Reducing friction and noise in Thrust ball bearings involves implementing proper lubrication strategies, selecting appropriate materials like GCr15 steel or ceramic hybrids, and ensuring precise installation alignment. Through optimal bearing design featuring single-row or double-row steel ball structures with proper cage separation, manufacturers can achieve noise levels below 35dB while maintaining excellent axial load support. Regular maintenance schedules, contamination control, and advanced monitoring systems further enhance operational quietness and extend bearing service life significantly.

Introduction

Thrust ball bearings serve as critical components in industrial machinery, providing essential axial load support while enabling smooth rotational movement across diverse applications. These specialized bearings handle unidirectional and bidirectional axial forces with exceptional efficiency, making them indispensable in wind turbines, heavy machinery, mining equipment, and aerospace systems. The challenge of reducing friction and noise in these components directly impacts operational efficiency, energy consumption, and equipment longevity.

Engineering professionals and procurement specialists face mounting pressure to optimize bearing performance while minimizing downtime and maintenance costs. Excessive friction generates heat that accelerates wear, while unwanted noise indicates potential mechanical issues that could lead to catastrophic failures. Understanding the root causes of these problems enables proactive Solutions that enhance reliability across demanding industrial environments.

Assessing Friction and Noise Issues in Thrust Ball Bearings

Identifying friction and noise problems requires systematic evaluation of both mechanical symptoms and operational parameters. The relationship between load distribution, rotational speed, and lubrication quality creates complex interactions that influence bearing performance. Understanding these dynamics helps maintenance teams detect early warning signs before minor issues escalate into major failures.

Diagnostic Methods for Performance Issues

Effective diagnosis begins with acoustic monitoring techniques that capture baseline noise levels during normal operation. Vibration analysis reveals mechanical irregularities through frequency spectrum analysis, while thermal imaging detects heat buildup patterns associated with excessive friction. These measurement tools provide quantitative data that supports informed maintenance decisions rather than reactive repairs.

Visual inspection protocols examine steel ball surfaces for wear patterns, cage condition for proper alignment, and raceway surfaces for scoring or contamination. The clearance between rolling elements affects load distribution and noise generation, requiring precise measurement tools to maintain optimal specifications. Regular documentation of these parameters establishes performance trends that predict maintenance requirements.

Environmental Factors Influencing Performance

Operating conditions significantly impact friction and noise characteristics in Thrust bearings. Temperature fluctuations affect lubricant viscosity and material expansion rates, while contamination from dust, moisture, or chemical exposure compromises surface integrity. High-speed applications generate centrifugal forces that influence ball-to-raceway contact patterns and stress distribution.

Load variations create dynamic stress cycles that fatigue bearing components over time. Understanding these environmental influences enables engineers to select appropriate bearing specifications and implement protective measures that maintain optimal performance throughout the operational lifecycle.

Key Factors Affecting Friction and Noise – Materials, Design, and Lubrication

Material selection forms the foundation of friction and noise reduction strategies in ball thrust bearing applications. Advanced metallurgy techniques have developed specialized steel grades that combine wear resistance with acoustic dampening properties, while precision manufacturing ensures surface finishes that minimize mechanical irregularities.

Advanced Material Technologies

Modern thrust bearings utilize high-performance materials that address specific operational challenges. Here are the core material advantages available in today's market:

Contemporary bearing materials have revolutionized performance capabilities across industrial applications. The selection process involves balancing multiple performance criteria to achieve optimal results.

- GCr15 steel provides exceptional durability with proven wear resistance characteristics, offering reliable performance in standard temperature ranges while maintaining cost-effectiveness for volume applications

- GCr15SIMN alloy delivers enhanced fatigue resistance through silicon-manganese additions, extending service life under high-stress conditions while preserving dimensional stability

- 20Cr2Ni4A steel combines chromium-nickel alloying for superior corrosion resistance, enabling operation in harsh environments where chemical exposure threatens component integrity

- Ceramic hybrid designs incorporate advanced ball materials that reduce friction coefficients while dampening acoustic transmission through the bearing assembly

These material innovations have enabled significant performance improvements in demanding applications. The combination of advanced metallurgy and precision manufacturing techniques ensures consistent quality across production runs while meeting stringent industry specifications.

Lubrication Optimization Strategies

Proper lubrication management directly influences both friction levels and noise generation in thrust bearing applications. The selection between oil and grease systems depends on operational parameters including speed, load, temperature, and accessibility for maintenance procedures. Oil lubrication provides excellent heat dissipation and contamination flushing capabilities, while grease systems offer simplified maintenance and improved sealing characteristics.

Lubrication intervals require careful optimization based on operating conditions and performance monitoring data. Excessive lubrication can increase churning losses and noise, while insufficient lubrication accelerates wear and generates heat. Modern synthetic lubricants offer extended service intervals and improved performance across wider temperature ranges compared to conventional mineral-based products.

