Because of their unique curved shape that makes sure the load is evenly spread out and friction is kept to a minimum, conical roller bearings make machines more efficient. These specialized parts use tapered rollers placed inside conical raceways. This design allows them to better handle both radial and axial forces compared to more standard bearings. The geometric configuration makes sure that the stress is spread evenly across the surfaces that are in touch. This makes the shape last longer and uses less energy in difficult industrial situations.

Understanding Conical Roller Bearings and Their Design Features

Today's industrial machines need bearings that can handle complicated loading situations while still meeting the highest standards of performance. Tapered Roller Bearings are a complex engineering answer that meet these difficult requirements through smart design.

Core Structural Elements

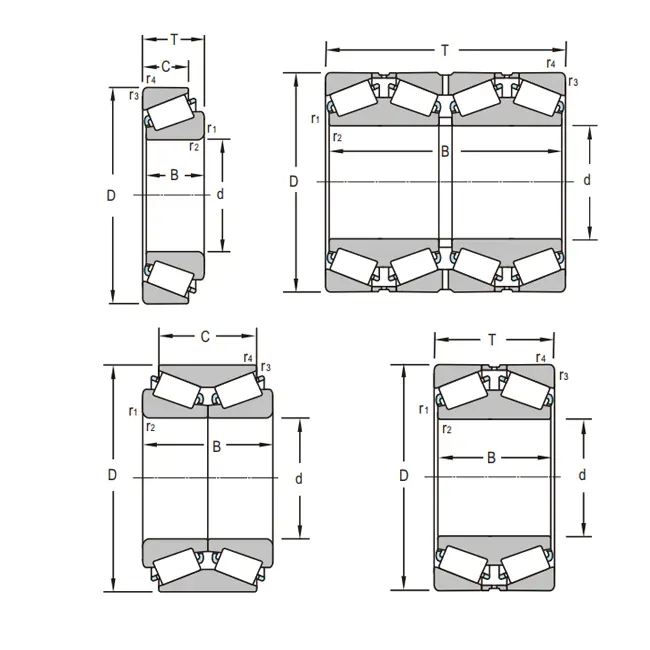

The basic structure of these bearings includes a few very important parts that work together. The inner ring has a finely shaped, tapered raceway that moves the rollers as they move. The outer ring's shape changes based on the needs of the application. Single-row designs use outer rings that can be taken off to make installation and upkeep easier, but double-row designs use set outer rings for better stability when loads go in both directions.

Using advanced production methods makes sure that these parts are very exact. GCr15, GCr15SiMn, 20Cr2Ni4A, and other high-quality materials are tough enough to be used in difficult conditions. The cage parts are made of either cast steel or brass. They keep the rollers spaced correctly and make sure they can rotate smoothly even when the load changes.

Precision Manufacturing Standards

Quality control methods make sure that performance is always the same across a wide range of uses. Most industries find that standard precision levels P0 and P6 are sufficient. However, more specialized fields require better precision grades, such as the P5 and P4 classifications. These standards of accuracy directly affect how well work can be done by minimizing vibration, lowering noise levels, and making the best possible power transfer characteristics.

How Conical Roller Bearings Work to Optimize Mechanical Performance?

Tapered roller bearings work in a way that makes them much better than other kinds of bearings. Engineers need to understand these ideas so they can make good choices about which parts to use in important uses.

Load Distribution Optimization

The curved shape makes it easier to handle heavy loads by spreading the force evenly across the shape. Cylindrical rollers make point contact, but the conical shape makes line contact all the way across the length of the roller. This larger area of contact lowers the concentration of stress and raises the ability to carry a load. This is especially helpful in heavy machinery applications where very high forces are common.

Combined load control is another big benefit. The angular contact design lets a single conical roller bearing unit deal with both radial and axial forces at the same time. With this feature, many apps no longer need to use different bearing setups. This simplifies things and makes the system more efficient.

Friction Reduction Mechanisms

The best rolling action that comes naturally to tapered designs makes friction lower. The geometric link between the roller angle and the raceway curvature reduces the friction from sliding and increases the friction that helps rolling motion. This idea leads to less energy use and lower temperatures in the machines' working lifetimes.

