Carb bearing failures can bring industrial processes to a halt, causing unexpected downtime and expensive repairs in the wind energy, heavy machinery, and metallurgy sectors. These specialized bearings have a ringless design with roller and cage assemblies. They face certain problems in tough settings. Understanding how things break helps procurement teams and repair engineers keep bearings from breaking and make equipment more reliable. This all-inclusive guide goes over the important ways that carb bearings can fail and gives B2B experts in charge of complicated industrial systems useful advice on how to fix these issues.

Understanding Carb Bearing Failures: Definition and Key Causes

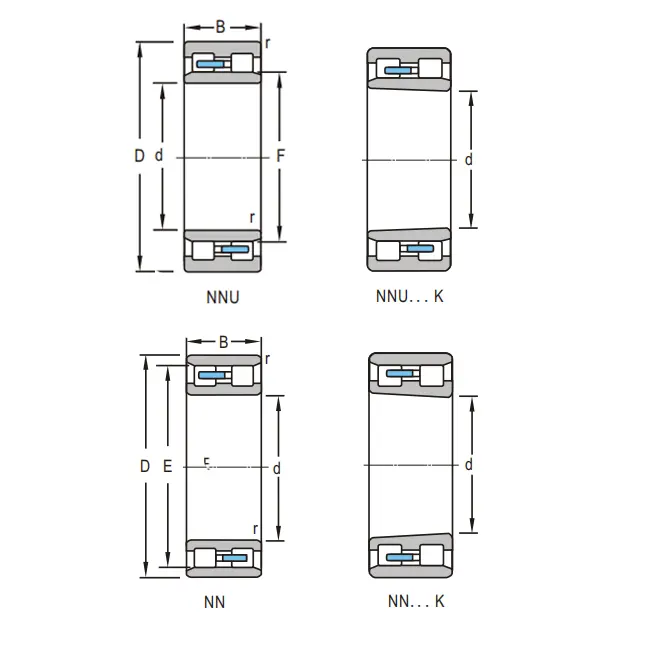

Carb bearings are a unique type of bearing that is made up of cage systems and ring rollers. They don't have the inner or outer rings that most bearings do. These parts rely on the positioning of the shaft and bearing housing to stay in the right position while supporting radial loads and making up for errors in the installation. Their ability to be installed in a variety of ways makes them useful for electric motors, machine tool spindles, conveying equipment, and heavy-duty uses.

Primary Failure Mechanisms

There are a number of related issues that compromise the operating integrity of carb bearings and cause them to fail in similar ways. As dust, debris, and moisture make their way into the bearing housing and damage the contact areas between the rollers and the raceways, contamination becomes the most common reason for early failure. This pollution speeds up the rate of wear and makes rough particles that damage bearing parts even more.

A lack of lubrication is another important failure mode, especially in situations where maintenance is done less often than suggested. A lack of lubrication causes more friction, higher temperatures, and faster material wear. If there isn't enough lubrication, the protective layer that stops the rolling elements from touching each other directly will be taken away.

Overloading situations happen often when equipment is used in ways that weren't planned or when loads increase suddenly. When dynamic loads greater than the bearing's stated capacity are applied, stress concentrations form which cause cracks to start and spread in the bearing material. Misalignment makes these problems worse by causing uneven load distribution across the roller contact areas.

Material Degradation Patterns

As carb bearings go through cycles with different load situations, material fatigue starts to set in over time. The GCr15 and GCr15SimN steels used in roller building have great strength, but repetitive stress can cause cracks to form on or below the surface. These tiny cracks will spread to the surface in the end, causing spalling and slowly damaging the bearing.

Diagnosing and Troubleshooting Carb Bearing Issues

Systematic monitoring methods that spot warning signs before total failure happen are needed for early discovery of bearing problems. To get an accurate picture of bearing state and how much longer it can be used, maintenance teams need to come up with detailed diagnostic routines that use a range of different assessment methods.

Symptom Recognition and Analysis

The first sign of bearing problems are often unusual noise patterns. Healthy carb bearings work with very little noise, usually keeping the level under 35 decibels even when they're in use. If you hear grinding, popping, or clicking sounds that come and go, they could mean that something is dirty or not getting enough grease, or that surface defects are forming. These noises mean that the situation needs to be looked into right away.