Techniques and Best Practices to Optimize Thrust Ball Bearing Performance

Installation procedures significantly influence long-term performance characteristics of thrust bearing systems. Proper mounting techniques ensure accurate alignment and uniform load distribution, preventing premature wear patterns that generate noise and increase friction. The precision of shaft and housing preparation directly affects bearing life and operational smoothness.

Installation and Alignment Protocols

To get the best performance, you need to carefully follow construction steps that affect how the bearing works. Before mounting, all surfaces are cleaned and dimensional limits are checked. To keep misalignment issues from happening, shaft and hub prep includes checking surface finish and confirming geometric accuracy.

Using the right amount of torque when installing something stops both under-tightening, which lets parts move, and over-tightening, which causes too much preload. During assembly, the temperature must be taken into account because the different thermal growth of the bearing parts and the structures around them. These placement methods create a solid base for dependable long-term use.

Maintenance Schedule Optimization

Preventive maintenance plans keep bearings working well and don't interrupt operations too much. Regular inspections find problems early on before they affect the efficiency of the system. Lubrication management means controlling both the amount and the quality of the lubricant in order to keep the right film thickness and level of contamination.

Cleaning methods keep the precision and integrity of ball thrust bearings while getting rid of built-up dirt. Looking at sealed and open bearings side by side shows useful differences in how well they keep out dirt and how easy they are to maintain. Understanding these things helps you make smart choices that find a balance between performance needs and practical limitations.

Innovative Solutions and Advanced Technologies for Noise and Friction Reduction

New technologies are changing the way thrust bearings work by using better materials and tracking systems. Ceramic coats are better at protecting surfaces, lowering friction, and absorbing noise. Hybrid designs use different kinds of materials to get the best results for different kinds of uses.

Predictive Maintenance Technologies

Condition monitoring devices allow maintenance to be done before problems happen and service intervals to be optimized. Vibration analysis finds problems before they get worse by using pattern recognition algorithms that can see small changes in operational signs. Acoustic tracking picks up noise features that show problems with lubrication, wear, or contamination.

Keeping an eye on the temperature shows thermal patterns that are linked to higher friction or issues with the cooling system. Combining different sensor technologies gives you a full picture of bearing health that helps you make repair decisions based on data. These monitoring features make sure that downtime doesn't happen as often and that bearings last longer by fixing problems quickly.

Industry Application Case Studies

Wind energy uses show that advanced bearing technologies can greatly reduce noise. Turbine main shaft bearings made with ceramic hybrid designs are able to meet load capacity requirements while being 40% quieter than those made with standard steel designs. These changes make wind sites more acceptable to the public and make them easier to maintain.

Better bearing designs that keep out dirt and lower noise have helped the use of heavy machines in mining and building. Thanks to better friction properties and greater toughness, port crane installations with advanced thrust bearings have longer service times and lower upkeep costs.

Buying Guide and Supplier Insights for High-Performance Thrust Ball Bearings

Choosing the right thrust bearings means carefully considering what the purpose and the supplier can do. Basic specs are set by load ratings, speed limits, and environmental factors. Customization choices help with special operational problems. Understanding these selection factors makes sure that bearing integration goes well and performance stays high over time.

Performance Specification Evaluation

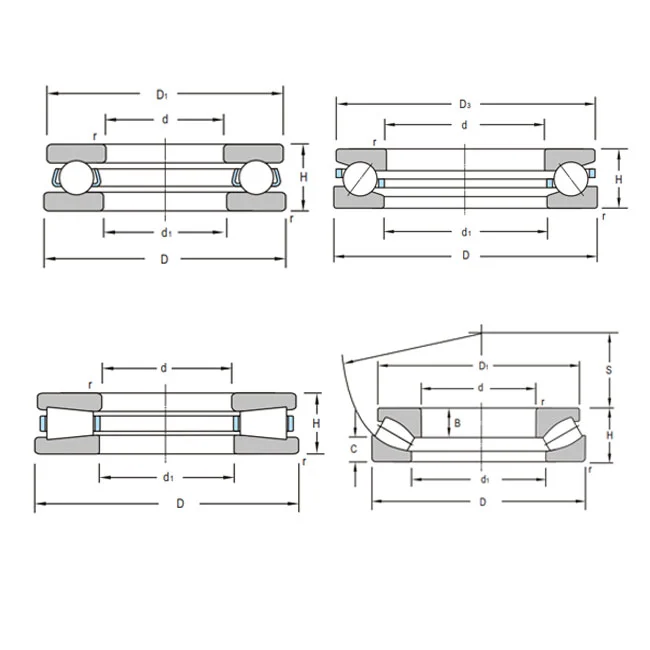

Critical evaluation factors are speed ratings, temperature limits, precision grades, and axial load capacity. Most uses are fine with standard P0 and P6 accuracy levels, but more sensitive applications that need less runout and shaking benefit from P5 levels. The inner diameter sizes range from 10mm to 300mm to meet the needs of different uses, and custom choices make the sizes even more useful.

