Conical roller bearings are always the first choice of gearbox makers because they are great at handling both radial and axial loads and offer exceptional durability even in the most difficult of environments. Unlike normal ball bearings that have trouble with heavy loads, conical roller bearings use tapered rollers and raceways to spread out the stress better. This makes them very important in industrial gears where reliability can't be compromised. This all-in-one guide talks about the basic ways to build these advanced bearing Solutions, the structural benefits they have, and the procurement factors that make manufacturers choose these bearings over others.

Choosing the right bearing type makes sure that the load is handled properly, the service life is increased, and the gearbox works reliably even when the working conditions change. Engineers and procurement workers need to know about technical details, performance benefits, and market options in order to make smart choices that meet performance needs while also being cost-effective and easy to maintain.

Understanding Conical Roller Bearings and Their Design

Fundamental Structure and Operating Principles

The inner ring of a conical roller bearing has a tapered raceway and the outer ring, which can be taken apart in single-row designs but is set in double-row designs. The rollers are shaped like cones and are made very carefully, and the cage system keeps the parts spaced correctly. This unique geometry spreads the load across several contact places and reduces friction at the same time, making them perfect for the tough conditions in industrial gearboxes.

When the tapered design is placed correctly, all load lines meet at a point on the bearing axis. This makes sure that the best distribution of stress happens. If you use this concept in engineering, the bearing can handle radial forces from gear meshing and axial forces from helical gear setups or external thrust loads all at the same time.

Structural Variations and Configurations

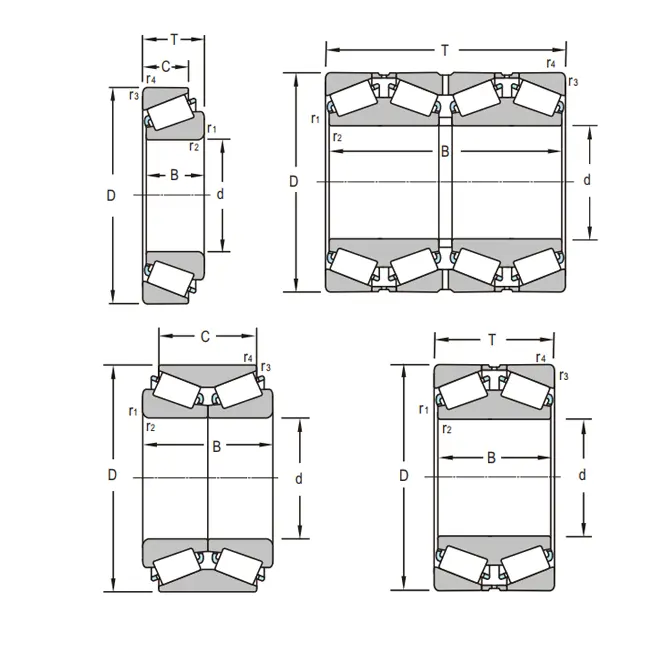

Today's conical roller bearings come in a range of setups to meet the needs of different gearboxes:

The outer rings of single-row bearings can be separated from the rest of the bearing, which makes installation and upkeep easier. These designs are usually used in situations where easy assembly is very important, and they can handle modest combined loads. Double-row bearings have fixed outer rings. They can handle higher load capacities and offer better rigidity for precise gearbox uses.

The rings and rollers in the bearing parts are made of high-quality materials, like GCr15 and GCr15SiMn steel. For very heavy-duty uses, specialty alloys such as 20Cr2Ni4A are used. Cage materials range from stamped steel, which is cheap, to brass, which lasts longer and lowers friction in tough conditions.

Size Range and Precision Specifications

Standard conical roller bearings come in a lot of different sizes. Their inner diameters range from 10 mm to 1,000 mm, their outer diameters range from 26 mm to 2,000 mm, and their widths range from 8 mm to 300 mm. For normal industrial use, precision levels usually meet P0/P6 standards. But for important gearbox systems that need very high accuracy, the high-precision versions reach P5/P4 tolerances.

Core Advantages of Conical Roller Bearings for Gearbox Manufacturers

Superior Load Handling Capabilities

Conical roller bearings have a superior load-bearing ability, which is the main reason manufacturers prefer them. The tapered roller design makes line contact with the raceways. This is better than point contact bearings because it spreads the forces over a bigger surface area. This feature is very useful in heavy-duty gearboxes because shock loads, vibrations, and long-term high-stress use would quickly break down other bearing types.

These bearings are very strong against misalignment conditions that happen a lot in big industrial gearboxes because of housing deflection, thermal expansion, or mounting issues. The built-in ability to handle mild angular misalignment without greatly affecting performance ensures that it works even when perfect alignment isn't possible.

Extended Service Life and Reliability

Gearbox makers love how long their products last because it means they don't have to spend as much money on upkeep and the equipment is available for use more often. The best load distribution, better material, and exact production methods give bearings a life that often far exceeds other designs in similar uses.

Proper lubrication methods specific to conical roller bearings further improve their performance. In mining, building, and marine settings where gearboxes need to work reliably even when things get tough, open designs make it easy for lubricants to flow, and sealed designs keep harsh environments from getting inside the gearbox.