Vibration analysis gives you frequency spectrum evaluation data about the state of the bearing in the form of numbers. Higher vibrating amplitudes at certain frequencies are linked to certain ways that things break, which makes it possible to fix things in a very focused way. Temperature tracking adds to vibration data by showing thermal patterns that mean too much friction or a breakdown in lubrication.

Diagnostic Procedures and Maintenance Protocols

If you do visual inspections in a planned and systematic way during scheduled maintenance periods, they can give you a lot of useful information about the state of the bearings. Pitting, scoring, or discoloration that shows heat damage should be looked at by technicians on roller surfaces. Cage condition assessment includes looking for cracks, changes in shape, or too much wear that makes it hard to guide the rollers and keep the right distance between them.

Cleaning must get rid of contaminants without harming bearing surfaces or adding new materials. Using the right chemicals and cleaning methods will keep stamped steel or brass cage materials in good shape while making sure that old lubricants and built-up dirt are completely removed.

Best Practices to Avoid Carb Bearing Failures

Implementing comprehensive prevention strategies significantly reduces bearing failure rates while extending operational service life. These approaches address installation quality, maintenance consistency, and operational monitoring to create robust bearing management programs that support continuous industrial operations.

Installation and Alignment Procedures

Proper installation procedures establish the foundation for reliable carb bearing performance throughout the service life. The ringless design requires precise shaft and housing preparation to ensure optimal roller positioning and load distribution. Surface finish specifications must meet manufacturer requirements to prevent premature wear and maintain proper contact geometry.

Alignment verification using precision measurement tools confirms that shaft and housing centerlines maintain concentricity within specified tolerances. Misalignment creates uneven loading patterns that accelerate wear and reduce bearing life expectancy. Installation documentation should record alignment measurements and any corrective actions taken to achieve proper geometry.

Lubrication Management and Contamination Control

Advanced lubrication practices extend bearing life while maintaining consistent performance under varying operational conditions. Lubricant selection must consider operating temperature ranges, load characteristics, and environmental conditions specific to each application. High-temperature applications benefit from synthetic lubricants that maintain viscosity stability above 150°C.

Contamination prevention strategies include implementing effective sealing systems that protect carb bearing internals from dust, moisture, and chemical exposure. Nitrile rubber seals provide adequate protection for standard applications, while fluororubber seals offer enhanced chemical resistance in aggressive environments. Regular seal inspection and replacement maintain barrier effectiveness throughout the bearing service interval.

Choosing Quality Carb Bearings: Comparison and Procurement Guide

Successful procurement strategies balance performance requirements with cost considerations while ensuring supplier reliability and product quality consistency. Procurement professionals must evaluate multiple factors including material specifications, precision levels, and supplier capabilities to make informed purchasing decisions that support operational objectives.

Material and Design Considerations

Steel composition selection impacts bearing performance across different operating environments and load conditions. GCr15 steel provides excellent durability for standard applications, while GCr15SimN offers enhanced hardenability for heavy-duty service. The 20Cr2Ni4A option delivers superior fatigue resistance for applications involving cyclic loading patterns.

Precision levels directly influence bearing performance and application suitability. P0 and P6 precision grades accommodate general industrial applications where moderate precision suffices. P5 precision bearings provide enhanced accuracy for applications requiring minimal runout and vibration, such as machine tool spindles and precision equipment.

Supplier Evaluation and Quality Assurance

Supplier assessment involves evaluating manufacturing capabilities, quality control systems, and delivery performance to ensure consistent product availability. Established manufacturers with ISO 9001 certification demonstrate commitment to quality management systems that support consistent product performance. Technical support capabilities become crucial when custom Solutions or application-specific modifications are required.

Quality verification processes should include dimensional accuracy checks, material composition analysis, and performance testing under simulated operating conditions. Roller roundness measurements ensure smooth operation while radial clearance verification confirms proper fit within specified tolerances.

