When engineers and procurement teams choose the best Thrust ball bearings for vertical motor uses, they face the important problem of managing axial loads while keeping the system efficient. When gravitational loads and operational stresses join, these specialized bearings do a great job of handling vertical forces in motor configurations. Single-row or double-row steel balls are used in modern thrust ball bearing designs to handle axial loads in either one or two directions with remarkably low friction. When your vertical motor systems need to be reliable, exact, and long-lasting in difficult manufacturing settings, you need to understand the fine details of how these parts work.

Understanding Thrust Ball Bearings in Vertical Motors

Thrust ball bearings are designed to handle mostly horizontal loads. This makes them very important for vertical motors where the load direction is the same as the direction of gravity. These bearings are better than radial bearings at holding downward force and letting rotation happen at the same time.

Core Design Principles and Working Mechanisms

The basic design of thrust ball bearings is based on how they can spread axial loads over several places of contact. Steel balls roll between raceways that have been perfectly shaped. This creates very little friction while holding up a lot of weight. This design theory makes sure that vertical motors run smoothly without damaging the integrity of the bearings under constant axial stress.

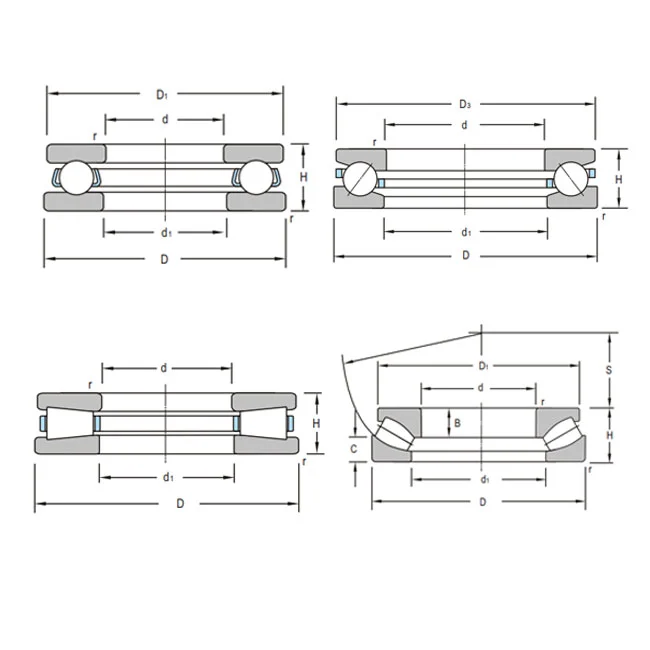

Unidirectional Thrust bearings have a shaft washer, a housing washer, and single-row steel balls that are kept apart by a cage structure. This setup only handles loads coming from one direction, so it's perfect for situations where thrust only happens in one way. Bidirectional types have an intermediate washer with double-row steel balls and double shaft washers. This lets the bearing handle forces coming from either way.

Material Engineering and Construction Quality

Premium thrust ball bearings use modern metallurgy to get the best performance. Shaft, housing, and intermediate washers usually use one of three types of steel: GCr15, GCR15SIMN, or 20Cr2Ni4A. Each type has different benefits when it comes to hardness, resistance to wear, and stress life. Rolling parts made of GCr15 or GCR15SIMN are very durable, and cage materials from cast steel to brass keep the balls separated and reduce friction.

Key Performance Criteria for Vertical Motor Applications

Choosing the best axial bearings for vertical motors means carefully looking at a lot of different technical factors that will affect how well the motors work. To get the best performance, engineers have to find a balance between load capacity needs and speed, temperature, and noise limits.

Load Capacity and Speed Rating Analysis

The most important criteria for vertical motor bearings is the axial load capacity. While keeping the structure sound during constant use, modern designs can handle loads of up to 200 kN. Speed ratings change a lot depending on the size of the ball thrust bearing, how lubrication is done, and the situations in which it is working. Bearings with inner diameters from 10 to 50 mm are usually able to rotate faster, but bigger bearings move more slowly and can handle more weight.

The relationship between load and speed sets operational boundaries that engineers must respect. Going beyond the suggested limits causes early wear and more heat, which can lead to total failure. Understanding these limits helps you choose the right bearing that meets the needs of the application without making the answer too complicated.

Temperature Management and Environmental Considerations

The temperature where the bearing is used affects both its performance and how long it lasts. Standard thrust ball bearings work well in normal temperature ranges. High-temperature thrust ball bearings, on the other hand, use ceramic hybrids and advanced greasing systems to keep working when temperatures go above 150°C.

Environmental factors like moisture, pollution, and chemical contact must be carefully thought about when choosing bearings. To keep the bearing working well until the end of its planned service life, sealing methods and material choices must match the conditions of the job so that nothing breaks down too soon.