Operational Stability Under Varying Conditions

Because conical roller bearings are naturally stable even when loads change, they are a great choice for gearbox uses where they need to be able to handle changing conditions. These bearings keep a steady level of performance that makes sure power transfer goes smoothly, whether they are dealing with the changing torque needs of wind turbine gearboxes or the shock loading that happens with mining equipment.

Comparing Conical Roller Bearings With Other Bearing Types for Gearboxes

Performance Analysis Against Alternative Designs

When you consider conical and Cylindrical roller bearings, conical bearings have a much higher axial load capacity but similar radial load ratings. Even though they can go faster, ball bearings can't handle as much weight or last as long in the tough situations where most industrial gearboxes are used. While Spherical roller bearings can self-align, they usually have more friction and make it harder to place things.

The friction coefficient analysis shows that conical roller bearings work well across a wide range of speeds and loads as long as they are properly lubricated. Needle roller bearings might save room, but they don't have the combined load capability that most gearboxes need when radial and axial forces are present at the same time.

Selection Criteria and Performance Metrics

Rotational speed limitations, load direction and size, limited room, and cost are all important factors in choosing a bearing. Conical roller bearings are great for situations where reliable support of moderate to heavy loads over long periods of time is necessary. This makes them the best choice for industrial gears that work in tough settings.

The leading bearing makers in the world have created specialized product lines that are optimized for gearbox applications. Each manufacturer has different strengths in materials technology, precision production, and making designs for specific applications. These differences make sure that they can serve a range of market segments and performance needs.

Procurement Insights for Gearbox Manufacturers

Supplier Evaluation and Selection Process

Successful procurement of conical roller bearings requires careful evaluation of supplier capabilities beyond basic price comparisons. Critical assessment factors include manufacturing quality consistency, technical support availability, customization capabilities for non-standard applications, and supply chain reliability for maintaining production schedules.

Established suppliers typically offer comprehensive testing documentation, material certifications, and performance validation data that support quality assurance requirements. The ability to provide rapid prototyping services and engineering consultation proves valuable when developing new gearbox designs or optimizing existing configurations.

Cost-Performance Optimization Strategies

Effective procurement balances initial bearing costs against total lifecycle expenses including maintenance, replacement frequency, and downtime impacts. Premium-grade bearings with enhanced materials and precision often justify higher initial costs through extended service intervals and improved reliability in critical applications.

Volume purchasing agreements, standardization initiatives, and long-term partnerships with reliable suppliers can yield significant cost advantages while ensuring consistent quality and availability. Custom bearing solutions may offer competitive advantages for specialized gearbox designs, particularly in niche markets where standard options cannot meet specific performance requirements.

