Carb bearings make wind turbines much more reliable by spreading the load evenly, reducing vibrations, and working well even when conditions change. These specialized roller bearings don't have the usual inner and outer rings. Instead, they use ring rollers and cages that are placed right by the shaft and bearing box. This new configuration can handle radial loads better and make up for mistakes in the installation. This makes them perfect for wind turbines where operating stability and a long service life are very important. Carb bearings significantly reduce downtime and operational costs due to their adaptable installation options and low upkeep requirements.

Reliability is still the most important part of running wind turbines. It has a direct impact on the amount of energy produced, the cost of upkeep, and the overall profit of a project. Modern wind turbines have to work in tough conditions. The strongest mechanical parts can break when they are hit by changing wind and temperature and by the stresses of constant spinning. In this difficult setting, bearing technology is very important for keeping things running smoothly and avoiding expensive mistakes.

Wind energy projects need parts that will work well for decades. Procurement managers and engineering teams know that choosing the right gear has a big effect on the long-term costs of running a turbine and how often it is available to run. When it comes to wind energy, high-tech bearing Solutions like carb bearings can help with specific problems. They make the system more reliable by using creative designs and careful manufacturing.

Understanding Carb Bearings and Their Function in Wind Turbines

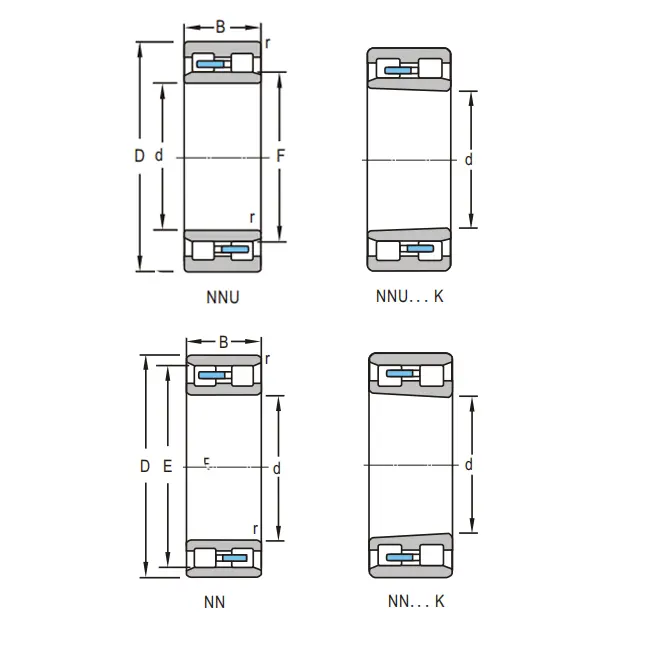

Carb bearings are a special kind of cylindrical roller bearing that are designed for uses that need great radial load capacity and freedom in how they can be used. Unlike ball and roller bearings that have inner and outer ring sections, these new parts use a ringless design that puts rollers right between the shaft and bearing housing through precision-made cages.

Structural Design and Load Distribution Capabilities

Carb bearings are made up of ring rollers and strong cages. Contact seals are used to keep the inside parts clean. This setup gets rid of standard ring limitations, which lets the whole roller contact area share the load more evenly. The design can handle inner diameters from 50 to 500 mm, outer diameters from 100 to 800 mm, and widths from 20 to 100 mm, making it useful for a range of turbine parts.

Manufacturing materials are very important for getting the best results. The premium steel metals GCr15, GCr15SiMn, and 20Cr2Ni4A are very strong and resistant to wear. Stamped steel or brass cages make sure the rollers stay in place. For wind turbines that have to work in harsh environments, sealing systems made of nitrile rubber or fluororubber keep wetness and contaminants out.

Precision Engineering and Performance Standards

Carb bearings can be configured to meet a variety of application needs thanks to their precision levels, which range from the normal P0/P6 grades to the highly precise P5. Due to the exact nature of the work, wind turbines can only operate in difficult conditions. This fine engineering leads directly to less vibration, smoother operation, and a longer overall service life.