INNO Bearing: Your Trusted Carb Bearing Manufacturing Partner

INNO Bearing's specialty is providing high-precision carb bearings that are built for tough industrial uses in a variety of fields. Our wide selection of standard and special products with inner diameters from 50 to 500 mm, outer diameters from 100 to 800 mm, and widths from 20 to 100 mm can meet a variety of needs.

Technical Excellence and Manufacturing Capabilities

Having developed and produced carb bearings for almost three decades, we are able to provide options that meet the most difficult operational needs. Advanced testing tools make sure that the dimensions are correct and the performance is steady. Also, strict quality control steps keep the product reliable at every stage of production.

Custom engineering skills help with applications that need dimensions or materials that aren't normal. Our technical team works with customers to come up with the best bearing solutions that keep costs low and shipping times short while also solving specific problems with the way they work.

Comprehensive Service and Support

Technical support services go beyond just delivering a product; they also include application building, installation help, and advice on how to maintain your product. To help people make smart choices during the procurement process, our team gives in-depth expert paperwork and performance information.

Quality assurance methods include extensive testing that checks the roundness of the roller, the radial clearance, and the performance of the seal contact before shipping. These steps make sure that the product quality is always the same and that the risk of failing too early or having performance problems is low.

Conclusion

A deep knowledge of how failures happen, along with proactive upkeep and good purchasing habits, can keep carb bearing failures from happening. The dependable performance of bearings depends on proper contamination control, lubrication, and installation. Regular checks and diagnostic tests help catch problems early on before they turn into expensive fails. Choosing good bearings from well-known companies with well-tested quality control systems makes sure that performance and service life are both great. If you follow these tips, you can greatly reduce downtime while making sure that your equipment is reliable and your operations are efficient.

FAQs

How long do carb bearings typically last in industrial applications?

Carb bearing service life varies significantly based on operating conditions, maintenance quality, and application demands. Under normal operating conditions with proper lubrication and contamination control, quality carb bearings typically provide 50,000+ hours of reliable service. Heavy-duty applications or harsh environments may reduce service life, while optimal maintenance practices can extend operational periods beyond standard expectations.

Can ceramic hybrid rollers improve carb bearing performance in high-temperature applications?

Ceramic hybrid designs offer enhanced performance characteristics for high-temperature applications, providing improved heat resistance and reduced thermal expansion compared to all-steel constructions. These advanced materials maintain dimensional stability at elevated temperatures while offering superior corrosion resistance in challenging environments. However, application-specific evaluation is necessary to determine cost-effectiveness and compatibility with existing systems.

What inspection frequency is recommended for carb bearings in critical applications?

Critical applications require monthly visual inspections combined with quarterly vibration analysis and temperature monitoring. Lubrication condition should be evaluated every six months or according to manufacturer recommendations. High-stakes operations may benefit from continuous monitoring systems that provide real-time bearing condition data and predictive maintenance capabilities to prevent unexpected failures.

Partner with INNO Bearing for Superior Carb Bearing Solutions

INNO Bearing stands ready to support your carb bearing procurement needs with precision-engineered solutions tailored to your specific industrial requirements. Our experienced engineering team provides comprehensive technical consultation to ensure optimal bearing selection and application success. Whether you need standard bearings or custom solutions, our commitment to quality and rapid delivery ensures your operations maintain peak performance. Contact Us at sales@inno-bearing.com to discuss your carb bearing supplier requirements and discover how our expertise can enhance your equipment reliability and operational efficiency.

References

Harris, Tedric A., and Michael N. Kotzalas. "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, 2020.

Budynas, Richard G., and J. Keith Nisbett. "Shigley's Mechanical Engineering Design." McGraw-Hill Education, 2019.

Hamrock, Bernard J., Steven R. Schmid, and Bo O. Jacobson. "Fundamentals of Machine Elements: Rolling Contact Bearings." SI Version, 2018.

Norton, Robert L. "Machine Design: An Integrated Approach to Bearing Failure Analysis." Pearson Education, 2021.

Khonsari, Michael M., and E. Richard Booser. "Applied Tribology: Bearing Design and Lubrication." John Wiley & Sons, 2017.

Tallian, Tibor E. "Failure Atlas for Rolling Element Bearings: Causes and Countermeasures." ASME Press, 2019.