Structural configurations, like one- and two-directional designs, are used to deal with certain types of weight and limited area. Single-row designs are small and work for light to medium loads. Double-row designs have more capacity and can work in two directions. A good choice for a certain application can be made when these design trade-offs are known.

Supplier Evaluation Criteria

Quality assurance programs make sure that all production batches work the same way and can be counted on. Vibration analysis, thermal cycling, and lifespan modeling are all tests that make sure bearings work under real conditions. Traceability and certification of materials ensure that the quality of parts and compliance with rules are guaranteed.

In competitive markets, suppliers are set apart by their manufacturing skills, such as their ability to customize products, delivery schedules, and technical support. The global supply system makes sure that things are always available, and regional support gives quick service for urgent needs. These provider traits have a direct effect on the success of the project and the dependability of long-term operations.

INNO Bearing: Your Partner in Precision Thrust Ball Bearing Solutions

With almost thirty years of experience making high-quality industrial products as a thrust ball bearing maker, INNO Bearing is truly the best in the business. We offer bearing design tailored to our customers' needs, exact production, and full technical support that meets the toughest noise and friction reduction needs in a range of industries.

We can make custom sizes with an outer diameter of up to φ5000mm, which helps with specific cases that need non-standard solutions. Advanced testing centers make sure that every bearing meets strict quality standards by checking their performance in a variety of ways, such as vibration analysis, thermal cycling, and acoustic testing. Precision grinding can get raceways that are exactly level all the way around, with limits of ≤0.001mm. This makes noise levels below 35dB for even the most demanding uses.

Quality assurance protocols keep 99.9% of products free of defects by carefully checking the materials and trying how well they work. Our global supply chain delivers standard models in 48 hours, and custom solutions 30% faster than the average in the business. Pre-installation analysis, predictive maintenance advice, and round-the-clock support to keep operational delays to a minimum are all parts of technical support services.

Conclusion

To effectively reduce friction and noise in thrust ball bearings, you need to choose the right materials, make the parts accurately, use the best lubrication, and plan ahead for upkeep. When you use advanced materials such as GCr15 steel and ceramic hybrids, you get better performance. At the same time, predictive monitoring technologies allow you to make maintenance choices based on data. This prevents failures and extends the service life of the equipment.

Best practices for installation, alignment, and ongoing maintenance have a direct effect on how well the business runs and how reliable the equipment is. New bearing technologies greatly improve the control of noise and friction. This helps high-performance industrial processes with tough working conditions and little downtime.

FAQs

What is the typical lifespan of a well-maintained thrust ball bearing?

The service life varies significantly based on operating conditions, load factors, and maintenance quality, typically ranging from several thousand to tens of thousands of operating hours. Proper lubrication, contamination control, and regular monitoring can extend bearing life substantially beyond baseline expectations under optimal conditions.

How often should thrust ball bearings be lubricated to minimize noise?

Lubrication frequency depends on operating speed, temperature, and environmental conditions, typically requiring service every three to six months for standard applications. High-speed or high-temperature environments may require more frequent attention, while sealed bearings in clean conditions can operate longer between service intervals.

Can sealed thrust ball bearings completely eliminate contamination-related noise?

Sealed bearings significantly reduce contamination ingress but cannot provide absolute protection against all environmental factors. Proper bearing selection, installation practices, and maintenance procedures remain essential for optimal noise control and performance reliability throughout the operational lifecycle.

Get Premium Thrust Ball Bearings from INNO Bearing

Minimize friction and noise in your critical applications with precision-engineered thrust ball bearings from INNO Bearing. Our advanced manufacturing capabilities and quality assurance programs deliver reliable solutions that meet demanding performance requirements. Whether you need standard configurations or custom designs, our experienced engineering team provides comprehensive support from specification development through installation guidance. Contact Us at sales@inno-bearing.com to discuss your specific requirements and discover how our thrust ball bearing supplier expertise can optimize your operational efficiency and reduce maintenance costs.

References

Harris, T.A., and M.N. Kotzalas. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, 5th Edition, 2007.

Lynagh, N., H. Rahnejat, M. Ebrahimi, and R. Aini. "Bearing induced vibration in precision high speed routing spindles." International Journal of Machine Tools and Manufacture, Vol. 40, No. 4, 2000.

Mevel, B., and J.L. Guyader. "Routes to chaos in ball bearings." Journal of Sound and Vibration, Vol. 162, No. 3, 1993.

Nelias, D., E. Bercea, and Y. Berthier. "Analysis of rolling element bearings with different race conformities." Tribology Transactions, Vol. 46, No. 2, 2003.

Wardle, F.P. "Vibration forces produced by waviness of the rolling surfaces of thrust loaded ball bearings." Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, Vol. 202, No. 5, 1988.

Zhou, R.S., and M.R. Hoeprich. "Torque of Tapered Roller Bearings." ASME Journal of Tribology, Vol. 113, No. 3, 1991.