Heat dissipation benefits further enhance performance reliability. The open design makes it easy for the lubricant to flow through the system, and the sealed versions keep the parts inside clean without having a big effect on how heat is handled. Because of these features, the service intervals are longer and the upkeep needs are lower.

Advantages of Using Conical Roller Bearings in Industrial Machinery

Mechanical parts in industry have tough needs, which makes choosing the right bearing very important for the success of the whole system. Tapered roller bearings offer very useful benefits that help meet these difficult operating needs.

Enhanced Durability and Load Capacity

These bearings have strong construction features that let them work in the very tough conditions that are common in industry settings. Mining equipment, steel mills, and heavy building all benefit from these better than normal load-handling capabilities, which are better than those of standard bearing types.

Size freedom makes it possible for a wide range of applications to work. The inner sizes of standard models range from 10 mm to 1,000 mm, and the outer diameters range from 26 mm to 2,000 mm. Custom Solutions greatly increase these ranges. For example, specialized manufacturers can make bearings up to 5000 mm across for special uses like wind turbine systems and big mining equipment.

Energy Efficiency Benefits

Better internal friction and load paths result in more efficient power transfer. In heavy-duty uses, studies show that using the right tapered roller bearings can cut energy losses by 15–25% compared to other bearing setups. These gains in speed lead to real savings in the cost of running the service over a long period of time.

Extension of maintenance intervals provides extra economic benefits. Quality designs have better resistance to wear and contamination. This means that equipment is available more often because it doesn't need to be serviced as much. This dependability is especially useful in places where equipment can't fail, because downtime in these settings is very expensive.

Selecting the Right Conical Roller Bearing for Your Industrial Needs

Choosing a conical roller bearing has to do with many things that affect long-term performance and cost, and these things should be thought about carefully. When procurement professionals make sure that supply chain help is always there, they need to keep technical needs and budget issues in mind.

Technical Evaluation Criteria

The basis of good bearing choice is load research. Engineers need to be able to correctly assess both radial and axial force components, including changes over time and shock loading conditions. Environmental factors like very high or low temperatures, exposure to pollution, and problems with lubrication have a big impact on the choice of materials and the needs for closing.

Critical inspection factors make sure that the supply chain always meets the right level of quality. Taper surface fitting precision, load-bearing proof, and operational stability tests give people faith in bearing performance in real-world conditions. These quality measures are very important for uses where failing has big safety or cost impacts.

Supplier Evaluation and Quality Assurance

Manufacturing capability review helps find suppliers who can meet certain needs. High-tech factories with a wide range of testing tools make sure that quality stays the same while also helping with unique design needs. For big projects that need to plan delivery times, the reliability of the supply chain is even more important.

Certification standards set clear standards for quality. ISO 9001 quality management systems and certifications that are specific to the business show that the supplier wants to keep doing a good job. Quality assurance programs are backed by documentation packages that contain performance test results, dimensional records, and material Certificates.

Case Studies: How Conical Roller Bearings Drive Mechanical Efficiency in Practice

Real-world applications demonstrate the practical benefits of implementing advanced bearing technologies across diverse industrial sectors. These examples illustrate measurable improvements in efficiency, reliability, and cost-effectiveness.

Heavy Machinery Applications

Construction equipment manufacturers have documented significant performance improvements through strategic bearing upgrades. Excavator swing mechanisms utilizing high-capacity tapered roller bearings demonstrate 30% longer service intervals while reducing maintenance complexity. The enhanced load distribution capabilities prove particularly beneficial in applications involving frequent direction changes and shock loading.

Mining operations present extreme challenges that highlight bearing performance advantages. Crusher assemblies equipped with specialized tapered roller bearings maintain operational efficiency despite exposure to abrasive environments and heavy impact loads. The extended service life characteristics reduce equipment downtime while improving overall productivity metrics.

Automotive and Transportation Sector

Commercial vehicle applications showcase efficiency benefits through reduced fuel consumption and extended maintenance intervals. Wheel hub assemblies utilizing advanced tapered roller bearings demonstrate measurable improvements in rolling resistance while maintaining superior load-carrying capacity. These benefits prove particularly significant in heavy-duty transportation applications where operational costs directly impact profitability.