Common Issues and Maintenance of Carb Bearings in Wind Turbines

Wind turbine carb bearings are best kept in good working order by closely watching them and fixing problems before they happen. Knowing how things go wrong and doing the right kind of maintenance helps bearings last much longer and prevents unexpected downtime.

Identifying Early Warning Signs and Failure Indicators

Before a catastrophic failure happens, repair teams with a lot of experience know the signs that show there might be a problem with the carb bearing. Bearing degradation is often first detectable through abnormal vibration patterns, which usually appear as operational vibration signatures with higher amplitude or frequency changes. Monitoring the temperature shows unusual heat patterns that suggest the bearings are not properly lubricated, loaded, or experiencing higher internal friction.

Acoustic monitoring methods identify noise patterns that are not normal. These patterns are signs of roller wear, cage damage, or contamination ingress. This diagnostic method lets the maintenance team plan routine check-ups instead of fixing sudden failures that stop power output.

Preventive Maintenance Protocols and Best Practices

Systematic maintenance plans include regular checks that are based on the unique needs of the system and its surroundings. Key inspection criteria include checking the roundness of the rollers, measuring the radial clearance, and testing the seal contact performance. These factors give a numerical evaluation of the bearing's condition and how much longer it can be used.

Choosing the right lubricant based on temperature, load, and environment is an important part of upkeep called lubrication management. Regular cleaning and good sealing upkeep keep the inside parts safe from moisture and debris that speed up the wearing process.

Advantages of Carb Bearings Over Alternative Bearings in Wind Turbine Applications

Comparative analysis reveals significant performance advantages when carb bearings replace conventional bearing types in wind turbine applications. These benefits translate into measurable improvements in reliability, maintenance costs, and operational efficiency.

Superior Load Handling and Durability Characteristics

The ringless design of carb bearings provides exceptional advantages in handling the variable and heavy loads characteristic of wind turbine operations. Here are the core performance benefits that make these bearings superior for renewable energy applications:

- Enhanced Load Distribution: The direct roller-to-housing contact eliminates ring stress concentrations, distributing loads more evenly across bearing surfaces. This design characteristic enables higher load capacities while reducing stress-related fatigue failures that commonly affect conventional bearings under fluctuating wind loads.

- Improved Vibration Dampening: The flexible mounting arrangement inherent in carb bearing design provides natural vibration isolation that reduces transmitted forces to adjacent turbine components. This dampening effect extends the service life of gearboxes, generators, and structural elements while improving overall system reliability.

- Installation Tolerance Compensation: The ability to accommodate installation deviations and shaft misalignments reduces assembly complexity and eliminates premature failures caused by geometric imperfections. This flexibility proves particularly valuable in large turbine assemblies where perfect alignment becomes increasingly challenging.

These performance advantages directly address the challenging operational environment of wind turbines, where components must withstand continuous load variations, environmental extremes, and extended operational periods without maintenance intervention. Industry case studies demonstrate that turbines equipped with advanced carb bearings experience significantly reduced maintenance requirements and extended service intervals compared to conventional bearing technologies.

Cost-Effectiveness and Return on Investment

Economic analysis reveals that carb bearings deliver superior long-term value despite potentially higher initial procurement costs. Reduced maintenance frequency, extended replacement intervals, and decreased downtime combine to generate substantial operational savings over typical turbine lifecycles. Leading wind energy operators report maintenance cost reductions exceeding 30% when upgrading to advanced bearing technologies.

Procurement Insights: Choosing and Buying Carb Bearings for Wind Turbines

Strategic procurement of carb bearings requires comprehensive evaluation of technical specifications, supplier capabilities, and long-term support services. Successful purchasing decisions balance initial costs with lifecycle value while ensuring compatibility with existing turbine systems and operational requirements.