Precision Grades and Noise Level Requirements

Precision class labels P0, P6, and P5 indicate the acceptable range of variations in a product and how well it should work. Standard uses use P0 or P6 grades, but precision machinery needs P5-grade bearings with tighter dimensional control and better surface finishes. In sensitive situations where sound must be kept to a minimum, a noise level below 35 dB is required.

Comparison of Thrust Ball Bearings with Alternative Bearing Types

To know when thrust ball bearings are better than other options, you need to look at what they can do compared to Thrust roller bearings, angular contact bearings, and other axial load control systems. Each kind of bearing has its own benefits based on how it will be used and the conditions in which it will be working.

Thrust Ball Bearings vs. Thrust Roller Bearings

Thrust roller bearings work best in situations where maximum load capacity is more important than speed. The line contact thrust ball design spreads the forces over a bigger area by making a line contact between the rollers and the raceways. This allows for higher load ratings than point contact thrust ball designs. For applications needing higher rotational speeds with moderate axial loads, thrust ball bearings are the best option because they offer superior speed capabilities and lower friction coefficients.

These kinds of bearings need very different kinds of maintenance. Thrust ball bearings usually need to be lubricated less often and can handle imbalance better. Their simpler design also makes it easier to install and replace them, which cuts down on maintenance time in important applications.

Angular Contact Bearings as Combined Load Solutions

Angular contact ball thrust bearings can handle horizontal and axial loads at the same time, making them useful in situations where there are multiple load directions. But, their form lowers the amount of pure axial load capacity they have compared to thrust ball bearings that are designed only for that purpose. Thrust ball bearings offer better performance and are more cost-effective when vertical motors produce mostly axial forces with little radial component.

In vertical motor uses, the simplicity of thrust ball bearing design also leads to increased reliability. It is easier to make this work because it has fewer complicated shapes.

Selecting the Best Thrust Ball Bearing for Vertical Motor Applications

Optimal bearing selection requires systematic evaluation of load magnitude, operational speed, temperature requirements, and spatial constraints specific to vertical motor configurations. This methodical approach ensures compatibility while maximizing performance and service life.

Critical Selection Factors and Design Considerations

Load magnitude serves as the primary selection criterion, requiring careful calculation of static and dynamic forces acting on the bearing during operation. Engineers must account for motor weight, operational loads, and potential shock forces that may occur during startup or emergency stops. Safety factors typically range from 2-5 depending on application criticality and operational conditions.

Spatial constraints within vertical motor assemblies often dictate bearing dimensions and configuration choices. Available axial space, shaft diameter limitations, and housing design parameters influence bearing selection more significantly than purely performance-based considerations. Balancing these geometric constraints with performance requirements requires careful engineering analysis.

Vendor Evaluation and Product Comparison

Leading bearing manufacturers offer comprehensive product lines spanning various performance levels and specialization areas. European manufacturers typically excel in precision applications, while manufacturers focus on heavy-duty industrial Solutions. Understanding each vendor's strengths enables informed procurement decisions aligned with specific application needs.

Quality certifications, testing standards, and manufacturing capabilities vary significantly across suppliers. Evaluating vendor track records, technical support capabilities, and supply chain reliability becomes essential for long-term partnership success. Some manufacturers offer extensive customization capabilities, while others focus on standardized solutions with proven performance records.

Procurement Strategy and Supply Chain Management

Bulk ordering benefits include reduced unit costs, priority delivery scheduling, and enhanced technical support access. However, inventory management considerations must balance cost savings against storage requirements and potential obsolescence risks. Establishing strategic partnerships with reliable suppliers ensures consistent quality and delivery performance while minimizing procurement risks.

Company Introduction and Product & Service Information

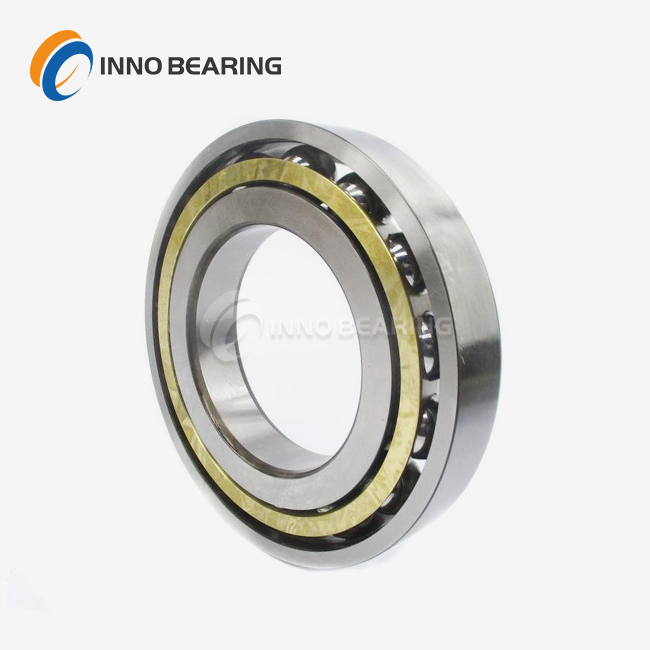

Luoyang INNO Bearing Co., Ltd. brings nearly three decades of specialized expertise in manufacturing precision thrust ball bearings for demanding vertical motor applications. Our comprehensive approach integrates advanced research and development capabilities with state-of-the-art production facilities and rigorous quality assurance protocols.

