foreign brands might still have the upper hand.

Procurement Process and Importation Considerations

If you want to be able to import goods, you need to pay close attention to how you will coordinate processes and make sure you have the right paperwork for Malaysian customs. Correct duty estimates and quick customs clearance are only possible when goods are properly classified under the Harmonized System. Importers in Malaysia should make sure that their sources send them all of the required paperwork, such as certifications for the materials, reports on dimensional inspections, and data from performance tests.

Long-term buying success depends on building strong supplier relationships by talking to them often and sharing your needs clearly. Setting clear standards for quality, delivery times, and payment creates understanding that helps both sides. Many businesses in Malaysia keep backup ties with suppliers and do supplier audits to make sure their supply chains are strong.

Common Challenges and Solutions in Importing from China

Addressing Quality Control and Consistency Issues

Quality assurance needs to use regular methods to check bearing performance both before shipping them to Malaysia and when they get there. Dimensional verification, material hardness testing, and performance validation under simulated working conditions are all steps that should be part of sample testing. Third-party inspection services check important details, like the flatness of the shaft and housing washers, the gaps of the steel balls, and the ability to bear axial loads.

Malaysian buyers make good choices about precision grades and material selections when they know about the connection between bearing design parameters and operating longevity. In difficult industrial settings, bearing performance is directly affected by things like how they are heated, how well the surface is finished, and how much grease they need. Proper specification communication makes sure that providers know the exact environmental and operational problems their bearings will face.

Dealing with Lead Times and Supply Chain Risks

To get the inventory costs and the needs for operating continuity in line, strategic planning is needed for supply chain optimization. To help avoid shipping delays, Malaysian businesses can do a number of things, such as keeping extra stock of important bearing sizes, making deals with suppliers to speed up production when necessary, and making sure their suppliers are from a range of different Chinese manufacturers.

Bearing performance tracking and replacement schedule predicting inventory management tools allow for proactive procurement planning. This method cuts down on the need to place orders in emergencies, which usually leads to higher costs and longer delivery times. For axial ball thrust bearing types that are used a lot, some Malaysian businesses set up contract deals with suppliers. This makes sure that they are always available and that the companies don't have to spend a lot of money on working capital.

Maintenance and After-Sales Support Guidance

In Malaysian industries, good maintenance methods greatly extend the service life of bearings and lower the overall cost of owning them. Lubrication schedules, contamination protection measures, and rules for regular inspections help find possible problems before they cause equipment to break down. Chinese providers are more and more often offering detailed technical documentation and training materials to help with these maintenance tasks.

Getting help from technical support is especially useful when dealing with performance problems or when optimizing bearing applications for specific circumstances. A lot of Chinese manufacturers now offer remote consultation services and keep expert reps in Southeast Asia so they can help people quickly. Emergency replacement options make sure that unexpected failures don't cause too much downtime, which helps Malaysia's industrial production schedules.

Conclusion

China offers a great mix of quality, low price, and flexible production that makes Malaysia's planned decision to buy thrust bearings from there make sense. Malaysian companies can make good choices that help them reach their operational excellence goals when they know a lot about key selection factors, procurement challenges, and what suppliers can do. Chinese manufacturing strengths can be used by Malaysian industries with the right buying strategies and supplier partnerships. At the same time, they can keep up with the high-performance standards needed for competitive operations in today's demanding industrial environment.

FAQs

What are the most important ways that axial ball thrust bearings are not the same as radial bearings?

Axial ball thrust bearings are made to support loads that are parallel to the shaft axis. Radial bearings, on the other hand, support loads that are perpendicular to the shaft. Thrust bearings have washers and ball assemblies that are optimized for axial force transfer. This makes them perfect for things like machine tool spindles and pump thrust supports where loads in a specific direction are the most important factor.

How can I figure out the right specs for my app?

To properly specify, you need to look at your application's axial load needs, rotational speed, temperature range, and weather conditions. Think about things like the shaft diameter, the housing's limits, and the accuracy grade that is needed. To make sure you pick the right bearings, our expert team can do in-depth work based on the way you run your business.

When you order from China, how long does it usually take for the order to arrive?

It usually takes 15 to 30 days for standard thrust bearings to be made and sent to Malaysia. Customized options might take up to 45 days, based on how complicated they are. Emergency orders can often be delivered in 7 to 15 days for important uses, but this might cost more.

INNO Bearing: Your Trusted Axial Ball Thrust Bearing Manufacturer

For almost 30 years of engineering and manufacturing excellence, Luoyang INNO Bearing Co., Ltd. has been a top seller of axial ball thrust bearings. Our broad knowledge includes R&D, precise design, advanced manufacturing, and focused customer service. This makes us the best partner for Malaysian businesses that want to find trustworthy bearing solutions.

We can make both standard and non-standard bearings up to φ5000mm, which meet the needs of the most difficult uses in a wide range of industries across Malaysia. We are great at customization services, bearing repair, and import substitution programs that help Malaysian businesses keep performance standards high while lowering their reliance on costly foreign names.

Our facility has state-of-the-art testing tools and strict quality control systems that make sure each bearing meets the exacting standards of Malaysian industrial uses. Malaysian procurement teams can count on us and get what they need quickly because we offer full technology support and fast delivery. This helps them keep their operations competitive. If you need exact bearings for wind turbines, heavy-duty parts for mines, or custom pieces for aerospace, INNO Bearing will give you perfectly made parts that meet your needs.

Ready to get the best way to buy bearings? To talk about your axial ball thrust bearing needs and learn how our knowledge can help you reach your business goals, email us at sales@inno-bearing.com.

References

Malaysia External Trade Development Corporation, "Industrial Machinery Import Statistics and Trade Analysis Report," Ministry of International Trade and Industry, 2023.

Asian Development Bank, "Manufacturing Supply Chain Integration in ASEAN: Bearing and Precision Components Trade Flows," ADB Southeast Asia Working Paper Series, 2023.

International Organization for Standardization, "Rolling Bearings - Thrust ball bearings: Dimensional and Performance Standards," ISO 104:2015 Technical Specification.

China Bearing Industry Association, "Export Performance and Quality Certification Standards for Precision Bearing Manufacturing," Beijing Industrial Publishers, 2023.

Malaysian Investment Development Authority, "Heavy Machinery and Component Import Requirements: Technical Guidelines for Industrial Procurement," MIDA Technical Bulletin, 2023.

Southeast Asia Machinery Manufacturers Association, "Bearing Technology and Application Standards for Tropical Industrial Environments," SAMMA Technical Review, Vol. 28, 2023.