Technical Specification and Compatibility Assessment

Procurement teams must evaluate dimensional compatibility, load ratings, and environmental specifications to ensure optimal bearing performance in specific turbine applications. Critical factors include operating temperature ranges, corrosion resistance requirements, and certification compliance with industry standards such as ISO 9001 and relevant turbine manufacturer specifications.

Quality assurance protocols should encompass raw material verification, manufacturing process validation, and comprehensive testing procedures that verify performance characteristics. Reputable suppliers provide detailed documentation including material certifications, dimensional inspection reports, and performance test results that enable informed procurement decisions.

Supplier Evaluation and Partnership Considerations

Establishing relationships with experienced bearing manufacturers ensures access to technical expertise, customization capabilities, and reliable supply chain support. Evaluation criteria should include manufacturing capacity, quality management systems, technical support capabilities, and global service networks that support international wind energy projects.

Company Introduction and Product & Service Information

INNO Bearing stands as a distinguished leader in precision bearing manufacturing, bringing nearly three decades of specialized expertise to the wind energy sector. Our comprehensive understanding of turbine bearing requirements enables us to deliver carb bearings that exceed performance expectations while providing exceptional reliability under demanding operational conditions.

Our advanced manufacturing capabilities support bearing production up to φ5000mm diameter, accommodating the largest turbine configurations with precision-engineered solutions. State-of-the-art testing equipment and rigorous quality control processes ensure consistent performance characteristics that meet the stringent requirements of wind energy applications. Every carb bearing undergoes comprehensive inspection including roller roundness verification, radial clearance measurement, and seal performance validation.

Customization services enable us to adapt standard bearing designs for specific turbine applications, environmental conditions, and operational requirements. Our engineering team collaborates closely with OEM partners and maintenance organizations to develop optimized bearing solutions that enhance turbine reliability while reducing lifecycle costs. Technical support services include bearing selection guidance, installation assistance, and maintenance consultation that maximizes bearing performance throughout service life.

Conclusion

Carb bearings represent a transformative technology for wind turbine reliability, offering superior load handling capabilities, enhanced durability, and flexible installation characteristics that address the unique challenges of renewable energy applications. The ringless design eliminates common failure modes associated with conventional bearings while providing exceptional vibration dampening and load distribution properties essential for turbine longevity.

Strategic implementation of advanced carb bearing technology delivers measurable improvements in operational reliability, maintenance cost reduction, and extended service intervals. As wind energy projects continue expanding globally, component technologies that enhance reliability while reducing lifecycle costs become increasingly valuable for achieving project profitability and sustainability goals.

FAQs

What maintenance schedule maximizes carb bearing performance in wind turbines?

Optimal maintenance intervals depend on operating conditions, but typically include quarterly vibration monitoring, semi-annual lubrication checks, and annual comprehensive inspections. Key monitoring parameters include roller roundness, radial clearance, and seal integrity to identify potential issues before they impact turbine operations.

How do carb bearings specifically improve wind turbine efficiency compared to traditional bearings?

Carb bearings enhance efficiency through reduced friction losses, superior load distribution, and vibration dampening that minimizes energy losses in the drivetrain. The ringless design eliminates stress concentrations while accommodating installation tolerances that would cause premature wear in conventional bearing systems.

What environmental factors most significantly influence carb bearing lifespan in wind applications?

Temperature extremes, humidity levels, and contamination exposure represent the primary environmental challenges. Advanced sealing systems using fluororubber materials and appropriate material selection for extreme conditions significantly extend bearing life in challenging offshore and extreme climate installations.

Partner with INNO Bearing for Superior Wind Turbine Reliability

INNO Bearing delivers precision-engineered carb bearing solutions that transform wind turbine reliability and operational efficiency. Our three decades of manufacturing expertise, combined with advanced customization capabilities and rapid delivery services, makes us the preferred carb bearing supplier for leading wind energy projects worldwide. Experience the difference that precision engineering and dedicated technical support can make for your turbine performance. Contact Us at sales@inno-bearing.com to discuss your specific requirements and discover how our carb bearing solutions can enhance your wind energy operations.