Advanced Manufacturing Capabilities and Quality Standards

Our manufacturing excellence centers on precision machining capabilities that achieve tolerances of ≤0.001mm across all critical bearing surfaces. Every bearing component undergoes comprehensive testing protocols including lifespan simulation, vibration analysis, and thermal cycling verification. Material consistency receives verification through spectrometer analysis, ensuring metallurgical properties meet exact specifications.

The production process incorporates advanced heat treatment procedures that optimize hardness distribution and residual stress patterns. Precision grinding operations create surface finishes that minimize friction while maximizing load distribution efficiency. Quality control procedures maintain a documented defect rate below 0.1% from raw material reception through final packaging.

Customization Excellence and Technical Support

Our engineering team specializes in developing custom solutions for unique vertical motor applications, including bearings with outer diameters up to φ5000mm. The customization process begins with detailed application analysis, progresses through CAD modeling and prototype development, and concludes with full-scale production utilizing proven manufacturing processes.

Technical support services include pre-installation analysis, predictive maintenance guidance, and 24/7 troubleshooting assistance. Our IoT-enabled monitoring solutions provide real-time bearing condition data, enabling proactive maintenance scheduling and optimal lubrication management. This comprehensive support approach minimizes unexpected downtime while maximizing bearing service life.

Conclusion

Choosing the best thrust ball bearing for vertical motor applications requires a lot of thought about the load needs, the situations in which it will be used, and how reliable it needs to be over time. Vertical motor systems work well when the following is done: knowing the important differences between bearing types, knowing the most important performance factors, and working with makers who have a lot of experience. Choosing the right bearings saves money on upkeep, extends service intervals, and makes operations more reliable. When modern thrust ball bearing technology is properly chosen and used in vertical motor setups, it can provide amazing levels of performance.

FAQs

What is the typical service life of thrust ball bearings in vertical motor applications?

Service life depends on operational conditions, load factors, and maintenance practices. Under normal operating conditions with proper lubrication, quality thrust ball bearings typically achieve 20,000-50,000 hours of operation. Heavy-load applications or harsh environments may reduce this to 10,000-20,000 hours, while light-duty applications can exceed 100,000 hours.

Can thrust ball bearings handle high-speed vertical motor applications effectively?

Yes, thrust ball bearings excel in high-speed applications due to their low friction coefficients and point contact design. Speed capabilities depend on bearing size, lubrication method, and cage material. Smaller bearings with advanced cage designs can operate at speeds exceeding 10,000 RPM while maintaining acceptable temperature and noise levels.

When should I choose thrust ball bearings over angular contact bearings for vertical motors?

Choose thrust ball bearings when axial loads dominate and radial forces remain minimal. They provide superior axial load capacity, simplified installation, and lower friction compared to angular contact bearings. Angular contact bearings become preferable when significant radial loads occur simultaneously with axial forces, or when space constraints require combined load handling in a single bearing.

Partner with INNO Bearing for Superior Thrust Ball Bearing Solutions

Discover how INNO Bearing's precision-engineered thrust ball bearings can optimize your vertical motor performance while reducing operational costs. Our experienced engineering team provides comprehensive application analysis, custom design solutions, and ongoing technical support to ensure optimal bearing selection and implementation. Whether you require standard configurations or specialized custom solutions, our 30% faster delivery and extensive inventory ensure your projects stay on schedule. Contact Us at sales@inno-bearing.com to discuss your specific requirements with our thrust ball bearing specialists and explore bulk procurement opportunities that deliver exceptional value for your organization.

References

Harris, Tedric A., and Michael N. Kotzalas. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis." 5th ed. CRC Press, 2006.

Hamrock, Bernard J., Steven R. Schmid, and Bo O. Jacobson. "Fundamentals of Machine Elements: SI Version." 3rd ed. McGraw-Hill Education, 2013.

ISO 104:2015. "Rolling bearings - Thrust bearings - Boundary dimensions, general plan." International Organization for Standardization, 2015.

Warda, Björn, and Peter Chudzik. "Fatigue Life Prediction of Rolling Bearings." In "Bearing Steel Technologies: 11th Volume, Advances in Steel Technologies for Rolling Bearings," ASTM International, 2017.

Tallian, Tibor E. "Failure Atlas for Hertz Contact Machine Elements." 2nd ed. ASME Press, 1999.

Eschmann, Paul, Ludwig Hasbargen, and Karl Weigand. "Ball and Roller Bearings: Theory, Design and Application." 2nd ed. John Wiley & Sons, 1985.