INNO Bearing's Excellence in Conical Roller Bearing Solutions

Three Decades of Manufacturing Expertise

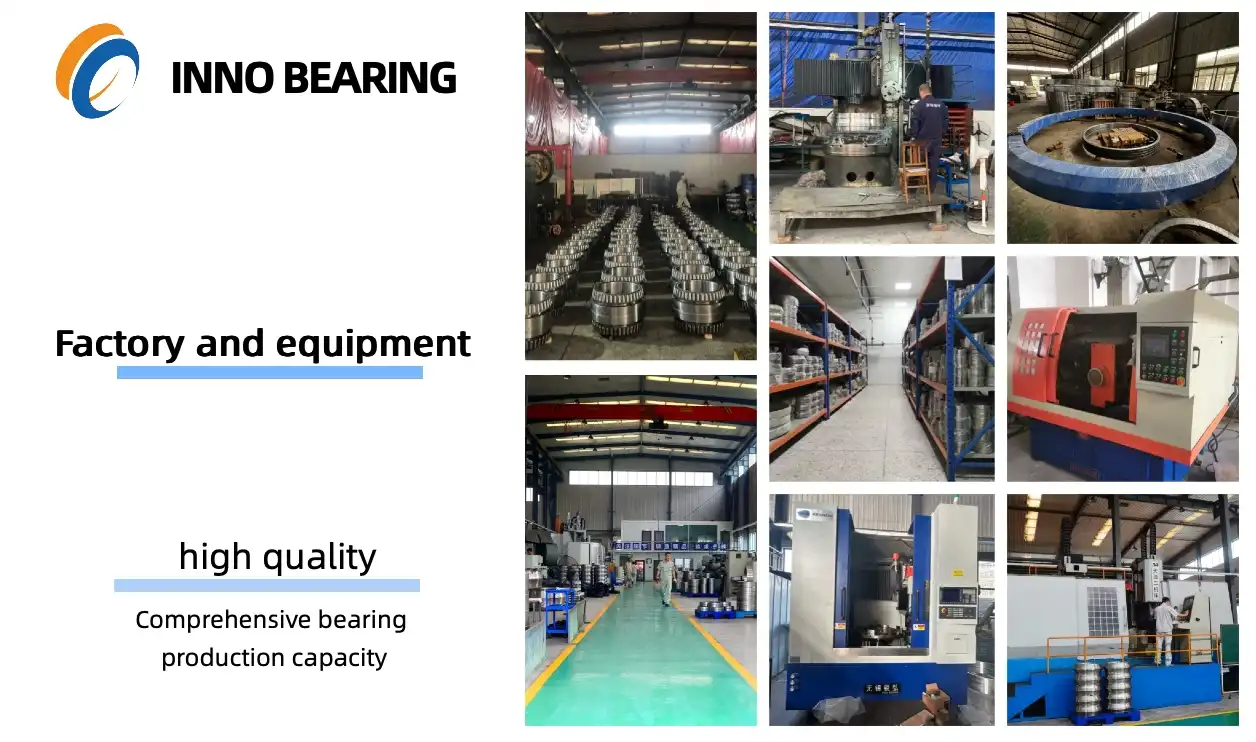

Luoyang INNO Bearing Co., Ltd. brings nearly 30 years of specialized experience in designing and manufacturing high-performance conical roller bearings for demanding industrial applications. Our integrated approach combines research and development, precision manufacturing, and comprehensive technical support to deliver solutions that exceed customer expectations in critical gearbox applications.

Our extensive product range addresses diverse gearbox engineering requirements, with customization capabilities extending to large and non-standard bearings up to φ5000mm diameter. This flexibility enables precise alignment with client specifications while maintaining the rigorous quality standards essential for mission-critical applications in heavy machinery, mining operations, and power generation systems.

Advanced Manufacturing and Quality Assurance

Our commitment to excellence encompasses every aspect of bearing production, from material selection through final inspection. Advanced testing equipment and strict quality control protocols ensure that each bearing meets or exceeds specified performance parameters. The comprehensive range includes both open-type and sealed configurations, with precision levels spanning standard P0/P6 grades through ultra-precision P4/P5 specifications.

Our technical support team provides proactive consultation services and dedicated after-sales care designed to foster long-term partnerships with clients worldwide. This customer-centric approach ensures seamless supply chain integration and ongoing performance optimization throughout the bearing lifecycle.

Conclusion

Gearbox manufacturers prefer conical roller bearings due to their exceptional ability to handle combined loads, deliver extended service life, and maintain reliable performance under demanding operational conditions. The tapered roller design provides superior load distribution compared to alternative bearing types, while the robust construction ensures consistent operation despite challenging environmental factors. These advantages translate directly into reduced maintenance costs, improved equipment availability, and enhanced overall system reliability.

The comprehensive range of sizes, materials, and precision levels available enables manufacturers to optimize bearing selection for specific application requirements. With proper supplier partnerships and procurement strategies, conical roller bearings represent an investment in long-term gearbox performance and operational efficiency.

FAQs

What maintenance practices help prolong the life of conical roller bearings in gearboxes?

Proper lubrication with appropriate grease or oil, regular inspection for wear indicators or contamination, periodic alignment verification, and monitoring of operating temperatures are essential. Maintaining clean lubricants and following manufacturer-recommended service intervals significantly extends bearing life while preventing premature failures.

How does the load capacity of conical roller bearings impact gearbox design choices?

Higher load capacity enables more compact gearbox designs while accommodating increased power transmission requirements without compromising durability. This allows engineers to optimize space utilization, reduce overall system weight, and achieve better power-to-size ratios in various industrial applications.

Can conical roller bearings operate effectively in high-speed gearbox applications?

Yes, with proper design considerations including optimized internal geometry, appropriate lubrication systems, and precision balancing, conical roller bearings perform reliably in moderate to high-speed applications while maintaining their superior load-handling capabilities compared to alternative bearing designs.

Partner with INNO Bearing for Superior Gearbox Solutions

Transform your gearbox performance with INNO Bearing's precision-engineered conical roller bearing solutions. Our three decades of manufacturing excellence, combined with custom sizing capabilities up to φ5000mm and rapid delivery from global distribution centers, ensures your projects stay on schedule while exceeding performance expectations. Whether you need standard configurations or specialized designs for unique applications, our expert engineering team provides comprehensive support from initial specification through installation guidance.

Connect with INNO Bearing today to discuss your specific requirements. Contact Us at sales@inno-bearing.com for detailed technical consultations, custom quotes, and access to our complete conical roller bearing manufacturer catalog.

References

Harris, T.A. & Kotzalas, M.N. (2019). "Essential Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press.

Hamrock, B.J., Schmid, S.R. & Jacobson, B.O. (2017). "Fundamentals of Machine Elements: Bearing Design and Applications." McGraw-Hill Education.

Tallian, T.E. (2018). "Failure Atlas for Hertz Contact Machine Elements: Bearing Performance in Industrial Gearboxes." ASME Press.

ISO 281:2020. "Dynamic load ratings and rating life for rolling bearings in gearbox applications." International Organization for Standardization.

Bearing Engineering Handbook (2020). "Industrial Gearbox Bearing Selection and Application Guidelines." Society of Tribologists and Lubrication Engineers.

Machine Design Reference Guide (2021). "Comparative Analysis of Bearing Types for Heavy-Duty Gearbox Applications." Mechanical Engineering Publications.