Railway systems benefit from the reliability characteristics inherent in quality bearing designs. Locomotive traction motor applications require bearings capable of handling complex loading while maintaining precise positioning tolerances. The proven performance of tapered roller bearings in these demanding applications validates their suitability for critical transportation infrastructure.

INNO Bearing: Engineering Excellence in Bearing Manufacturing

Luoyang INNO Bearing Co., Ltd. brings nearly three decades of specialized experience to the global bearing market, focusing on large and non-standard solutions that exceed conventional size limitations. Our comprehensive capabilities encompass research, design, production, and technical support services tailored to demanding industrial applications.

Advanced Manufacturing Capabilities

Our production facilities integrate cutting-edge technology with rigorous quality control systems to deliver conical roller bearings that meet the most stringent performance requirements. Specialized equipment enables manufacturing of custom bearings up to 5000mm diameter, addressing unique applications in wind energy, mining, and heavy machinery sectors.

Quality assurance protocols ensure consistent performance across all product lines. Advanced testing equipment validates dimensional accuracy, material properties, and operational characteristics before shipment. This comprehensive approach delivers the reliability that industrial customers require for critical applications.

Custom Engineering Solutions

Technical consultation services help customers optimize bearing selection for specific operational requirements. Our engineering team collaborates with clients to develop custom solutions that address unique challenges while maintaining cost-effectiveness. This collaborative approach ensures optimal performance integration within existing machinery designs.

Rapid delivery capabilities support urgent replacement requirements and new project timelines. Streamlined manufacturing processes combined with comprehensive inventory management enable responsive service that meets demanding project schedules without compromising quality standards.

Conclusion

Tapered roller bearings represent a proven technology for improving mechanical efficiency across diverse industrial applications. Their superior load-handling capabilities, reduced friction characteristics, and enhanced durability provide measurable benefits in terms of energy savings, extended service life, and reduced maintenance requirements. The strategic selection of quality bearings from experienced manufacturers ensures optimal performance while supporting long-term operational objectives. As industrial machinery continues evolving toward higher performance standards, the role of advanced bearing technologies becomes increasingly critical for maintaining competitive advantages in global markets.

FAQs

What factors determine the lifespan of conical roller bearings?

Bearing lifespan depends primarily on load conditions, lubrication quality, operating temperature, and contamination exposure. Proper installation, regular maintenance, and appropriate lubrication can extend service life significantly. Environmental factors such as vibration, shock loads, and temperature cycling also influence operational longevity.

How do sealed bearings compare to open designs in terms of efficiency and maintenance?

Sealed bearings provide superior contamination protection and require less frequent lubrication, making them ideal for harsh environments. Open bearings offer better heat dissipation and easier maintenance access but require more frequent lubrication. The choice depends on specific application requirements and environmental conditions.

Can conical roller bearings be customized for unique specifications?

Yes, experienced manufacturers can produce custom bearings to meet specific dimensional, material, and performance requirements. Custom solutions address unique load conditions, space constraints, and environmental challenges. Lead times vary depending on complexity, but specialized manufacturers typically deliver custom solutions within reasonable timeframes.

Partner with INNO Bearing for Superior Tapered Roller Solutions

INNO Bearing stands ready to support your bearing requirements with advanced engineering solutions and reliable supply chain support. Our experienced technical team provides comprehensive consultation services to optimize bearing selection for your specific applications. As a trusted conical roller bearing manufacturer, we deliver custom solutions that enhance mechanical efficiency while reducing operational costs. Contact Us at sales@inno-bearing.com to discuss your bearing requirements and discover how our expertise can improve your machinery performance.

References

Harris, T.A. and Kotzalas, M.N. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, 2006.

Palmgren, A. "Ball and Roller Bearing Engineering, Third Edition." SKF Industries Inc., 1959.

Hamrock, B.J., Schmid, S.R., and Jacobson, B.O. "Fundamentals of Machine Elements: SI Version, Second Edition." McGraw-Hill Education, 2005.

ISO 281:2007. "Rolling bearings - Dynamic load ratings and rating life." International Organization for Standardization, 2007.

Budynas, R.G. and Nisbett, J.K. "Shigley's Mechanical Engineering Design, Tenth Edition." McGraw-Hill Education, 2014.

Stachowiak, G. and Batchelor, A.W. "Engineering Tribology, Fourth Edition." Butterworth-Heinemann, 2013.